Testomat ECO User manual

Testomat®ECO

Operating instructions

Contents

Introduction ..................................... 1

Short description ................................ 1

Reagents available for the Testomat®ECO ........... 1

Notes for the user ................................ 2

Note about the operational reliability ................ 2

Safety Notes .................................... 2

Installation and commissioning .................... 3

Installation ..................................... 3

Electrical Connection ............................. 3

Mains water supply .............................. 3

Operation with small aerator ..................... 4

Water to drain ................................ 4

Commissioning ................................. 4

Installation diagram (Example) ................... 4

General description .............................. 5

Internal construction ............................. 5

Terminal block identification ....................... 6

Functions .................................... 6

Description of displays and operating features ......... 7

Display functions ................................ 7

Status of limit value displays ..................... 7

Measured value display ......................... 7

Limit value display ............................. 7

Alarm message ............................... 7

Description of the relay outputs ..................... 8

LV1 and LV2 limit value outputs .................. 8

Alarm fault message output ..................... 8

Description of the signal inputs and output ............ 9

Stop external analysis stop ...................... 9

IN water meter input ........................... 9

OUT interface output .......................... 9

Function characteristics .......................... 9

Mode of operation ............................... 9

Analysis cycle ................................. 10

Displayed unit ................................. 10

Type of reagent ................................ 10

Setting the timer ................................ 10

Flush / Interval pause ........................... 10

Monitoring of limit value .......................... 10

Hysteresis .................................... 11

Logic functions ................................. 11

BOB-operation ................................. 11

Function STOP ................................ 11

Water meter ................................... 12

Interface ...................................... 12

Structure of the menu ........................... 12

Selection and input ............................. 12

Start menu .................................. 12

Selection ................................... 12

Input ...................................... 12

End menu .................................. 12

Informations menu "i" ........................... 13

Structure of the "i" - menu ........................ 13

Call .......................................... 13

Operating values ............................... 13

Program values ................................ 13

Program menu "M" .............................. 14

Service I ...................................... 14

Input reagent ................................ 14

Manual operation ............................. 14

Language .................................. 14

Diagnosis .................................. 14

Basic program ................................. 15

Programming .................................. 15

Structure of the program menu "M" ............... 15

Error messages / trouble shooting ................. 16

Further information ............................. 17

Maintenance ................................... 17

Description of maintenance work ................... 17

Cleaning the measuring chamber&sight-glass windows 17

Cleaning the filter housing ...................... 17

Note on care for the unit ......................... 17

Spare parts list Testomat®ECO ................... 18

Technical appendix ............................. 19

Block diagram "Testomat®ECO" .................. 19

Technical data ................................. 19

1 / 19

Introduction

This operating instruction describes installation, operation and programming of the analysis unit Testomat®ECO.

We recommend that, whilst familiarising yourself with the operation of the unit aided by this manual, you have

immediate access to the unit in order to perform the functions and combinations as described. As certain functions are

interrelated, it is advisable to follow the instructions in the given order.

Should problems or questions arise which are not described in this manual and/or cannot be solved, our customer

service is always at your disposal.

Try to identify the problem as accurately as possible and record the conditions under which it has occurred. This will

enable us to offer you swift effective assistance.

Symbols and abbreviations used in these instructions:

LNote for the user "STANDBY" = STANDBY lamp is “ON”

Important to observe / warning note "M" = Press menu key M TTip: Helpful hint

ºSERVICE ºMANUAL OPERATION ºFLUSH = Sequence in a menu selection

Short description

The Testomat®ECO is used for the automatic measuring and monitoring of the total water hardness.

The parameter to be measured is determined by the choice of the reagent and by the corresponding user program.

Reagents available for the Testomat®ECO

The various measuring parameters and ranges are determined by the choice of the reagents. The table gives a

summary of the different possibilities.

Parameter/Type of reagent

Water

hardness

TH 2005

Water

hardness

TH 2025

Water

hardness

TH 2100

Water

hardness

TH 2250

Unit

°dH

(Resolution) 0.5 - 0.0

(0.1) 0.5 - 2.0

(0.5) 1.0 - 10.0

(0.2) 2.5 - 25.0

(0.2)

°f

(Resolution) 0.09 - 0.89

(0.02) 0.45 - 4.48

(0.1) 1.79 - 17.9

(0.4) 4.48 - 44.8

(0.4)

ppm CaCO3

(Resolution) 0.89 - 8.93

(0.2) 4.47 - 44.7

(0.9) 17.9 - 179

(3.8) 44.7 - 447

(3.8)

mmol/l

(Resolution) 0.01 - 0.09

(0.01) 0.04 - 0.45

(0.01) 0.18 - 1.79

(0.04) 0.45 - 4.48

(0.04)

LAconsistently reliable result can be guaranteed by the TESTOMAT®ECO only with the use of original

HEYL Testomat®2000 reagents !Failure or problems which are caused by the use of different indicators

are not covered by the warranty or refund services.

When monitoring residual/total hardness, larger quantities of heavy-metal ions in the softened water can affect

the colour reaction, especially iron above 0.5 mg/l, copper above 0.1 mg/l and aluminium above 0.1 mg/l

(brownish-red colour indication).The measuring is possible in a range of pH 4-10.5.

At a concentration of more than 100 mg/l of CO2(carbon dioxide) in the water, the excess carbon dioxide must

be removed by installing a Type R aerator in the feed water line to the TESTOMAT®ECO unit. When using the

TESTOMAT®ECO for monitoring a de-carbonisation installation (weakly acidic cation exchanger) without its

own irrigator, a small scale irrigator must always be installed upstream of the device.

Concentration values of these ingredients can be determined safely and simply with our TESTOVAL colorimetric test

comparators.

2 / 19

Notes for the user

•Repeated switching 'on' and 'off':

Wait at least for 5 seconds before you switch the unit repeatedly 'on' or 'off' at the main switch.

• Observation of the environmental conditions:

In order to guarantee a reliable operation, the unit must only be used under the environmental conditions described

in the technical data. Protect the controller against excessive humidity, condensation and water-splash.

• Safety seal:

The original seals attached during manufacture (e.g. EPROM labels) must not be broken, otherwise all warranty

rights are lost.

• Malfunction / repair of defective units:

The repair of a defective unit is only possible when the unit is dismantled and returned to us with a description of the

fault.This in no way affects the guarantee rights. In addition, please inform your supplier of the reagent type used and

of the quality of treated water measured.

Before you return the unit for repair, remove the reagent bottle and ensure that the measuring chamber is flushed out

and empty.

• Electrical load capacity

The maximum electrical load capacity of the relay outputs and the total power rating must not be exceeded.

• Operate the Testomat® ECO strictly in accordance with the manufacturer's instructions.

• Environmental protection regulations

Please observe the environmental protection regulations and collect any unused reagent for safe disposal in

accordance with local statutory requirements.

Operational Checks

Careful handling of the unit increases both the operational reliability and the service life!

Therefore the following visual inspection should be carried out at regular intervals.

•Are the hose connections with the dosing pump free of leaks?

•Is there any air inside the dosing hoses?

•Are all the water connections free of leaks?

•Are the doors of the unit properly closed?

•Is the unit unduly contaminated with dirt?

Maintenance and servicing notes

(see page 17)

Safety notes

• The unit must be installed and operated in compliance with the relevant standards (e. g. DIN, VDE, UVV).

• Some functions (e. g. the manual analysis) allow the direct manipulation of the installation without locking or

monitoring. These functions may only be used by trained staff and for this reason they are only accessible after a

pass word has been entered.

• If you observe the unit malfunctioning, switch it off immediately. Then shut off the water supply and contact your

supplier.

• Do not attempt to repair the unit yourself (loss of warranty rights); instead always get in touch with the authorised

service staff. This is the only way a reliable and safe operation of the unit can be ensured.

•After a protective circuit (fuse) has tripped, first of all, attempt to correct the cause of the malfunctioning (e. g. replace

the solenoid valve) before reactivating the protective circuit. Frequent tripping is always due to a fault which, in

certain circumstances, may also cause damage to the unit.

• Observe the safety notes about working with reagents, chemicals and cleaning agents.

Ignoring these notes can result in damage to the unit as well as the installation and may result in a loss of

warranty rights.

3 / 19

360

266

Dimensioned sketch

Installation and commissioning

Installation and commisioning must be undertaken only by

authorised technicians!

Installation

The unit should be fixed vertically!

Avoid tension of the housing.

The unit doors swing to the left when they are opended. Please

ensure that there is sufficient space for opening them. In this

way, you facilitate the electrical installation and later

maintenance and service work.

Electrical connection

Check supply voltage on the rating plate!

Basic requirements

The external cables (e.g. water meter, interface) should be kept as short as possible and clear of power cables.

Connection

Loosen both fastening screws and open the upper door. Pierce the required rubber cable glands with a screwdriver and

insert the cable (1). Then pull back the cable until the bush (2) has been turned over. Ensure that the leads are held

securely in the terminals then close the upper door after the installation is completed using the two fastening screws.

Mains water supply

The temperature of the sample water must be between 10 °C and 40 °C. Higher water temperatures can lead to

damage to all parts coming into contact with water (e. g. filter housing, measuring chamber)!

Lower water temperatures can cause misting on the sight-glass windows.

LIn the event of higher temperatures, the Type KCN cooler must be installed in the branch line of the TESTOMAT®

ECO.

Hot water can lead to scalding!

The branch line should be positioned as close as possible to the outlet from the water softening plant. The branch line

to the Testomat®ECO with a hand-operated shut-off valve must be kept as short as possible and not longer than a

maximum of 5 meters. It is important that the branch line connection is taken vertically from the top of the main soft

water line in order to prevent dirt particles from entering into the measuring chamber.

When operating the Testomat®ECO with the pressure range of 3 to 8 bar install the valve and the regulator/ filter

housing from our range.

Plug connector

The unit is equipped as a standard with a plug connector for opaque plastic hoses 6/4 x 1 (external diameter 6 mm/

internal diameter 4 mm).

Quick-acting coupling (accessory: Optional adapter for water inlet, Order no. 40123)

LOnly with installed regulator / filter housing (optional available)

When fabric reinforced pressure hoses (e.g. for existing installations) are used, please replace the plug connector at the

controller and filter housing with a plug for the quick-acting coupling (not included with the delivery).

4 / 19

Operation with small aerator

If the sample water to the TESTOMAT®ECO contains more than 100 mg/l of CO2,it will be necessary to install a Type R

small aerator. The aerator must be installed at least 1 m above the TESTOMAT®ECO.

Water to drain

The feed water flows through the measuring chamber then, via the outlet pipe, to the drain (hose connection internal

diameter 14 mm). Make sure, by using a funnel for example, that the water can run freely to drain and cannot back-up

into the measuring chamber. A hose impervious to light should also be used for the drain pipe (to discourage algae

formation).

Commissioning

1. Afull reagent bottle must be connected before commissioning and switching on. Attach the vacuum connection onto

the reagent bottle using the union nut.

2. Switch the unit 'on' and press the "STANDBY" key. In this mode, an analysis is prevented from being carried out

before a correct program has been entered which could possibly result in an error or alarm message.

3. Then bleed the dosing pump and the capillary by repeatedly pressing the "Manual" key on the dosing pump. Ensure

all air is removed from the tubing ! (If necessary tighten up the connections.)

4. Program the unit as applicable to your requirements, e. g.: - Mode of Operation - Type of reagent

- Displayed unit - Limit values

- Flush time/interval - Analysis interval

For a description of programming see from page 12.

5. Then remove all air from the water supply side of the unit by manual flushing.

"M" ºSERVICE ºMANUAL OPERATION ºFLUSH ("ENTER" press repeatedly).

You should continue flushing until no bubbles can be seen in either the measuring chamber or the filter housing.

6. Check all connections for tightness.

7. By pressing the "Manual" key you carry out the first analysis.

Installation diagram (Example):

5 / 19

Valve

block

Reagent

TESTOMAT

2000

Dosing pump

Mains water supply

Inlet (without primary filter and pressure regulator)

and outlet

Terminal block for inputs

Stop, IN 2 (water meter) and output OUT

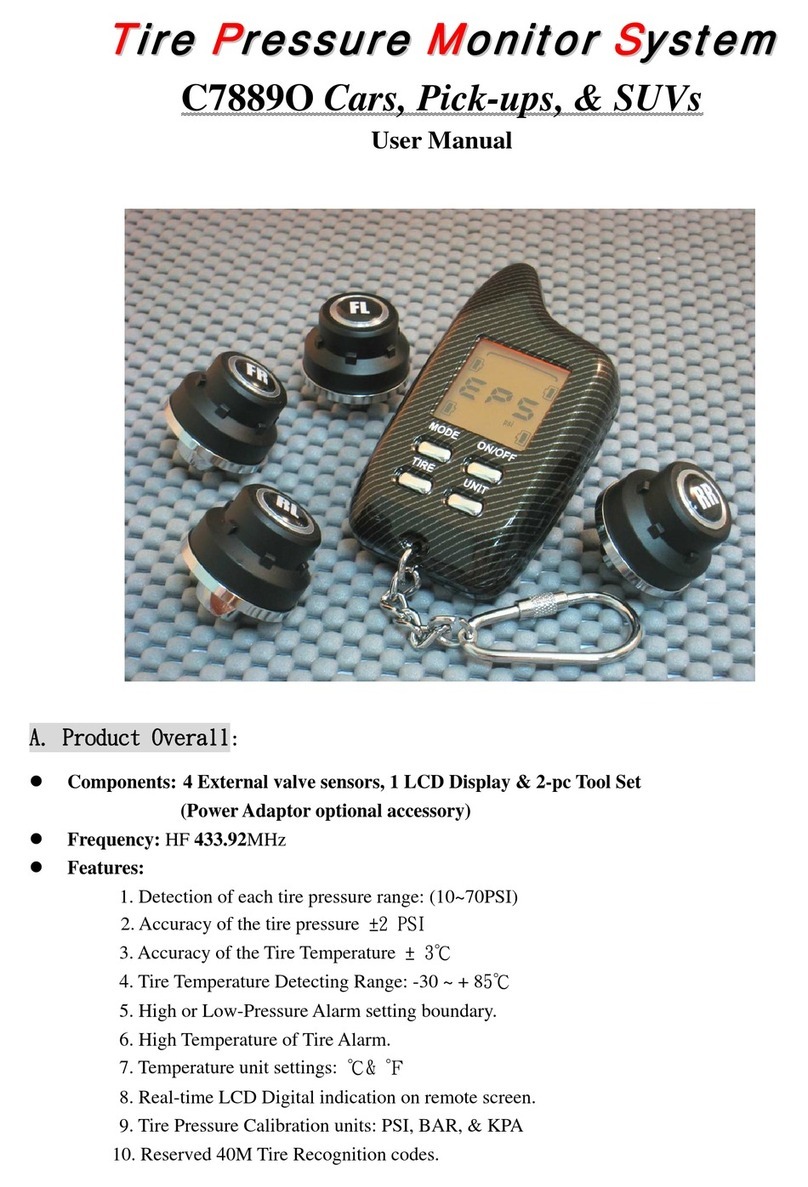

General description

Internal construction

6 / 19

Terminal block identification

Functions

IN = Input, OUT = Output

Nr. Terminal Type Function Note

-PE IN Mains - Protective earth (5x)

1

2L

NIN Mains, L = Live

Mains, N = Neutral Mains - input

230 - 240 V AC

3-5

6-8 n

lOUT Neutral, switched (8 x)

Live, switched (8 x) Mains voltage, max. 4 A

9

10

11 LV1 OUT Limit value output 1 - Normally closed

Limit value output 1 - Common

Limit value output 1 - Normally open

Volt-free relay output

max. load 240 V AC, 4 A

12

13

14 LV2 OUT Limit value output 2 - Normally closed

Limit value output 2 - Common

Limit value output 2 - Normally open

Volt-free relay output

max. load 240 V AC, 4 A

15

16

17 Alarm OUT Fault message - Normally closed

Fault message - Common

Fault message - Normally open

Volt-free relay output

max. load 240 V AC, 4 A

18

19 Stop

2

IN External analysis stop

Common earth for inputs Only volt-free normally

open/normally closed contact!

20

21 IN

2

IN

Water meter input

Common earth for inputs Only for volt-free normally

open/normally closed contact/ Note

technical data of turbine!

22

23 OUT +

OUT - OUT 0/4 - 20 mA Potential output !

22 = + 0/4 - 20 mA, 23 = -

24 +OUT +12V for Hall-Sensor (turbine) Note technical data of turbine!

Max. power input of sensor is not

allowed to exceed 20 mA !

7 / 19

STANDBY

Description of displays and operating features

(1) Power switch

The 'ON'/'OFF' switch is located on the right-

hand side panel.

(2) Unit fuse (inside the unit)

Protects outputs against overload and short

circuit.

3Status of limit value displays

Displays the status of the limit values LV1 (1)

and LV2 (2).

4Text display

Displays the current analysis, all important

status results and programming data in a 2-

line LC-Display.

5Alarm

Displays a function fault.

6 Analysis message

Displays current analysis.

7Programming keys (Cursorblock with ENTER)

These keys are used to enter all values and

programming data.

Function keys:

8"Manual" = manual start of an analysis

9STANDBY = manual analysis stop/standby

10 "Alarm" = cancels alarm message

11 i-key

Call-up all unit information (see i-menu).

12 M-key

Call-up the programming menu for user and specific unit

settings (see M-menu).

Display functions

Status of limit value displays 1 and 2

The display signals the status of the limit values.

1: The red display lamp lights up if the limit value 1 is reached or exceeded.

Lights up green if the measured value falls below the set limit value.

2: The red display lamp lights up if the limit value 2 is reached or exceeded.

Lights up green if the measured value falls below the set limit value.

Status and measured value display

In continuous operation the current measured value is shown in the upper line.

When the measured value falls below the measuring range "<" is displayed: e. g. < 0.05 °dH

When the measured value exceeds the measuring range ">" is displayed: e. g. > 10.0 °dH

When the analysis interval is stopped in operation (Analysis Stop), “STANDBY“and measured value are displayed

alternately.

The sign “

BA

“ in the line of measured value symbolises active BOB - operation.

Limit value displays

The adjustable limit values are shown in the bottom display line.

Alarm message

Display of present error messages (red)

LError messages are displayed alternately with the normal display text and can only be deleted by cancellation

and correction of the fault.

8 / 19

Description of the relay outputs

LV1 and LV2 Limit value outputs

For reporting that a limit value has been exceeded, two volt-free relay contacts are available. For both contacts the limit

values, the hysteresis and the function can be independently programmed:

Function Type of contact Action

LV1

Sactive at

limit value in excess of

limit value 1

volt-free

change-over contact

programmable:

SContinuous contact

SImpulse (1 - 99 seconds/minutes)

SInterval (1 - 99 seconds/minutes)

STwo -step regulator

SHysteresis (1, 2 or 3 limit value in excess)

LV2

Sactive at

limit value in excess of

limit value 2

volt-free

change-over contact

programmable:

SContinuous contact

SImpulse (1 - 99 seconds/minutes)

SInterval (1 - 99 seconds/minutes)

SHysteresis (1, 2 or 3 limit value in excess)

Menu values:

"M" ºBASIC PROGRAM ºPROGRAM VALUES ºLIMIT VALUES

"M" ºBASIC PROGRAM ºPROGRAM VALUES ºFUNCTION LV1

"M" ºBASIC PROGRAM ºPROGRAM VALUES ºFUNCTION LV2

"M" ºBASIC PROGRAM ºPROGRAM VALUES ºHYSTERISIS LV1

"M" ºBASIC PROGRAM ºPROGRAM VALUES ºHYSTERISIS LV2

Alarm Fault message

The "Alarm" output is a volt-free change-over relay contact. During trouble-free operation the contact between the

terminals 16 – 17 is closed and the one between terminals 15 – 16 is open. When the voltage fails or the alarm is

activated, the contact between terminals 15 – 16 is closed and the one between 16 – 17 is open.

T

The unit is equipped with a range of monitoring functions.

- The "Alarm" output remains activated (with terminals 15 – 16 closed) as long as the fault persists.

-The red LED "Alarm" and the text on the display indicate a fault.

-The error signal at the "Alarm" output is deleted by cancelling the fault with the "Horn" key.

-An error message can only be deleted after the fault has been corrected.

- Exception: “Reagent low level“, this message is confirmed in the M-menu by entering in the new reagent level.

The following faults activate the "Alarm" output and are displayed:

Low-water pressure

Function fault optics

Measuring fault analysis

Function fault dosing pump

Function fault outlet to drain

Reagent low level

Measuring fault dirtiness

Measuring fault turbid

Measuring range exceeded

Error messages are described on page 16.

For a more detailed description of the programming refer to page 14. For general maintenance refer to page 17.

9 / 19

Description of the signal inputs and output

LConnect the signal inputs “Stop“, “IN" with volt-free contacts only !

Stop external analysis stop

Function Type of contact Test time Action

Stop

Sexternal analysis stop

(e. g. via flow controller or from the

process controller)

programmable

normally

closed/normally

open volt-free!

none

SSo long as the contact at the input is

‘open‘ or ‘closed‘, no analyses are

carried out.

IN

SWater meter input

normally closed/

normally open

volt-free!

or turbine

none

SQuantity recording to start an analysis

"M" ºBASIC PROGRAM ºPROGRAM VALUES ºINPUT STOP

"M" ºBASIC PROGRAM ºPROGRAM VALUES ºWATER METER

Installation example for the water meter

OUT Interface output

Function Terminal Test time Action

power interface 0/4-20mA max. load

350 Ohm -programmable

S0 - 20 mA

S4 - 20 mA

"M" ºBASIC PROGRAM ºPROGRAM VALUES º0/4-20mA

Function characteristics

Mode of operation (Analysis controller)

1. Time control: Internal triggering by a timer. The shortest interval = 0 minutes between analyses, longest interval

= 99 minutes.

(see page 10, interval periods)

LThe analysis interval is determined by the duration of the set flush times the programmed (interval) and the

duration of the analysis. The analysis duration is a direct function of the value to be measured.

2. Quantity control: Triggered by the water meter.

Minimum interval = 1 litre, maximum interval = 9999 litres.

After the programmed water quantity is measured, the analysis is carried out. Prior to the analysis, the capillary

and the measuring chamber are flushed (observe the programmed flush times).

LThe current analysis interval can be interrupted by making contact at the "Stop" input.

10 / 19

Analysis cycle (Example with schematic cycle diagram)

1Flush branch line and measuring chamber (note flush time of the sampling line)

2Fill measuring chamber

3, 4 Check the sample for dirtiness, dosing reagent (stirring mechanism is "ON")

5Evaluate and display reaction

6Drain measuring chamber

7Pause period up to the next analysis (time or quantity analysis interval), Tp.

TI= total analysis interval, ch = measuring chamber

Displayed unit

Programmed hardness unit is displayed. You have the choice of °dH, °f, ppm CaCO3and

mmol/l. The unit entered will now be displayed as programmed.

Type of reagent

Select the reagent type you are utilising in the unit, e. g. reagent TH 2005 means 8.93 ppm CaCO3upper limit of the

measuring range and 0.89 ppm CaCO3lower.

Setting the timer

Flush

In order to ensure the analysed sample represents the current value, the sampling tube must be sufficiently well flushed

taking its length into consideration. After the installation has been out of operation for a longer period or in the case of

long analysis intervals, it is sensible to select a flushing time in excess of 60 seconds. Flush is initiated by

simultaneously opening the Testomat®ECO’s inlet and the outlet valves.

LThe analysis interval directly depends on the programmed flush time. If a flush time of, for example, 90 seconds is

set, the analysis interval itself cannot be shorter than 90 seconds.

Example: For 3 bar pressure, a connection longer than 5 m, an internal tube diameter of 4 mm, and a minimal

internal flushing time of 10 seconds is required to ensure a valid sample is taken from the sampling tube.

The quantity of flush water for an internal flush of 1 minute is 0.5 litre.

Interval pause

In the case of timed triggering of the analysis, the interval between two analyses (plus flush time) is determined by the

interval pause. The shortest interval can be 0 minute. In this case, the analyses are carried out continuously. The

longest interval is 99 minutes.

Monitoring of limit value

Two outputs for the limit value are available for monitoring. You can program the limit value on a continuous scale. The

range for the limit value depends on the reagent type used and on the programmed unit. The functions of these outputs

can be programmed independently from each other.

When the limit value LV1 is exceeded, limit value control display lights up LV1 RED and the relay output LV1 reacts as

programmed in the switch function. As long as this limit value is not exceeded, the display lights up GREEN.

The unit operates in the same way for the limit value LV2.

11 / 19

Hysteresis

Each limit value output reacts only after the 1st,2nd or 3rd bad analysis result has been detected (suppression of the first

or the second measured value).

This increases the reliability during the evaluation of the analysis e. g. after the measuring point has been switched over

or if the sampling line has possibly not been flushed sufficiently. The hystereses of the two outputs LV1 and LV2 can

be set independently from each other.

Operation: With a hysteresis of 2 a further analysis is carried out immediately after the limit value has been exceeded.

Only if the limit value of this analysis is exceeded again, the corresponding output is energised. If you have set a

hysteresis of 3, the corresponding output reacts only after the limit value has been exceeded for the 3rd time in

succession.

Logic functions of the limit value outputs LV1 and LV2

Logic function 0, Duration

Output relay LV1 or LV2 pulls up when the measured value rises above limit value LV1 or LV2. If the measured value

falls below the limit value LV1 or LV2 the relevant relay drops out again.

Logic function 1, Impulse

If the measured value rises above limit value LV1 or LV2, the relevant output pulls up for a set time t. Independent of the

time taken for the limit value to rise above the set limit, the relevant output always remains in the "ON" position for the

set time.

Logic function 2, Interval

If the measured value rises above one limit value, the relevant output pulls up at intervals with the time

set.(Impulse/Pause)

Logic function 3, Two-point

If the upper limit value LV1 is exceeded, the output relay LV1 pulls up. If the lower limit value LV2 falls below the set

limit, output relay LV1 drops out.

The output relay LV2 pulls up according to the programmed logic function.

LThis function is possible only if different values are selected for LV1 and LV2. For

example for LV1 =0.2° dH and for LV2 =0.1° dH.

BOB-Operation (BOB = Operation without constant supervision)

The Testomat ECO conforms to the german TRD 604 safety standard for monitoring of water hardness associated with

steam boiler installations, when operation without constant supervision is a relevant safety feature (= Betrieb Ohne

ständige Beaufsichtigung = BOB -operation).

When the BOB function is programmed, the unit constantly monitors the reagent quantity available. For calculating the

reagent consumption per analysis, a measured value of 1.48 ppm CaCO3(0.015 mmol/l alkaline earth ions) is used. An

alarm is activated if the residual reagent quantity is insufficient for the set BOB period of 72 hours.

BOB on: Continuous monitoring of the residual reagent quantity. ALARM message when the available quantity falls

below the minimum quantity for the BOB period: “Alarm“ flashes, the Alarm output is energised.

BOB off: Without BOB function: the residual reagent quantity is only monitored for the minimum quantity (10 %

level).

Example: BOB-Duration = 72 Hours Number of analyses per hour = 10

Necessary quantity of reagent for 72 h = 72 h x 10 Analysis/h x (3 x 30) µl/Analysis = 64.8 ml.

(That corresponds to approx. 13% of a full level bottle)

Funktion STOP

The active analysis interval can be interrupted through contact with the stop input. The active condition has to be

programmed according to your requirements.

12 / 19

Displayed function

"i" (Key) "M"

Information Menu Program Menu

Water meter

For quantity dependent analysis triggering it is necessary to connect a water meter to the IN2 input.

Program the corresponding water meter rating under menu item "WATER METER", or enter the impulse number of the

turbine water meter.

Interfaces

Interface 0/4-20 mA

Another possibility for monitoring the analysis is the connection of

arecorder. For this purpose the unit is equipped with a

programmable current output.

Standard values of 0 - 20 mA and 4 - 20 mA can be selected.

LA maximum working resistance of 350 Ùmust not be

exceeded! In situations where interferences might occur and

where very long cables are used (approx. 20m) a screened

cable should be used if possible

Structure of menu

Selection and input

Start menu

Select one of the two menus by pressing the "M" or the "i" key.

Selection

The active line position is displayed in CAPITALS. Using the "ENTER" key, the line is activated to enter a submenu.

Using the arrow key "w", the next parameter appears below the lowest display line:

in this way you scroll the menu.

Entry function (only possible in the "M" menu)

•You select a programming step by means of the arrow keys "w"and "v"and activate the entry function by pressing the

"ENTER" key.

•In the case of digits to be entered, the first digit to be modified flashes.

•You can change the value using the arrow keys "w" and "v".

•By pressing the arrow keys ">" and "<", you confirm the entry and simultaneously change to the next or the preceding

digit (which then starts flashing).

•You terminate the entry function by pressing "ENTER".

•The following line is activated.

•By pressing the "M" key you change to the menu one level up.

End menu

By pressing the “M“ or the “i“ key you return to the menu one level up. After returning from the highest menu level the

unit is again in the display mode.

13 / 19

i-button

E

1

2

3

4

4a

E

2 lines are displayed

(black scale)

<0.05 °dH

1:0.20 2:0.40

OPERATING VALUES

Program values

Reag. level 30%

Version 39DXXX

Mode of operat.

Display of unit

Type of reagent

Limit values

Flush time

Interval

Water meter

Type TH2005

Type TH2025 *

Type TH2100

Type TH2250

Type TH2025

0,05 - 0,50 °dH

Information Menu "i"

Strukture of the "i" menu

You can use the information menu to call up

the active settings and status of the unit.

Call (1)

You call up the information menu "i" by

pressing the “i“ key.

Operating values (3)

Display of current values

Reagent level

Softwareversion

Program values (4)

By pressing the arrow keys you can call up the menu item "Program values". By

pressing "ENTER" you open the list with the set values. The active setting of a

parameter can be queried by pressing "ENTER":

For example (4a):

"i" ºINFORMATION ºPROGRAM VALUES ºTYPE OF REAGENT

The selected function is marked by a star (in this context there are no active

lines).

14 / 19

10

M - key

PROGRAM MENU

Testomat ECO

BASIC PROGRAM

E

E

1

2

3

4

5

6

7

8

9

E

E

Reag.level:100%

FLUSH *

Fill chamber

Drain chamber

Flush chamber

E

GERMAN *

Italian

French

English

E

Language

INPUT REAGENT

Manual operation

Diagnosis

SERVICE

Basic program

OUTPUT LV1 *

Output OUT 255

Output Alarm *

Input Stop *

Input IN *

Output LV2 *

<0.05 °dH

1:0.20 2:0.40

Polish

Program Menu "M"

Call (1)

By pressing the "M" key the program menu

"M" is selected.

Except for the basic programming, you can

call up all functions without pass word

protection.

Service I (2)

Input Reagent (3)

After every refill or replacement of the

reagent bottle or of the reagent type, you have

to enter the new level. As soon as the menu

item for the filling level "INPUT REAGENT (0 -

100%)" has been selected by pressing

"ENTER", the value is preset to 100%. If only

a partially filled bottle is connected, enter the

corresponding % value. When you have

connected a full bottle, confirm this value by

pressing "ENTER".

Manual operation (4)

After you have confirmed the information

message (4) by pressing ENTER, you can

select the desired function using the arrow

keys and then activate them by pressing

"ENTER".

These functions are only used for monitoring

the operation and for commissioning.

LAll manual functions can only be selected during an interval between two analyses. During manual operation, no

analysis is carried out.

All signal inputs and outputs are locked.

Flush (5)

Start the flushing of the sampling tube through the internal valve by pressing "ENTER". When "ENTER" is pressed

again, this function is terminated.

Flush chamber (6)

By pressing "ENTER", the measuring chamber is flushed once.

Drain chamber (7)

By pressing "ENTER" you open the outlet valve to drain the water from the measuring chamber.

By pressing the "ENTER" key again, this function is terminated.

Fill chamber (8)

When "ENTER" is pressed, the measuring chamber is filled.

Language (9)

Chose language of display.

Diagnosis (10)

You can call up the current status of the signal inputs and outputs from a list.

An active status is marked with a * (see menu structure).

The value of the output OUT corresponts to 1/10 mA (e. g. 150 = 15. 0mA).

15 / 19

PROGRAM - MENU

Testomat ECO

BASIC PROGRAM

ENTER

PROGRAM VALUES

MODE OF OPERAT.

Display of unit

Type of reagent

Limit values

Flush time

Interval

Water meter

Function LV1

Function LV2

Hysteresis LV1

Hysteresis LV2

Function Stop

Interface

ENTER

BOB operation

TIME CONTROLLED *

Volume interval

TYPE TH2005

Type TH2025 *

Type TH2100

Type TH2250

LV1:0,25°dH

LV2:0,35°dH

FLUSH 10s

Function off *

FUNCTION ON

DURATION *

Impulse

Interval

Time 00m:10s

HYSTERESIS LV2 1

TYPE 0-20 mA

Type 4-20 mA *

Time 10m

Volume 000l

DISPLAY °dH *

Display °f

Display ppm CaCO3

Display mmol/l

1 L/IMPULSE

10 l/Impulse

5 l/Impulse

100 l/Impulse *

500 l/Impulse

2.5 l/Impulse

1000 l/Impulse

Imp./l xxx.x

DURATION *

Impulse

Interval

Two point

Time 00m:10s

HYSTERESIS LV2 1

NORM.OPEN CONT.

Norm.closed con *

BASIC PROGRAM

After you have entered the menu with "ENTER", you can carry out the BASIC PROGRAMMING of the unit.

PROGRAM VALUES

To call up the factory-set basic default setting, briefly hold down the "M" and "i" key while switching the unit "ON".

Values and settings are described in the structure of the basic program.

Structure of the BASIC PROGRAMMING

Abbreviations: s = seconds m = minutes, h = hours, d = days, l = litres

To call up the factory-set basic default setting, briefly hold down the “M“and “i“ key while switching the

unit“ON“. CAUTION the last set of programming will be erased!

16 / 19

Error Messages / Trouble Shooting

Displayed Message

(flashes at selected display)Unit result functions Possible causes Remedies

Ff. DOSING PUMP

CANCEL WITH HORN-KEY

SAfter programming:

Continuous alarm

SStandby

• Dosing pump defective

• No dosing message from the

dosing pump

Replace dosing pump

Check cable to the dosing pump for

correct connection

Mf. TURBID

CANCEL WITH HORN-KEY

SAfter programming:

Continuous alarm

SContinue measurements

• The water is turbid / dirty

MEASURING RANGE EXCEEDED

CANCEL WITH HORN-KEY

SAfter programming:

Continuous alarm

SContinue measurements

• The measuring range is

exceeded Choose another type of reagent

(Basic program)

LOW WATER-PRESSURE

CANCEL WITH HORN-KEY

SAfter programming:

Continuous alarm

SStandby

• No water input although LED

"IN" lights up

• Inlet pressure too low

• Overflow reagent is not active

Check water inlet

Connector of the inlet valve

oxidised

Clean filter strainer

Replace valve block

Extract pressure regulator valve

Carry out adjustment

Ff. OUTLET TO DRAIN

CANCEL WITH HORN-KEY

SAfter programming:

Continuous alarm

SStandby

• Water remains in the

measuring chamber although

LED "OUT" lights up

Check water outlet

Connector of the outlet valve

oxidised

Replace valve block

REAGENT LOW

CANCEL WITH HORN-KEY

SAfter programming:

Continuous alarm

SContinue measurements

• Reagent quantity is below

minimum setting

without BOB: 50 ml (10 %),

with BOB: after calculation!

Check reagent level, fill up if

necessary

(enter level: "M" ºSERVICE)

Mf. DIRTINESS

CANCEL WITH HORN-KEY

SAfter programming:

Continuous alarm

- Continue measurements

• Sight-glass windows dirty Clean sight-glass windows

Ff. OPTICS

CANCEL WITH HORN-KEY

SAfter programming:

Continuous alarm

SStandby

• Plug-in circuit board defective

• Error at the optic component

(Transmitter or Receiver

defective)

Replace plug-in circuit board

Replace measuring chamber

sealing rings

Mf. ANALYSIS

CANCEL WITH HORN-KEY

SAfter programming:

Continuous alarm

SStandby

Incorrect analysis, e.g:

• Air in the dosing capillary

• incomplete blending

• Reagent too old or use of third-

party reagent

Tighten connections of the dosing

pump

Replace stirring mechanism

Replace suction insert in the bottle

Replace reagent, only use HEYL

Testomat® 2000 reagent

Ff. DOSING FAULT

CANCEL WITH HORN-KEY

SAfter programming:

Continuous alarm

SContinue measurements

• Dosing inaccuracy of the

dosing pump Replace dosing pump or return to

the supplier for calibration

Ff. = Function fault

Mf. = Measuring fault

17 / 19

Further Information

Fault Possible causes Remedies

Interface works

incorrectly • incorrect measuring value at the output or no power

supply

SMax. load exceeded

Although unit is

switched "ON"

No display

• Fuse F9, F5 or F2 (240 V: F1) defective

• Power switch defective

•Multi-pin strap cable at display circuit board or base

circuit board loose contact

• Fault on display circuit board or base circuit board

SReplace fuses

SReplace power switch

SCheck and reconnect

SReplace display or base circuit board

Maintenance

Regular maintenance is necessary in order to ensure trouble-free operation of the unit!

Please carry out the maintenance work described in the following section when

Sthe programmed maintenance date has been reached (display "maintenance date exceeded")

Sthe unit displays the following error messages: " Mf.dirtiness " or " Reagent low level"

Sthe last maintenance was carried out more than 6 months ago

Never use organic solvents to clean the measuring chamber and other plastic parts!

Please observe the safety rules when handling cleaning agents!

LIf the measuring range has been exceeded over an extended period, a coloured coating can form on the sight-

glass windows. This stubborn coating can be easily removed with alcohol.

Description of maintenance work

Cleaning the measuring chamber and the sight-glass windows

1. Switch the unit 'off' or press the "STANDBY" key (drain measuring chamber completely !).

2. Close the hand-operated valve on the branch line to the TESTOMAT®ECO.

3. Unhook toggle type fastener, tip the measuring chamber upwards and extract.

4. Slacken both sight-glass window holders, extract and clean the sight-glass windows.

5. This stubborn coating can be easily removed with alcohol.

6. Clean the measuring chamber with 10% hydrochloric acid and then rinse well.

7. After cleaning, replace the sight-glass windows and secure these with the sight-glass windows holder

(do not forget the O-ring seals and check for correct seating in the recess).

8. Insert the measuring chamber by tilting it backwards until the slot engages with the rear

guide bar and press down. Finally secure the chamber with the toggle type fastener.

Cleaning the filter housing

1. Close the hand-operated valve on the branch line to the TESTOMAT®ECO.

2. Undo the hose connections to the filter housing.

3. Unscrew inlet connection remove sealing ring, spring and filter strainer and clean.

4. Extract the retaining pin and withdraw the flow regulator and finally remove the valve

body.

5. Clean filter housing with water or alcohol and and reassemble.

Insert filter strainer point downwards!

6. Install the hose connections to the filter housing.

Water Leakage from of the seals can result in damage to parts of the unit

TTip: Please check the unit for leaks before carrying out the first analysis

•switch the unit to STANDBY

•manually fill the measuring chamber •manual reagent dosing (key "Manual")

•check the connections and seals for leaks

Note on care for the unit

The surface of the unit has not been treated. Therefore, a contamination with reagent, oil or grease should be avoided.

Should the housing, however, be contaminated, please clean the surface with isopropanol (never use other solvents).

18 / 19

SPARE PARTS LIST Testomat® ECO

Item

No. Pressure regulator

40120 Regulator / filter housing

40129 Regulator plug T2000, kpl.

11225 Flow regulator valve (1 - 8 bar)

11230 Retaining pin for regulator plug

11217 Inlet filter

11218 Spring for inlet filter

40121 Inlet connector

40153 Plug in connector - G 1/4" -6

Measuring chamber

40173 Sight-glass window 30 x 3 with seal

40170 Sight-glass window 30 x 3

40176 Sight-glass retaining disc

33253 Screw spindle M3x40

40032 Latch fastener TL 800-7-1

11203 Plastic plug

40022 Measuring chamber T2000

Holding block for measuring chamber

40030 Holding block complete (without measuring

40050 Magnetic stirrer

40186 Plug in connector -G 3/8" -10

40018 Solenoid valve, 2/2-Way

40181 Rear guide bar for measuring chamber 5 x 60

Dosning pump DOSIClip®

40001 Jet pump complete, complete

40011 Suction capillary complete, complete

40016 Pressure capillary complete

37232 Base circuit board TI, complete

34668 Magnet 24 VDC

32046 Plastic cover CNH 45 N

Bottle connection/Suction tube

40131 Screwed cap with bottle insert T2000

40130 Screwed cap GL32 - only

40135 Bottle insert for screwed cap with push-fit suction

Item

No Electrical components

31582 Fuse M4A

37245 Base circuit board T-ECO, complete 230V

40192 Control circuit board T-ECO, complete.

40071 EPROM T-ECO

40190 Cable sleeve 5 -7

40191 Cable sleeve 7 -10

40197 Mains on / off switch Testomat 2000

40198 Cover for Mains on / off switch

31713 Multi-pin strap cable 10 pol. with EMI filter clamp

40096 Multi-pin strap cable 26 pol. with EMI filter clamp

40060 Cable loom 2V complete (for valves)

40062 Cable loom 2P complete (for max. 2 dosing pumps)

40200 Cable loom for Mains on / off switch complete

31622 Fuse T0,16A

31592 Fuse T1,0A

Spare parts requirement for 2 -3 years of operation

40173 Sight-glass window 30 x 3 with seal 2 x

11217 Inlet filter (optional) 1 x

40124 Gasket set T2000 (after maintenance) X*

31622 Fuse T0,16A 1

31592 Fuse T1,0A 1

X* Accurate operation of the TESTOMAT®ECO can

be assured only with regular maintenance and

replacements of seals / gaskets (see text on

maintenance).

Accessories:

Order no.

040123 Optional adapter for water inlet (Quick-

acting plug and -coupling).

(Applicable only with optional pressure control)

Reagents:

Order no.

152005 TH2005 Water hardness 0.89 - 8.93 ppm CaCO3

152025 TH2025 Water hardness 4.47 - 44.7 ppm CaCO3

152100 TH2100 Water hardness 17.9 - 179 ppm CaCO3

152250 TH2250 Water hardness 44.8 - 448 ppm CaCO3

Table of contents

Other Testomat Measuring Instrument manuals

Popular Measuring Instrument manuals by other brands

NOMIS Seismographs

NOMIS Seismographs Mini-SuperGraph II user guide

uRADMonitor

uRADMonitor SMOGGIE quick start guide

Powelectrics

Powelectrics IN4MA Metron-p Technical Manual and Specifications

Klein Tools

Klein Tools CL1100 instruction manual

Gill

Gill WindSonic M 1405-PK-201 user manual

Thermo Scientific

Thermo Scientific Thermo Scientific AquaSensors RDO Pro-X manual