Testomat 2000 THCL User manual

Testomat 2000

®

THCL

Combined process photometer for

total chlorine 0 – 2.5 ppm

and process titrator for water hard-

ness 4.47 – 44.7 ppm CaCO

3

Operating Instructions

Contents

2

Contents

Contents...............................................................................................2

Important safetyinformation ..............................................................4

Intended use .........................................................................................4

Qualification of the staff ........................................................................4

Warning notices in these instructions ...................................................5

Further documents................................................................................5

Pay particular attention to .....................................................................5

General instructions ..............................................................................5

Installation .............................................................................................6

Operation ..............................................................................................6

Cleaning ................................................................................................6

De-installation .......................................................................................6

Disposal ................................................................................................6

Scope of delivery ................................................................................7

Performance specifications ...............................................................7

Indicators/Reagents for Testomat 2000

®

-THCL ...................................8

Application instructions.....................................................................9

Installation .........................................................................................10

Operating Testomat 2000

®

THCL in the pressure range 0.3 to 1 bar 10

Installing Testomat 2000

®

THCL .........................................................10

Connecting the water inlet and outlet .................................................11

Water inlet ...........................................................................................11

Water outlet.........................................................................................11

Connecting the power supply and devices .........................................12

Block diagram Testomat 2000

®

THCL ................................................12

Internal design Testomat 2000

®

THCL ...............................................13

Connecting the mains voltage.............................................................14

Connecting the plant components ......................................................15

Connecting the inputs and outputs .....................................................16

Commissioning .................................................................................17

Inserting indicator bottles ....................................................................17

Extracting indicators............................................................................17

Opening the water inlet .......................................................................18

Instrument settings and data input......................................................18

Functions of the operating and display elements.........................18

Switching Testomat 2000

®

THCL on/off..............................................18

Display functions .................................................................................19

Operating elements and function keys ...............................................20

Operating system................................................................................21

Password protection and basic program .......................................22

Entering basic program data...............................................................22

Selecting the display units ..................................................................22

Selecting the operating mode .............................................................23

Entering further basic program data ..............................................25

Internal flushing...................................................................................25

External flushing .................................................................................25

Interval pause .....................................................................................26

Limit value monitoring .........................................................................26

Hysteresis ...........................................................................................27

Contents

3

Switch functions of the limit value outputs LV1 and LV2 ....................28

Switch function 0, duration..................................................................28

Switch function 1, impulse ..................................................................28

Switch function 2, interval ...................................................................28

Function IN1........................................................................................28

Water meter ........................................................................................29

Alarm / Message .................................................................................29

Function AUX ......................................................................................30

Service II .............................................................................................30

Reset operating time...........................................................................30

Maintenance interval...........................................................................31

Description of the signal inputs/outputs........................................32

Interfaces (optional) ............................................................................34

Monitoring the measuring points.........................................................34

Calculating the output currents ...........................................................35

Serial interface RS232 ........................................................................35

Description of the relay outputs......................................................36

Flushing (external flush valve) ............................................................36

LV1 and LV2 limit value outputs .........................................................36

Measuring points 1 or 2 (measuring point switch-over)......................37

AUX (programmable function output) .................................................37

Alarm (fault message output)..............................................................38

Maintenance (output for maintenance message) ...............................38

Information menu "i" ........................................................................39

Request options: Customer service, operating values, program

values, error history, maintenance......................................................39

Program menu "M" ...........................................................................40

Programming of: Indicator, manual mode, flushing, flush chamber,

drain chamber, fill chamber, self-test, confirm maintenance,

diagnosis, date, time, basic program with password ..........................40

Structure of the basic program............................................................42

Error messages / Troubleshooting .................................................43

Further information..............................................................................44

Maintenance ......................................................................................45

Description of maintenance work........................................................45

Service instructions .............................................................................46

Testomat 2000

®

spare parts and accessories................................47

Accessories.........................................................................................48

Technical data ...................................................................................49

Product overview Testomat 2000

®

instruments ............................50

Important safetyinformation

4

Important safetyinformation

Please read these operating instructions carefully and completely

prior to working with the instrument.

Ensure that these operating instructions are always available for all

users.

These operating instructions must always be passed on to the new

owner should Testomat 2000

®

THCL change hands.

Always adhere to hazard warnings and safety tips when using

reagents, chemicals and cleaning agents. Please adhere to the re-

spective safety data sheet! Download the safety data sheets for

the supplied reagents at http://www.heyl.de .

Intended use

Testomat 2000

®

THCL is used for the automatic determination and

monitoring of residual total hardness (water hardness from 0.25 to

2.5 °dH) and the determination of total chlorine content from 0 to 2.5

mg/ltr (ppm) in water. The feed water must be clear, colourless and

free of undissolved particles.

Always adhere to the performance limits stated in the section enti-

tled “Technical data”.

Always observe the application areas/application limits of the indi-

cators and the requirements of the medium being measured.

To ensure correct and intended usage, always read and understand

these instructions, especially the section entitled “Important safety

information”, prior to use.

The instrument is not used as intended if

• it is used in areas not specified in these instructions.

• it is used in areas which do not correspond to the ones described

in these instructions.

Qualification of the staff

Assembly and commissioning require fundamental electrical and

process engineering knowledge as well as knowledge of the respec-

tive technical terms. Assembly and commissioning should therefore

only be carried out by a specialist or by an authorised individual su-

pervised by a specialist.

A specialist is someone who due to his/her technical training, know-

how and experience as well as knowledge of relevant regulations can

assess assigned tasks, recognise potential hazards and ensure ap-

propriate safety measures. A specialist should always adhere to the

relevant technical regulations.

Important safetyinformation

5

Warning notices in these instructions

The warning notices in these instructions warn the user about poten-

tial dangers to individuals and property resulting from incorrect han-

dling of the instrument. The warning notices are structured as follows:

Description of the type or source of danger

Description of the consequences resulting from non-observance

Preventive measures. Always adhere to these preventive meas-

ures.

“DANGER” indicates an immediate hazardous situation which, if not

avoided, will result in death or serious injury.

“WARNING” indicates a potentially hazardous situation which, if not

avoided, could result in death or serious injury.

“CAUTION” indicates a potentially hazardous situation which, if not

avoided, could result in minor or moderate injuries or property dam-

age.

“NOTE” indicates important information. If this information is not ob-

served, it may result in an undesirable result or state.

Further documents

Testomat 2000

®

THCL is a plant component. Therefore, always ob-

serve the maintenance manual of Testomat 2000

®

/ ECO

®

and the

documentation of the plant manufacturer.

Pay particular attention to

General instructions

• Please adhere to health and safety regulations, electrical equip-

ment safety regulations, and environmental protection regulations

valid in the country of use and at the installation site.

• Adhere to national and local regulations during installation and

commissioning.

• Always protect the instrument against moisture and humidity. It

should never come into contact with condensation or splash water.

• Do not carry out any changes or actions at the instrument which

are not described in these instructions

;

failure to adhere to these

instructions will negatively affect any warranty claims that you

make thereafter.

SIGNAL WORD

WARNING

!

Important safetyinformation

6

Installation

• Always completely disconnect the relevant plant part before install-

ing the instrument or connecting/disconnecting it to/from the power

supply. Secure the plant against reconnection.

• Only connect the instrument to the mains voltage specified on the

rating plate.

• Always observe technical data and ambient parameters.

• Testomat 2000

®

THCL requires an interference free and stable

power supply. If necessary, use a mains filter to protect Testomat

2000

®

THCL against interference voltages caused, e.g., by sole-

noid valves or large motors. Never lay connecting cables parallel to

power cables.

Operation

• Ensure that the maximum electrical load capacity of the relay out-

puts is never exceeded.

• Immediately switch off Testomat 2000

®

THCL and contact service

staff if malfunctioning occurs. The warranty will be void if you tam-

per with or attempt to repair Testomat 2000

®

THCL. Repairs must

be carried out by authorised service staff.

Cleaning

• Only use a dry, lint-free cloth for cleaning.

De-installation

• Prior to de-installing a defective instrument, always write down a

description of the error (failure effect). It is only possible to repair a

defective instrument (irrespective of the warranty period) if it has

been de-installed and returned to us with a description of the error.

Disposal

• Dispose of the instrument in accordance with national regulations.

WARNING

!

HINWEIS

Scope of delivery

7

Scope of delivery

1 Testomat 2000

®

THCL

1 plastic bag with screw caps with a hole and an insert for the

screw caps of the indicator bottles

1 operating instructions

Performance specifications

Testomat 2000

®

THCL is used for the automatic determination and

monitoring of residual total hardness (water hardness from 0.25 to

2.5 °dH) via titration and the determination of total chlorine content

from 0 to 2.5 mg/ltr (ppm) in water. The analysis of total chlorine is

carried out by adding three reagents; the analysis result is displayed

after a reaction time of approx. 1 minute (without flushing times).

• Simple, menu-driven operating and programming via a plain

text display

• Measurement via titration of residual hardness and

photometric determination of the total chlorine content

• Freely selectable hardness units in °dH, °f, ppm CaCO3 or

mmol/l and chlorine units in mg/l or ppm

• High measuring accuracy provided by a precise piston-

dosing pump

• Analysis initiation:

- Automatic interval operation

(interval pause can be set from 0-99 minutes)

- External control

- Quantity dependent via impulse water meter

• One limit value with hysteresis (1, 2 or 3 bad analyses) for

residual hardness (LV1) and total chlorine (LV2) and settable

switch functions

• Monitoring of both measuring points (change-over via exter-

nal solenoid valves)

• Internal error documentation

• Programmable service address

• Programmable maintenance interval for a maintenance re-

quest

• Extended operating periods due to 500 ml indicator storage

bottle

• optional

Interface card (0/4-20 mA or 0/2-10 V)

Interface RS 232 (for a protocol printer)

Performance specifications

8

Indicators/Reagents for Testomat 2000

®

-THCL

Water hardness

Indicator type TH 2025

°dH

(Resolution)

0.25 – 2.50

(0.05)

°f

(Resolution)

0.45 – 4.48

(0.1)

ppm

CaCO

3

(Resolution)

4.47 – 44.7

(0.9)

Unit

mmol/l

(Resolution)

0.04 – 0.45

(0.01)

Total chlorine

Reagent CL2250A, CL2250B, CL2250C

Unit

mg/l (ppm)

(Resolution)

0.0 – 2.5

(0.1)

Application instructions

9

Application instructions

• Wait at least 5 seconds before switching the instrument on and

then off again at the main switch.

• In order for Testomat 2000

®

THCL to operate reliably, use Heyl

Testomat 2000

®

indicators in the pH-range 4 – 10.5!

• With Testomat

®

instruments for water hardness monitoring, larger

quantities of heavy metal ions in the softened water might influ-

ence the colour reaction, especially iron above 0.5 mg/I, copper

above 0.1 mg/I and aluminium above 0.1 mg/l (brownish-red col-

our display).

• If the measuring water contains more than 20 mg/I CO

2

(carbonic

acid), incorrect evaluations cannot be excluded.

• The concentration of influencing contents can be determined by

using our colourimetric TESTOVAL

®

test kit.

• Careful handling of the instrument increases both its operational

reliability and service life! Therefore, carry out a visual inspection

at regular intervals as described below.

- Has the use-by date of the indicator expired?

- Are the hose connections of the dosing pump free of leaks?

- Is there air inside the dosing hoses?

- Are all the water connections free of leaks?

- Are the doors of the instrument closed properly?

- Is the instrument heavily soiled?

- Are the measuring chamber and the drain duct/drain hose

clean?

• Trouble-free operation is only possible when maintenance is car-

ried out on a regular basis (For maintenance and service instruc-

tions, please refer to the section entitled “Maintenance” and the

"Maintenance manual of Testomat 2000

®

/ ECO

®

")

• If problems occur, please refer to the section entitled "Error mes-

sages/Troubleshooting.

Installation

10

Installation

Risks resulting from incorrect installation!

Install Testomat 2000

®

THCL at a location where it is protected

against dripping or splash water, dust and aggressive substances

– e. g. in a switch cabinet or on a suitable wall.

Information for trouble-free operation

Install Testomat 2000

®

THCL vertically and without mechanical

stress.

Install Testomat 2000

®

THCL at a vibration-free site.

Operating Testomat 2000

®

THCL in the pres-

sure range 0.3 to 1 bar

Prior to installation, please check whether lower operating pressure is

required. The instrument is factory set for the operating range 1 to 8

bar. Remove the flow controller valve body j

jj

jto operate the instru-

ment in the operating range 0.3 to 1 bar (e.g. when using an aerator

type R). This involves removing the retaining pin i

ii

ifrom the

controller / filter receiver g

gg

g. Subsequently use the metal bracket to

remove the controller plug k

kk

kfrom the borehole. Subsequently

remove the flow controller valve body j

jj

jand reinsert the controller

plug and the retaining pin.

Installing Testomat 2000

®

THCL

Select an installation site where the water inlet hose can be kept as

short as possible (max. 5 m).

Please leave sufficient space on the left-hand side of the instru-

ment to open the door.

Drill the mounting holes as shown in the drawing on the left.

Use three screws to attach the instrument at a suitable position in

the switch cabinet or on a wall.

Remove for

pressure

range 0.3 to

1 bar

g

gg

g

i

ii

i

j

jj

j

k

kk

k

WARNUNG

!

NOTE

Installation

11

Connecting the water inlet and outlet

Information for trouble-free operation

The water pressure must be between 0.3 bar and 8 bar

Avoid strong pressure fluctuations

The measuring water temperature must be between 10 °C and 40

°C

For temperatures above 40°C, the KCN type cooler should be in-

stalled in the branch line of Testomat 2000

®

THCL.

Water inlet

The measuring water is taken from the main water line of the water

treatment plant and fed to the inlet connection of Testomat 2000

®

THCL. The instrument is equipped with a plug connector for plastic

hoses 6/4 x 1 (external diameter 6 mm/ internal diameter 4 mm, wall

thickness 1 mm) as standard.

Install the connection for the branch line of Testomat 2000

®

THCL

directly at the main water line

①

directly after the water treatment

plant

It is important that the branch line connection is laid vertically up-

wards in order to prevent dirt particles from entering the instru-

ment from the main water line

.

Install a manually operated shut-off valve

②

in the branch to Tes-

tomat 2000

®

THCL.

Use an opaque plastic hose 6/4 x 1 (max. length 5 m) for the water

inlet

③.

Flush the inlet to remove any dirt particles

When operating within a pressure range of 0.3 to 1 bar, please re-

move the valve body from the controller and the filter housing.

When using a cooler

The hot water can cause burns and damage wetted parts of

Testomat 2000

®

THCL.

Water outlet

The feed water flows through the measuring chamber to the drain via

the outlet hose.

Connect the outlet connection of Testomat 2000

®

THCL to an

opaque outlet hose

④

(internal diameter 14 mm).

Lay this hose without backwater development and any syphoning

effect, e.g. via an open funnel, to the drain.

⑤

①

②

③

⑤

④

⑤

NO !!

"Sagging"

causes back-

water!

NOTE

CAUTION

!

Installation

12

Connecting the power supply and devices

Risk of electric shocks during installation!

If the power supply is not disconnected prior to installation, it may

result in personal injuries, destruction of the product or damage to

plant parts.

Always disconnect the relevant plant parts before installing Tes-

tomat 2000

®

THCL.

Only use tested cables with sufficient cross-sections for the con-

nections.

Risk of damages caused by electromagnetic fields!

If Testomat 2000

®

THCL or the connecting cables are installed

parallel to power cables or in close proximity to electromagnetic

fields, the instrument may be damaged or measurements incor-

rect.

Ensure that connecting cables are as short as possible.

Always install connecting cables and power cables separately.

Connect the instrument to the protective earth conductor (for

230/115 VAC).

Protect Testomat 2000

®

THCL against interference voltages – e.g.

via a mains filter.

Shield the instrument against strong electromagnetic fields.

Block diagram Testomat 2000

®

THCL

Drawn relay positions: Instrument de-energised

WARNING

!

NOTE

Installation

13

Internal design Testomat 2000

®

THCL

①

Terminal block for inputs Start, Stop, IN1, IN2, and output OUT

②

Mains switch

③

Terminal block for mains inputs and mains outputs

④

Terminal block relay outputs

⑤

Dosing pumps (DosiClip1=left, DosiClip4=right))

⑥

Water connections, inlet and outlet

⑦

Controller / Filter receiver

⑧

Measuring chamber

①

①①

①

②

②②

②

③

③③

③

④

④④

④

⑤

⑤⑤

⑤

⑧

⑧⑧

⑧

⑦

⑦⑦

⑦

⑥

⑥⑥

⑥

Installation

14

Connecting the mains voltage

Only connect the instrument to the specified mains voltage. Refer to

the rating plate for the appropriate mains voltage. Connect the cables

as follows:

Loosen both fastening screws

①

and open the upper door. The

terminal box is now accessible.

Pierce the required rubber cable glands

②

with a screwdriver and

insert the cable through the bush into the terminal box (1)

Subsequently pull back the cable until the bush has been turned

over (2).

Connect the power supply to terminals PE,N,L or for 24 V instru-

ments to terminals U, V.

Connect the conductor to the terminal block as shown on the left

➂

.

Ensure that the leads are held securely in the terminals.

Proceed as shown in figure

➃

to loosen the connection.

Terminal

description

Typ

e Function Comment

PE IN Mains – protective earth

(5x)

Only with mains

115/230 V !

N

(U)

L

(V)

IN Mains, N=neutral (U=24 V)

Mains, L=live (V=24 V)

Mains input

24 V / 115 V / 230 V

n

lOUT

Neutral, switched (8x)

Live, switched (8x)

Mains for consumers,

max. 4 A

Insert the conductor with

ferrule or the solid conductor

into the round input.

➂

①

②

①

1. Insert a screwdriver into the

square opening without force in

order to open the terminal.

2. Once the terminal has been

opened, remove the conductor.

➃

Installation

15

Connecting the plant components

Connect the plant components to the output terminals of relays 1

to 19 (e.g. valves).

If the plant components require mains voltage, connect the

switched mains voltage (l) to the common contact

①

of the re-

spective relay (see the connection example for 230 VAC on the

left).

Connect the neutral conductor of the plant component to one of the

terminals (n).

For components with a protective earth conductor connection,

connect it to the PE connection.

Ensure that the leads are held securely in the terminals.

No.

Terminal

description

Type

Function Comment

1

2 flushing OUT

External flush valve Volt-free relay output,

max. 240 VAC, 4 A

3

4

5

LV1 OUT

Limit value output 1 – Normally closed

Limit value output 1 – Normally open

Limit value output 1 – Common

Volt-free relay output,

max. 240 VAC, 4 A

6

7

8

LV2 OUT

Limit value output 2 – Normally closed

Limit value output 2 – Normally open

Limit value output 2 – Common

Volt-free relay output,

max. 240 VAC, 4 A

9

10

11

Measur-

ing points

1/2

OUT

Measuring point 1 – Normally closed

Measuring point 2 – Normally open

Measuring point switch-over - Common

Volt-free relay output,

max. 240 VAC, 4 A

12

13 AUX OUT

Universal output Volt-free relay output,

max. 240 VAC, 4 A

14

15

16

Alarm OUT

Fault message output – Normally closed

Fault message output – Normally open

Fault message output – Common

Volt-free relay output,

max. 240 VAC, 4 A

17

18

19

Mainte-

nance OUT

Maintenance message – Normally

closed

Maintenance message – Normally open

Maintenance message – Common

Volt-free relay output,

max. 240 VAC, 4 A

Connection example:

Limit value contact LV 1

switches mains voltage

n

l

3

4

5

e.g.

solenoid

valve

PE

①

Installation

16

Connecting the inputs and outputs

Testomat 2000

®

has the following connections for control and moni-

toring functions.

Do not connect external voltage to these connections!

Ensure that the leads are held securely in the terminals.

Use the two fastening screws to close the upper door once installa-

tion has been completed.

For more information, please refer to the section entitled "Description

of the signal inputs/outputs".

No.

Terminal

description

Typ

e Function Comment

20

21 Start IN External analysis start

Common earth for inputs

Only for volt-free normally

open

22

23 Stop IN External analysis stop

Common earth for inputs

Only for volt-free normally

closed/normally open

24

25 IN1 IN

Universal input

1

Common earth for inputs

Only for volt-free normally

closed/normally open

26

27 IN2 IN Universal input 2 (water meter)

Common earth for inputs

Only for volt-free normally

open

┴

28

29

OUT OUT

Earth

0/4 - 20 mA galvanically separated

or serial interface RS232

Earth = ┴

28 = (+) or (TxD)

29 = (-) or (RxD)

Commissioning

17

Commissioning

Handling of reagents/indicators

Please adhere to the respective safety data sheets!

Trouble-free operation of Testomat 2000

®

THCL is only possible

when using Heyl Testomat 2000

®

indicators/reagents!

Inserting indicator bottles

Open the lower housing door by pulling on the right-hand side.

Remove the caps from the indicator bottles.

Remove the plastic bag from inside the housing. The plastic bag

contains the screw caps with hole

①

and the inserts

②

for the

screw caps.

Connect the parts as shown on the left.

Obeserve correction allocation of the indicators to the pumps:

TH2025=DosiClip1 (left), CL2025A=DosiClip2, CL2025B= Dosi-

Clip3 and CL2025C=DosiClip4 (right)

Screw the hose connectors

③

of the intake hoses

④

hand-tight

into the inserts

②.

Place the inserts with the screwed-in intake hoses into the indica-

tor bottles.

Now screw the screw caps with hole

①

hand-tight onto the indica-

tor bottles.

⑤

Switch the instrument on and press the "STANDBY" key

.

Enter the filling levels of all the indicator bottles in "%":

In the menu, select

>SERVICE I

=>

INPUT REAGENTS

=>

INDICATOR TH FILLING (100%)

(New/Full bottle = 100% filling level)

Press "ENTER" to confirm the entry

Enter further filling levels accordingly

Extracting indicators

Switch the instrument on and press the "STANDBY" key

During operation, the pumps (DOSIClip1 - 4)

⑥

automatically ex-

tracts the indicator.

To ensure that indicator is available for the initial analyses, the

intake hose

④

and the transport hose

⑦

must be filled with indi-

cator from the pump up to the measuring chamber.

Press the "manual"

⑧

key several times until the intake hose

④

and the transport hose

⑦

are filled with indicator up to the meas-

uring chamber

If necessary, manually tighten the hose connectors of the intake

and transport hose slightly in case of bubble formation

①

②

③

④

⑤

⑥

⑦

⑧

CAUTION

!

Functions of the operating and display elements

18

①

②

Opening the water inlet

Open the lower housing cover.

Slowly open the manually operated shut-off valve to prevent the

measuring chamber overflowing. The flow regulator requires a few

seconds to function correctly.

Make sure that the water conducting parts are not leaky.

If water sprays from the vent hole

①

of the measuring chamber

②

, reduce the amount of inlet water via the manually operated

shut-off valve. It should take 2 to 6 seconds to fill the measuring

chamber!

Instrument settings and data input

Please read the following information before carrying out settings

and entering data for operating the instrument.

Functions of the operating and dis-

play elements

The Testomat 2000

®

THCL display shows operating statuses and

measured values. The input keys for programming (cursor block) and

the function keys are located underneath the display.

Switching Testomat 2000

®

THCL on/off

(1) Mains switch

Use this switch to switch the instrument on or off.

(2) Instrument fuse (inside the instrument)

This fuse protects Testomat 2000

®

THCL and the outputs

against overloads and short circuits.

(1)

(2)

Functions of the operating and display elements

19

Display functions

1 Status of limit value displays (red/green)

The display 1 illuminates red if limit value 1 (water hardness) has

been reached or exceeded. The display 1 illuminates green if the

value falls below the limit value. The same principle applies to limit

value 2 (total chlorine) and display 2.

2 Text display (4 lines)

Displays the current analysis result as well as all important

statuses and programming data.

2a = The current measured value for measuring point 1 (water

hardness) is displayed in Line 1.

Value falls below the measuring range = "<" e.g. < 4.47 ppm

CaCO

3

Value exceeds the measuring range = ">" e.g. > 44.7 ppm

CaCO

3

The current measured value for measuring point 2 (total chlorine)

is displayed in line 2.

Value exceeds the measuring range = ">" e.g. > 2.5 ppm

2b = The set limit values GW1 (water hardness) and GW2

(total chlorine) are displayed in line 3 and 4

3Alarm (red)

Indicates malfunctioning/error message or warning message

4 Maintenance message (yellow)

Indicates current maintenance requests

5 Status display of the active instrument components (line)

Six displays indicate the current instrument and analysis status

Cancelling error messages/warning messages

Press to acknowledge the message and, if necessary,

eliminate the cause of the fault.

Inlet

valve

Anal

y-

sis

Outlet

valve

Dosing

message

Without

function!

Analysis

stop

2

a

2b

All error and

warning messa

ges

are alternately

shown in line 1 of

the standard

display!

NOTE

Functions of the operating and display elements

20

Operating elements and function keys

If you wish to carry out settings or enter data, or if alterations are

necessary, press the "M" key to open the programming mode. Use

this key when in the menu to go to the higher order menu items or to

exit the programming mode. Please note: The basic program is

password protected!

Programming keys (cursor block)

Use the programming keys (cursor block) to navigate in the menu, to

select the desired functions and to enter necessary instrument and

plant specific data. Press the "ENTER" key to select the submenu

item and to confirm and accept the selection or data input.

Function keys

Manually start an analysis via the "Manual"

①

key

Set the instrument to standby mode via the "STANDBY"

②

key (automatic analyses are not carried out: analysis

stop)

Acknowledge error and warning messages via the "Horn"

③

key

Open the program menu for user-specific and instrument-

specific settings via the "M"

④

key

Retrieve all instrument information and settings via the "i"

key

⑤

(M)neu key

①

①①

①

②

②②

②

③

③③

③

④

④④

④

⑤

⑤⑤

⑤

Programming

keys

(cursor block)

THCL

Cursor block

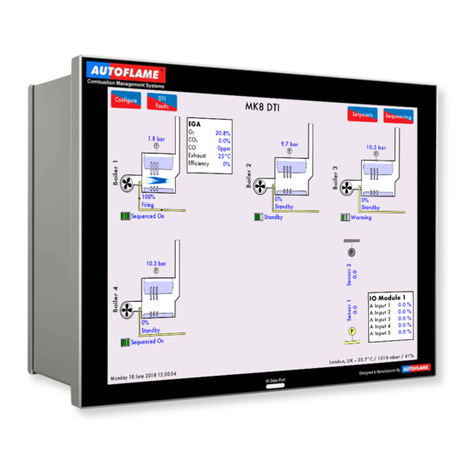

Table of contents

Other Testomat Measuring Instrument manuals

Popular Measuring Instrument manuals by other brands

Cole Parmer

Cole Parmer MB-200-40 instruction manual

Megger

Megger SVERKER 900 Application note

Endress+Hauser

Endress+Hauser Cerabar M PMC51? Cerabar M PMP51 Brief operating instructions

HollySys

HollySys HT5 Series Instructions for use

YEO-KAL

YEO-KAL 801C user manual

Bellingham and Stanley

Bellingham and Stanley ADP440 user guide

PCE Instruments

PCE Instruments PCE-TDS 100 H user manual

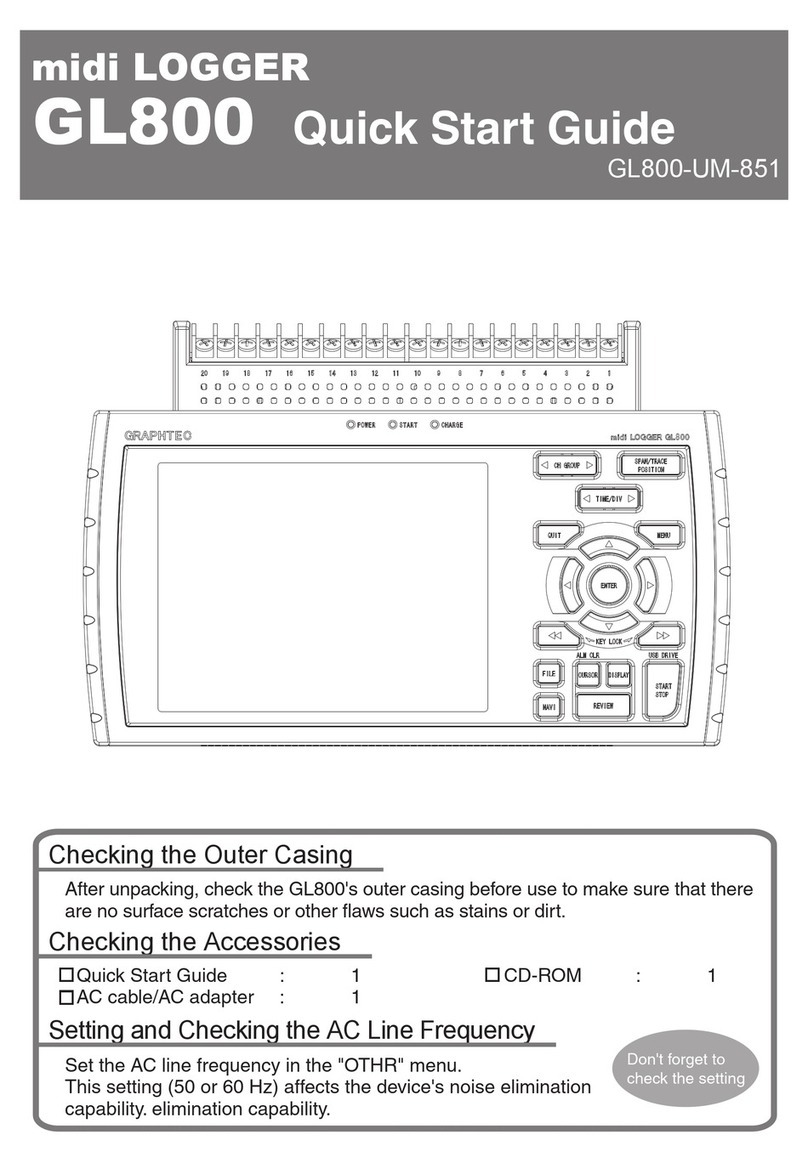

GRAPHTEC

GRAPHTEC midi LOGGER GL800 quick start guide

VOLTCRAFT

VOLTCRAFT VC-533 AC/DC operating instructions

NSK

NSK Bruel & Kjaer Vibro VCM-3 instructions

Kurth Electronic

Kurth Electronic KE401 IT quick start guide

Benning

Benning CM 9-2 operating manual