Tetra Pak COMET RC User manual

CRC910B

Wehopethattheinformationcontainedinthismanual

will be of help to you. It is based on concrete data

andonthebestofourcurrentknowledge.

Readthecontentsofthismanual carefully,including

warningsandrecommendations.

No part of this manual may be reproduced or

transmittedtothirdparties without the prior written

consentofTETRAPAKHOYER.

Tetra Pak

Hoyer

Tetra Pak Hoyer A/S Tetra Pak Hoyer Inc. Tetra Pak Hoyer S.p.A.

Soeren Nymarks Vej, 13 753 Geneva Parkway Via Monferrato, 52

DK 8270Hoejbjerg P.O. Box 280 20098 San Giuliano Milanese (Milano)

Denmark Lake Geneva, WI 53147 Italy

Telephone + 45 89 393939 U.S.A. Telephone +39 2 98292.1

Telefax + 45 86 292200 Telephone +1 414 249 7400 Telefax +39 2 9880171

Telex 68770 Alhoy DK Telefax +1 414 249 7500

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

Machine HOYERCOMETRC(cones/cups)

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

SerialNo.

CRC910B

Tetra Pak

Hoyer

1Machine identification data

2General

3Description of the machine and technical data

4Installation

5Adjustment procedures and product changeover

6Operating procedures

7Cleaning and maintenance

8Troubleshooting

9Spare parts for standard machine

10 Spare parts for cone product

11 Spare parts for cup product

HOYER COMET RC

CRC804BA1-1

Tetra Pak

Hoyer

Contents

1 - MACHINE IDENTIFICATION DATA

1.1 Introduction ............................................................................................................... 1-2

1.2 Identificationplate ...................................................................................................... 1-2

1.3 Servicecentres........................................................................................................... 1-3

CRC804BA1-2

Tetra Pak

Hoyer

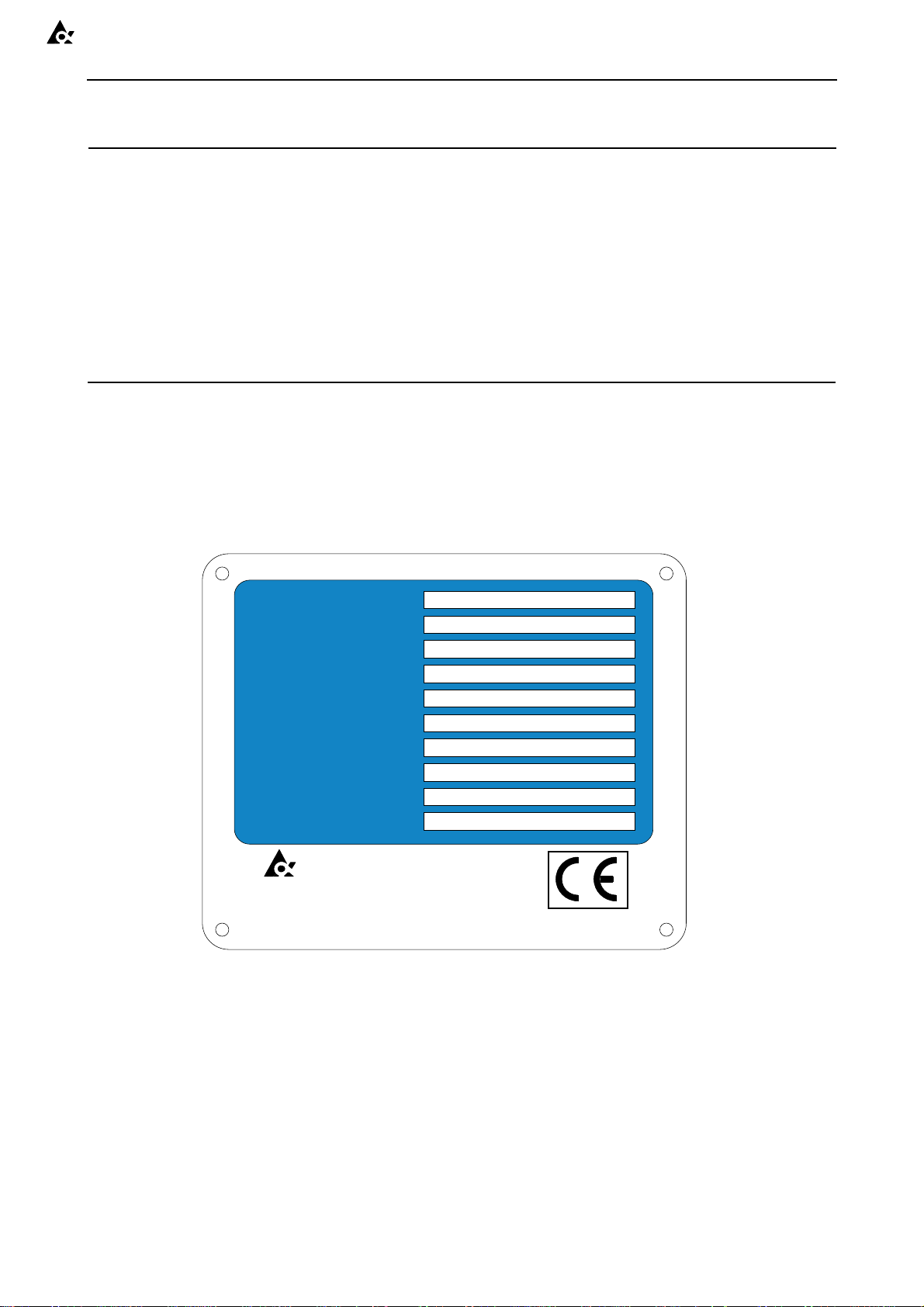

1.2 Identification plate

For maintenance and service operations not de-

scribedinthismanual,orforanyotherproblemsof

atechnicalnature,ourServiceDepartmentisatyour

completedisposalforinformationortoarrangefor

Fig.1.1- Identification plate

1.1 Introduction

Thankyouforbuyingamachinemanufacturedby

TetraPakHoyer.

Werecommendyoureadthismanualasitisessential

fortheinstallation,checkingandmaintenanceop-

erationsrequiredtokeepyourmachineinperfect

condition.

Themanualcontainstables,drawingsanddiagrams

whichwillallowyoutogainfamiliaritywithallparts

ofthemachine.

thenecessarymeasurestobetaken.

WhencontactingourServiceDepartment,please

quotethedatagivenontheidentificationplateaffixed

tothemachineandshowninFig.1.1.

MODEL

SERIAL N.:

YEAR OF CONSTRUCTION:

ELECTRICAL SUPPLY:

PNEUMATIC SUPPLY:

REFRIGERANT:

HEATING GAS:

THERMAL CAPACITY:

kW

Kg.

Kcal/h

Via Monferrato, 52 - 20098 San Giuliano Milanese

( MI ) Italia - Tel. 02-982921 - Fax 02-9880171 Made in Italy

Tetra Pak

Hoyer

V

bar Nlt/min.

ph Hz

Type

CRC804BA 1-3

Tetra Pak

Hoyer

1.3 Service Centres

Ifyouhaveanyrequirementorproblemthatrequires

ourassistance,please contact one of thefollowing

service centres, which are authorised to perform

maintenanceand technical serviceunderwarranty

toTetraPakHoyermachines.

EUROPEand

MIDDLEEAST:

Tetra Pak HoyerA/S

SoerenNymarks Vej13

DK-8270Hoejbjerg

Denmark

Phone: +45 89 39 39 39

Fax: +45 86 29 22 00

Tlx:68770alhoydk

Tetra Pak HoyerS.p.A.

Via Monferrato,52

I- 20098 San GiulianoMilanese

(Milan)

Italy

Phone: + 39 2 98 29 21

Fax: + 39 2 98 80 171

Tetra Pak HoyerFrance

c/oTetraLavalService SARL

R.C.S.VersaillesB403 276 223

P.O. Box 56

F-78340Les Clayes-Sous-Bois

France

Phone: +33 1 30818184

Fax: +33 1 30818120

NORTHAMERICA:

Tetra Pak HoyerInc.

753GenevaParkway

P.O. Box 280

Lake Geneva, WI 53147

USA

Phone: +1 414 249 7400

Fax: +1 414 249 7500

SOUTHAMERICA:

Tetra Pak Hoyer Industria e

ComércioLtda.

Rua Napoleao de Barros, 1038

Cep04024-003 Sao Paulo-SP

Brazil

Phone: +55 11 573 9422

Fax: +55 11 549 5420

ASIA/PACIFIC:

TetraPakHoyer Shanghai

Shanghai Overseas Chinese

Mansion

Room 2105-2107

No.129, Yan'an Xi Lu

200040Shanghai

P.R.China

Phone: +86 21 6249 0860

Fax: +86 21 6249 9064

Tetra Pak Hoyer Service

3rdFloor,MolaceBuilding

2231PasongTamo Street

Makati,Metro Manila

Philippines

Phone: +63 2 8132848

Fax: +63 2 8132866

SOUTHKOREA:

HoyerLtd.

4fl.DookyongBldg.

66-1/9Hannam-Dong

Yong San-Ku

140-210 Seoul

SouthKorea

Phone: +82 2 796 0362

Fax: +82 2 796 0365

THAILAND:

TetraPakHoyer(Thai) Ltd.

1042Soi Poosin, Sukhumvit Soi

66/1

Bangchak,Prakanong

Thailand

Phone: +66 2 3611680

Fax: +66 2 3612310

C.I.S.:

TetraPakHoyer A/O

4thRostovsky peureulok

Dom1,stroenie1

R-11921 Moscow

C.I.S.

Phone: +7 502 2242160

Fax: +7 502 2242162

HOYER COMET RC

CRC804BB2-1

Tetra Pak

Hoyer

Contents

2 - GENERAL

2.1 Declarationofconformity ........................................................................................... 2-2

2.2 Preliminarypoints ....................................................................................................... 2-2

2.3 Generalsafetyrules .................................................................................................... 2-2

2.4 Specialwarnings ........................................................................................................ 2-3

2.5 Ambientoperatinglimits ............................................................................................. 2-3

CRC804BB2-2

Tetra Pak

Hoyer

2.1 Declaration of conformity

Thismachinehasbeenmanufacturedinaccordance

withinternational standards andhygieneand sani-

tarylegislationapplicabletofoodmachinery.Inpar-

ticular,Tetra PakHoyercertifies,throughtheDec-

larationofConformitysupplied together with the

machine, that the HOYERCOMETRC(cones/

cups) production unit has been designed and

manufacturedin accordancewiththeprovisionsof

Directive89/392/CE(MachineryDirective) andin

linewiththeabovementionedstandardsapplicable

tothisDirective.

•Theillustrationsanddrawingsshowingthema-

chineareintendedforgeneralreferenceonlyand

arenot necessarily accurateinevery detail.

•Themachinedimensionsandspecificationsgiven

inthis manual arenotbindingand may change

withoutadvancewarning.

•Thedrawingsandallotherdocumentsprovided

asa partofthis machineremainthe propertyof

Tetra Pak Hoyer andmustnot be passed on to

thirdpartieswithoutthewrittenpermissionof

Tetra PakHoyer.

•Themanual includestheinstructions forallac-

cessoriesmountedon the standardmachine.

•Themachineiscoveredbywarrantyaslaid

downinthepurchase contract. Anyrepair

work not authorised by Tetra Pak Hoyer

carriedoutduringthewarrantyperiodwill

automaticallyinvalidatethewarranty.

2.2 Preliminary points

2.3 General safety rules

•THESE SAFETY RULES HAVE BEEN

DRAWN UP IN YOUR INTEREST. Strict

observance will reduce the risk of accident to

yourself ortoothers.

•DONOT attempt the move,install or operate

themachinebeforereadingandassimilatingthe

contents of this manual. Ask your superior in

caseof doubt.

•Makesure that alltheguardsand safety covers

areinpositionBEFOREstartingthe machine.

•NEVERleavetools, mechanical partsorother

foreignmaterialsonorinsidethemachine.

•If a malfunction occurs, press the emergency

stopbutton.

•NEVER PLACE YOUR HANDS INSIDE

THEMACHINE WHILE IT IS RUNNING.

•Proceed with the utmost care even when the

mainswitchisintheOFFpositionasthepower

cablesarestilllive.

•Turnofftheairsupplybeforedisconnectingany

pneumaticparts.

•Makesure that allguardsandsafety covers are

correctlyinplaceBEFORErestartingthe pro-

ductioncyclesubsequentto maintenanceorre-

pairoperations.

•Proceed with caution at all times. Remember

thatyouareresponsibleforyourownsafetyand

forthat ofyourcolleagues.

•Makesurethatalltheapplicableregulationsare

observedwhenmovingorliftingthemachine.

Ι

CRC804BB 2-3

Tetra Pak

Hoyer

• All personnel operating the machine must be

familiarwiththe general safetyrulesandmust

observe them strictly. Failure to follow these

rulesmayresultinpersonalinjuryordamageto

machinecomponents.

• Maintenanceworkmustbeperformedwiththe

machineturnedoff.Themainswitchmustbein

the OFF position, the air valve closed and a

“workinprogress”signaffixedtothemachine.

• Theusermustmakesurethatalltheinstructions

giveninthismanualarestrictlyobserved.

• Userswillbesolelyresponsibleforriskscaused

bytamperingwiththesafetysystem.

• Thesafetyofotherplantusedtogetherwiththis

machine,unless supplied directlybyTetra Pak

Hoyer,istheresponsibilityof thecustomer.

• Thepressure, speed, temperature and voltage

limitsandallinstructions givenareindispensa-

bleforthecorrectoperationof themachineand

mustalwaysbecompliedwithbythecustomer.

• Ambientconditions mustbetaken intoconsid-

erationduringinstallation.

• Nationallegislation governingthistypeof ma-

chinemustalso be observed.

Themachineisabletooperatewithinthefollowing

ambientlimits:

• Temperature: from 4°C to 40°C

• Humidity : from20%to95%.

FNOTE:

Our company will accept no responsibility for

damageor injury causedbyfailure to complywith

theabovewarnings.

2.4 Special warnings

2.5 Ambient operating limits

HOYER COMET RC

CRC804BC3-1

Tetra Pak

Hoyer

Contents

3 - DESCRIPTION OF THE MACHINE AND TECHNICAL DATA

3.1 Descriptionofthemachine.......................................................................................... 3-2

3.2 Technicaldata ............................................................................................................ 3-3

3.3 Controlpanel ............................................................................................................. 3-4

CRC804BC3-2

Tetra Pak

Hoyer

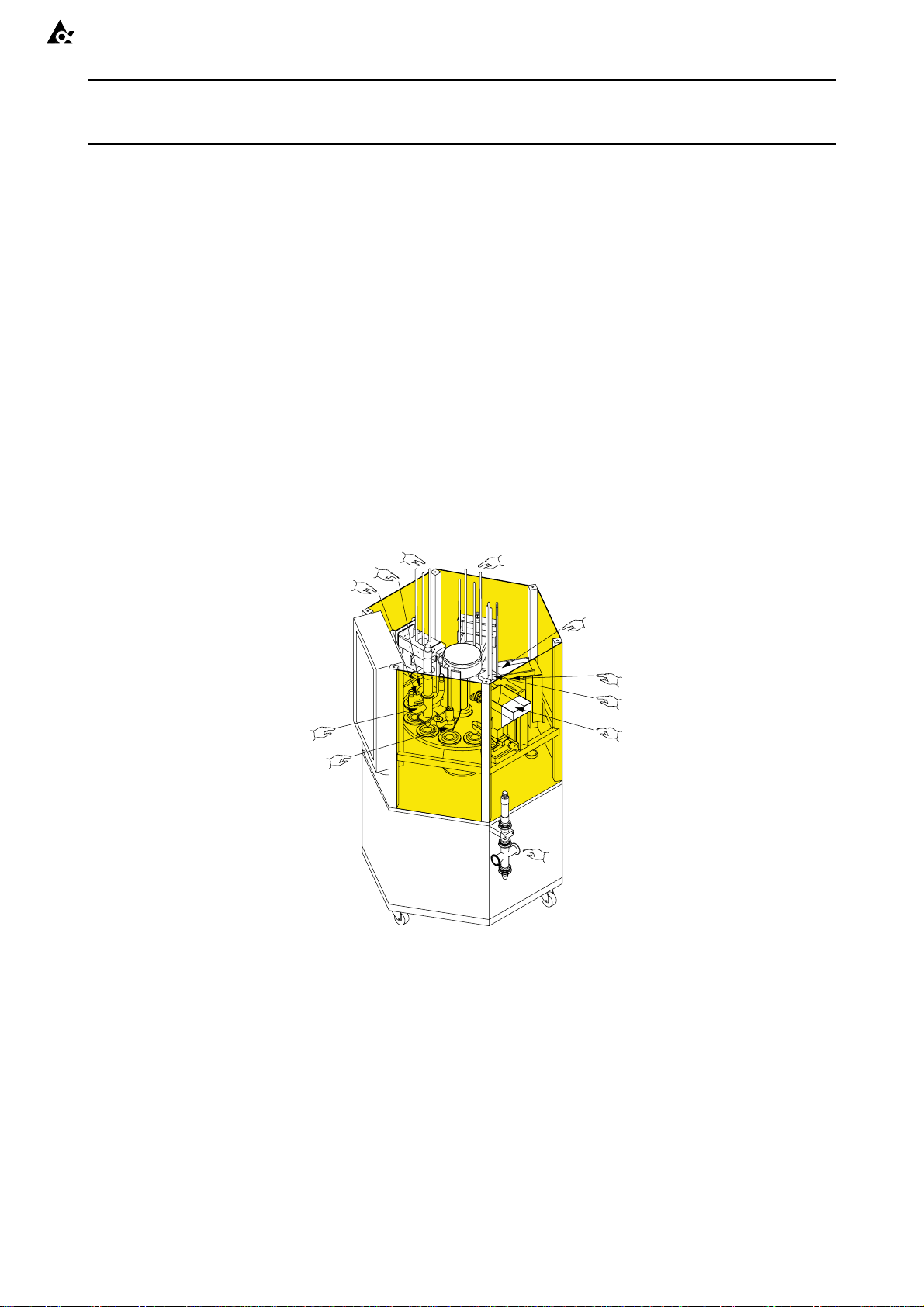

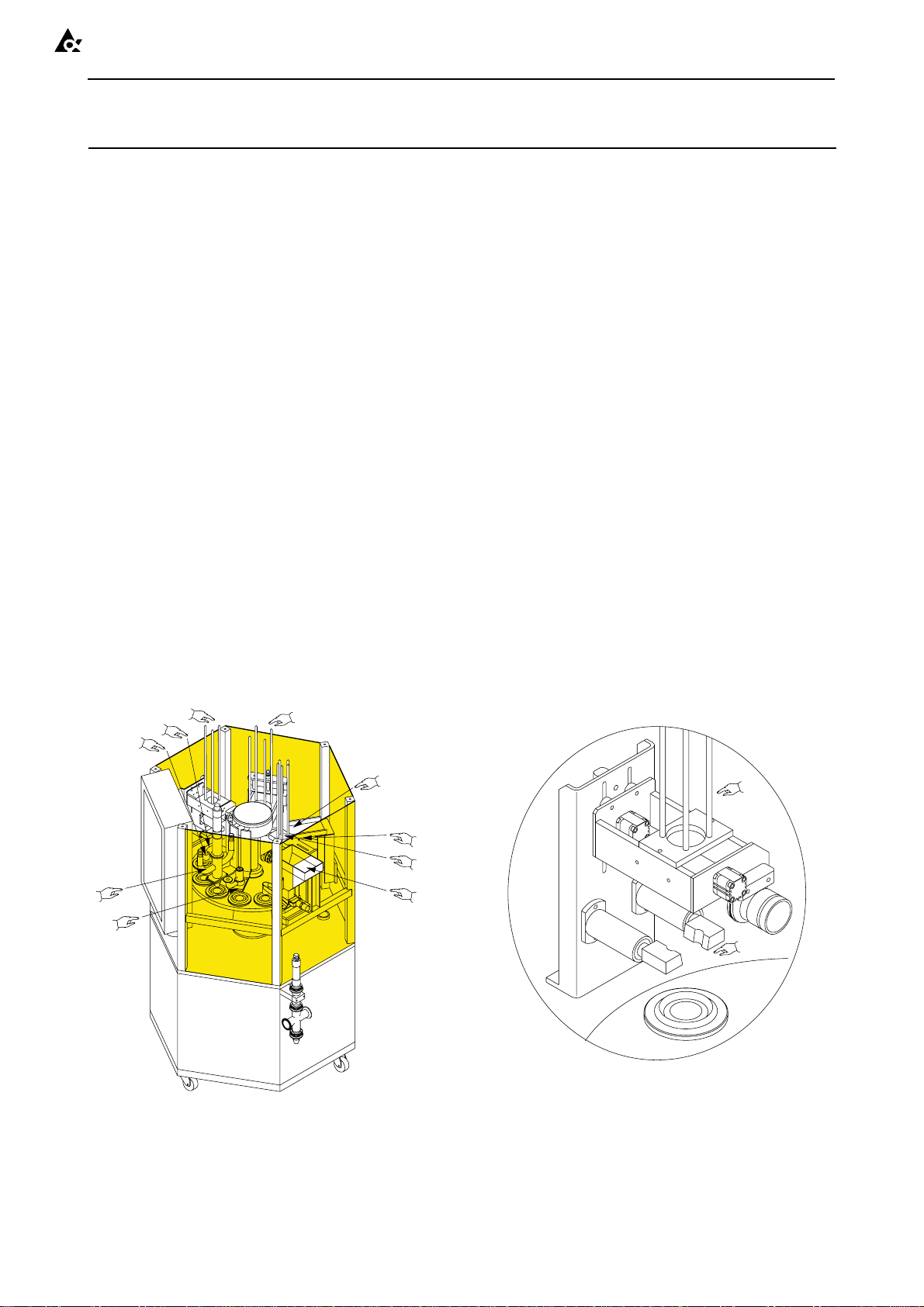

3.1 Description of the machine

TheHoyerCometRC rotary filler is designed and

builttoprovidethedependabilityandsafetyrequired

ofmachineryforthe productionoficecreamcones

andcups.

TheHoyerCometRCrotaryfillerconsistsofafree-

standing stainless steel structure on which the

followingcomponentsaremounted:

- inthelowerpartofthemachine,mechanisms

whichcommandtherotationofthe rotating

tableandthemovement oftheworkstations;

- anice cream bypass unit(Pos. 1, Fig. 3.1);

- a cone/cup feed unit (Pos. 2, Fig. 3.1);

- adosing and fillingunit(Pos.3,Fig.3.1);

- alid pick-up unit (Pos.4, Fig. 3.1);

- alidsealingunit(Pos. 4, Fig. 3.1);

- adatestampingunit;

- an ejector unit (Pos. 6, Fig. 3.1).

A combination of mechanical and pneumatic

movementsis used to pickup an empty cone/cup

fromthe magazineandputitinpositionina sloton

therotating table. The tableis jogged to bringthe

cone/cupintoalignmentwiththeoperatingunitslisted

above, so that it can be filled, packaged and then

ejected.

Fig. 3.1

1

4

9

6

5

32

8

10

11

7

CRC804BC 3-3

Tetra Pak

Hoyer

Mainmotor: 0,75 kW

Chocolatetubheater: 0.5 kW

Sprayerheater: 0.05 kW

Accessories: 0.15 kW

Totalinstalledpower: 3.5 kW

Compressedair:

Totalconsumption: 800Nl/min

Inletpressure: 6-7 bar

Connectiondiameter(inches): 1/2"

Dimensions

A = 1050 mm

B = 1050 mm

C = 1800 mm

Totalweight: approx. 375 kg

No.of operators: 1

The position of the operator during operation is

illustratedinFig.3.2

Standardpowersupply: 380 V/ 50 Hz

Noise level: 70.5 dBA

Equivalent Weighted Acoustic Pressure A at 1

metre:70.5 dBA – leq (A)

Max.InstantaneousWeighted AcousticPressureC

intheworkplace:less than 130 dB/20uPa

Max. Instantaneous Non-Weighted Acoustic

Pressureintheworkplace:Lessthan140dB/20uPa

3.2 Technical data

Fig. 3.2

AB

C

CRC804BC3-4

Tetra Pak

Hoyer

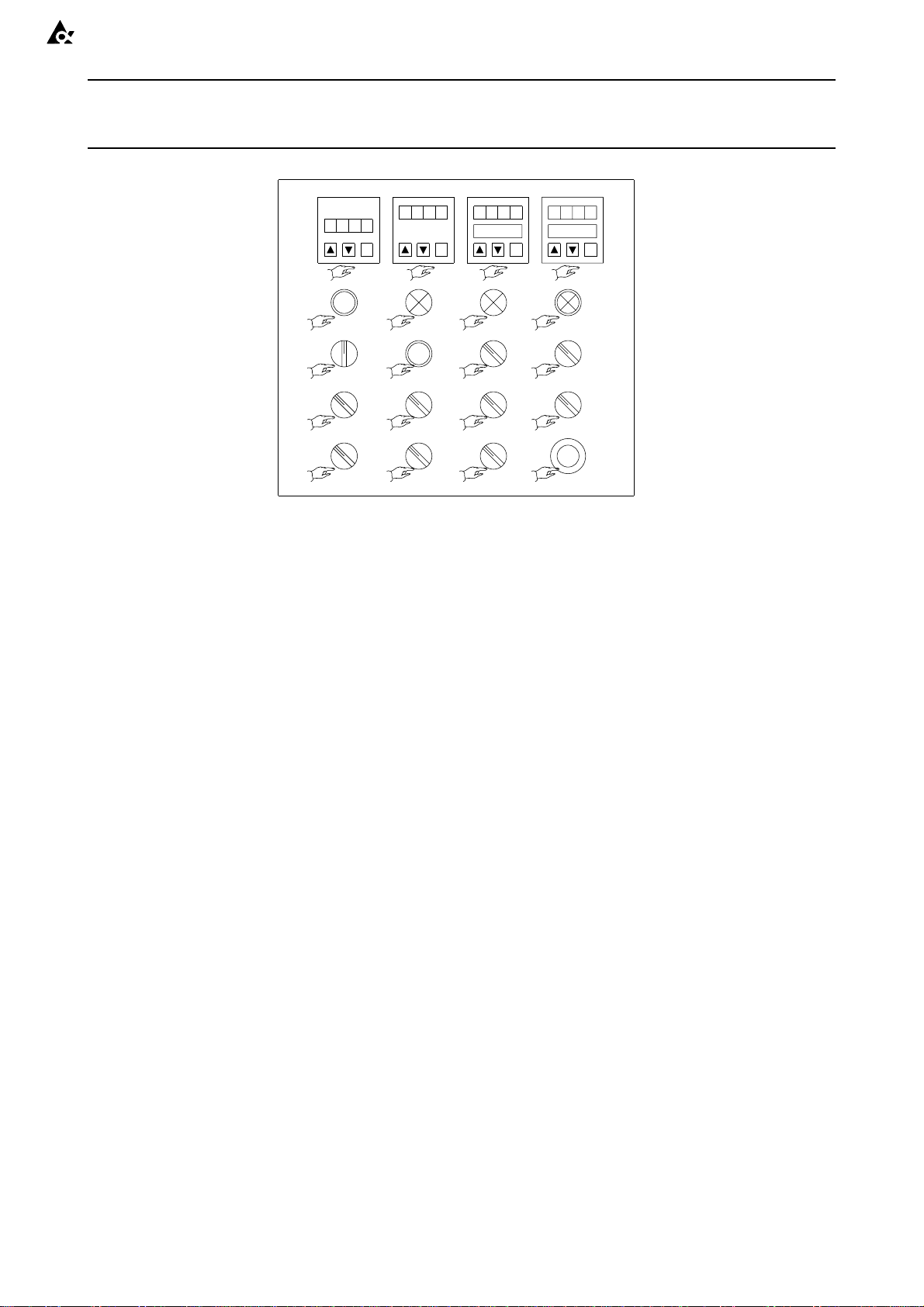

3.3 Control panel

1 Strokecounter

2 Dosingtime

3 Decorationtime(optional)

4 Temperatureofsealing head(optional)

5 Bypasson switch

6 Overloadindicatorlight

7 Noairsupplyindicatorlight

8 Resetbuttonwithlight

9 Jogswitch

10 Stop button

11 Cupfeedswitch

12 Cone/chewinggumfeedswitch

13 Chocolatepumpswitch

14 Dosingswitch

15 Toppingswitch

16 Granuleswitch

17 Lidfeedswitch

18 Datestamping/decorationswitch

19 Chocolatetubheatingswitch

20 Emergencybutton

Fig.3.3

1 2 3

5 6 7 8

910 11 12

13 14 15 16

17 18 19 20

F F F F

4

HOYER COMET RC

CRC801BD4-1

Contents

Tetra Pak

Hoyer

4.1 Transportingpackages................................................................................................4–2

4.2 Unpacking anddeliverychecks...................................................................................4–3

4.3 Transportandinstallation ............................................................................................4–3

4.4 Checkingfunctioning .................................................................................................. 4-4

4 - INSTALLATION

CRC804BD4-2

Tetra Pak

Hoyer

4.1 Transporting packages

The simplest way to move the crate in which the

HoyerComet RCfillerissupplied istouse apallet

truckor lifttruck.Thecrate shouldbedeposited as

closeto theplaceofinstallation aspossible.

Fig. 4.1

When the crate has been positioned correctly,

unpackasfollows:

a. Remove the nails in the lid and remove it. Do

thesamethingwiththesidepanels.Payparticular

attentionto the wooden spacer blocks located

betweenthesidesof the crate.

b. Remove the spare parts box and other

componentsfrom the crate.

c. Removethenailsinthewoodenblocksthathold

themachineinplaceduringtransportandremove

thecellophane sheet.

d. Checkthat thecontentsofthe cratecorrespond

to the description given in the shipping

documents.

4.2 Unpacking and delivery checks

e. Checkthat all thecoversand panels havebeen

correctlyfittedandthattherearenolooseparts.

f. Visuallyinspectalltheelectricalcomponentsto

makesurethattheyarenotdamaged.

g. Ifanypart/componentismissing,stopunpacking

andimmediatelynotifyTetra PakHoyer.

h. Ifthemachinehasbeendamagedduringtransit,

notifytheinsurancecompanyimmediately.Do

not proceed with unpacking until you are

authorisedto do so.

Allinformationrequiredto identifythecontentsof

thecrateismarkedontheoutside of the crate:

- addressesofbuyer and sender

- dimensions:length–width–height

- grossweight, netweight,tare

- packinglistplate

CRC804BD 4-3

Tetra Pak

Hoyer

Fig. 4.3

4.3 Transport and installation

4.3 Functional checks

Beforestartingupthemachine,performthefollowing

controlprocedures:

a. Check that the emergency button is released

(Pos. 3, Fig. 4.3).

b. Turn on the main power switch (Pos. 6, Fig.

4.3).

c. Turn the switch (Pos. 4, Fig. 4.3) to start the

motor.Checkthatthetableturnsin the correct

direction (Pos. 5, Fig. 4.3). If not, invert the

phases.

Fig. 4.2

MODEL

SERIAL N.:

YEAR OF CONSTRUCTION:

ELECTRICAL SUPPLY:

PNEUMATIC SUPPLY:

REFRIGERANT:

HEATING GAS:

THERMAL CAPACITY:

kW

Kg.

Kcal/h

Via Monferrato, 52 - 20098 San Giuliano Milanese

( MI ) Italia - Tel. 02-982921 - Fax 02-9880171 Made in Italy

Tetra Pak

Hoyer

V

bar Nlt/min.

ph Hz

Type

1

4

3

1

5

6

F F F

Themachineisassembled on wheels (Pos.1,Fig.

4.3)sothatit is easyfortheoperatorto push it into

place.

a. Put the machine in position in the production

area,checking that there is sufficientspace to

allowremoval oftheguardsand easeofaccess

tointernalmachineparts.

b. Checkthedatashownontheplatetomakesure

thatthe machineiscompatible withthefactory

powersupply (Fig.4.2).

c. The machine’s components are protected

electrically against short circuits (with

appropriate safety devices). Connect up the

electricalcabledown-lineofamasterswitchwith

thermaloverload cutoutandultrarapid fusesof

adequate amperage or an automatic

magnetothermalcircuitbreakerofadequatesize.

d. Connect the compressed air supply to the

manifoldand checkthatthepressurereduceris

set to 6 bar.

IMPORTANT:

Connections must be made only by skilled

technicians familiar with accident prevention

legislation.

HOYER COMET RC

CRC910BE5-1

Contents

Tetra Pak

Hoyer

5.1 Productchangeover ...................................................................................................5–2

5.2 Mechanicaladjustmentofthestations .........................................................................5–3

5.2.1 Conefeed stationadjustment............................................................................. 5-3

5.2.2 Cupfeed stationadjustment .............................................................................. 5-3

5.2.3 Gaugingstationadjustment ................................................................................ 5-4

5.2.4 Chocolatespray stationadjustment.................................................................... 5-4

5.2.5 Icecream doser/variegatorstationadjustment.................................................... 5-4

5.2.6 Topping/pencilfillerstationadjustment ............................................................... 5-5

5.2.7 Granulestationadjustment................................................................................. 5-5

5.2.8 Lidfeedstationadjustment................................................................................ 5-6

5.2.9 Conelidclosurestationadjustment .................................................................... 5-6

5.2.10 Cuplidclosurestationadjustment...................................................................... 5-7

5.2.11 Lidsealingstationadjustment ............................................................................ 5-7

5.2.12 Stampingstationadjustment .............................................................................. 5-8

5.1.13 Coneejectionstationadjustment ....................................................................... 5-8

5.2.14 Cupejectionstationadjustment ......................................................................... 5-8

5.3 Pneumaticsettings ......................................................................................................5–9

5.3.1 Granulestationadjustment................................................................................. 5-9

5.3.2 Gauge– chocolatespraystationadjustment ....................................................... 5-9

5.4 Settingsonthecontrolpanel ....................................................................................... 5-9

5.4.1 Mechanicalandpneumaticsettings............................................................................ 5-10

5 - ADJUSTMENT PROCEDURES AND PRODUCT CHANGEOVER

CRC910BE5-2

Tetra Pak

Hoyer

TheHOYERCOMETRCCONE– CUPmachine

fillsand sealscontainers(conesand cups).

It can produce cones and cups up to 100 mm in

diameter.

Standard cone production involves use of the

followingstations:

- cone feed (Pos. 1, Fig. 5.1);

- gauge (Pos. 3, Fig. 5.1);

- chocolate spray (Pos. 4, Fig. 5.1);

- stationfordosingice creamoricecreammixes

(Pos. 5,Fig. 5.1) in oneor two flavours;

- topping (Pos. 6, Fig. 5.1);

- granule(Pos. 7, Fig.5.1);

- lid feed (Pos. 8, Fig. 5.1);

- lidclosure (pos. 9,Fig. 5.1);

- product ejector (Pos. 10, Fig. 5.1).

Standard cup production involves the use of the

followingstations:

- cup feed (Pos. 2, Fig. 5.1);

- stationfor dosingicecreamoricecreammixes

(Pos. 5, Fig. 5.1) in one or two flavours;

5.1 Product changeover

- lid feed (Pos. 8, Fig. 5.1);

- lid closure (pos. 9, Fig. 5.1);

- product ejector (Pos. 10, Fig. 5.1).

Whenchangingtoaconeformat ofadifferentsize,

it is necessary to replace the slot set, cone feed

magazines,gaugingpads, lid feed magazines, and

crimpers.

When changing format from cones to cups, it is

necessaryto replacetheslot set,assembledthe cup

feedwith its suction cup holdersin place, replace

thelidfeedmagazines,replacetheconelidcrimpers

withlidpresses, and replacetheconeejector(Pos.

10, Fig. 5.1) with the cup ejector (Pos. 11, Fig.

5.1),replacing theexpulsionplates.

FNOTE:

Ifthemachineissetupforconeandcupproduction,

thetoppingandgranule stationsmaybeusedto de-

coratestandard cups.

Fig.5.1

Fig.5.2

3

8

5

4

12

7

9

10

6

1

2

CRC910BE 5-3

Tetra Pak

Hoyer

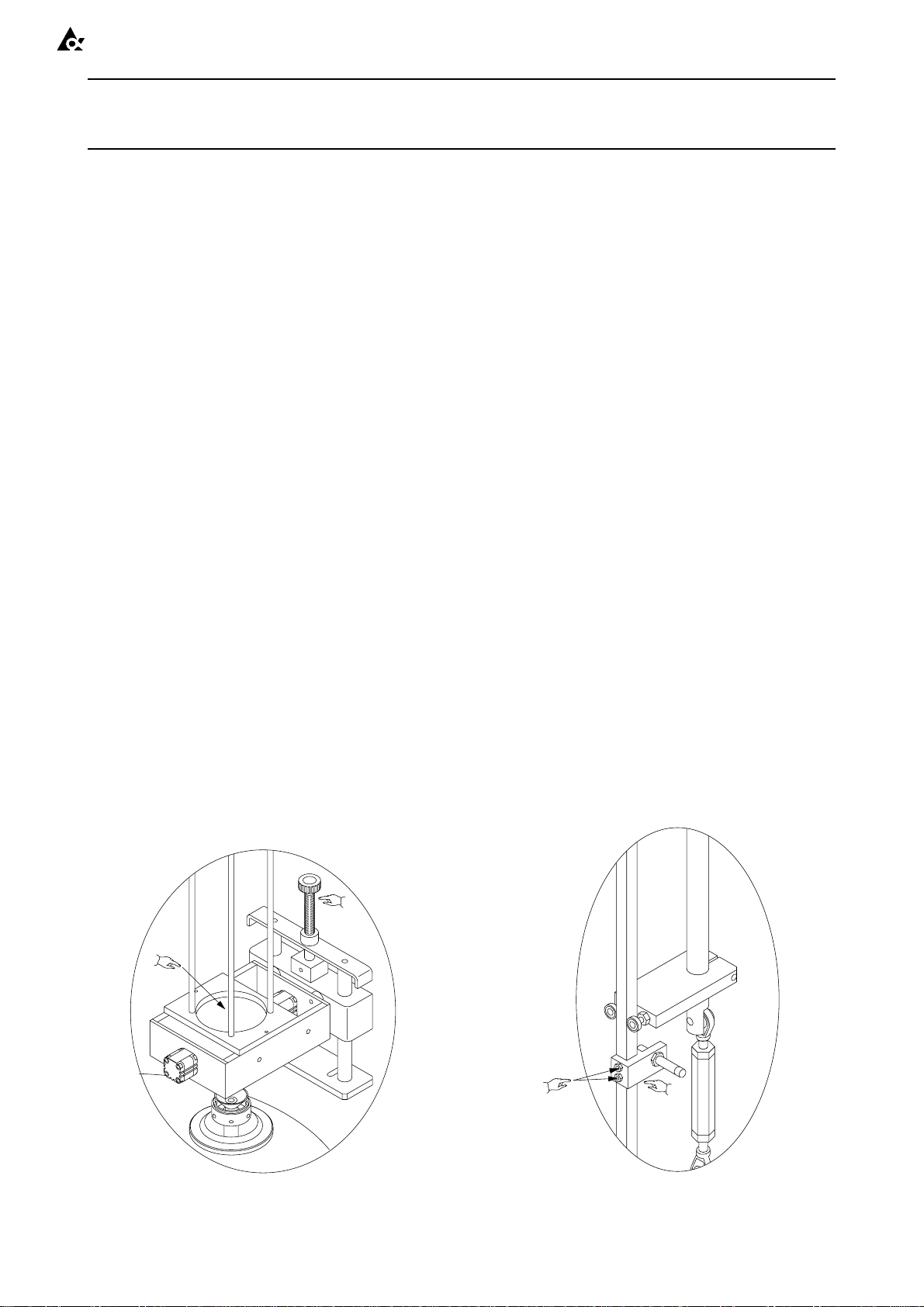

5.2 Mechanical adjustment of the stations

5.2.1 Conefeedstationadjustment

Turnontheconefeedstationusingtheswitch(Pos.

12,Fig. 5.17) on thecontrol panel.

Work the jog switch (Pos. 8, Fig. 5.17) until the

upperconeholderblades open.

Withthemachinestoppedandtheconestopblades

open, insert two cones into the magazine (Pos. 1,

Fig. 5.2).

Check that the cone in the released position rests

correctlyinthecalliperholesintheoscillatinglevers

(Pos. 2, Fig. 5.2), then make sure that the cone in

thereleased positionis5 mmbelowthe stopblade.

Makesure that the oscillatingcone release levers

5.2.2 Cupfeedstationadjustment

Workthejog switch (Pos.9, Fig. 5.17)toposition

thesuctioncupsattheirmaximumheight.

Loosen the screws (Pos. 1, Fig. 5.3a) and check

thatthevacuum on sensor (Pos. 2, Fig. 5.3a) is in

thecorrect position.

Next put a cup into the cup magazine and check

that the blades (Pos. 1, Fig. 5.3) hold the cup in

placewithout squashingit.Adjust theheightof the

cupfeedbyturning theknob(Pos. 2,Fig.5.3)until

Fig.5.3

holdthecornetswithoutexertingtoomuchpressure.

Ifthedistanceis greater than 5 mm, lower themo-

bile part of the cone stop blade and magazine

support. If the released cone is between the cone

stopblades, raise the mobile partof the cone stop

bladeand magazine supporttothecorrect height.

After these adjustments, make sure that the cone

pusherplatejusttouches the edge of the cornet; if

not,adjust itsposition.

At this point check that at low speed the cone is

released immediately after the lamella chain has

stopped.

thesuctioncuptouchesthebottom of the cup.

Carry out the procedure described above when

changingproductformat.

FNOTE:

Ifthemachineissetuptoproducedifferenttypesof

cups, make a note of the correct settings for each

typetospeed up changeover procedures.

Fig.5.3a

2

1

12

CRC910BE5-4

Tetra Pak

Hoyer

Fig.5.6

5.2.5 Icecreamdoser/variegatorstationadjustment

Fig.5.5

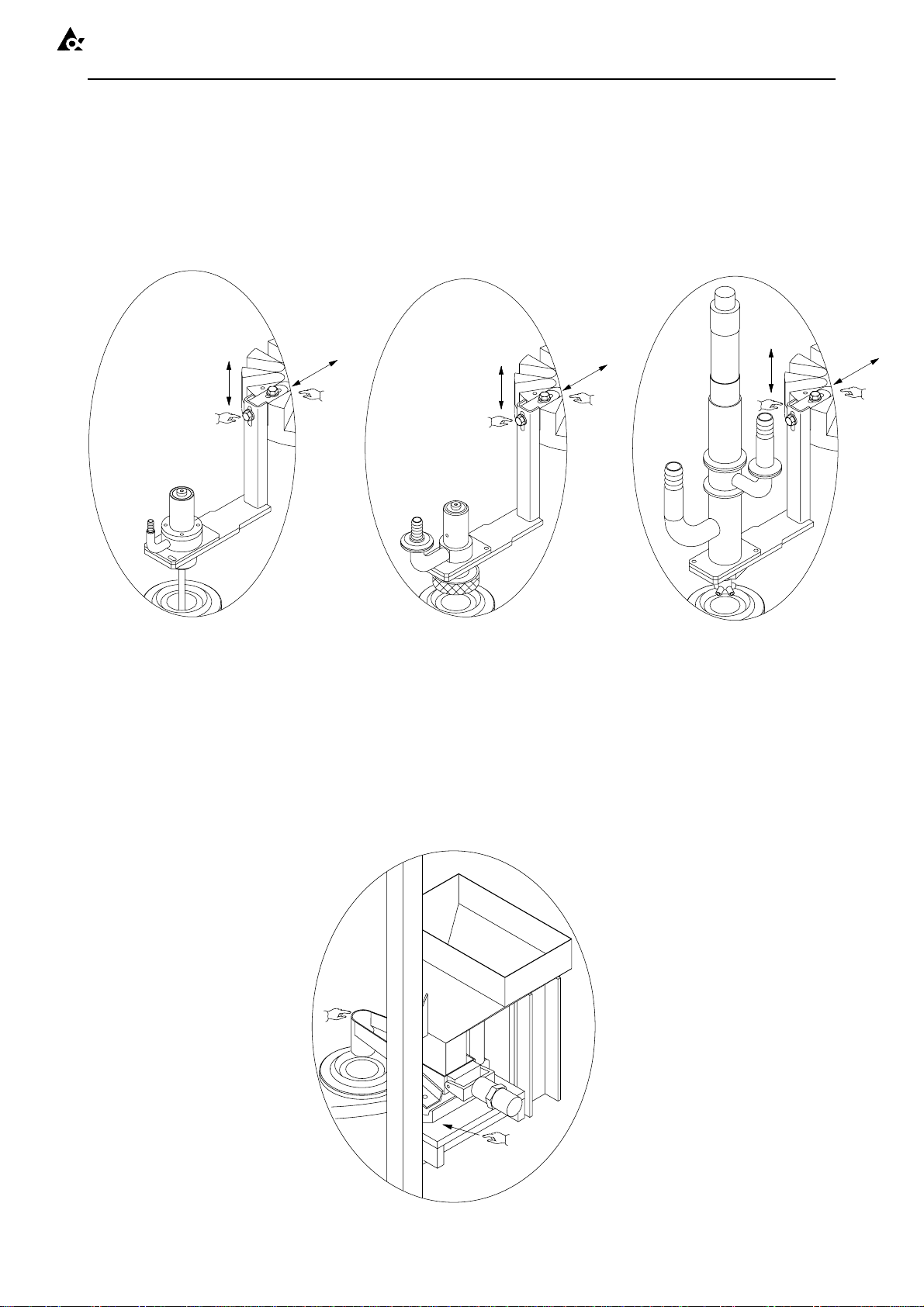

5.2.3 Gaugingstationadjustment

Fig.5.4

Adjust doser/distributor height and centre it over

theslot bylooseningthescrews(Pos. 1/2,Fig.5.6-

5.6a) to achieve the desired dosing/variegation

position(turningclockwisetoincreasethestrokeof

thepneumaticcylinderoranticlockwisetodecrease

it).

Tighten the screws (Pos. 1, Fig. 5.6-5.6a) when

finished.

Theendofthedosingnozzlesshouldnormallybe

insidethe container, below thelid position, when

dosing,so that theicecream decoration willnotbe

damagedwhenthelid is pressed on.

Thegaugingstationservestospreadthe mouth of

thepaper wrapped around the cones, whichtends

tofoldoverduringfeeding.

5.2.4 Chocolatespraystationadjustment

Loosen the screws (Pos. 1/2, Fig. 5.5) to adjust

theheight ofthespraynozzle andcentreit overthe

slot,thentightenthescrewsagainwhenfinished.

Loosen the screws (Pos. 1/2, Fig. 5.4) to adjust

height and centring over the slot, then tighten the

screwswhenfinished.

2

1

2

1

3

2

1

CRC910BE 5-5

Tetra Pak

Hoyer

5.2.6 Topping/pencilfillerstationadjustment

Loosen the screws (Pos. 1/2, Fig. 5.7-5.7a) to

adjusttopping/pencilfillerheightandcentreitover

theslot,thentightenthescrewsagainwhenfinished.

Turn on the chocolate heater thirty minutes before

5.2.7 Granulestationadjustment

Beforebeginningproduction,checkthatthehopper

anddosing channelsarecompletelydry.

Alsocheckthatthedosingchannelsarecentredover

startingproductionusingtheswitch(Pos.8,Fig.5.17).

FNOTE:

Makesurethatthereiswaterinthewaterjacketat

alltimestoprevent theheatersfromburning.

Fig.5.8

theslots,andifnot,adjustthepositionofthestation

byslackening the screws (Pos.1, Fig. 5.7) on the

fixingblocks.

2

1

Fig.5.6a

2

1

2

1

2

1

Fig.5.7 Fig.5.7a

Table of contents

Other Tetra Pak Industrial Equipment manuals