Test Summary

www.ti.com

4SLUUC27B–June 2019–Revised January 2020

Submit Documentation Feedback

Copyright © 2019–2020, Texas Instruments Incorporated

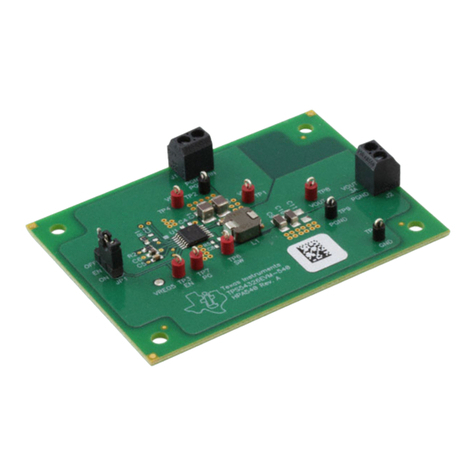

BQ25611D, BQ25619 (BMS025) Evaluation Module

Table 3. EVM Shunt and Switch Installation (continued)

Jack Description BQ25611D Setting BQ25619 Setting

JP7 Thermistor NORMAL temperature setting. Connect jumper to simulate charger

entering TNORMAL (T2-T3) temperature region. Installed Installed

JP8 Thermistor WARM temperature setting. Connect jumper to simulate charger

entering TWARM (T3-T5) temperature region. Not Installed Not Installed

JP9 Thermistor HOT temperature setting. Connect jumper to simulate charger

entering THOT (>T5) temperature region. Not Installed Not Installed

JP10 Micro B USB input D+ connection to charger D+ pin Installed Not Installed

JP11 PG pin LED indicator connection. On PG enabled chargers, this indicates the

Power Good status Not Installed Not Installed

JP12 STAT pin LED indicator connection. This indicates the current charger Status Installed Installed

JP13 Charger D+ pin and charger D- pin short connection. Connect this on D+/D-

detection enabled chargers to simulate the connection of a DCP-type USB port

as defined by USB BC1.2

Not Installed Not Installed

JP14 CE pin connection to ground to enable charging. When removed, CE pin will pull

up to disable charge Installed Installed

JP15 PSEL pin input current selection. Connect this to HIGH on PSEL enabled

chargers to select 500mA default input current limit. Connect this to LOW on

PSEL enabled chargers to select 2.4-A default input current limit

Not Installed Short PSEL to

LOW

JP16 VPB status LED indicator connection. On power bank PMID_GOOD enabled

chargers, this indicates VPB rail is active Not Installed Not Installed

S1 QON control switch. Press either for exiting Shipping Mode or System Reset. Default Off Default Off

Table 4 lists the recommended operating conditions for this EVM.

(1) BQ25619EVM maximum IBAT is 1.5A.

Table 4. Recommended Operating Conditions

Symbol Description MIN TYP MAX Unit

VVBUS, VVAC Input voltage applied to VAC and VBUS pins 3.9 14.0 V

VBAT Battery voltage applied to BAT pin 0 4.208 4.52 V

IVBUS Input current into VBUS 0 3.2 A

ISW Output current (SW) 3.2 A

IBAT Fast charging current 0 3.0 (1) A

Discharging current through internal BATFET 6 A

2 Test Summary

2.1 Equipment

This section includes a list of supplies required to perform tests on this EVM.

1. Power Supplies: Power Supply #1 (PS1): A power supply capable of supplying 5 V at 3 A is required.

While this part can handle larger voltage and current, it is not necessary for this procedure.

2. Loads: Load #1 (4-Quadrant Supply, Constant Voltage < 4.5 V): A "Kepco" Load, BOP, 20-5M, DC 0

to ±20 V, 0 to ±5 A (or higher)

Alternative Option: A 0–20V/0–5 A, > 30-W DC electronic load set in a constant voltage loading mode

Load #2(Electronic or Resistive Load): 10 Ω, 5 W (or higher)

3. Meters: (6x) "Fluke 75" multimeters, (equivalent or better).

Alternative Option: (4x) equivalent voltage meters and (2x) equivalent current meters. The current

meters must be capable of measuring at least 5-A.

4. Computer: A computer with at least one USB port and a USB cable. Must have the latest version of

Battery Management Studio installed.

5. USB-TO-GPIO Communication Kit: EV2300/EV2400 USB-based PC interface board.