Mazda L8 Instruction manual

CONTENTS

Engine

Workshop

Manual

L8

LF

L3

FOREWORD

This manual explains the disassembly,

inspection, repair, and reassembly

procedures for the above-indicated engine.

In order to do these procedures safety,

quickly, and correctly, you must first read

this manual and any other relevant service

materials carefully.

The information in this manual is current

up to March, 2002. Any changes that occur

after that time will not be reflected in

thisparticularmanual.Therefore,thecontents

of this manual may not exactly match

the mechanism that you are currently

serving.

Mazda Motor Corporation

HIROSHIMA, JAPAN

© 2002 Mazda Motor Corporation

PRINTED IN The Netherlands, MARCH 2002

1731–1E–02C

Title Section

General Information GI

Engine B

Technical Data TD

Special Tools ST

1731‑1E‑02C(INDEX).fm1ページ2002年3月13日 水曜日 午後5時8分

WARNING

Servicing a vehicle can be dangerous. If you have not received

service-related training, the risks of injury, property damage, and

failure of servicing increase. The recommended servicing procedures

for the vehicle in this workshop manual were developed with

Mazda-trained technicians in mind. This manual may be useful to

non-Mazda trained technicians, but a technician with our

service-related training and experience will be at less risk when

performing service operations. However, all users of this manual are

expected to at least know general safety procedures.

This manual contains "Warnings" and "Cautions" applicable to risks

not normally encountered in a general technician's experience.

They should be followed to reduce the risk of injury and the risk that

improper service or repair may damage the vehicle or render it unsafe.

It is also important to understand that the "Warnings" and "Cautions"

are not exhaustive. It is impossible to warn of all the hazardous

consequences that might result from failure to follow the procedures.

The procedures recommended and described in this manual are

effective methods of performing service and repair. Some require tools

specifically designed for a specific purpose. Persons using procedures

and tools which are not recommended by Mazda Motor Corporation

must satisfy themselves thoroughly that neither personal safety nor

safety of the vehicle will be jeopardized.

The contents of this manual, including drawings and specifications, are

the latest available at the time of printing, and

Mazda Motor Corporation

reserves the right to change the vehicle designs and alter the contents

of this manual without notice and without incurring obligation.

Parts should be replaced with genuine Mazda replacement parts or

with parts which match the quality of genuine Mazda replacement

parts. Persons using replacement parts of lesser quality than that of

genuine Mazda replacement parts must satisfy themselves thoroughly

that neither personal safety nor safety of the vehicle will be

jeopardized.

Mazda Motor Corporation is not responsible for any problems which

may arise from the use of this manual. The cause of such problems

includes but is not limited to insufficient service-related training, use of

improper tools, use of replacement parts of lesser quality than that of

genuine Mazda replacement parts, or not being aware of any revision

of this manual.

1731‑1E‑02C(WARNING).fm1ページ2002年3月13日 水曜日 午後5時9分

GI–1

GI

GI

GENERAL INFORMATION

HOW TO USE THIS MANUAL ............................. GI-2

RANGE OF TOPICS.......................................... GI-2

SERVICE PROCEDURE ................................... GI-2

SYMBOLS.......................................................... GI-3

ADVISORY MESSAGES ................................... GI-4

UNITS ................................................................... GI-5

UNITS ................................................................ GI-5

FUNDAMENTAL PROCEDURES ........................ GI-6

PREPARATION OF TOOLS AND

MEASURING EQUIPMENT............................ GI-6

SPECIAL SERVICE TOOLS.............................. GI-6

DISASSEMBLY.................................................. GI-6

INSPECTION DURING REMOVAL,

DISASSEMBLY............................................... GI-7

ARRANGEMENT OF PARTS ............................ GI-7

CLEANING OF PARTS...................................... GI-7

REASSEMBLY................................................... GI-7

ADJUSTMENT................................................... GI-8

RUBBER PARTS AND TUBING........................ GI-8

HOSE CLAMPS ................................................. GI-8

TORQUE FORMULAS....................................... GI-9

VISE................................................................... GI-9

SST.................................................................... GI-9

ELECTRICAL SYSTEM...................................... GI-10

ELECTRICAL PARTS...................................... GI-10

CONNECTORS................................................ GI-10

NEW STANDARDS ............................................ GI-13

NEW STANDARDS.......................................... GI-13

ABBREVIATIONS .............................................. GI-15

ABBREVIATIONS............................................ GI-15

1731‑1E‑02C.book1ページ2002年4月26日 金曜日 午前10時30分

GI–2

HOW TO USE THIS MANUAL

RANGE OF TOPICS A6E201000001E01

•This manual contains procedures for performing all required service operations. The procedures are divided

into the following five basic operations:

— Removal/Installation

— Disassembly/Assembly

— Replacement

— Inspection

— Adjustment

•Simple operations which can be performed easily just by looking at the vehicle (i.e., removal/installation of

parts, jacking, vehicle lifting, cleaning of parts and visual inspection) have been omitted.

End Of Sie

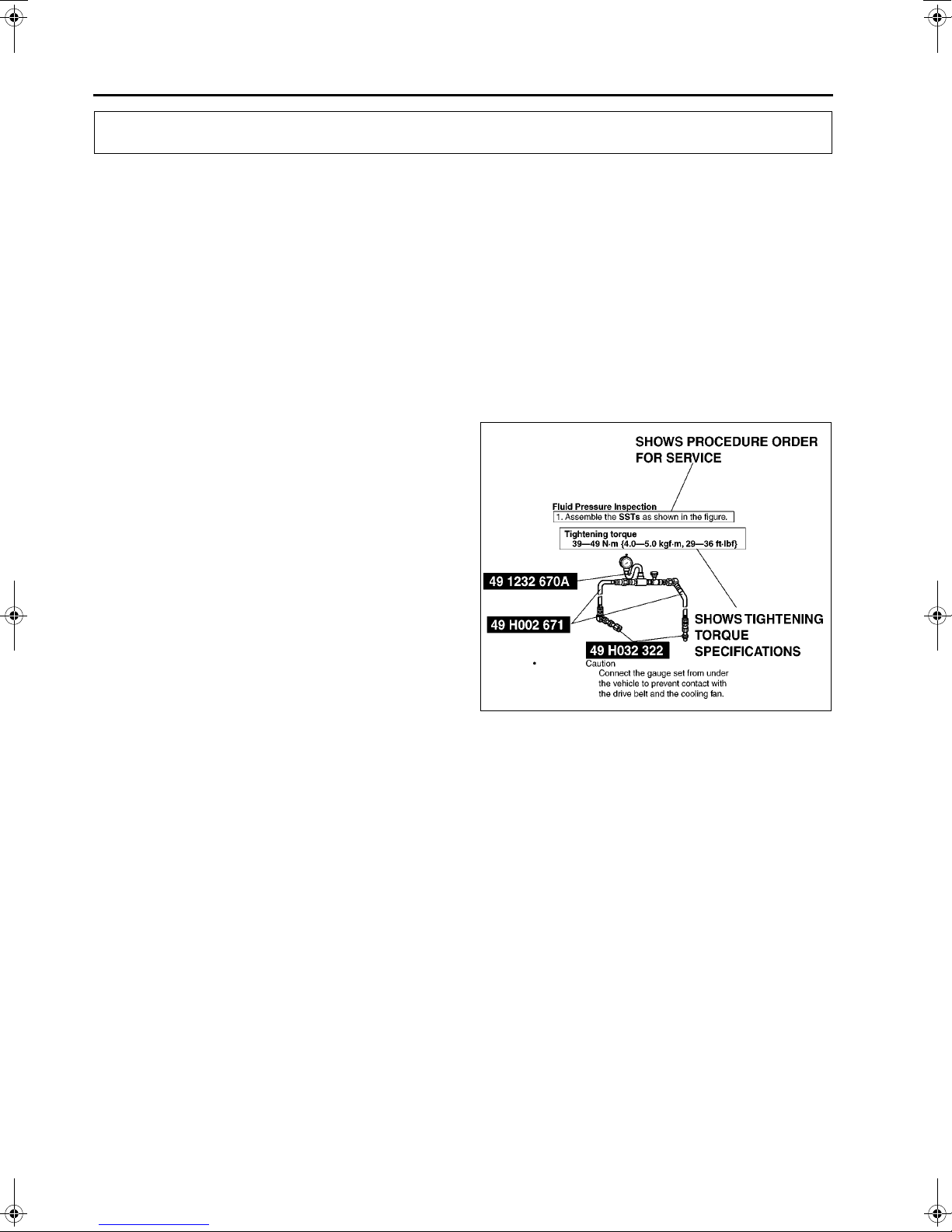

SERVICE PROCEDURE A6E201000001E02

Inspection, adjustment

•Inspection and adjustment procedures are divided into steps. Important points regarding the location and

contents of the procedures are explained in detail and shown in the illustrations.

Repair procedure

1. Most repair operations begin with an overview illustration. It identifies the components, shows how the parts fit

together and describes visual part inspection. However, only removal/installation procedures that need to be

performed methodically have written instructions.

2. Expendable parts, tightening torques and symbols for oil, grease, and sealant are shown in the overview

illustration. In addition, symbols indicating parts requiring the use of special service tools or equivalent are also

shown.

3. Procedure steps are numbered and the part that is the main point of that procedure is shown in the illustration

with the corresponding number. Occasionally, there are important points or additional information concerning a

procedure. Refer to this information when servicing the related part.

HOW TO USE THIS MANUAL

XME2010001

1731‑1E‑02C.book2ページ2002年4月26日 金曜日 午前10時30分

HOW TO USE THIS MANUAL

GI–3

GI

4.

End Of Sie

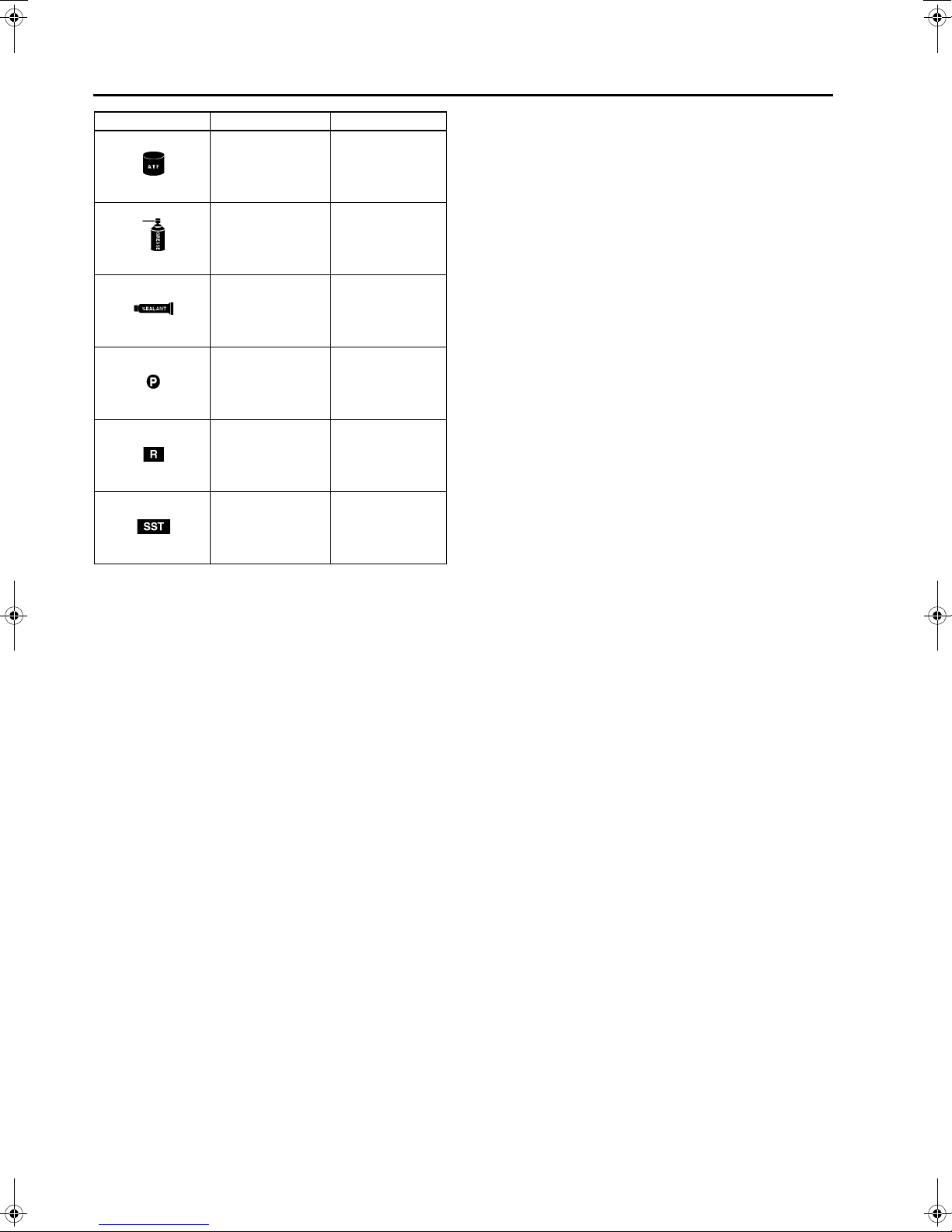

SYMBOLS A6E201000001E03

•There are eight symbols indicating oil, grease, fluids, sealant, and SST or equivalent use. These symbols show

application points or use of these materials during service.

XME2010010

Symbol Meaning Kind

Apply oil New appropriate

engine oil or gear

oil

Apply brake fluid New appropriate

brake fluid

1731‑1E‑02C.book3ページ2002年4月26日 金曜日 午前10時30分

GI–4

HOW TO USE THIS MANUAL

End Of Sie

ADVISORY MESSAGES A6E201000001E04

•You'll find several Warnings, Cautions, Notes, Specifications and Upper and Lower Limits in this manual.

Warning

•A Warning indicates a situation in which serious injury or death could result if the warning is ignored.

Caution

•A Caution indicates a situation in which damage to the vehicle or parts could result if the caution is ignored.

Note

•A Note provides added information that will help you to complete a particular procedure.

Specification

•The values indicate the allowable range when performing inspections or adjustments.

Upper and lower limits

•The values indicate the upper and lower limits that must not be exceeded when performing inspections or

adjustments.

End Of Sie

Apply automatic

transaxle/

transmission fluid

New appropriate

automatic

transaxle/

transmission fluid

Apply grease Appropriate

grease

Apply sealant Appropriate

sealant

Apply petroleum

jelly Appropriate

petroleum jelly

Replace part O-ring, gasket,

etc.

Use SST or

equivalent Appropriate tools

Symbol Meaning Kind

1731‑1E‑02C.book4ページ2002年4月26日 金曜日 午前10時30分

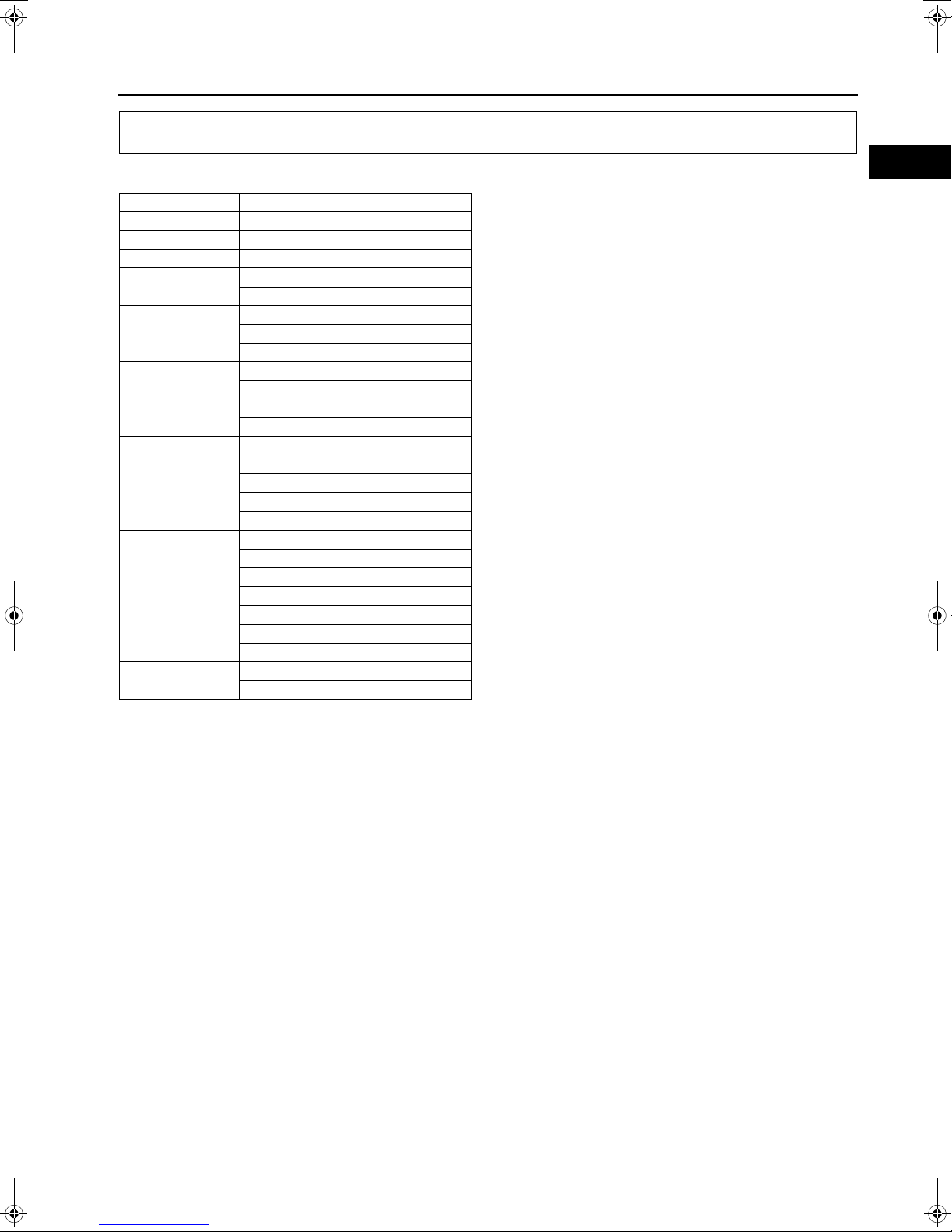

UNITS

GI–5

GI

UNITS A6E201200002E01

Conversion to SI Units (Système International d'Unités)

•All numerical values in this manual are based on SI units. Numbers shown in conventional units are converted

from these values.

Rounding Off

•Converted values are rounded off to the same number of places as the SI unit value. For example, if the SI unit

value is 17.2 and the value after conversion is 37.84, the converted value will be rounded off to 37.8.

Upper and Lower Limits

•When the data indicates upper and lower limits, the converted values are rounded down if the SI unit value is

an upper limit and rounded up if the SI unit value is a lower limit. Therefore, converted values for the same SI

unit value may differ after conversion. For example, consider 2.7 kgf/cm2in the following specifications:

210—260 kPa {2.1—2.7 kgf/cm2, 30—38 psi}

270—310 kPa {2.7—3.2 kgf/cm2, 39—45 psi}

•The actual converted values for 2.7 kgf/cm2are 264 kPa and 38.4 psi. In the first specification, 2.7 is used as

an upper limit, so the converted values are rounded down to 260 and 38. In the second specification, 2.7 is

used as a lower limit, so the converted values are rounded up to 270 and 39.

End Of Sie

UNITS

Electrical current A (ampere)

Electric power W (watt)

Electric resistance ohm

Electric voltage V (volt)

Length mm (millimeter)

in (inch)

Negative pressure kPa (kilo pascal)

mmHg (millimeters of mercury)

inHg (inches of mercury)

Positive pressure

kPa (kilo pascal)

kgf/cm2(kilogram force per square

centimeter)

psi (pounds per square inch)

Torque

N·m (Newton meter)

kgf·m (kilogram force meter)

kgf·cm (kilogram force centimeter)

ft·lbf (foot pound force)

in·lbf (inch pound force)

Volume

L (liter)

US qt (U.S. quart)

Imp qt (Imperial quart)

ml (milliliter)

cc (cubic centimeter)

cu in (cubic inch)

fl oz (fluid ounce)

Weight g (gram)

oz (ounce)

1731‑1E‑02C.book5ページ2002年4月26日 金曜日 午前10時30分

GI–6

FUNDAMENTAL PROCEDURES

PREPARATION OF TOOLS AND MEASURING EQUIPMENT A6E201400004E02

•Be sure that all necessary tools and measuring

equipment are available before starting any work.

End Of Sie

SPECIAL SERVICE TOOLS A6E201400004E03

•Use special service tools or equivalent when they

are required.

End Of Sie

DISASSEMBLY A6E201400004E07

•If the disassembly procedure is complex,

requiring many parts to be disassembled, all parts

should be marked in a place that will not affect

their performance or external appearance and

identified so that reassembly can be performed

easily and efficiently.

End Of Sie

FUNDAMENTAL PROCEDURES

X3U000WAH

X3U000WAJ

X3U000WAL

1731‑1E‑02C.book6ページ2002年4月26日 金曜日 午前10時30分

FUNDAMENTAL PROCEDURES

GI–7

GI

INSPECTION DURING REMOVAL, DISASSEMBLY A6E201400004E08

•When removed, each part should be carefully

inspected for malfunction, deformation, damage,

and other problems.

End Of Sie

ARRANGEMENT OF PARTS A6E201400004E09

•All disassembled parts should be carefully

arranged for reassembly.

•Be sure to separate or otherwise identify the parts

to be replaced from those that will be reused.

End Of Sie

CLEANING OF PARTS A6E201400004E10

•All parts to be reused should be carefully and

thoroughly cleaned in the appropriate method.

Warning

•

••

•Using compressed air can cause dirt and

other particles to fly out causing injury to

the eyes. Wear protective eye wear

whenever using compressed air.

End Of Sie

REASSEMBLY A6E201400004E11

•Standard values, such as torques and certain

adjustments, must be strictly observed in the

reassembly of all parts.

•If removed, these parts should be replaced with

new ones:

—Oil seals

—Gaskets

—O-rings

—Lockwashers

—Cotter pins

—Nylon nuts

X3U000WAM

X3U000WAN

WGIWXX0030J

WGIWXX0031J

1731‑1E‑02C.book7ページ2002年4月26日 金曜日 午前10時30分

GI–8

FUNDAMENTAL PROCEDURES

•Depending on location:

—Sealant and gaskets, or both, should be

applied to specified locations. When sealant

is applied, parts should be installed before

sealant hardens to prevent leakage.

—Oil should be applied to the moving

components of parts.

—Specified oil or grease should be applied at

the prescribed locations (such as oil seals)

before reassembly.

End Of Sie

ADJUSTMENT A6E201400004E12

•Use suitable gauges and/or testers when making

adjustments.

End Of Sie

RUBBER PARTS AND TUBING A6E201400004E13

•Prevent gasoline or oil from getting on rubber

parts or tubing.

End Of Sie

HOSE CLAMPS A6E201400004E14

•When reinstalling, position the hose clamp in the

original location on the hose and squeeze the

clamp lightly with large pliers to ensure a good fit.

End Of Sie

WGIWXX0032J

X3U000WAS

WGIWXX0034E

WGIWXX0035J

1731‑1E‑02C.book8ページ2002年4月26日 金曜日 午前10時30分

This manual suits for next models

2

Table of contents

Other Mazda Engine manuals