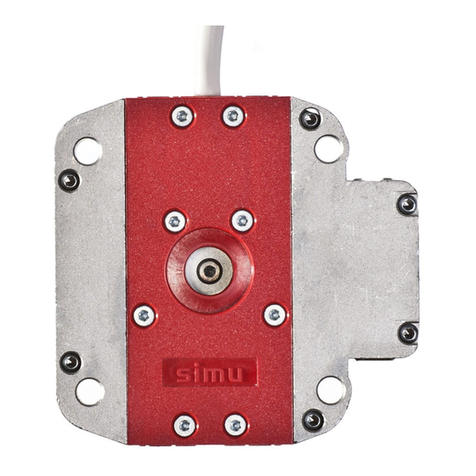

Simu T5 AUTOSHORT BHz Series User manual

OCTOEASY

MANDATORY

STEEL

1

3

2

2

1

3

1

4

2

5.3 Nm max

These instructions apply to all T5 AUTOSHORT BHz drive, the dierent versions of which are available in the current catalogue.

Field of application: T5 AUTOSHORT BHz drive are designed to drive all types of roller shutters equipped with stop

blocks and rigid links. The installer, who must be a motorisation and home automation professional, must ensure that the

drive product is installed in accordance with the standards in force in the country in which it is installed such as EN 13659

relating to roller shutters.

Liability: Before installing and using the drive, please read operating and installation guide carefully. Please

read these instructions carefully before installing and using the drive. In addition to following the instructions given in this

guide, the instructions detailed in the attached Safety instructions document must also be observed. The drive must be

installed by a motorisation and home automation professional, according to instructions from Simu and the regulations

applicable in the country in which it is commissioned. It is prohibited to use the drive outside the eld of application

described above. Such use, and any failure to comply with the instructions given in this guide and in the attached

Safety instructions document, absolves SIMU of any liability and invalidates the warranty. The installer must inform its

customers of the operating and maintenance conditions for the drive and must provide them with the instructions for use

and maintenance, and the attached Safety instructions document, after installing the drive. Any After-Sales Service

operation on the drive must be performed by a motorisation and home automation professional. If in doubt when installing

the drive, or to obtain additional information, contact a SIMU adviser or go to the website www.simu.com.

Instructions which must be followed by the drive and home automation professional installing the

drive:

- Methods of wiring are given by national standards or IEC60364 standard.

- Cables which pass through a metal wall must be protected and isolated using a sheath or sleeve.

- The cable for the motor can be removed. If it is damaged, replace by the same. The cable may only be

connected to the motor by qualied personnel. The connector is to be assembled without damaging the

contacts. The continuity of the earth connection must be ensured.

Recommendations: Keep a minimum distance of 20 cm between two T5 AUTOSHORT BHz motors. Keep

a minimum distance of 30 cm between T5 AUTOSHORT BHz motors and BHz transmitters. A radio appliance

using the same frequency (868-870 MHz) may deteriorate our product’s performance. To receive information

regarding the compatibility of the motor and the roller shutter or/and accessories, contact the roller shutter

manufacturer or SIMU.

Drilling of the tube:

Mounting:

Installation

1

351 4 x Ø5 / 90°

47

min.

364

387

4

22,8

55

48 IP44

120

45 24

T5 AUTOSHORT BHz 06/17

1/4

EN

SIMU S.A.S. au capital de 5 000 000 € - Z.I. Les Giranaux - BP71 - 70103 ARC-LÈS-GRAY CEDEX - FRANCE - RCS VESOUL B 425 650 090 - SIRET 425 650 090 00011 - n° T.V.A CEE FR 87 425 650 090

EN T5 AUTOSHORT BHz

(230V~50Hz)

5140363A

Original

instructions

-20°C / +60°C

i

Wiring

2

- You must have the possibility to switch o

individually each motor.

- Attach cables to prevent any contact with moving

parts.

- If the motor is used outdoors and if the power

supply cable is of the H05-VVF type, then run the

cable in a UV-resistant conduit, e.g. trunking.

PE

L

N

T5 AUTOSHORT BHz

230V~50Hz

Blue

Green / Yellow

Brown

Compatible transmitters (9 transmitters (1 channel) max. for one motor)

Memorizing the automatic settings

3

4

1 : 1 channel Wall BHz transmitter

2 : 1/5 channels Mobile BHz transmitter

iCompatible with io-homecontrol®transmitters;

Location of the PROG key on BHz transmitters:

Do not position the transmitter near metal in order to avoid range losses.

If the installation includes several motors, only one motor is to be powered during this programming

procedure. It will avoid interferences with the other motor during the procedure.

4.1- Learning mode:

- Switch the motor ON.

- Simultaneously press the "UP" and "DOWN" buttons of a

BHz transmitter.

The motor will run for 0,5 second in one direction, then in the other.

i The transmitter now controls the motor in unstable mode. Move to stage 4.2.

4.2- Checking the rotation direction:

aOK 4.3

OK 4.3

b

>> >>

>> >>

>> >> >>

Press the "UP' key of the transmitter:

a. If the motorized tube runs in the UP direction, move to next stage 4.3.

b. If the motorized tube runs in the DOWN direction, reverse the rotation direction by pressing the "Stop" key

for at least 3 seconds. The motor will run for 0,5 second in one direction, then in the other direction. Move

to the stage 4.3.

4.3- Memorizing the automatic settings:

1- Simultaneously press the "UP" and "DOWN" keys of a

transmitter. The motor will run for 0,5 second in one direction and

then in the other.

2- Press the "Stop" key for 2 s. The motor will run for 0,5 second in

one direction and then in the other. The operation is completed.

Go to stage §5.

>>

ON

2s

1 2

2/4 EN

If you do not want to use this transmitter as the individual control:

- cut the power supply (2 seconds minimum).

- repeat the opération 4.1* with a new transmitter and then go to step §5.

* In this case, the motor will run for 0,5 second in both directions, that means the limits setting is already done.

Programming the rst individual control point

Programming a new (individual, group or general) control point

5

6

This operation can only be performed from the

transmitter that was used for operation 4.1.

- Press the transmitter PROG button for approximately one

second. The motor will run for 0,5 second in one direction

and then in the other.

i Your transmitter is now programmed to control the motor in stable mode.

6.1- Open the memory of the receiver from the control

transmitter:

- Press the PROG key of the transmitter for about 3 seconds.

The motor will run for 0,5 second in one direction and then

in the other.

6.2- Conrm the operation from the new transmitter you

want to program:

- Press the PROG key of the transmitter for 1 second. The

motor will run for 0,5 second in one direction and then in

the other.

- For group controls, repeat operations 6.1 and 6.2 for each motor in the group.

- For general controls, repeat operations 6.1 and 6.2 for each motor in the installation.

- To delete an transmitter from the memory of a motor, perform operations 6.1 with a programmed transmitter,

then perform the operation 6.2 with the transmitter to be deleted.

Recording / controlling / deleting intermediate position

7

Modication of the rotation direction (in user mode):

8

Recording:

- Move the motor to the wanted

position.

- Press 5 seconds on the "Stop"

key. The motor will run for 0,5

second in one direction and

then in the other.

Control:

- Press the "Stop"

key for 0,5 second.

The motor runs to the

intermediate position.

Deleting: Position the motor on the intermediate position. Press 5 seconds on the "Stop" key, the intermediate

position is deleted.

i It would be only possible to set or control an intermediate position, after the rst two consecutive opening

and closing of the shutter (see §7).

Do not move the roller shutter to the up or down end limit position.

- Press the "Up" and "Down" buttons simultaneously for 5 seconds.

The motor runs briey in one direction, then in the other.

- Within 2 seconds, press the Stop button for 2 seconds. The motor

briey runs in one direction, then in the other. The rotation direction

has been changed.

After stage 1, if no operation is carried out before 2 seconds, the motor runs again briey in one

direction and then in the other, and the rotation direction is not changed.

>>

1

PROG 1s.

>>

2

1

PROG < 1s.

>>

1

PROG ≥ 3s.

2

5s

1

2s

2s

2

5s

0,5s

3/4

EN

Cancelling programming & settings

9

9.1- Switch o the power supply to the motor for 2 seconds.

9.2- Switch the power to the motor back on for 7 seconds.

9.3- Switch o the power supply to the motor for 2 seconds.

9.4- Switch the power to the motor back on.

If the motor is on the end limit position (up or down), the

motor will run briey in one direction and then in the other,

otherwise, the motor runs for 5 seconds in random direction.

The motor is now in the "cancelling mode".

Operation and maintenance

Technical Data

10

11

- This drive is maintenance-free.

- Press the ▲ button on the control point to raise the motorised product.

- Press the ▼ button on the control point to lower the motorised product.

- If the motorised product is moving: briey press the "Stop" button, the motorised product stops automatically.

- The motorised product is then stopped, press 0,5s on the "Stop" button. The motorised product moves to the

programmed intermediate position. (To modify or delete an intermediate position, see the section §7).

Tips and recommendations for use:

PROBLEMS POSSIBLE CAUSES SOLUTIONS

The motorised product does not

operate.

The overheating protection on the

drive has been activated.

Wait for the drive to cool down.

The BHz control point battery is low. Check the battery and replace it

as required.

If the motorised product still does not work, contact a drive and home automation professional.

- Radio frequency 868-870 MHz, tri-band two-way.

- Frequency bands and Maximum power used:

868.000 MHz - 868.600 MHz ERP <25 mW

868.700 MHz - 869.200 MHz ERP <25 mW

869.700 MHz - 870.000 MHz ERP <25 mW

- Power supply: 230 V ~ 50 Hz

- Operating temperature : - 20 °C to + 60 °C

- Protection rating : IP44

- Safety level: Class I

OFF

9.19.2 9.39.4

s2 7s

5s

2s

ON ONOFF

If you switch o the power to several motors, they will all be in cancelling mode. That is why, you

must "eject" out of this mode all the receivers that are not to be deprogrammed by sending a command

from their individual control transmitter (UP or Down).

9.5- Then, conrm the cancelling of the concerned motor from the individual control:

- Press the PROG key of the transmitter more than 7 seconds.

Maintain the pressure until the motor will rst run for 0,5 second in

one direction and then in the other, and a few second later, it will run

again in both direction.

i The motor is now as it was originally congured, and no transmitter

and no settings is saved in its memory and is ready for a new programming.

2s 7s

>> >>

PROG >7s

9.5

Simu SAS, F-70103 GRAY as manufacturer hereby declares that the drive covered by these instructions when marked for input voltage

230V~50Hz and used as intended according to these instructions, is in compliance with the essential requirements of the applicable

European Directives and in particular of the Machinery Directive 2006/42/EC, and the Radio Directive 2014/53/EU. The full text of the EU

declaration of conformity is available at www.simu.com. Emmanuel CARMIER, general director, GRAY, 01/2018.

4/4 EN

This manual suits for next models

1

Table of contents

Other Simu Engine manuals

Simu

Simu T3.5 DC E Hz User manual

Simu

Simu DMI 5 Hz User manual

Simu

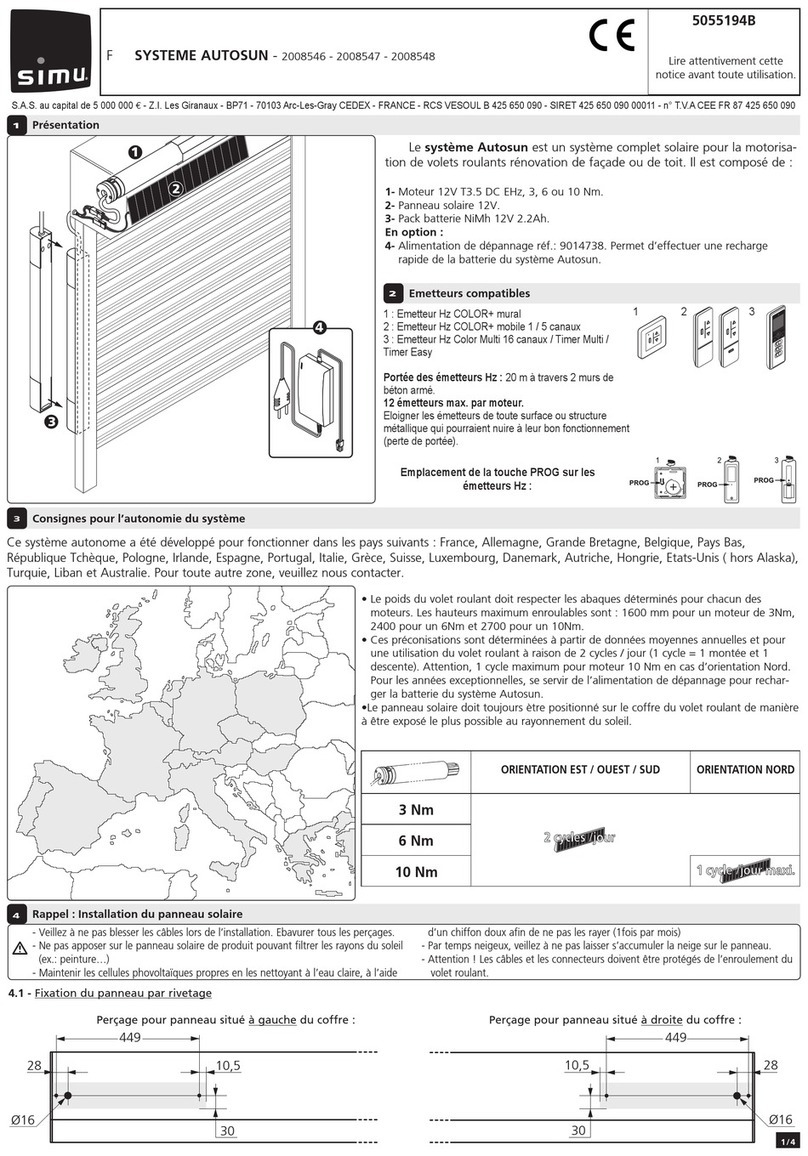

Simu AUTOSUN 2008546 User manual

Simu

Simu T5 E Hz User manual

Simu

Simu DMI5 Hz User manual

Simu

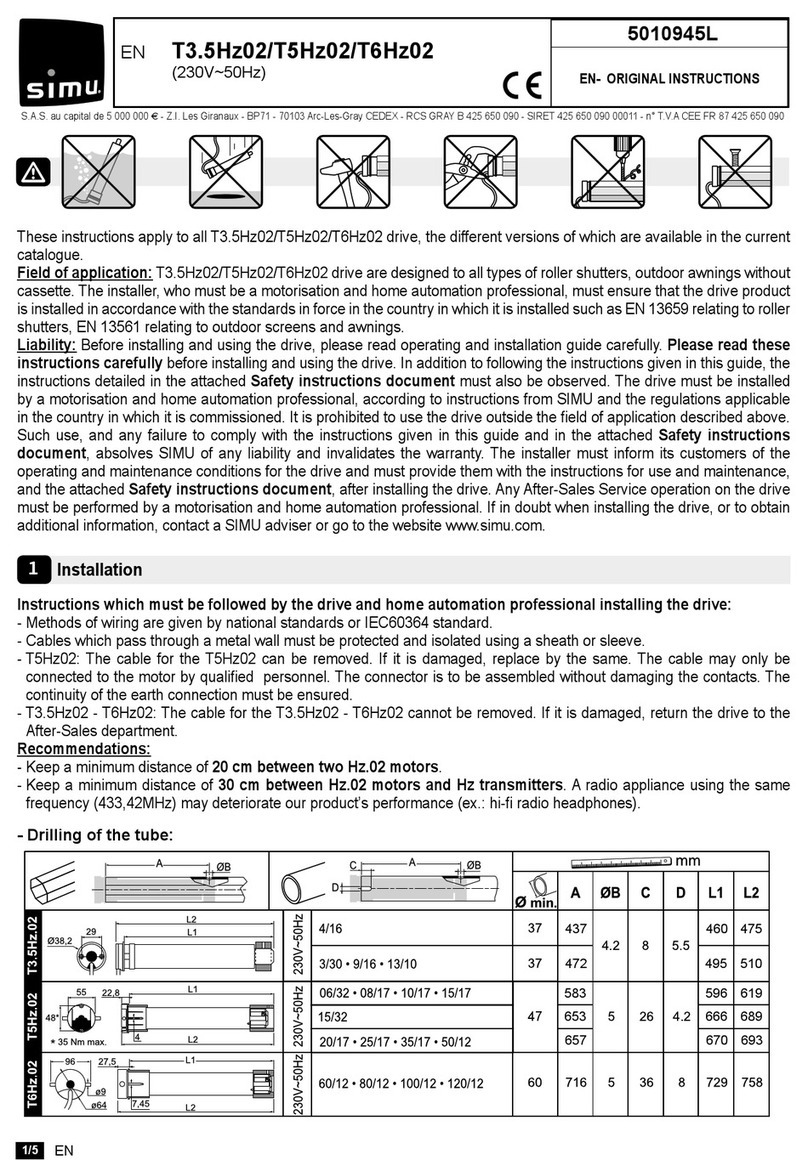

Simu T5 Hz.02 User manual

Simu

Simu T3.5Hz02 User manual

Simu

Simu DMI6 Hz User manual

Simu

Simu T3.5 DC E Hz User manual

Simu

Simu T5 Hz.02 User manual

Popular Engine manuals by other brands

Mobatime

Mobatime BU 192t Mounting and instruction manual

Yamaha

Yamaha F100C Service manual

Volvo Penta

Volvo Penta PENTA owner's manual

Conrad Electronic

Conrad Electronic 1396900 operating manual

MDL Solutions

MDL Solutions PFWSL-01 Installation, operation & service manual

CONTINENTAL AIRCRAFT ENGINE

CONTINENTAL AIRCRAFT ENGINE A65 Series Maintenance manual