The Handy THLC09715 User manual

THLC09715 - 193844002

12/05/2016

INSTRUCTION

MANUAL

LIGHT CONSTRUCTION

PETROL MINI TRANSPORTER

SPARES & SUPPORT: 01793 333212

ASSEMBLY REQUIRED –MINIMUM OF TWO PEOPLE

Please read & understand this manual, paying particular attention to the safety instructions, before

use.

The manufacturer reserves the right to change the product specification and livery according to

continued product improvements.

CONTENTS

GENERAL SAFETY INSTRUCTIONS

SPECIFICATION

COMPONENTS

ASSEMBLY

KNOW YOUR MACHINE

FUEL SAFETY

OPERATION

SERVICE

MAINTENANCE

STORAGE

TROUBLE SHOOTING

PARTS DIAGRAM

PARTS LIST

WARRANTY

EC DECLARATION OF CONFORMITY

WE RECOMMEND

Assembly Is Required

This product requires assembly before use. See the “Assembly” section for instructions.

Please check that all parts required for the assembly of this spreader are included. If for any reason

you believe a part for the assembly is missing or damaged, please contact us.

If you require any assistance with regards to the contents or operation of your

machine, please contact us:

TEL: 01793 333212

(MON –FRI 8.00AM TO 5.30PM EXCL. BANK HOLIDAYS)

GENERAL SAFETY INSTRUCTIONS

Read and understand the owner’s manual and labels affixed to the machine. Learn its application

and limitations as well as the specific potential hazards. Retain these instructions for future

reference. The operator is responsible for following the warnings & instructions in this manual and

on the product.

WARNING! Failure to comply with these instructions may result in damage to the machine or

other property and/or personal injury.

Read & understand this

manual before using the

machine.

Wear safety gloves

Hot surfaces.

Contact may cause

physical damage.

Wear ear & eye

protection

Do not remove

protection or safety

devices.

Wear safety footwear

Fire Risk

Fire and its vapors are

extremely flammable &

explosive.

Fire or explosion can

cause severe burns or

death.

Acoustic power level

LWA accordance with

directive 2000/14/EC +

2005/88/EC

(Please see machine &

specification within this

manual for actual

reading)

Do not smoke when

operating

Keep bystanders,

children & pets a

minimum of 20 metres

away from the machine.

If they approach, stop

the machine

immediately.

Keep hands and feet

away from tracks and

rotating parts.

Caution: Thrown objects.

STAY ALERT

Do not operate the machine while under the influence of drugs, alcohol, or any medication that

could affect your ability to use it properly. Do not use this machine when you are tired or distracted

from the job at hand. Be aware of what you are doing at all times. Use common sense.

AVOID DANGEROUS CONDITIONS

Make sure there is adequate surrounding workspace. Cluttered areas invite injuries.

Keep your work area clean with sufficient light. Keep the area around the machine clear of

obstructions, grease, oil, rubbish and other debris which could cause persons to fall onto moving

parts.

This machine is intended for transporting soil, concrete and other materials. It is not suitable for the

transporting of flammable or explosive substances. Do not use it in areas where fumes from paint,

solvents or flammable liquids pose a potential hazard.

INSPECT YOUR MACHINE

Check all bolts, nuts, and screws for tightness before each use, especially those securing guards and

drive mechanisms. Vibration during use may cause these to loosen.

Form a habit of checking to see that all the adjusting tools and other equipment are removed from

the machine before turning it on.

Replace damaged, missing or failed parts before using it. Warning labels carry important

information. Replace any missing or damaged warning labels.

DRESS PROPERLY

Do not wear loose clothing, gloves, scarfs, neckties or jewelry (rings, wrist watches), which can be

caught in moving parts. Protective electrically non-conductive gloves and non-skid footwear are

highly recommended when working. Wear a face or dust mask if the operation is dusty. Always wear

safety glasses/goggles and/or face shields. Everyday eyeglasses have only impact resistant lenses;

they are not safety glasses/goggles. Wear protective hair covering to contain long hair, preventing it

from getting caught in machinery.

KEEP BYSTANDERS, CHILDREN & ANIMALS AWAY

Keep unauthorised persons a minimum distance of 20 metres away from the machine. If

approached, stop the machine immediately. Do not allow children to handle, climb on or in the

machine.

NEVER CARRY PASSENGERS

The machine should never be used to carry adults, children or animals.

DO NOT OVERREACH

Keep proper footing and balance at all times when loading or unloading the machine. Never stand

on the machine. Serious injury could occur if the machine is tipped or if the moving parts are

unintentionally contacted. Do not store anything above or near the machine where anyone might

stand on the machine to reach them.

AVOID INJURY FROM UNEXPECTED ACCIDENT

Keep hands out of the way of all moving parts. Do not place any part of your body or any tool e.g.

in moving parts during operation arm.

DO NOT FORCE TOOL

Always work within the rated capacity. Do not use the machine for a purpose for which it was not

intended. The machine is not to be towed by any vehicle.

NEVER LEAVE RUNNING UNATTENDED

Do not leave the machine unattended until it has come to a complete stop.

MAINTAIN YOUR MACHINE WITH CARE

Clean the machine immediately after use. Keep the machine clean to ensure it operates to it’s full

and safest performance. When maintaining this machine, only the manufacturer’s original

replacement parts should be used. The use of non-original manufacturer parts may invalidate your

warranty.

PROTECT THE ENVIRONMENT

Recycle unwanted materials to an authorised collection point or follow the stipulations in the

country where the machine is used. Do not discharge into drains, soil or water.

ENGINE MANUFACTURER

The Engine manufacturer is responsible for all engine-related issues with regards to performance,

power rating, specifications, warranty and service. Please refer to the Engine Manufacturer’s

owner’s/operator’s manual, packed separately with your unit, for more information.

Safety Alert Symbol. Used to alert you to potential personal injury hazards. Obey all safety messages

that follow this symbol to avoid possible injury.

DANGER

Indicates an imminently hazardous situation which, if not avoided, will result in serious injury.

WARNING

Indicates a potentially hazardous situation which, if not avoided, could result in serious injury

CAUTION

Indicates a potentially hazardous situation which, if not avoided, may result in minor or moderate

injury.

CAUTION

Used without the safety alert symbol indicates a potentially hazardous situation which, if not

avoided, may result in property damage.

SPECIFICATION

Model

THLC09715

Product Number

193844002

Engine

Briggs & Stratton CR950 Series

Weight

179kg

Load Capacity (Weight)

300kg

Track Width

180mm

Sound Power Level (LwA)

103 dB(A)

Sound Pressure Level (LpA)

92 dB(A)

Vibrating Level on Handlegrips (m/s²)

Left 10.1 –Right 11.3

Forward Speeds

1.57km/h - 2.93km/h - 3.66km/h

Reverse Speed

1.14km/h

The manufacturer reserves the right to change the product specification and livery according to

continued product improvements.

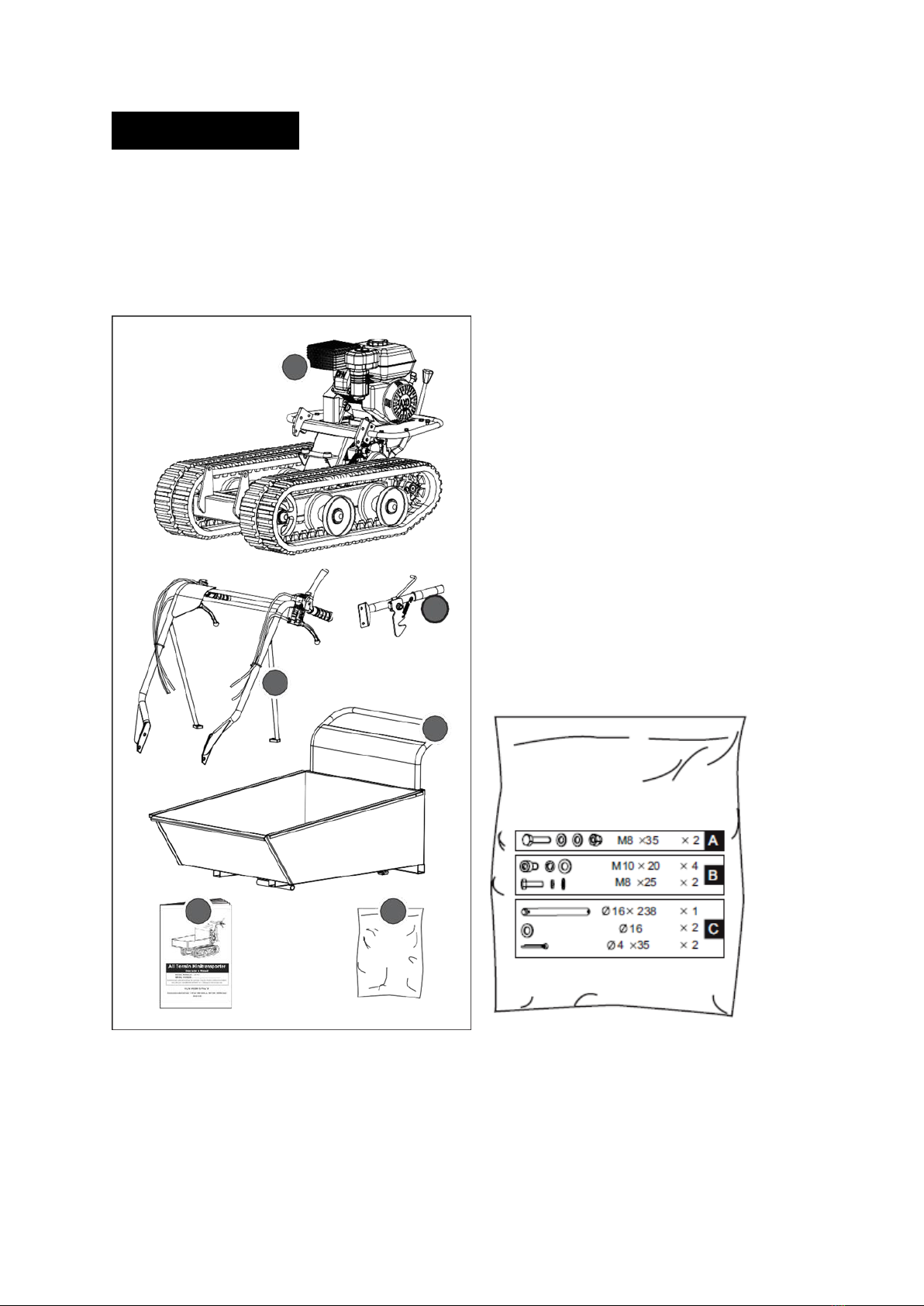

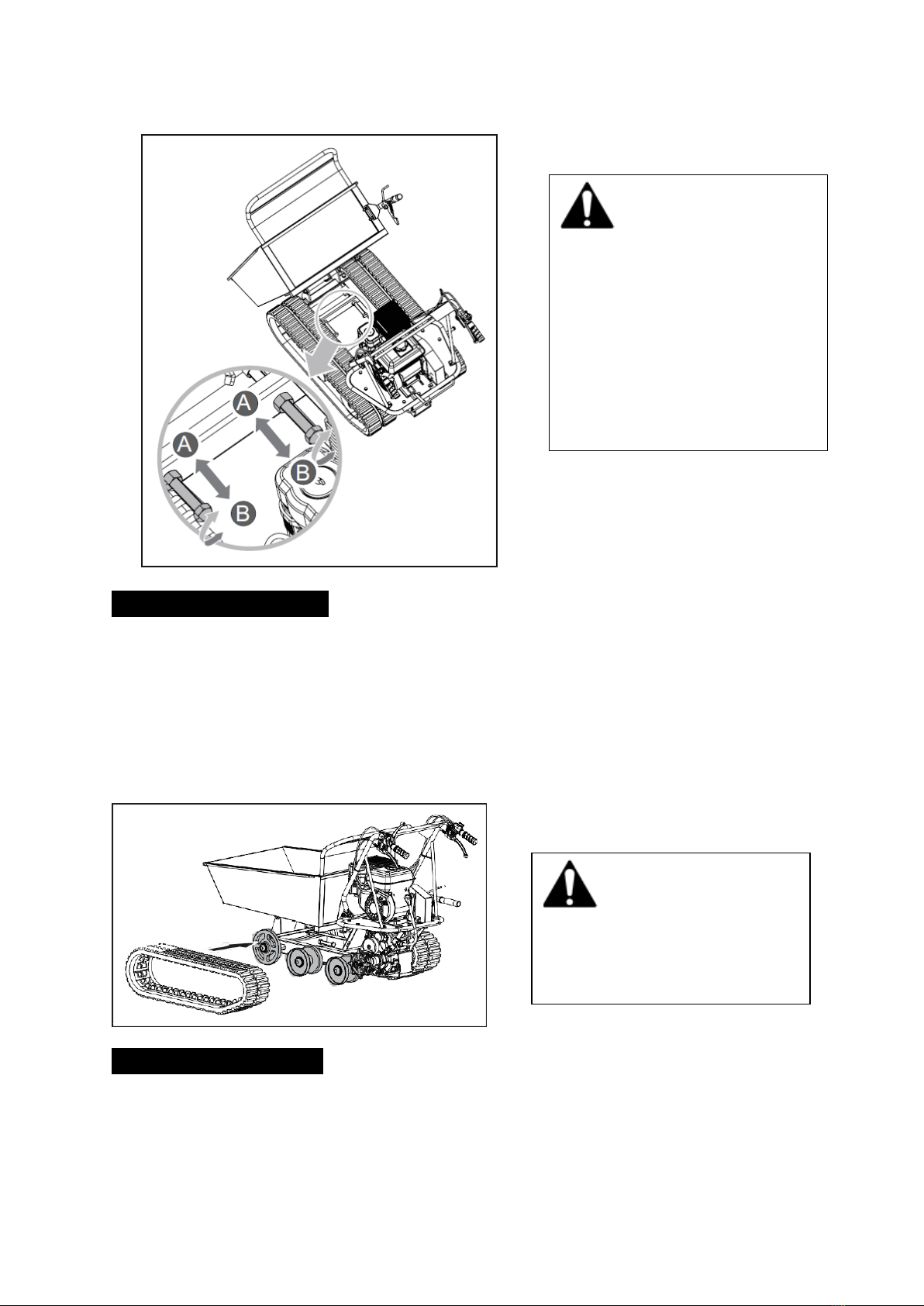

COMPONENTS

The machine is supplied partially assembled from the Distributor. Ensure all the components are

included in your package.

If you believe you are missing or have received defective parts, please contact:

Email: customerservice@handydistribution.co.uk

Telephone: 01793 333212 (Mon to Fri –8.00am to 5.30pm excl. Bank Holidays).

Main Body, Handlebar Assembly, Tipping Handle, Tub, Instruction Manual, Hardware Bag

ASSEMBLY

Follow the below assembly instructions carefully, you should be able to assemble the machine in a

short period.

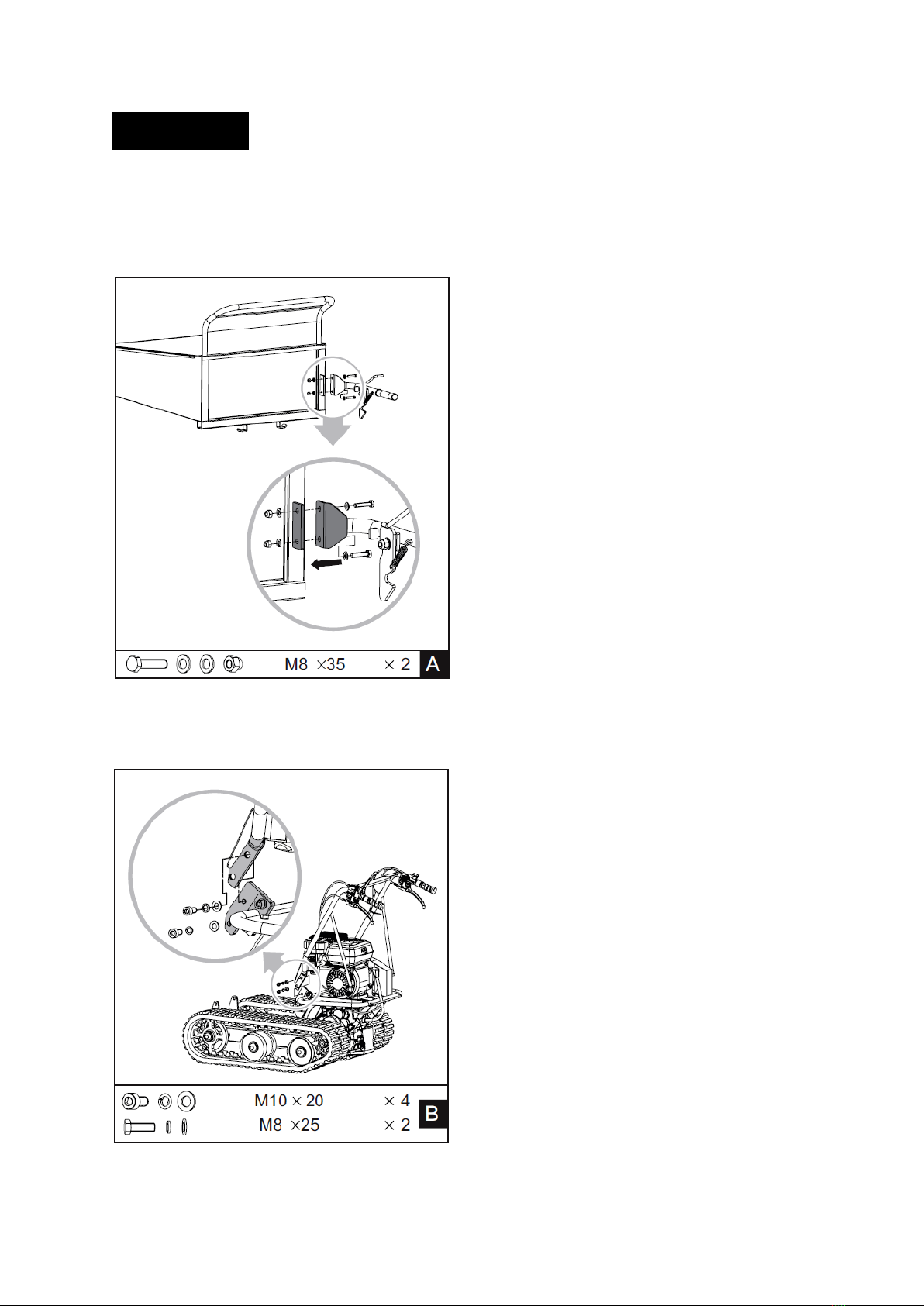

Mount the tipping handle on the right side of the box. Align the holes and fasten with two M8x35

hex bolts, four washers and two nuts.

Align the holes of the handlebar with the mount bracket and secure each with a spring washer, flat

washer and a M10x20 bolt. Fasten each handlebar support onto the engine deck with a spring

washer, flat washer and a M8x25 hex bolt.

Position the bottom panel inside the mounting bracket. Align the holes with the mounting bracket.

Insert a long pin through the holes and secure each side with a flat washer and cotter pin

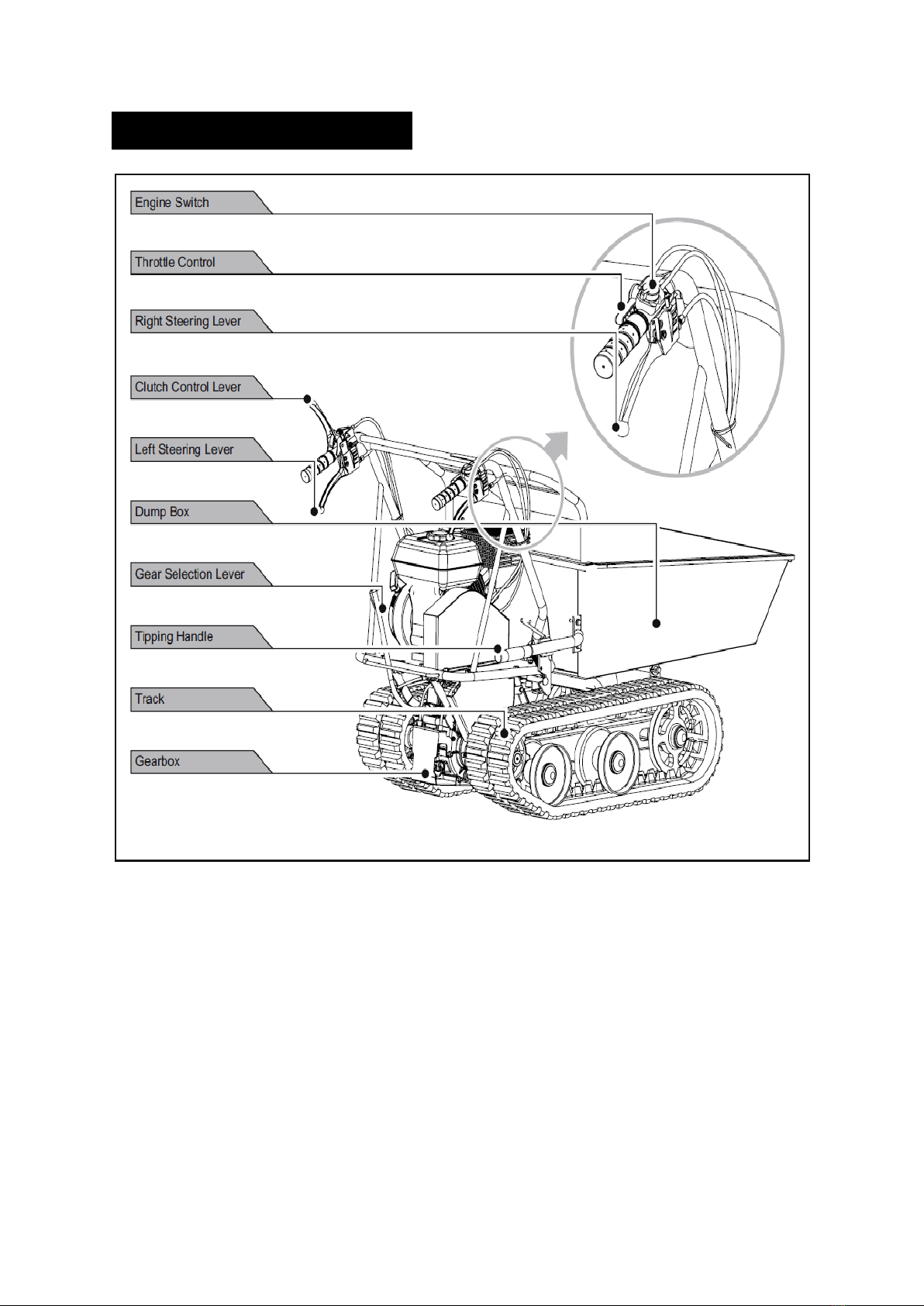

KNOW YOUR MACHINE

ENGINE SWITCH

The engine switch enables and disables the ignition system.

The engine switch must be in the ON position for the engine to run.

Turning the engine switch to the OFF position stops the engine.

CLUTCH CONTROL LEVER

Squeeze the control lever to engage the clutch. Release the lever to disengage the clutch.

THROTTLE CONTROL

This controls the engine speed. The throttle control can be set at low speed (L), high speed (H) or an

intermediary position between L and H.

LEFT STEERING LEVER

Operate the lever to turn left.

RIGHT STEERING LEVER

Operate the lever to turn right.

GEAR SELECTION LEVER

It controls forward or reverse movements of the machine.

TIPPING HANDLE

This controls the tipping of the dump box. Pull the handle up to release the dump box's locking

device and raise the dump box.

When the dump box is lowered, the locking mechanism operates, locking the dump box. To check

whether the dump box is locked securely, try to lift it without pulling up the tipping handle.

FUEL SAFETY

Fuel is highly flammable, and its vapours can explode if ignited. Take precautions when using to

reduce the chance of serious personal injury.

Only refill or drain the fuel tank in a clean well-ventilated outdoor area. Use an approved fuel

storage container. Do not smoke, or allow sparks, open flames or other sources of ignition near

the area while adding fuel or operating the unit. Never fill the fuel tank indoors.

Keep grounded conductive objects, such as tools, away from exposed, live electrical parts and

connections to avoid sparking or arcing. These events could ignite fumes or vapours.

Always stop the engine and allow it to cool before filling the fuel tank. Never remove the cap of

the fuel tank or add fuel while the engine is running or when the engine is hot. Do not operate

the machine with known leaks in the fuel system.

Loosen the fuel tank cap slowly to relieve any pressure in the tank.

Never overfill the fuel tank. Fill the tank to no more than 12.5mm (1/2”) below the bottom of

the filler neck to allow space for expansion as the heat of the engine can cause fuel to expand.

Replace all fuel tank and container caps securely and wipe up spilled fuel. Never operate the unit

without the fuel cap securely in place.

Avoid creating a source of ignition for spilled fuel. If fuel is spilled, do not attempt to start the

engine but move the machine away from the area of spillage and avoid creating any source of

ignition until fuel vapours have dissipated.

Store fuel in containers specifically designed and approved for this purpose.

Store fuel in a cool, well-ventilated area, safely away from sparks, open flames or other sources

of ignition.

Never store fuel or a machine with fuel in the tank inside a building where fumes may reach a

spark, open flame, or other sources of ignition, such as a water heater, furnace, clothes dryer or

similar.

Allow the engine to cool before storing in any enclosure.

ADDING FUEL

Fill the fuel tank as instructed in the separate Engine Manual packed with the machine.

Fill the tank to no more than 12.5mm (1/2”) below the bottom of the filler neck to allow space for

expansion.

OPERATION

Never park the machine in a place with unstable ground which could give way, particularly when

the dump box is full.

Disengage the clutch lever before starting the engine.

Start the engine carefully according to the instructions and with your feet well away from the

moving parts.

Never leave the operating position when the engine is running.

Always hold the unit with both hands when operating. Keep a firm grip on the handlebars. Be

aware that the machine may unexpectedly bounce upward or jump forward if the machine should

strike buried obstacles such as large stones.

Walk, never run with the machine.

Do not load the machine over its capacity. Drive at a safe speed, adjusting the speed to the slope

of the land, the surface conditions of the road, and the weight of the load.

Use extreme caution when in reverse or pulling the machine towards you.

Exercise extreme caution when operating on or crossing gravel drives, walks, or roads. Stay alert

for hidden hazards or traffic.

On soft ground, drive at the first forward/reverse gear. Do not rapidly accelerate, turn sharply or

stop.

Pay the utmost attention when working on frozen ground as the machine may tend to skid.

If possible, avoid driving on pebbly river beds, crushed stone terrains, steel, concrete, stumpy

field, logs etc., since such operation will cause fatal damage or shorten the life span of the

tracks.

Do not operate the machine in confined areas where there may be a risk of crushing the operator

between the machine and another object.

Never operate the machine on slopes where the angle is over 20° degrees.

When moving over a slope, whether moving forward or in reverse, always make certain that the

weight is evenly balanced. Always move in directions parallel with the slope. To

avoid danger, do not shift gears on slopes.

When tipping the load from the dumper, the centre of gravity will change continuously and the

stability of the machine will vary depending on the conditions of the ground beneath it. There

are special hazards for dumpers working on soft ground and when the load is sticking to the

machine e.g. wet clay.

CAUTION

Engine Oil has been drained for shipping.

Failure to fill the engine sump with oil before starting the engine will result in permanent damage

and will void the engine manufacturers warranty.

ADD OIL ACCORDING TO THE ENGINE MANUFACTURERS ENGINE MANUAL, PACKED SEPERATELY

WITH YOUR MACHINE.

STARTING THE ENGINE

A more detailed description of the engine operation and all related precautions and procedures can be

found in the Engine Manual packed separately with the machine.

Follow the procedure below for cold starts:

1. Turn the choke lever on the engine to the full choke position.

2. Set the throttle lever on the handlebar at the

half-way position.

3. Turn the engine switch on.

4. Pull the starting cord slowly several times to allow the petrol to flow into the engine’s

carburetor. Then hold the start handle firmly and pull the cord out a short distance until you

feel some resistance. Then pull the cord smoothly and briskly, and return the cord gently. Do

not let the cord snap back. If necessary, pull the cord several times until the engine starts.

5. Allow the engine to run for several seconds to warm up. Then, gradually move the choke lever to

the “OPEN” position.

Restarting an engine that is already warm from previous use does not normally require use of the

choke.

1. Set the throttle lever on the handlebar at the half-way position.

2. Hold the start handle firmly and pull the cord out a short distance until you feel some resistance.

Then pull the cord smoothly and briskly and return the cord gently. Do not let the cord snap back.

After the engine warms up, pull throttle lever to accelerate the engine speed.

Engage the required gear and slowly squeeze the clutch control lever. If the gear does not engage

straight away, slowly release the clutch lever and try again. The Transporter will start moving.

The Transporter has its steering levers on the handlebars and this makes steering very easy. To turn

right or left, simply operate the corresponding right or left steering lever.

The sensitivity of the steering increases in proportion to the speed of the machine and the weight of

its load. A light pressure on the lever is all that is needed to turn an empty machine. When the

machine is loaded, more pressure is required.

The Transporter has a maximum capacity of 300kg. However, it is advisable to assess the load and

adjust it according to the ground on which the machine will be used. It is therefore advisable to use a

low gear and take care when moving heavy loads or working on soft ground. In such situations, the

machine should be kept in low gear for the whole job.

Avoid sharp turns and frequent changes of direction while moving the machine, in particular on

rough, hard terrain full of sharp, uneven points with a high degree of friction.

Even though the unit has rubber tracks, remember to be careful when working in adverse weather

conditions (ice, heavy rain and snow) or on types of ground that could make the Transporter

unstable.

Please note that as this is a tracked vehicle, it may pitch considerably when passing over bumps,

holes and steps.

When the clutch control lever is released, the machine will stop and brake automatically.

If the machine is stopped on a steep slope, a wedge should be placed against one of the tracks.

IDLE SPEED

Set the throttle control lever to its “SLOW” position to reduce stress on the engine when it is not in

use. Lowering the engine speed to idle the engine will help extend the life of the engine, as well as

conserve fuel and reduce the noise level of the machine.

STOPPING THE ENGINE

To stop the engine in an emergency, simply turn the engine switch to the OFF position. Under

normal conditions, use the following procedure:

Move the throttle lever to the SLOW position.

Let engine idle for one or two minutes.

Turn the engine switch to the OFF position.

Turn the fuel valve lever to the OFF position

DO NOT MOVE THE CHOKE LEVER TO ‘CHOKE’ TO STOP THE ENGINE. BACKFIRE OR ENGINE

DAMAGE MAY OCCUR, ANY DAMAGE WILL NOT COVERED BY THE ENGINE MANUFACTURERS

WARRANTY

SERVICE

Before cleaning, repair, inspecting, or adjusting, shut off the engine and make certain all moving

parts have stopped. Disconnect the spark plug wire, and keep the wire away from the plug to

prevent accidental starting.

Have your machine serviced by qualified repair personnel using only identical replacement parts.

This will ensure that the machine remains safe to use.

MAINTENANCE

Proper maintenance and lubrication will help keep the machine in perfect working condition.

PREVENTIVE MAINTENANCE

Turn off the engine and disengage all command levers. The engine must be cool.

Inspect the general condition of the unit. Check for loose screws, misalignment or binding of moving

parts, cracked or broken parts, and any other condition that may affect its safe operation

Remove all debris and other materials that may have accumulated in the track and unit. Clean after

each use. Then use a premium quality lightweight machine oil to lubricate all moving parts

CAUTION

NEVER USE A “PRESSURE WASHER” TO CLEAN THE UNIT. WATER CAN PENETRATE TIGHT AREAS OF

THE MACHINE AND ITS TRANSMISSION CASE AND DAMAGE SPINDLES, GEARS, BEARINGS, OR THE

ENGINE. THE USE OF PRESSURE WASHERS WILL REDUCE SERVICE LIFE AND SERVICEABILITY

ADJUSTING THE CLUTCH

As the clutch wears the lever action may become wider making it less comfortable to use. At this

point you will need to adjust the cable, setting

the clutch lever to its original position by adjusting the adjustment device and the counter-nut.

ADJUSTING THE STEERING

If you have difficulty steering the unit, you will need to adjust the steering levers with the special

adjusters. Slacken off the locknut and unscrew the adjusters to eliminate the play in the cable, which

can occur after initial use or normal wear. Be very careful not to unscrew the adjusters too much

because this can lead to a loss of traction.

Remember to tighten the locknut when you have finished.

GEARBOX LUBRICATION

The gearbox is pre-lubricated and sealed at the factory.

Check the oil level every 50 hours of use. Remove the plug and check, with the machine horizontal,

that oil reaches the two notches. If necessary, add more oil.

Use portable tool lithium #0 grease such as Lubriplate 6300AA , Lubriplate GR-132, or Multifak,

e.g. EP-O.

Oil must be replaced when hot by unscrewing the filler cap and plug equipped with an oil dipstick.

When oil is completely drained, replace the filler cap and fill up with new oil.

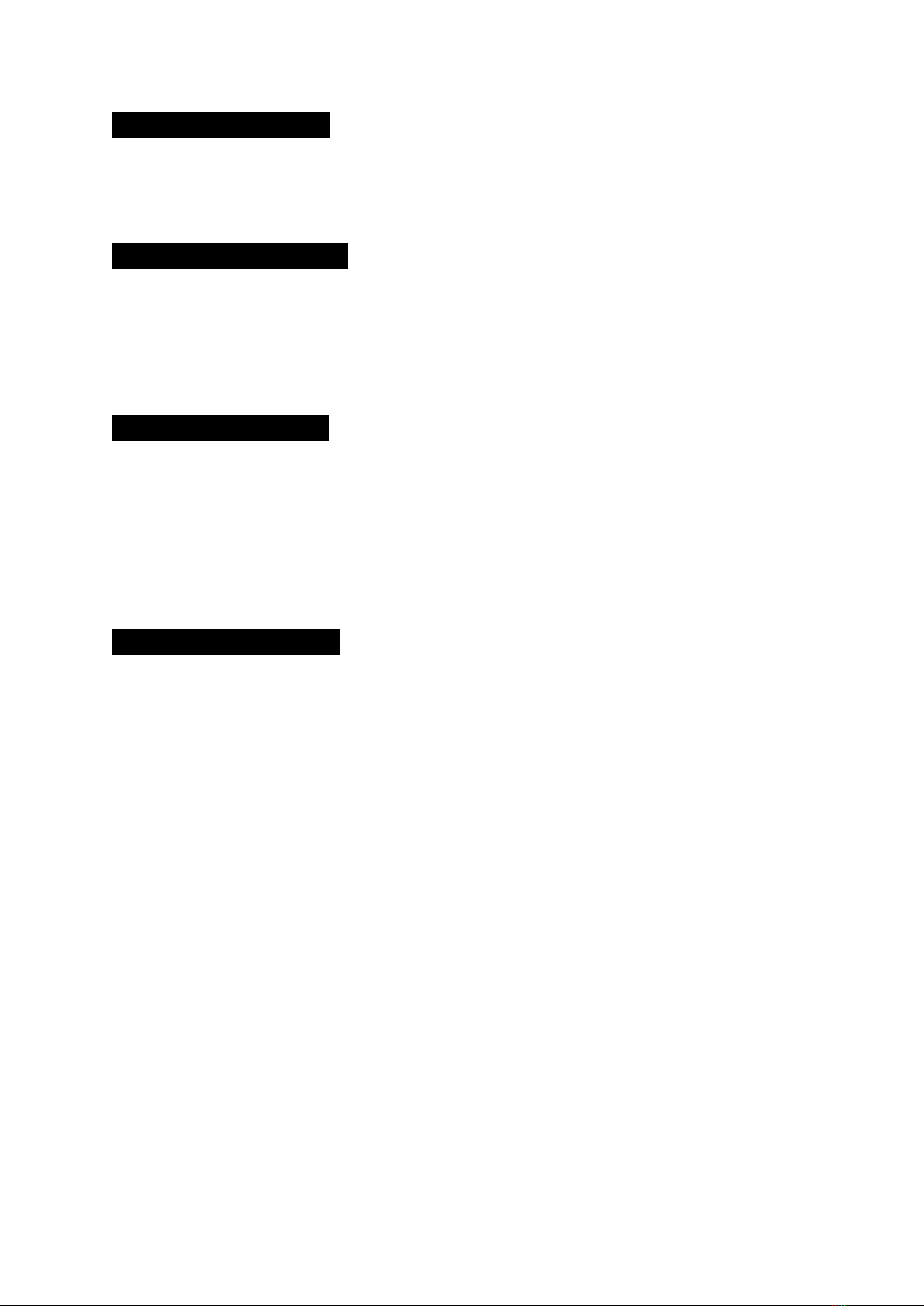

TIGHTENING THE TRACKS

With use, the tracks tend to loosen. When operating with loose tracks, they will tend to slip

over the

driving wheel causing it to jump its housing this can be very dangerous and can damage the housing.

To check track tightness, proceed as follows:

1. Set the machine on a flat surface with compact ground, preferably on asphalt or a stonepavement.

2. Lift the machine and set it on blocks or supports rated for the weight of the machine so that the

tracks are approximately 100mm off of theground.

3. The gap between the track and the middle wheel must not exceed 10-15mm.

If the distance is greater, proceed at follows.

1. Use the tipping handle to tip the dump box and set it on blocks or supports rated for the weight

of the box.

2. Loosen Lock Nut A

3. Tighten Bolt B to the correct tightness.

4. Secure Bolt B by tightening Lock Nut A thoroughly.

5. Return the dump box to its original position.

REPLACING THE TRACKS

Check the condition of the checks periodically. If any track is cracked or frayed, it should be replaced

before the machine is used.

1. Loosen locknut A and bolt B shown in previous figure to loosen the tracks.

2. Slip the old tracks off & install the replacements

3. Adjust Bolt B to ensure the correct tightness.

4. Secure Bolt B by tightening Lock Nut A thoroughly

ENGINE MAINTENANCE

Refer to the Engine Manual included with your machine for information on engine maintenance.

Your engine manual provides detailed information and

a maintenance schedule for performing tasks.

All engine enquiries should be raised with the engine manufacturer or one of their approved service

dealers.

CAUTION

The adjustment of the track and the

brakes are linked, therefore be very

careful because if the track is over-

tightened, the braking effect will be

lost.

If the adjustment bolt cannot be

adjusted any further, the tracks

may have to be replaced.

CAUTION

When removing or installing the

tracks, be careful not to get your

fingers caught between the track

and the pulley.

STORAGE

If the Transporter will not be used for a period longer than 30 days, follow the steps below to

prepare your unit for storage.

1. Drain the fuel tank completely. Stored fuel containing ethanol or MTBE can start to go stale

within 30 days. Stale fuel has a high gum content and can clog the carburetor and restrict fuel

flow.

2. Start the engine and allow it to run until it stops. This ensures no fuel is left in the carburetor.

This helps prevent gum deposits from forming inside the carburetor and damaging the engine.

3. Gummed carburetor repairs are not covered by Engine Manufacturer warranties.

4. While the engine is still warm, but not hot, drain the oil from the engine. Refill with fresh oil of

the grade recommended in the Engine Manual.

5. Use clean cloths to clean off the outside of the machine & to keep the air vents free of

obstructions.

6. Inspect the machine for any loose or damaged parts. Repair or replace damaged parts & tighten

loose screws, nuts & bolts.

7. Store your machine on flat ground in a clean, dry building that has good ventilation.

Do not use strong detergents or petroleum based cleaners when cleaning plastic parts. Chemicals

can damage plastics

Do not store the machine containing fuel in a non-ventilated area where fuel fumes may reach

flames, sparks, pilot lights or any other ignition sources.

TROUBLE SHOOTING

Problem

Cause

Remedy

Engine fails to

start.

1. Spark plug wire

disconnected.

2. Out of fuel or stale fuel.

3. Choke not in the open

position.

4. Blocked fuel line.

5. Fouled spark plug.

6. Engine flooding.

1. Attach the spark plug wire securely

to the spark plug.

2. Fill with clean, fresh petrol.

3. Throttle must be positioned at choke

for a cold start.

4. Clean the fuel line.

5. Clean, adjust spark plug gap, or

replace.

6. Wait a few minutes to restart, but do

not prime.

Engine runs

erratically.

1. The spark plug wire is loose.

2. The unit is running on

CHOKE.

3. Blocked fuel line or stale

fuel.

4. The vent is plugged.

5. Water or dirt in the fuel

system.

6. Dirty air cleaner.

7. Improper carburetor

adjustment.

1. Connect and tighten the spark plug

wire.

2. Move the choke lever to OFF.

3. Clean the fuel line. Fill the tank with

clean,

fresh petrol.

4. Clear the vent.

5. Drain the fuel tank. Refill with fresh

fuel.

6. Clean or replace the air cleaner.

7. Refer to the Engine Manual.

Engine overheats.

1. Engine oil level low.

2. The air cleaner is dirty.

3. Air flow is restricted.

4. The carburetor is not

adjusted properly.

1. Fill the crankcase with proper oil.

2. Clean the air cleaner.

3. Remove the housing and clean.

4. Refer to the Engine Manu. al.

One of the two

tracks is blocked.

Foreign bodies have worked

their way between the track

and the frame.

Remove the foreign body.

Machine does not

move while the

engine is running.

1. Gear is not properly

selected.

2. The driving tracks are not

tight enough.

1. Ensure the gear lever is not in-

between two different gears.

2. Tighten the driving tracks.

NOTES

_____________________________________________

_____________________________________________

_____________________________________________

_____________________________________________

_____________________________________________

_____________________________________________

_____________________________________________

_____________________________________________

_____________________________________________

_____________________________________________

_____________________________________________

_____________________________________________

_____________________________________________

_____________________________________________

_____________________________________________

_____________________________________________

_____________________________________________

_____________________________________________

_____________________________________________

_____________________________________________

_____________________________________________

_____________________________________________

_____________________________________________

_____________________________________________

_____________________________________________

_____________________________________________

_____________________________________________

PARTS DIAGRAM –THLC09715 (193844002)

NOTE: Parts Lists are supplied for

information purposes only, not

all parts are stocked individually

& we recommend you contact

our Spares Team on 01793

333212 for expert advice.

Other manuals for THLC09715

1

Table of contents

Other The Handy Farm Equipment manuals