GENERAL SAFETY INSTRUCTIONS

It is important that you read and understand the owner’s manual and labels affixed to the machine. Learn its

application and limitations as well as the specific potential hazards. Retain these instructions for future

reference. The operator is responsible for following the warnings & instructions in this manual and on the

product.

WARNING! Failure to comply with these instructions may result in damage to the machine or other property

and/or personal injury.

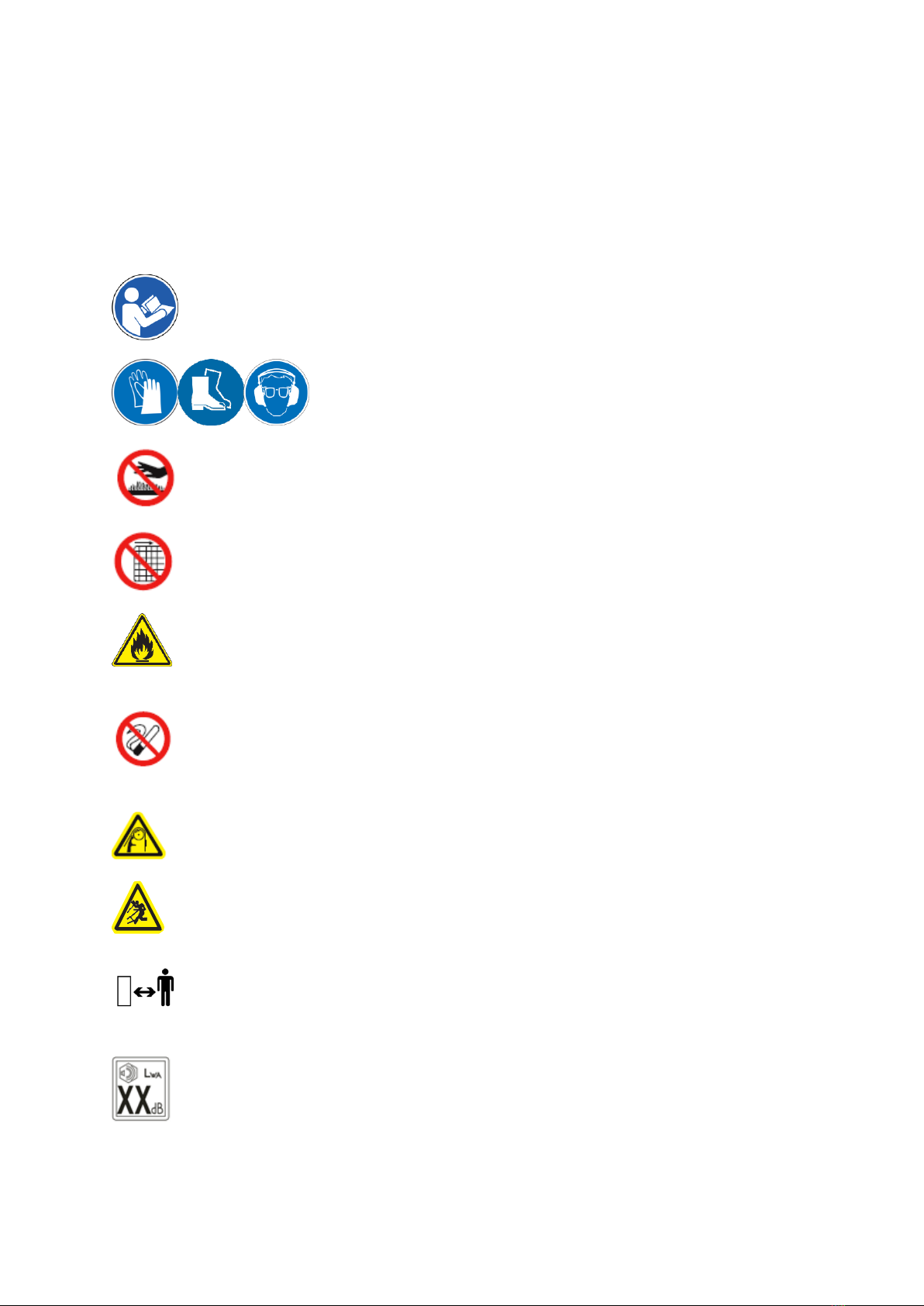

Read & understand instructions before using the machine.

Wear safety gloves. Wear ear & eye protection. Safety footwear, gloves.

Hot surfaces. Contact may cause physical damage.

Do not remove or alter protection and safety devices or guards.

Fire Risk. Fire and its vapors are extremely flammable & explosive. Fire or explosion can cause severe burns or

death.

Do not smoke or have open flames when operating. Use extreme caution when storing, handling and using

fuels, as they are highly volatile and explosive in a vapour state.

Keep hands and feet away from tracks and rotating parts.

Caution: Thrown objects.

Keep bystanders, children & pets a minimum of 20 metres away from the machine. If they approach, stop the

machine immediately.

Acoustic power level LWA accordance with directive 2000/14/EC + 2005/88/EC (Please see machine &

specification within this manual for actual reading)