- 5 -

TABLE OF CONTENTS

Any use and / or reproduction of all or part of this manual without written authorization from Gregoire-Besson is strictly prohibited.

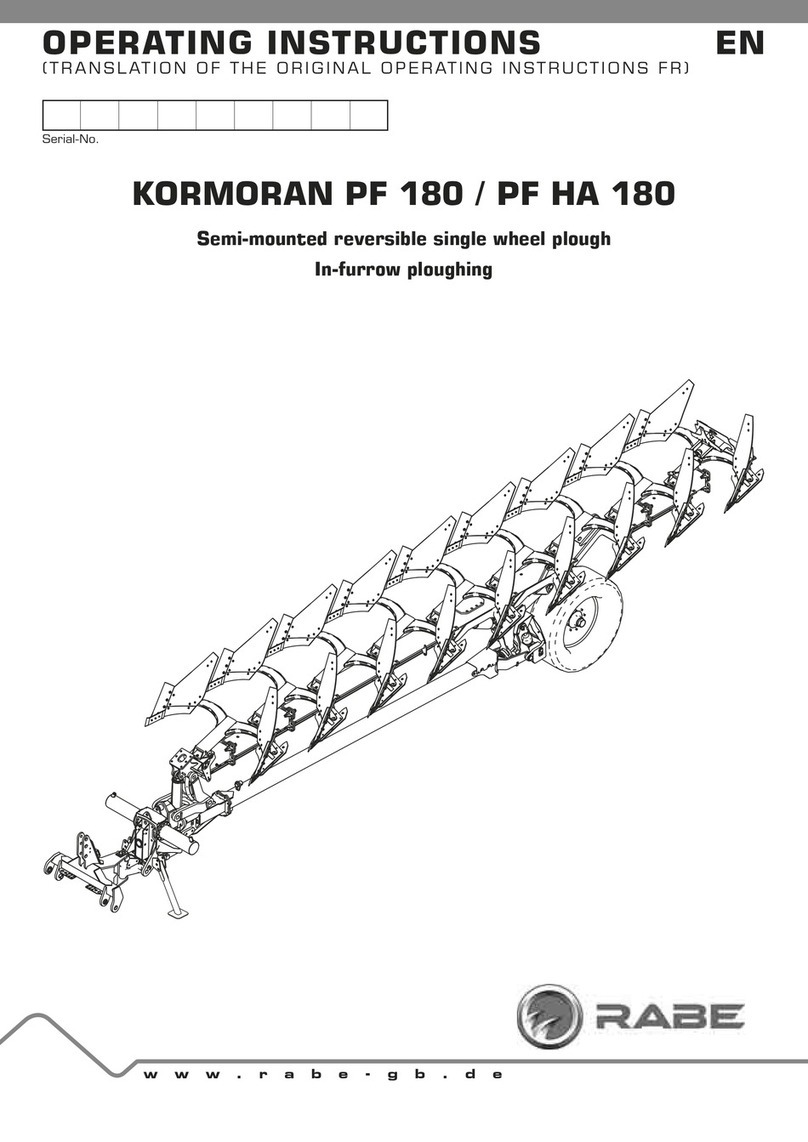

9901.00.07EN04SF - 02/2017 6XEMHFWWRWHFKQLFDOPRGL¿FDWLRQV

INTRODUCTION

1 Instructions..................................................7

1.1 Product documentation .......................................7

1.2 Explanation of symbols ........................................7

1.3 Regulations and legal provisions ...........................7

1.3.1 CE label ......................................................7

1.4 Identification of your equipment ...........................7

1.4.1 Type plate ...................................................7

1.4.2 Location of type plate ..................................7

1.4.3 Identification of your equipment ....................7

1.5 Associated documents ........................................7

2 Safety instructions and rules .........................8

2.1 Safety instructions .............................................8

2.1.1 General instructions ....................................8

2.1.2 Operator qualification ..................................8

2.1.3 Hitching and unhitching the implement...........8

2.1.4 Hydraulic circuit and couplings......................8

2.1.5 Use of the implement ...................................8

2.1.6 Transport on the public highway ....................9

2.1.7 Maintenance ...............................................9

2.1.8 Loading and unloading ..................................9

2.1.9 Safety stickers..........................................10

USE

3 Description of the implement .......................12

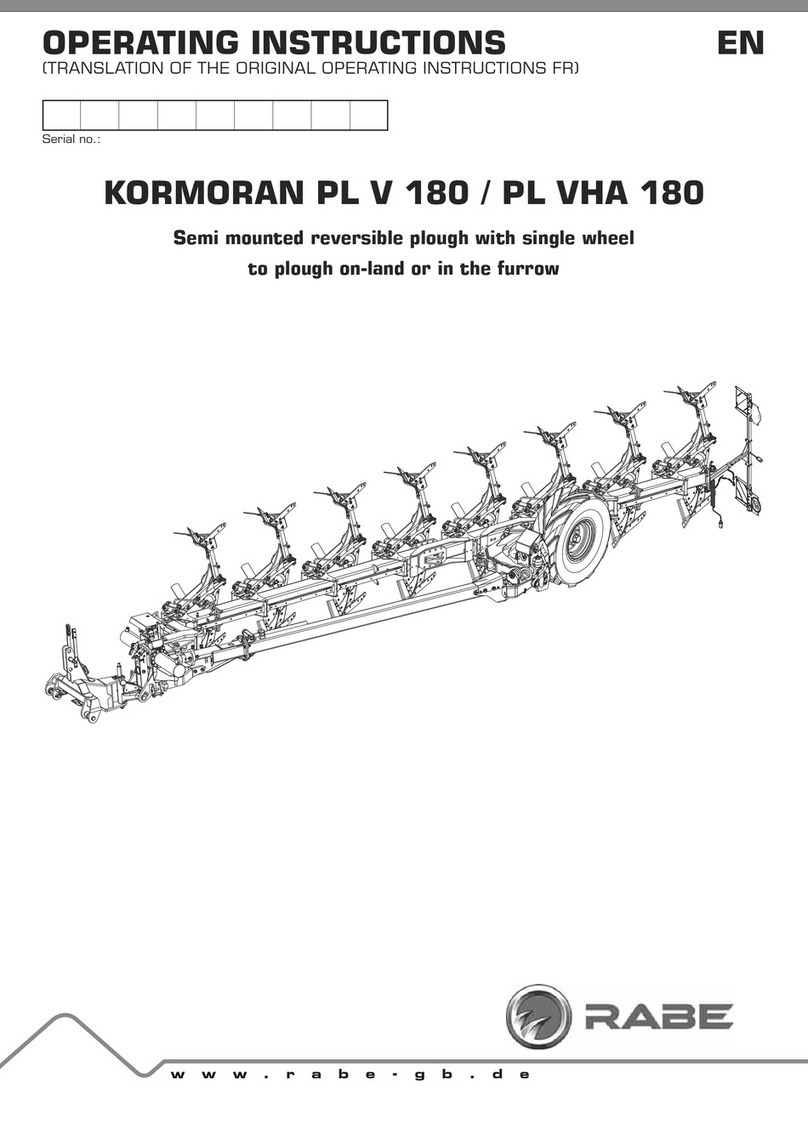

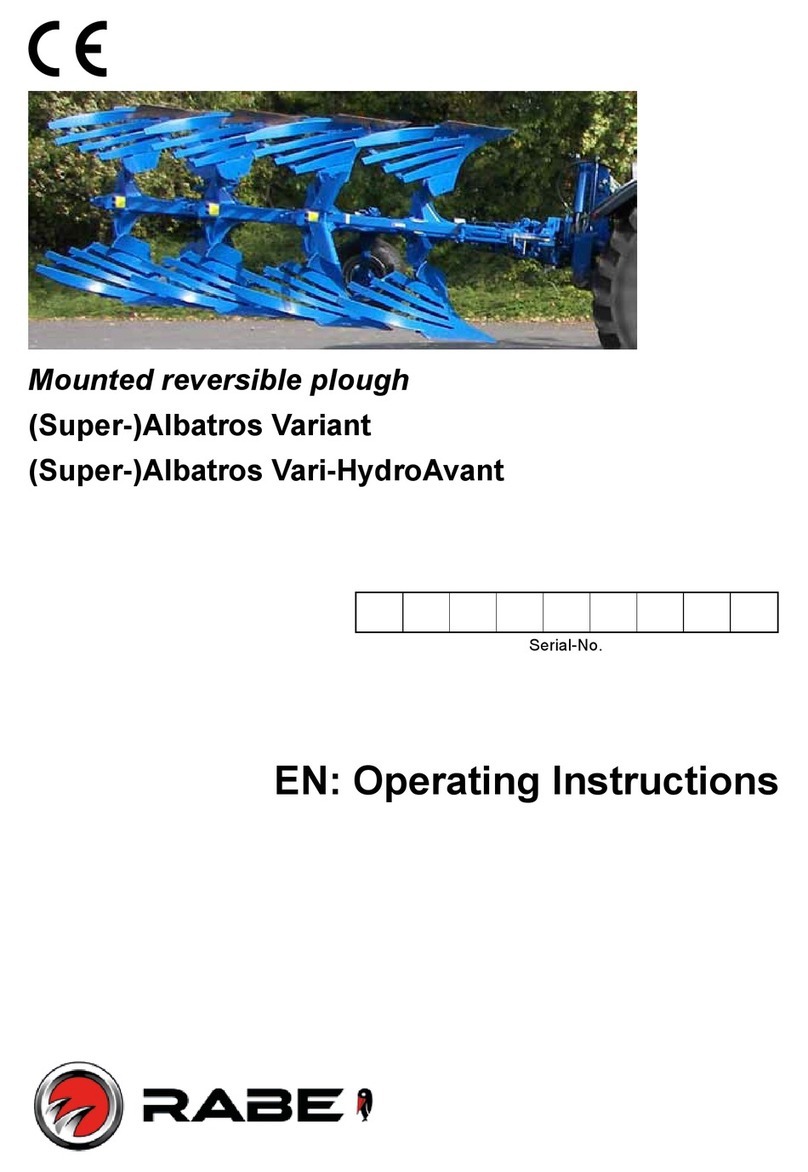

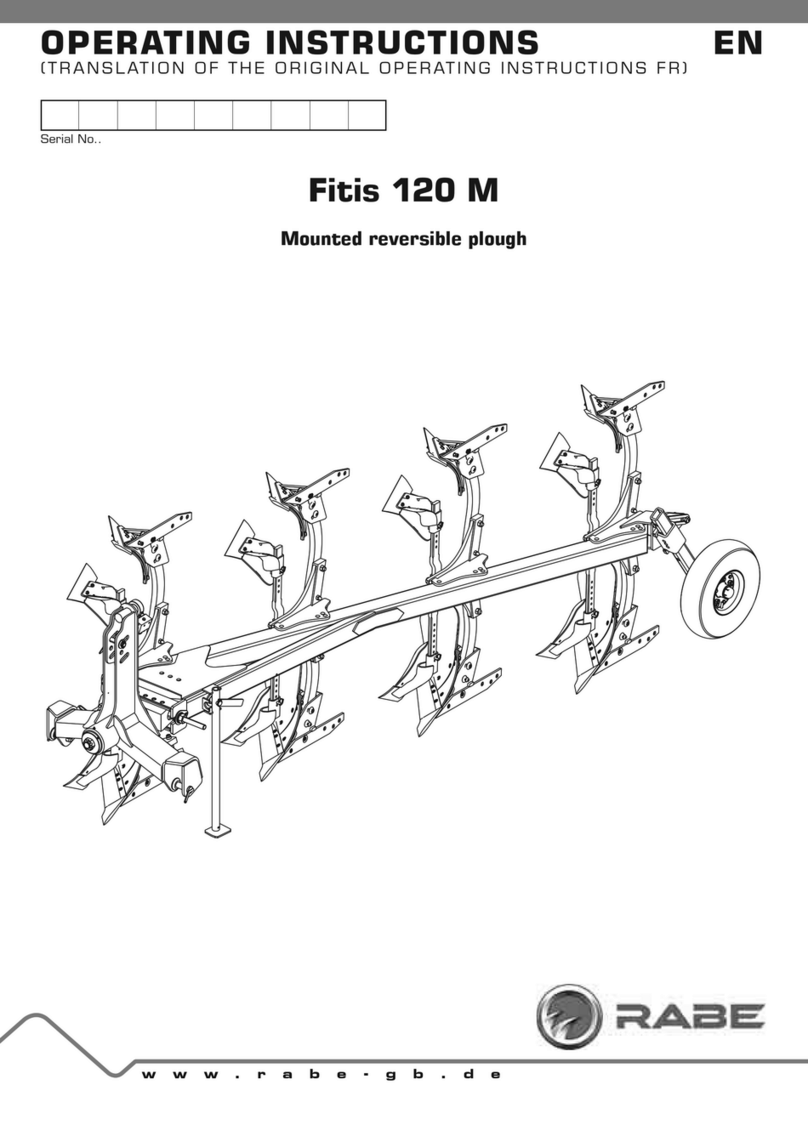

3.1 General views...................................................12

3.2 Technical specifications .....................................13

3.3 Technical characteristics - solid body..................13

3.4 Technical characteristics - slatted body ..............14

3.5 Technical characteristics - accumulator 0.75L ....14

3.6 Technical characteristics - accumulator 3.5L .....14

3.7 Dimensions and weights ....................................14

3.8 Rack and pinion assembly ..................................15

3.8.1 Offset slide ...............................................15

3.9 Hydraulic weight transfer control (optional).........16

3.10 The "Z" beam ....................................................16

3.11 Extensions (optional) .........................................17

3.12 The wheel unit ..................................................17

3.13 Working width ..................................................18

3.14 Mould board .....................................................18

3.15 Ploughshare .....................................................18

3.16 Fin coulter (Optional).........................................19

3.17 Deflector (Optional) .........................................19

3.18 Disc coulter [optional] .......................................19

3.19 Safety devices..................................................19

3.19.1 Mechanical safety device............................19

3.19.2 "Hydro Avant" hydraulic safety device

(optional) ..................................................19

3.20 Lighting and signals (optional) ............................20

4 Preparing the tractor..................................20

4.1 Required tractive power ....................................20

4.2 Tractor wheels .................................................20

4.2.1 Tractor tyres ............................................20

4.2.2 Tyre spacing.............................................21

4.3 Ballasting the tractor .......................................21

4.4 Length of the lifting links ...................................22

4.5 Position of the stabilisers..................................22

4.6 Top link. ...........................................................23

5 Hitching and unhitching ...............................23

5.1 Hitching the implement to the tractor ................23

5.1.1 Tractor equipped with link arms with fixed

ball joints ..................................................23

5.1.2 Tractor equipped with link arms with

removable ball joints ..................................23

5.1.3 Releasing the latch ....................................24

5.1.4 Hitching the top link...................................24

5.1.5 Electrical connection of the signalling

equipment.................................................24

5.1.6 Hydraulic connections ................................24

5.1.7 Position of support legs .............................25

5.2 Locking and unlocking the turnover mechanism ....25

5.3 Unhitching the implement from the tractor .........26

5.3.1 6.3.1 Decompression kit ............................26

6 Hydraulic connections ................................. 27

6.1 Required hydraulic control valves .......................27

6.2 Max. hydraulic ..................................................27

6.3 Hydraulic connections .......................................27

6.4 Function selector (optional)................................28

6.4.1 Installing the function selector....................28

6.4.2 Electrical connections of the solenoid valves 28

6.4.3 Using the function selector ........................29

6.4.4 Special characteristics of the selector ........29

7 Preparing the implement before work............30

7.1 Locating the adjustment points ..........................30

7.2 Working width adjustment .................................31

7.3 Wheel angle adjustment.....................................31

7.4 Calibration of non-stop hydraulic safety devices...32

7.5 Offset adjustment (width of 1st furrow) ...............33

7.6 Installing the subsoiler (optional) ........................34

7.7 Implement wheel ...............................................34

7.7.1 Tyre pressures ..........................................34

7.7.2 Tightening of wheel studs ...........................34

8 Changing between transport and working

position...................................................... 35

8.1 Changing to transport position...........................35

8.2 Changing to working position..............................35

8.3 Driving on the road ...........................................36

9 Field adjustment .........................................36

9.1 Use in the field .................................................36