The Handy THSBENCH-G User manual

01-11-2018

2200W ELECTRIC

SAW BENCH WITH GUARD

MODEL NO: THSBENCH-G -- PRODUCT NO: 1938188001

EN - ORIGINAL INSTRUCTIONS

ASSEMBLY REQUIRED –TWO PERSON

SAVE THESE INSTRUCTIONS

SPARES & SUPPORT: 01793 333212

FOR YOUR SAFETY

Please read & understand this manual, payingattention to the safety instructions, before use.

Incorrect use of the product could put the operator or machine in danger.

Whilst every effort has been made to ensure the accuracy of information contained in this manual, our

policy of continuous improvement determines the right to make modifications without prior warning.

Images used are for illustration purposes only

INSTRUCTION MANUAL

Copyright Notice

Copyright © Handy Distribution

Permission is granted to reproduce this publication for personal & educational use only.

Commercial copying, redistribution, hiring or lending is prohibited.

No part of this publication may be stored in a retrieval system or transmitted in any other form or means without

written permission from Handy Distribution.

In all cases this copyright notice must remain intact.

CONTENTS

SPECIFICATIONS

IMPORTANT INFORMATION

GENERAL SAFETY INSTRUCTIONS

SET UP & PREPARATION FOR OPERATION

ASSEMBLY

KNOW YOUR MACHINE

OPERATION

MAINTENANCE

STORAGE

WIRING DIAGRAM

TROUBLE SHOOTING

PARTS DIAGRAM & LIST

EC DECLARATION OF CONFORMITY

WARRANTY

ASSEMBLY IS REQUIRED –TWO PERSON

This product requires assembly before use. See the “Assembly” section for instructions.

Please check that all parts required for the assembly of this spreader are included. If for any reason you

believe a part for the assembly is missing or damaged, please contact us.

If you require any assistance with regards to the contents or operation of

your machine, please contact us:

TEL: 01793 333212

(MON –FRI 8.00AM TO 5.30PM EXCL. BANK HOLIDAYS)

SPECIAL WARNINGS & INSTRUCTIONS

•Carefully read through this entire operator’s manual before using your new saw bench. Take special care

to heed the cautions and warnings.

•The cutting operation of the machine is designed to be activated by one person. While there is the

possibility that additional operators could be working with the machine (e.g. for loading and unloading),

only one operator should activate cutting operations;

•The machine shall not be used by children;

•Description of functional tests of the machine;

SPECIFICATIONS

The manufacturer reserves the right to change the product specification and livery according to continued

product improvements.

Model Number

THSBENCH-G

Product Number

1938188001

Motor*

(230VAC 50Hz) 2200W, S2 15min*

Short Circuit Rating

1 kA

Protection Category

IP 54

Blade Size

Ø 405 × Ø 30 mm

Number of Saw Teeth

32

Log Capacity Diameter (mm)

140

Log Capacity Length (mm)

Min 300 –1000 Max

Blade Speed

2800 / min

Weight (kg)

N.W 36.3

Sound emission level (LpA)

96 db(A) k=4 db(A)

Sound pressure level (LpA)

101 db(A) k=4 db(A)

Sound power level (LwA)

115 db(A) k=4 db(A)

Vibration

<2.5 m/s²

*S2 15 minutes, Short-time duty. After continuous operation of 15 minutes the drill stops until the device

temperature deviates by less than 2 K (2°C) from the room temperature.

IMPORTANT INFORMATION

ELECTRICAL REQUIREMENTS

Connect the main leads to a standard 230V±10% (50Hz±1Hz) electrical supply which has protection devices of under-

voltage, overvoltage, over-current as well as a residual current device (RCD) which maximum residual current rated at

0.03A.

EXTENSIONS CABLES/CORDS OR LEADS

Improper use of extension cords may cause inefficient operation of the log saw which can result in overheating. Be

sure the extension cord is no longer than 10 metres and its section is no less than 2.5mm² to allow sufficient current

flow to the motor. Avoid use of free and inadequately insulated connections. Connections must be made with

protected material suitable for outdoor use.

WORKING CONDITIONS

This saw bench is a domestic use model. It is designed for operating under ambient temperatures between +5°C and

40°C and for installation at altitudes no more than 1000m above M.S.L. The surrounding humidity should be less than

50% at 40°C. It can be stored or transported under ambient temperatures between -25°C and 55°C.

INSPECT YOUR LOG

Make sure there are no nails or foreign objects in logs to be split. The ends of the logs must be cut square.

Branches must be cut off entirely so that the trunk is relatively smooth.

GENERAL SAFETY INSTRUCTIONS

It is important that you read and understand the owner’s manual and labels affixed to the machine. Learn its

application and limitations as well as the specific potential hazards. Retain these instructions for future

reference. The operator is responsible for following the warnings & instructions in this manual and on the

product.

Read & understand

operator’s manual before

using the machine. Failure

to follow instructions could

result in death or serious

injury.

Wear protective gloves to

protect your hands

CAUTION!

Wear ear-muffs. The impact

of noise can cause damage

to hearing. Wear safety

goggles. Sparks generated

during working or splinters,

chips & dust emitted by the

device can cause loss of

sight.

CAUTION!

Wear a breathing mask.

Dust which is injurious to

health can be generated when

working on wood and other

materials. Never use the device

to work on any materials

containing asbestos!

Wear protective clothing

Wear safety protective

footwear

It is forbidden to remove or

tamper with the protection

devices and safety devices.

CAUTION! RISK OF INJURY!

Failure to keep your hands

away from the blade will result

in serious personal injury.

Do not use in the rain.

Disconnect the mains plug

prior

to the repair, cleaning, and

maintenance of the machine!

Keep your work space tidy!

Untidiness may result in

accidents.

Keep all bystanders & animals

at least 10 metres away from

the machine during operation.

If approached, stop the

machine immediately.

Safety alert symbol. Used to

alert you to potential

personal injury hazards.

Obey all safety messages

that follow this symbol to

avoid possible injury.

DANGER

Indicates an imminently

hazardous situation which, if

not avoided, will result in

serious injury.

WARNING

Indicates a potentially

hazardous situation which,

if not avoided, could result

in serious injury

CAUTION

Indicates a potentially

hazardous situation which, if

not avoided, may result in

minor or moderate injury.

CAUTION

Used without the safety

alert symbol indicates a

potentially hazardous

situation which, if not

avoided, may result in

property damage.

Recycle unwanted materials

instead of disposing of them as

waste. All tools, hoses and

packaging should

be resorted, taken to the local

recycling centre and disposed

of in an environmentally safe

way.

UNDERSTAND YOUR SAW BENCH

Read and understand the owner’s manual and labels affixed to the log saw. Learn its application and

limitations as well as the specific potential hazards peculiar to it.

STAY ALERT

Do not operate the machine while under the influence of drugs, alcohol, or any medication that could affect

your ability to use it properly. Do not use this machine when you are tired or distracted from the job at hand.

Be aware of what you are doing at all times. Use common sense.

AVOID DANGEROUS CONDITIONS

Always operate your saw bench on dry, solid, level ground. Never operate your saw bench on slippery, wet,

muddy, or icy surfaces. The location you choose should be free from any tall grass, brush, or other

interferences. There should be plenty of room for handling, and help the operator stay alert. Keep your

work area clean and well lighted. Cluttered areas invite injuries. To avoid tripping, do not leave tools, logs, or

other components laying around the work area. Do not use the saw bench in wet or damp areas or expose it to

rain. Do not use it in areas where fumes from paint, solvents or flammable liquids pose a potential hazard.

INSPECT YOUR MACHINE

Check your log saw before turning it on. Keep guards in place and in working order. Use correctly sharpened

saw blades. Make sure only saw blades made in conformity to EN847-1:2005 shall be used on the machine.

Form a habit of checking to see that keys and adjusting wrenches are removed from tool area before turning it

on. Replaced damaged, missing or failed parts before using it. Make sure all nuts, bolts, screws, etc. are

securely tightened. Never operate your log saw when it is in need of repair or is in poor mechanical condition.

DRESS PROPERLY

Do not wear loose clothing, gloves, neckties or jewellery (rings, wrist watches). They can be caught in moving

parts. Protective electrically non-conductive gloves and non-skid footwear are recommended when working.

Wear protective hair covering to contain long hair, preventing it from getting caught in machinery.

PROTECT EYES & FACE

Any saw bench may throw foreign objects into the eyes. This can cause permanent eye damage. Always wear

safety goggles. Every day eyeglasses have only impact resistant lenses. They are not safety glasses. Also use

face or dust mask if cutting operation is dusty.

EXTENSIONS CABLES/CORDS OR LEADS

Improper use of extension cords may cause inefficient operation of the log saw which can result in overheating. Be

sure the extension cord is no longer than 10 metres and its section is no less than 2.5mm² to allow sufficient current

flow to the motor. Avoid use of free and inadequately insulated connections. Connections must be made with

protected material suitable for outdoor use.

AVOID DIRECT AND INDIRECT ELECTRICAL SHOCK

Check that the electric circuit is adequately protected and that it corresponds with the power, voltage and

frequency of the motor. Check that there is a ground connection, and a regulation differential switch

upstream. Ground the log saw. Prevent body contact with grounded surfaces: pipes, radiators, ranges, and

refrigerator enclosures. Never open the switch / plug box. Should this be necessary, contact a qualified

electrician. Make sure your fingers do not touch the plug’s metal prongs when plugging or unplugging

the saw bench.

KEEP BYSTANDERS AND CHILDREN AWAY

Allow only one person to load and operate the log saw. Always keep bystanders, including visitors, children

and pets away from the work area, especially when the saw bench is under operations. Only the operator

should stand near the machine and only within the safe operating area prescribed in this manual. Never use

another people to help you with freeing jammed log. No one under the age of 16 should be allowed to operate

the saw bench. Any individual under the age of 18 should have the necessary training, skills to perform the

functions properly and safely and should always be under the supervision of adult.

INSPECT YOUR LOG

Never attempt to cut logs containing nails, wire or debris. Branches must be cut of flush with the trunk.

DO NOT OVERREACH

Keep proper footing and balance at all times. Never stand on the saw bench. Serious injury could occur if the

tool is tipped or if the cutting tools is unintentionally contacted. Do not store anything above or near the saw

bench where anyone might stand on the tool to reach them

LIFTING

Due to the weight of the saw bench, we recommend it is lifted by a minimum of two people.

AVOID INJURY FROM UNEXPECTED ACCIDENT

Do not attempt to load or unload logs until the saw bench has stopped. To refrain from removing any off-cut

or other part of the workpiece from the cutting area whilst the machine is running except by using a push stick.

Keep hands out of the way of all moving parts. Never use a damaged saw blade or if has been dropped.

Do not reach around the saw blade with either hand while the cutter is running. Do not stand or have any part

of your body in line with the path of the sawblade. Avoid awkward cutting operations and hand positions here

a sudden slip could cause your hand to move into the saw blade. Never plie logs to be split in a manner that

will cause you to reach across the saw bench. Only use your hands to operate the control handle. Never use

your foot, knee, or any other extension device. Never attempt to free a stalled saw blade without first turning

the log saw off.

DO NOT FORCE TOOL

It will do a better and safer job at its design rate. Don’t use saw bench for a purpose for which it was not

intended. Do not, under any circumstances, alter your log saw. This equipment was designed and engineered

to be used in accordance with the operating instructions. Altering the equipment or using the equipment in

such a way as to circumvent its design capabilities and capacities, could result in serious or fatal injury and will

void the warranty. Never try to cut logs larger than those indicated in the specifications table. This could be

dangerous and may damage the machine.

NEVER LEAVE MACHINE RUNNING UNATTENDED

Do not leave the machine unattended, until it has come to a complete stop and the power removed from the

electrical source.

DISCONNECT POWER

Unplug when not in use, before making adjustments, changing parts, cleaning, or working on the saw bench.

All servicing and repairs are recommended to be undertaken by an approved service dealer.

MAINTAIN YOUR MACHINE WITH CARE

Always clean the unit after each use. Keep the saw bench clean for best and safest performance. Follow

instructions for lubricating. Control handles and power switches must be kept clean, dry and free from oil and

grease at all times. The use of non-original manufacturer parts or modifications may invalidate your warranty.

STORE IDLE EQUIPMENT

When not in use, Lock the area where machine stored. Store the saw bench away from children and others not

qualified to use it.the machine should be stored in a dry location, away from direct sunlight. Keep the machine

away from children and others not qualified to use it.

This symbol on the product or on its packaging indicates that this product may not be

treated as household waste. Instead it shall be handed over to the applicable collection

point for the recycling of electrical and electronic equipment.

For more detailed information about recycling of this product, please contact your local

council office, your household waste disposal service or shop where you purchased the

product.

SET UP & PREPARATION FOR OPERATION

The saw bench comes partially assembled. After all the parts have been removed from the carton, you should

have the below components. If you believe you are missing any components, please contact us:

1. Motor

2. Base Frame

3. Log Carriage Extension

4. Pivoting Log Carriage

5. Inner Saw Blade Cover

6. Saw Blade Guard 2

7. Outer Saw Blade Cover

8. Saw Blade Guard 1

9. Front Clamping Flange

10. Rear Saw Blade Flange

11. Saw Blade

12. Limit Plate

13. Handle

14. Top Guard

15. Back Plate 1

16. Back Plate 2

17. Guide Pipe with Return Spring

18. Cross Brace (x2)

19. Wrenches

20. Operators Manual

21. Hardware Bag including:

ASSEMBLY

This log saw was partially assembled at the factory. To assemble your machine follow the below instructions.

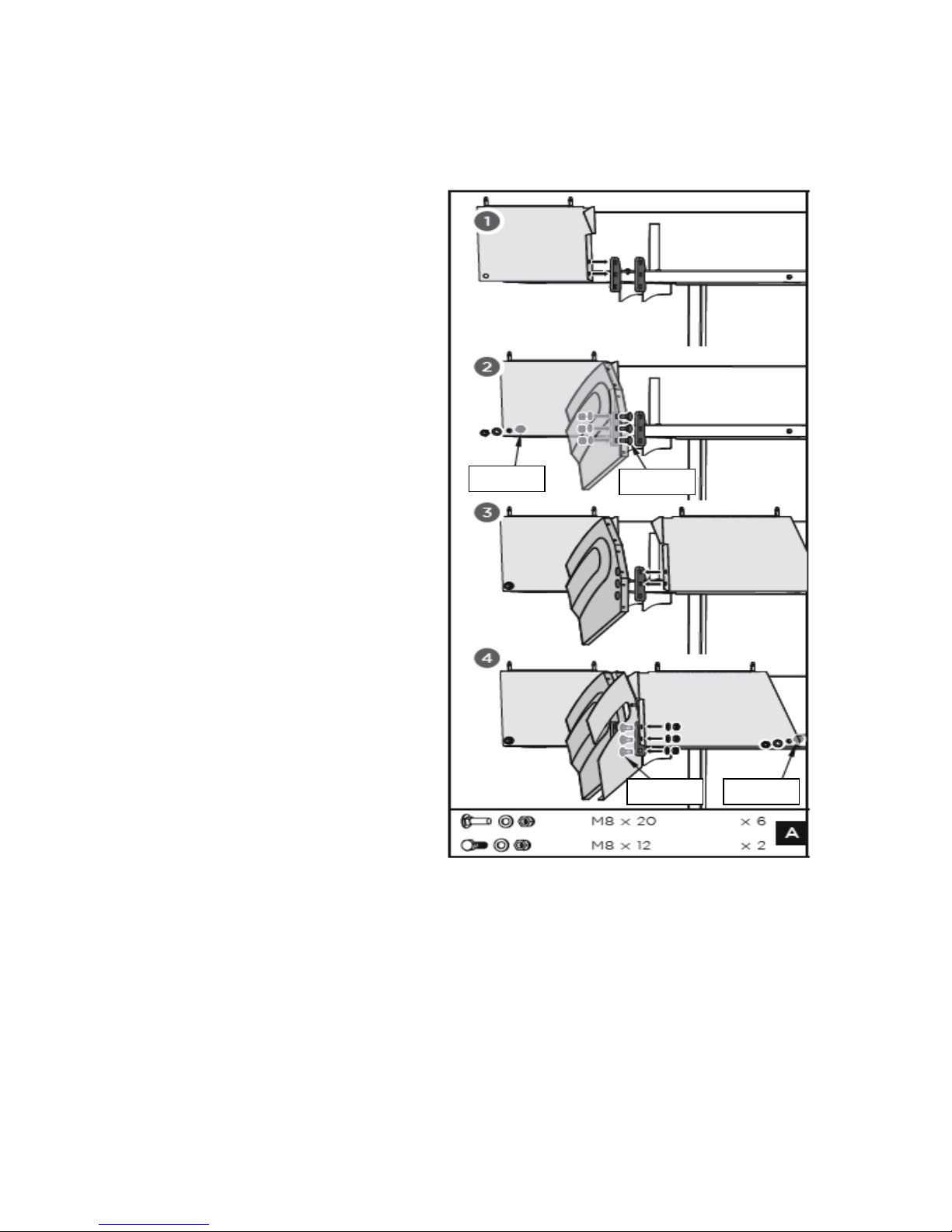

SAW BLADE GUARDS

Fig. A, illustration 1.

Place back plate 1 against outside of the

connecting part at the log carriage and align

its two holes with the upper two holes of the

connecting part.

Fig. A, illustration 2

Fix back plate 1 to the table with one M8×12

bolt, flat washer and nut.

Fig. A, illustration 3 & 4.

Put the saw blade guard 1 against inner side

of the same connecting part, align the holes

and bolt the saw blade guard 1, connecting

part and back plate 1 together with three

M8×20 bolts, washers and nuts.

Repeat the same assembly steps on the other

side for back plate 2 and saw blade guard 2.

M8x12 (x1)

M8x20 (x3)

M8x20 (x3)

M8x12 (x1)

HANDLE

Attach the handle to the back of the log

carriage. Secure it with two M8×25 bolts and

lock nuts (Fig. B). Screw the wing bolt M5×20

into the hole at the upper right corner.

ON/OFF SWITCH

Fix the switch to the motor plate with M4×58

bolts and nuts (Fig. C).

RETURN SPRING

Fix one end of the guide pipe with return

spring on the left leg with M8×55 bolts,

washers and lock nut (Fig. D).

M5x20 (x1)

M8x25 (x2)

M4x58 (x2)

M8x55 (x1)

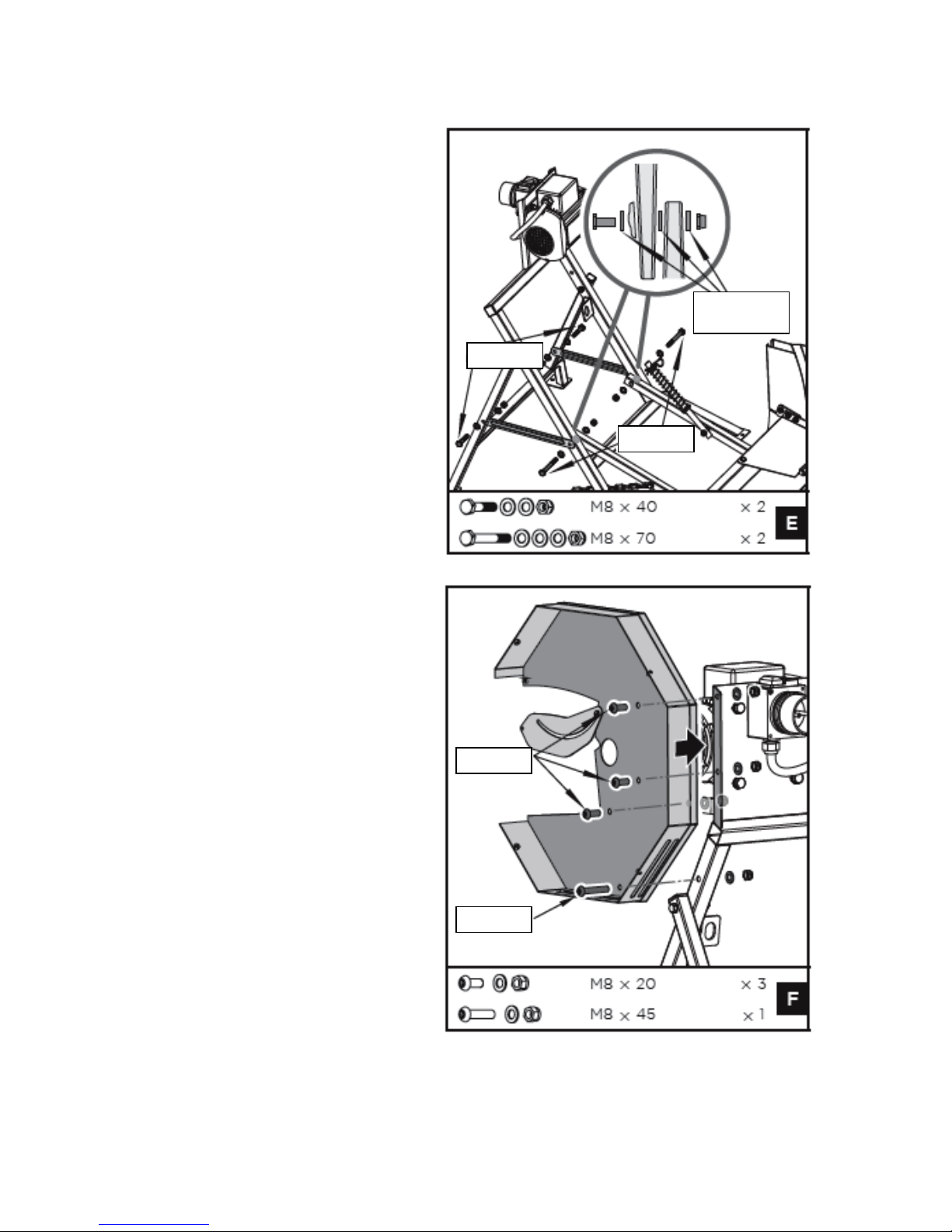

CONNECTING PIVOTING LOG CARRIAGE AND BASE FRAME

Lay the pivoting log carriage on the ground

with legs inside the base frame, and put one

end of the cross brace outside (Fig. E).

Fasten them together with M8×40 bolts,

washers and lock nuts on both sides.

Fix the other end of the cross brace from the

inner side of the base frame with M8×70

bolts, washers and lock nuts on both sides.

INNER SAW BLADE COVER

Slide the shaft through the centre hole of the

inner saw blade cover and align its other

holes with those on the motor plate (Fig. F).

Secure it with three M8×20 bolts, washers

and lock nuts on the upper side and one

M8×45 bolt, washer and lock nut on the

lower.

M8x40 (x2)

M8x70 (x2)

FLAT WASHER

(x3)

M8x20 (x3)

M8x45 (x1)

SAW BLADE

Fig. G, illustration 1

Slide the rear saw blade flange onto the

motor shaft. Place the saw blade together

with the front clamping flange onto the rear

flange and secure it with nut M20×1.5.

ATTENTION

The arrow on the saw blade has to point in

the direction of the operating side!

Fig. G, illustration 2 & 3.

Tighten the nut with the saw blade wrench by

holding the front clamping flange with the

face wrench in order to stop back.

Keep all wrenches provided in a safe place

for later use.

OUTER SAW BLADE COVER

Tighten the outer saw blade cover to the

inner cover with four M5×10 cross head

screws and flat washers (Fig. H).

M20x1.5

(x1)

SHAFT

M5x10 (x4)

FIXING RETURN SPRING AND CHAIN

Fig. I, step 1.

Take the cotter pin and washer from the

guiding pipe with spring.

Fig. I, step 2.

Push the log carriage to the base frame until

the open end of the guiding pipe is inserted

into the angle part at the base frame.

Fig. I, step 3

Secure the pipe with the washer and cotter

pin.

Fig. I, step 4.

Fix the open end of the chain to the base

frame at the left side with bolt M8×50, two

washers and a nut.

GUARD PLATE OF INNER SAW BLADE COVER

Fig. I, step 5

Install the guard plate of the inner saw blade

cover on the saw blade guard with a M5 nut

and two flat washers.

FLAT WASHER

(x2)

M8x50 (x1)

FLAT WASHER

(x2)

M5 (x1)

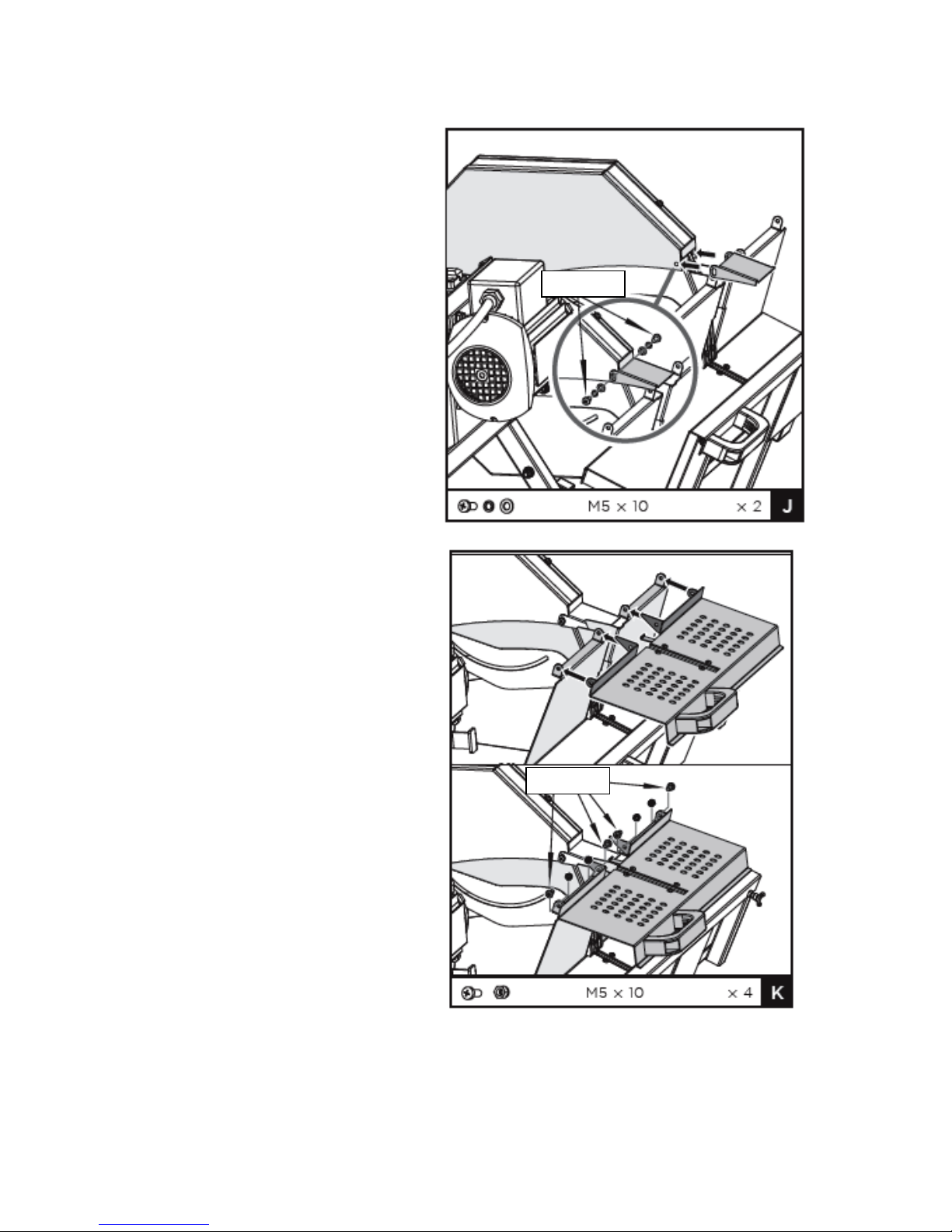

LIMIT PLATE

Mount the limit plate and fasten with two

M5×10 screws and washers (Fig. J).

TOP GUARD

Mount the top guard with four M5×10 bolts

and lock nuts (Fig. K).

M5x10 (x2)

M5x10 (x4)

LOG CARRIAGE EXTENSION

Loosen the wing bolt M5×20 on the back side

of the log carriage until the log carriage

extension can be inserted into the opening.

Slide the log carriage extension into the

channel and align it correctly. Then tighten it

with the wing bolt.

KNOW YOUR MACHINE

Make yourself aware of the compnents and operational levers of the machine, prior to attempting any work.

M5x20 (x1)

SAW BLADE COVER

GUARD PLATE

ON/OFF SWITCH

LIMIT PLACE

PLUG

HANDLE (RIGHT)

MOTOR

TOP GUARD

LOG CARRIAGE

EXTENSION

HANDLE (LEFT)

RETURN SPRING

LOG CARRIAGE

LOG RULER

OPERATION

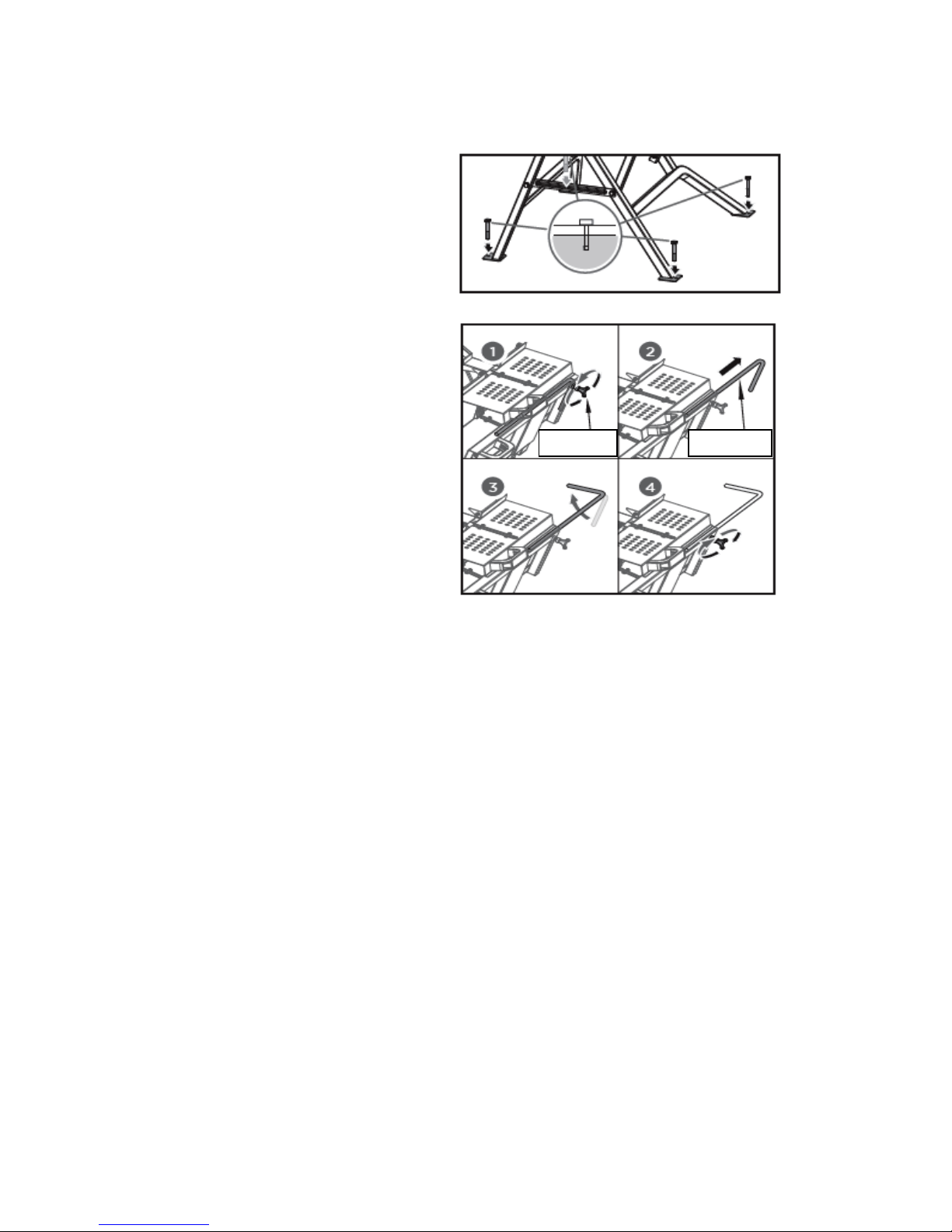

STAKE ON LEVEL GROUND

To secure your saw bench, use four bolts or

stakes on level ground. Due to varying ground

surfaces, these are not included.

Choose the right type of bolt or stake for your

surface type.

SET THE LOG RULER

Loosen the wing bolt M5×20 to allow the log

ruler to be pulled out freely. Set the desired

length on the scale.

Turn it clockwise as shown in illustration 3

and secure it by tightening the wing bolt.

POWER SUPPLY AND OPERATION

Put the plug in the socket and turn on the motor switch. Once motor switch is turned on, the cutting blade

starts rotation. Open the top guard, place the log to the cutting position on the log carriage and close the

guard. Grip the handle at the left side of log carriage and push it towards the saw blade cover. The movable

saw blade guard will open and show the saw blade. Keep pushing with even strength until the log on the log

carriage is cut. Stop pushing and log carriage will retract to its original position. Move the rest of log to the

cutting position and continue next cycle until the work is accomplished. To stop the machine, turn the motor

switch off until the cutting blade gradually comes to a complete standstill. Put the plug out of the socket and

clean the machine with cloth.

PREVENTIVE MAINTENANCE

Inspect the general condition of the log saw. Check for loose screws, misalignment or binding of moving parts,

cracked or broken parts, and any other condition that may affect its safe operation. Remove all debris from the

saw bench with a soft brush, vacuum or compressed air. Make maintenance a regular part of daily operation.

• Check nuts, bolts, and fittings –make sure all are tight and secure.

• Cutting blade conditions – sharpen or replace a dull or damaged blade.

FREE BLOCKED LOG

If a blockage is likely to occur. Switch off the device immediately.

• Wait until the saw comes to a stop.

• Pull out power plug.

• Remove the blocked log from the machine carefully.

SHARPENING THE SAW BLADE

The saw blade can be sharpened. This saw-blade can be sharpened several times without removing it from the

machine. Use a fine-cut square-blade file of 8-12" for sharpening. During manual sharpening, only file the front

rake of the tooth over a distance of about 5-7mm.

Always keep the original shape of the tooth. Do not make sharp notches at the root of the tooth with the file.

Always clean the blade-clamps carefully. Check the blade carefully to ensure you are never sawing with a

cracked blade.

M5x20

LOG RULER

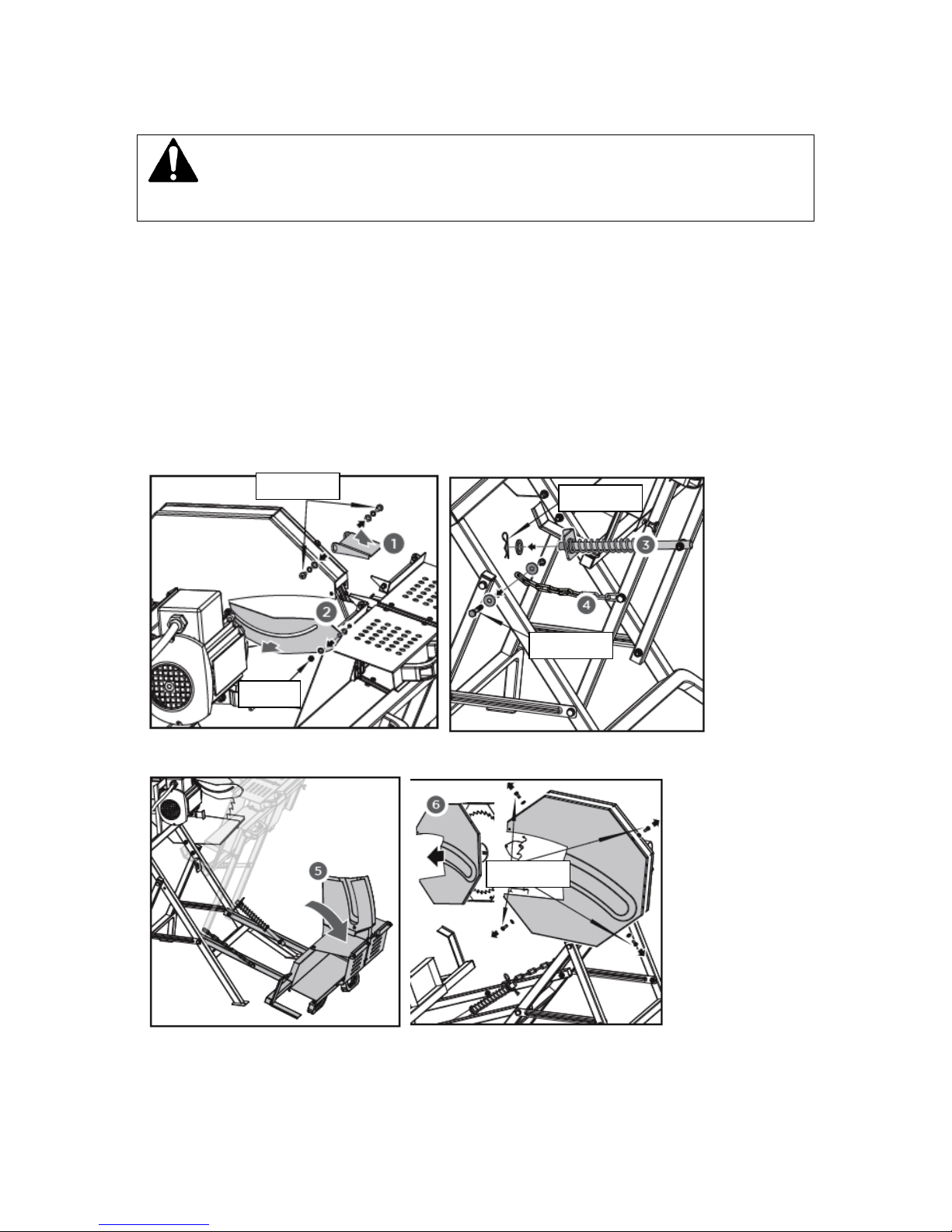

MAINTENANCE

WARNING

Prior to any adjustment, maintenance or service work disconnect the mains power plug!

GENERAL MAINTENANCE MEASURES

Keep all safety devices, air vents and the motor housing free of dirt and dust as far as possible. Wipe the

equipment with a clean cloth or blow it with compressed air at low pressure.

We recommend that you clean the device immediately each time you have finished using it.

Clean the equipment regularly with a damp cloth and some soft soap. Do not use cleaning agents or solvents;

these could attack the plastic parts of the equipment.

Ensure that no water can seep into the device. The ingress of water into an electric tool increases the risk of an

electric shock.

In order to extend the service life of the tool, oil the rotary parts once monthly. Do not oil the motor.

SAW BLADE CHANGE

1. Disassemble the limit plate by loosening the M5×10 screws, spring washers and flat washers.

2. Remove the M5 nut and flat washers from the guard plate.

3. Pull the cotter pin and washer from the return guiding pipe.

4. Remove the M8×50 bolt, washers and nut fixing the chain.

5. Slowly lower the log carriage towards the ground.

6. Remove the four M5×10 screws & washers from the saw blade guard and also the outer saw blade cover.

M5x10 (x2)

M5 (x1)

M5x10 (x4)

M8x50 (x1)

COTTER PIN

7. Disassemble the nut M20×1.5 and the front clamping flange. Take down the old saw blade.

STORAGE

Store unused equipment in a dry, locked place out of the reach of children. Before a longer period of storage

carry out the following to extend the saw service life and ensure an easy operating.

• Thoroughly clean the device.

• Treat all movable parts with an environmentally friendly oil.

WIRING DIAGRAM

M20x1.5 (x1)

THERMAL

PROTECTOR

WHITE

22AWG

YELLOW-

GREEN

BLACK

BLACK

BLACK

BLACK 16AWG

BROWN

RED 16AWG

RED 16AWG

BLUE 16AWG

SWITCH

BLUE

CAPACITOR 30uF/450V

230V

TROUBLE SHOOTING

PROBLEM

PROBABLE CAUSE

REMEDY SUGGESTED

Saw blade gets loose after

turning off the motor

Fastening nut tightened

insufficiently

Tighten fastening nut right-hand

thread.

Motor does not start

1. Failure mains fuse

2. Extension cable defect

3. Connections of the motor or

switch defect

4. Motor or connections defect

1. Check mains fuse

2. Replace extension cable

3. Have it checked by an electrician

4. Have it checked by an electrician

Wrong direction of

motor rotation

Capacitor defect

Have it checked by an electrician

Motor unable to run the

fuse is tripped

1. Cross section of the extension

cable insufficient

2. Overload by dull saw blade

1. See “WIRING DIAGRAM” in the

operating manual

2. Exchange saw blade

Burns on the cutting

surface

1. Dull saw blade

2. Wrong saw blade

1. Insert a sharpened saw blade

2. Exchange saw blade

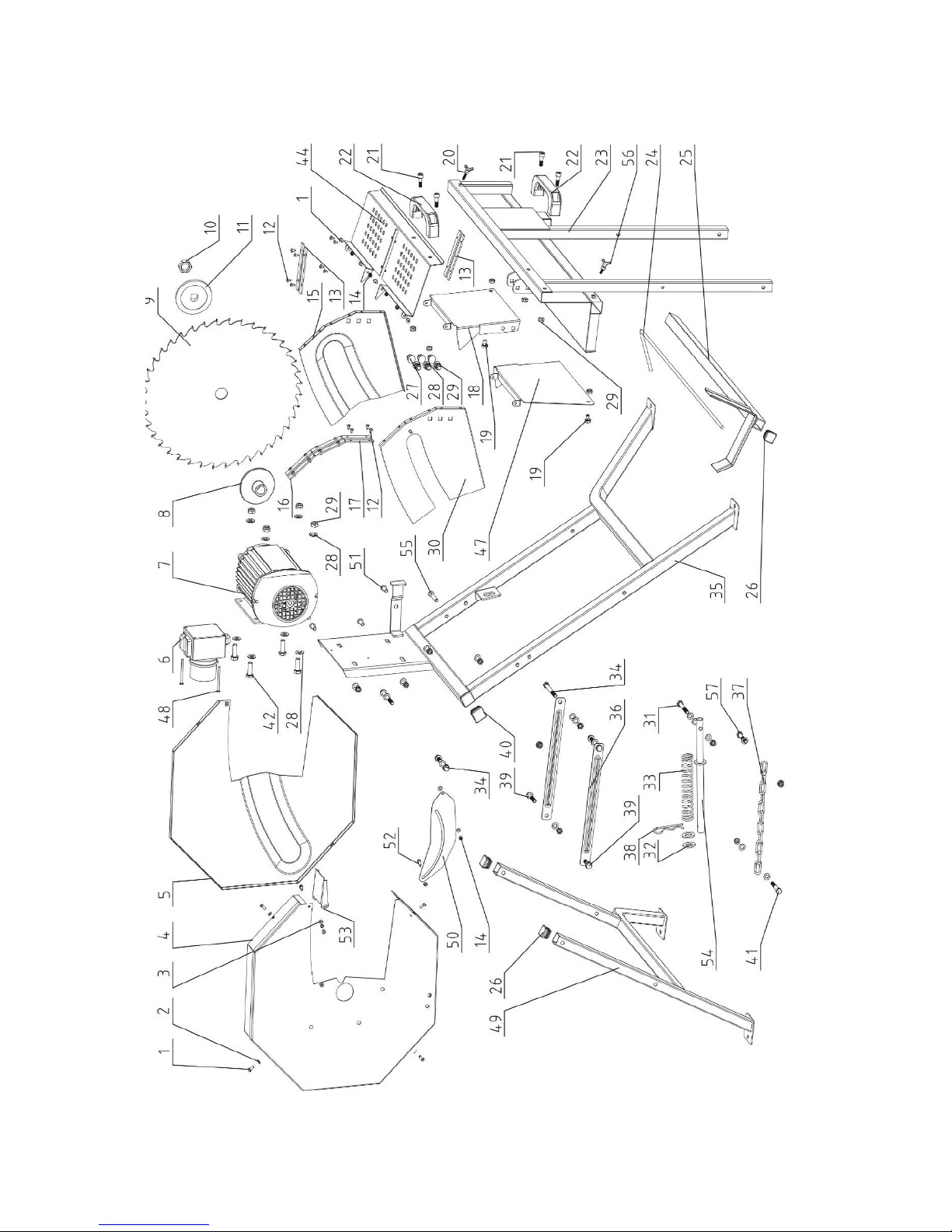

PARTS DIAGRAM –THSBENCH-G (1938188001)

Table of contents