The Light Source MegaBatten User manual

THE LIGHT SOURCE, INC.

MADE IN THE USA

MEGABATTEN

Connector Strip

INSTALLATION MANUAL

BEFORE YOU BEGIN

READ THESE INSTRUCTIONS COMPLETELY AND CAREFULLY

WARNING/AVERTISSEMENT

RISK OF ELECTRIC SHOCK

•TURN POWER OFF BEFORE INSPECTION,

REPAIR, INSTALLATION, OR REMOVAL.

•PROPERLY GROUND ELECTRICAL

ENCLOSURE.

•FOLLOW ALL NEC AND LOCAL CODES.

•USE ONLY UL APPROVED WIRE FOR INPUT

OUTPUT CONNECTIONS.

RISQUES DE DÉCHARGES ÉLECTRIQUES

•COUPEZ L’ALIMENTATION AVANT D”INSPECTER, INSTALLER OU

DÉPLACER LE LUMINAIRE.

•ASSUREZ-VOUS DE CORRECTEMENT METTRE À LA TERRE LE

BOÎTIER D’ALIMENTATION ÉLECTRIQUE.

•RESPECTEZ TOUS LES CODES NEC ET CODES LOCAUX.

•N’UTILISEZ QUE DES FILS APPROUVÉS PAR UL POUR LES

ENTRÉES/SORTIES DE CONNEXION.

SAVE THESE INSTRUCTIONS

USE PRODUCT ONLY IN THE MANNER INTENDED BY THE MANUFACTURER. IF YOU HAVE ANY QUESTIONS, PLEASE

CALL

THE LIGHT SOURCE, INC. 704-504-8399.

1

CAUTION

ALL MECHANICAL AND ELECTRICAL CONNECTIONS ARE TO BE MADE BY

QUALIFIED INDIVIDUALS FAMILIAR WITH LOCAL CODES, CONSTRUCTION

PRACTICES, AND THE HAZARDS INVOLVED.

PREPARING FOR ASSEMBLY

Before starting the assembly process, please check the contents against all provided drawings for

completeness. Splice set screws are shipped in a bag secured to the MEGABATTEN. While unloading

your MEGABATTEN, check for damage that may haveoccurred during shipping.

Prepare an adequate space to assemble your MEGABATTEN. When fully assembled, the

MEGABATTEN will be difficult to move, so assembly near the final install location is suggested.

ASSEMBLY

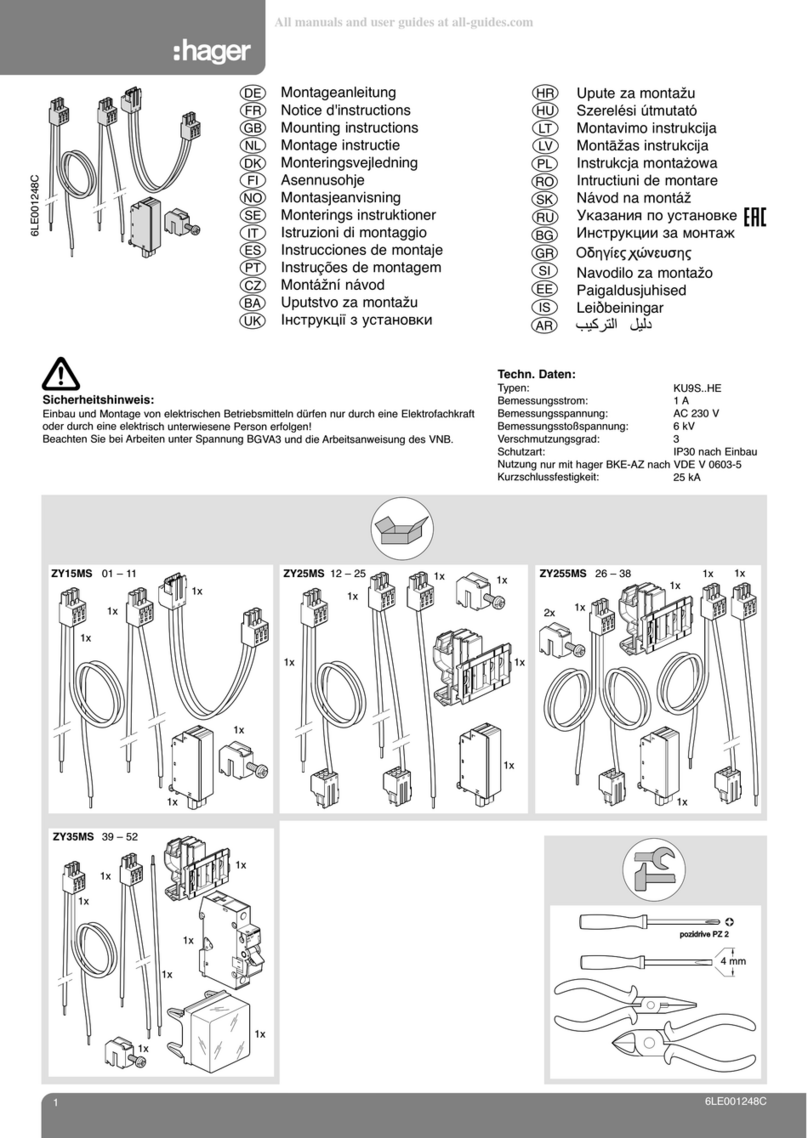

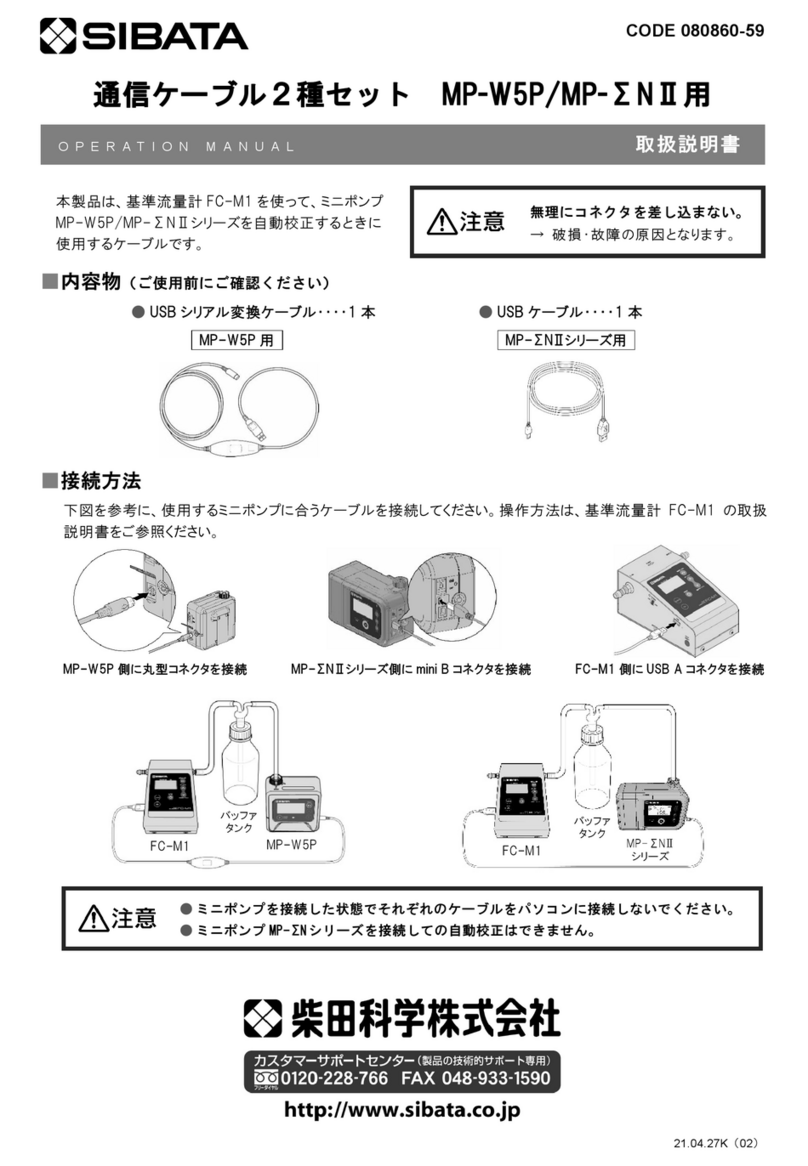

Assembling the MEGABATTEN Connector Strip

When you receive your MEGABATTEN, it will be folded at the hinges for shipping.

Carefully unfold the batten at the hinges, ensuring that the internal wires do not get pinched.

When the batten is unfolded, use a 3/8” hex key wrench and loosen the hinge bolts. Slide the splices

into place. A¼” cap screw is provided to use as a handle. Remove the bolts securing the hinges. Once

removed, discard the hinges and the bolts that were securing the hinges. Then install the provided 1/2”

set screws to secure the splices in the installed position. Once the splices are installed, use a 3/16” hex

key wrench to remove all ¼” cap screws from the splices and discard.

Once the batten has all the splices installed, it is ready to be installed into position.

REMOVE HINGE

AND HARDWARE

INSTALL ½

SET SCREWS

INSTALLATION

Mechanical Installation of the MEGABATTEN

The MEGABATTEN has been designed to be installable using all industry standards with regards to

batten installation. The 1.5” MEGABATTEN is listed to support a load of 30 pounds per linear foot when

supported on a maximum of 8-foot centers. The 2” MEGABATTEN is listed for 50 pounds per linear foot

when supported on a maximum of 8-foot centers.

We recommend the following hardware for a Dead Hung Batten installation.

CAUTION! PRIOR TO INSTALLATION, VERIFY WITH A STRUCTURAL ENGINEER THAT

SUPPORTING STRUCTURAL ELEMENTS ARE CAPABLE OF SUPPORTING THE MEGABATTEN AT

MAXIMUM LOAD. PLEASE ENSURE THAT RIGGING IS IN COMPLIANCE WITH LOCAL BUILDING

CODES AND SAFETY PRACTICES.

Mega-Folding Batten Clamp

Rated for 1675 Lbs, the Mega-Folding Batten Clamp is hinged for convenience and uses a single 7/16”

hex bolt to secure a light batten. It has a ½” clearance hole for rigging hardware.

Mega-Folding

Batten Clamp

Mega-Folding Batten Clamp

with threaded rod adapter.

Options available for 1/2” or

3/8” threaded rod.

Mega-Folding Batten

Clamp with 5/16” shackle

for wire rope and chain

rigging applications.

Installation using the Mega-Folding Batten Clamp

1. First, identify all rigging positions where the MEGABATTEN will be supported.

2. Assemble the Mega-Batten Clamp around the MEGABATTEN.

3. Attach the rigging hardware to the Mega-Batten Clamp.

4. Verify the orientation of the MEGABATTEN, then tighten all hardware.

MAKING ELECTRICAL CONNECTIONS

Connecting Power

There are four options for Power input into the batten.

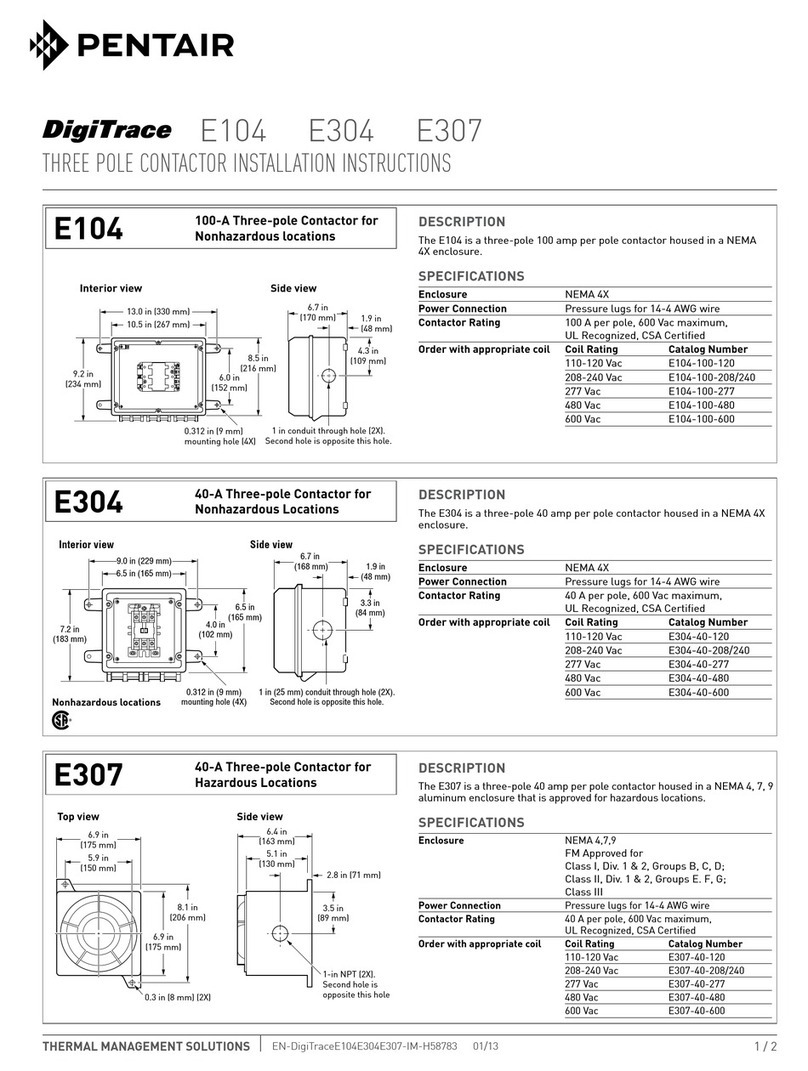

19 Pin Male Circular Connector (Socapex) – This connector comes pre-wired ready to connect to a

female connector

SO Cable –The number of circuits determines the number of conductors, either 12/3, 12/4, or 12/5.

The length of cable extending beyond the batten is fixed at the factory according to approved

drawings. A connector is not supplied, so choose a connector that will meet code requirements in your

area.

Terminal Box –The batten will have a terminal with a terminal strip for connection of wires.

Extended Internal Conductors – The end of the batten has a ¾” NPT threaded socket for electrical

fittings. The conductors will need to be enclosed in conduit provided by others. Each power circuit

will have a hot and neutral conductor (up to six circuits), and there will be one ground that is shared by

all circuits. Connection to building power should be done by a licensed electrician. See the color code

chart for circuit conductor colors.

SO Cable

Extended Internal conductors

Terminal Box

ELECTRICAL CONNECTIONS MAY ONLY BE MADE BY INDIVIDUALS

FAMILIAR WITH THE CONSTRUCTION AND OPERATION OF THIS

PRODUCT AND THE HAZARDS INVOLVED.

19 Pin Connector

Maintenance

The MEGABATTEN requires very little maintenance once installed. The MEGABATTEN has a powder coat

finish so it can be wiped down with a damp cloth to remove accumulated dust. In the event of a damaged

outlet, turn off power to the MEGABATTEN. A replacement can be ordered and repaired on site by a

qualified individual.

Table of contents