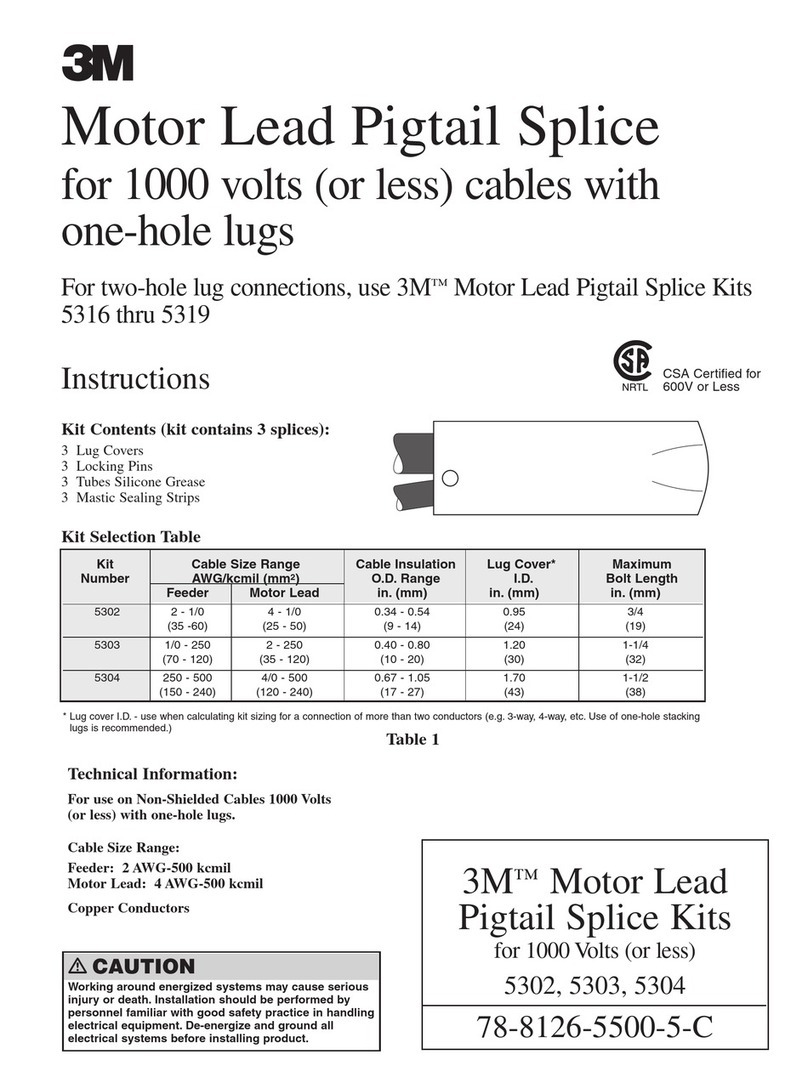

For JCN to JCN Splices

2.3 Connect Neutral Wires for JCN Splices

2.3.1 Route neutrals straight across the splice body and secure using vinyl tape.

2.3.2 Wrap the neutral pad over one end of the splice and cable semi-con. Secure pad with two wraps of vinyl

tape. Wrap a mastic strip around each cable semi-con next to the neutral wires.

Neutrals straight across splice

Note: If grounding splice, leave sufficient neutral wire length to extend neutral wires through the inline

compression connectors for connection to the ground wire per Wisconsin Electric specifications.

Connect the neutral wires using inline compression connectors. The neutral wires should pass through the

connector, making an overlap crimp. Trim excess neutral wire on both sides for a non-grounded splice or

on the spice body side only for a grounded splice. All connections must be made over the neutral pad.

After all of the neutral wires are connected. Wrap a mastic strip over the end of the cable jacket and the

previously applied mastic on both sides of the splice.

Neutral connection without splice grounding Neutral connection for a grounding splice

2.3.3 For grounded splices, route the grounding wires over the mastic seal and secure with vinyl tape. Wrap

another mastic strip over the grounding wires and mastic seal.

2.3.4 Cover crimped connectors with vinyl tape.

Neutral Pad

Mastic Strip

Neutral wire ends

Mastic

Neutral wire ends Grounding wires

Mastic Seal Mastic