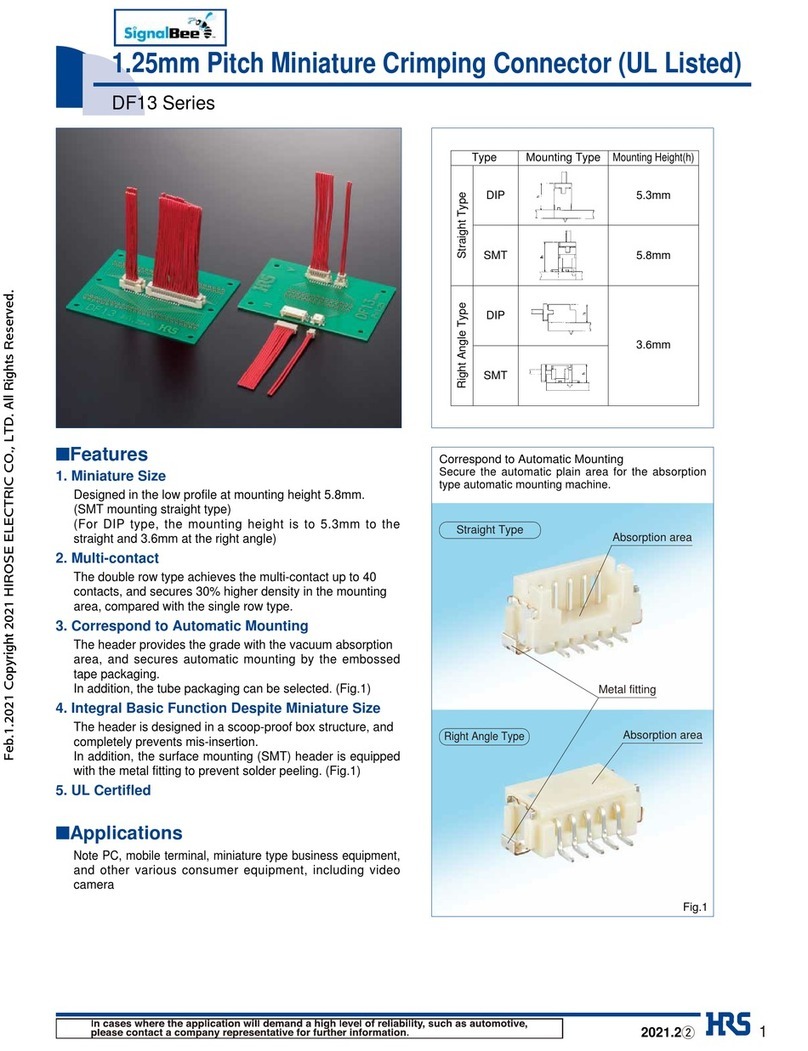

・Do not use in situations where vibration or impact that exceeds the product specifications of

our products is applied.

・Do not use a damaged or missing connector.

・Do not ride on the connector or place heavy objects on it. There is a risk of damage.

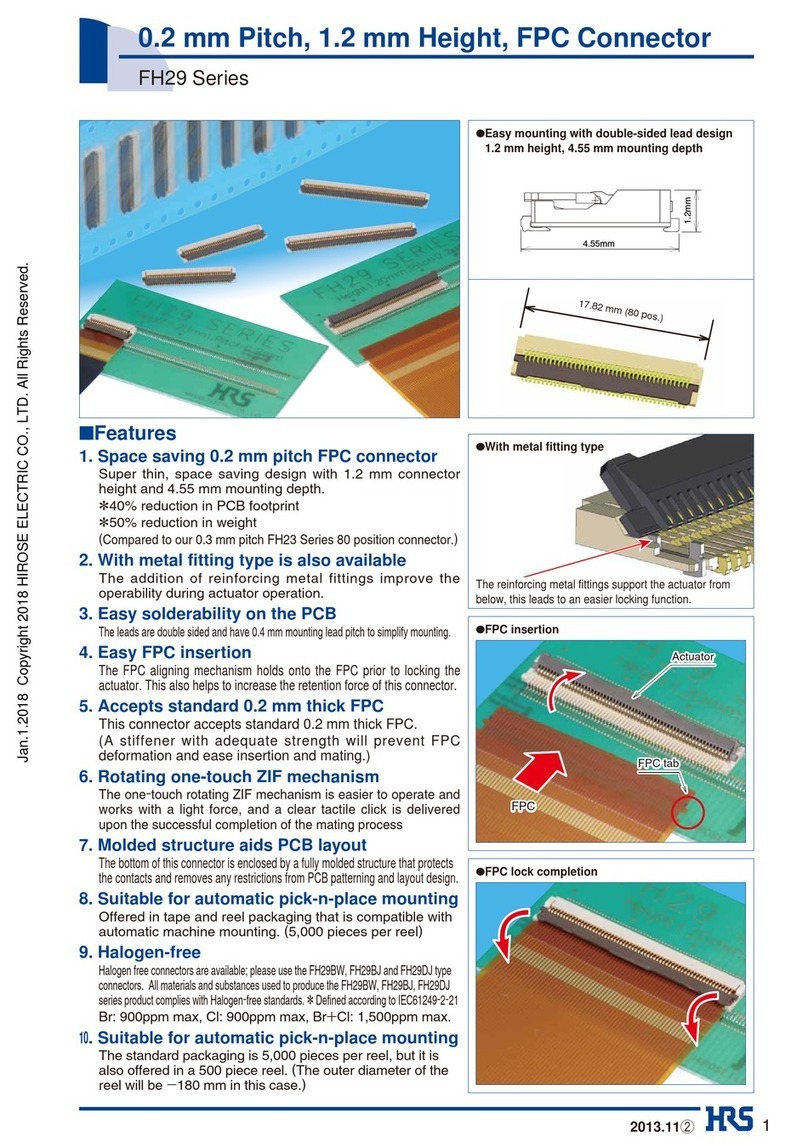

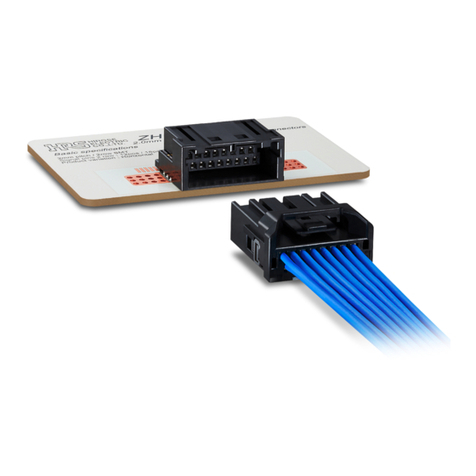

・Follow this guideline when inserting and removing the plug. Incorrect operation may

damage the connector.

Please check if the lock is completed before use. If the lock is not completed, there is a risk

of poor continuity, disconnection of the plug, and damage.

・When removing the plug, make sure that the lock is completely unlocked.

・When routing the cable, bend it gently so that the connector and cable are not overloaded.

・When using the cable in a long harness state, fix it so that the vibration load of the cable is

not applied to the connector.

Do not store or use this product under conditions that contain corrosive substances that may

cause deterioration of plastic properties or metal rust.

If it is unavoidable to apply a solvent to this product to strengthen insulation or protect it,

make sure that the physical properties of the plastic do not deteriorate before using it.

・Do not use in an environment where it is constantly exposed to oil mist, oil water, corrosive

gas, flammable gas and dust.

・This product is designed for indoor use and should not be used outdoors.

・This product does not take any measures against salt damage.

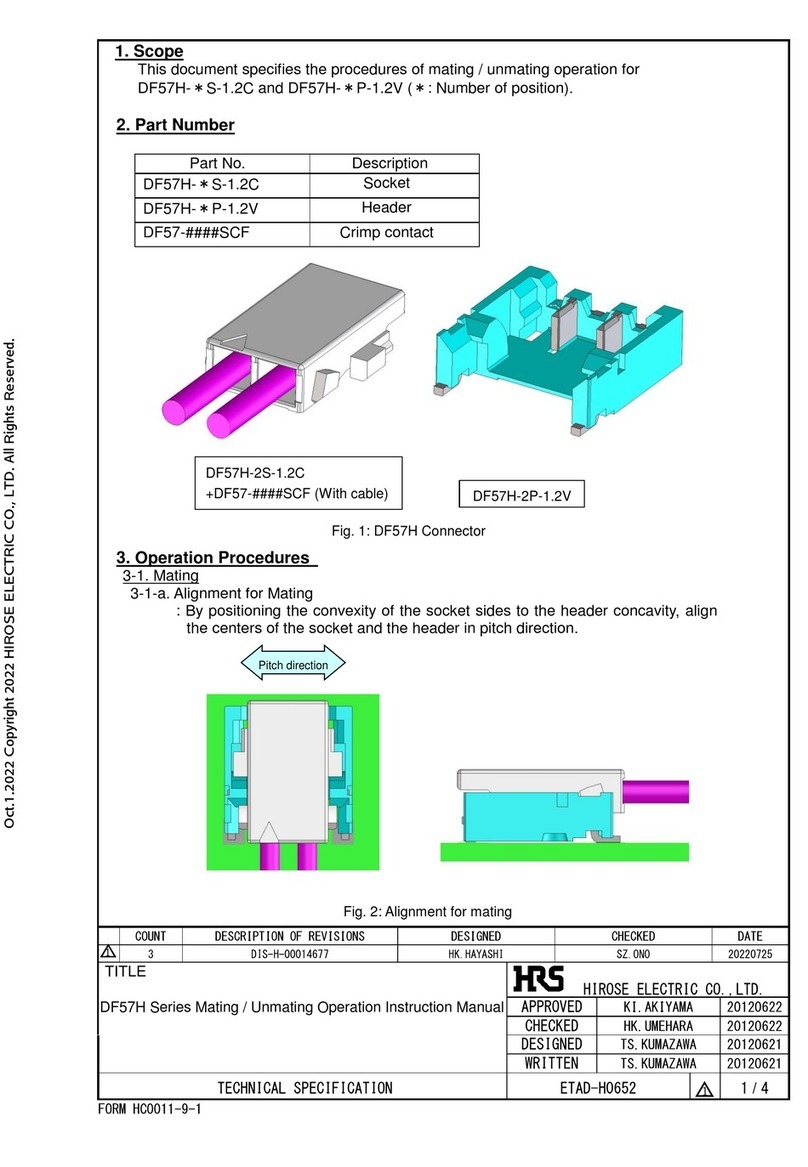

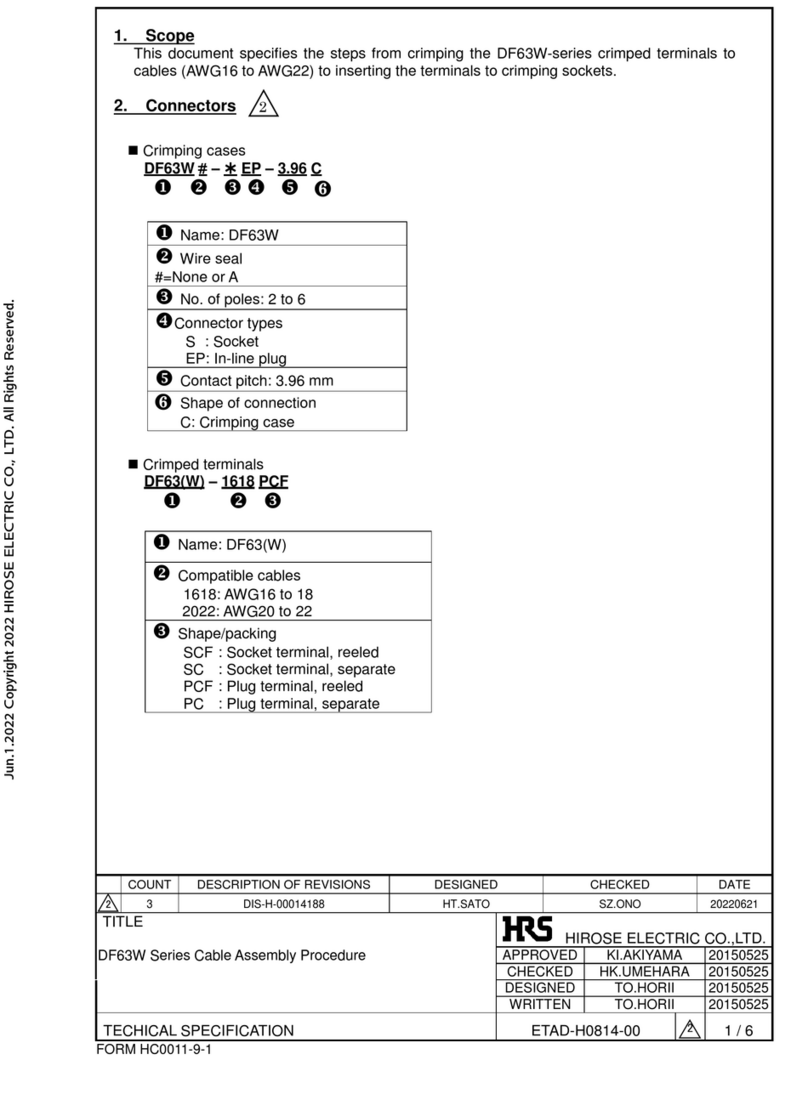

Use the specified crimp contact, and check in advance that there is no deformation, oil, etc.,

and that there is no abnormality in contact resistance before use.

Do not store or use this product near the sea or under conditions that contain a lot of salt.

If the metal is significantly rusted or discolored, replace it with a new one.

・Store and use this product under conditions that do not freeze or condense.

・This product is designed for use in the internal connection of equipment, so please do not

use it for any other purpose.

※Please check the product specifications and product variations of this product from our website.

Homepage address:https://www.hirose.com/

Apr.1.2022Copyright2022HIROSEELECTRICCO.,LTD.AllRightsReserved.