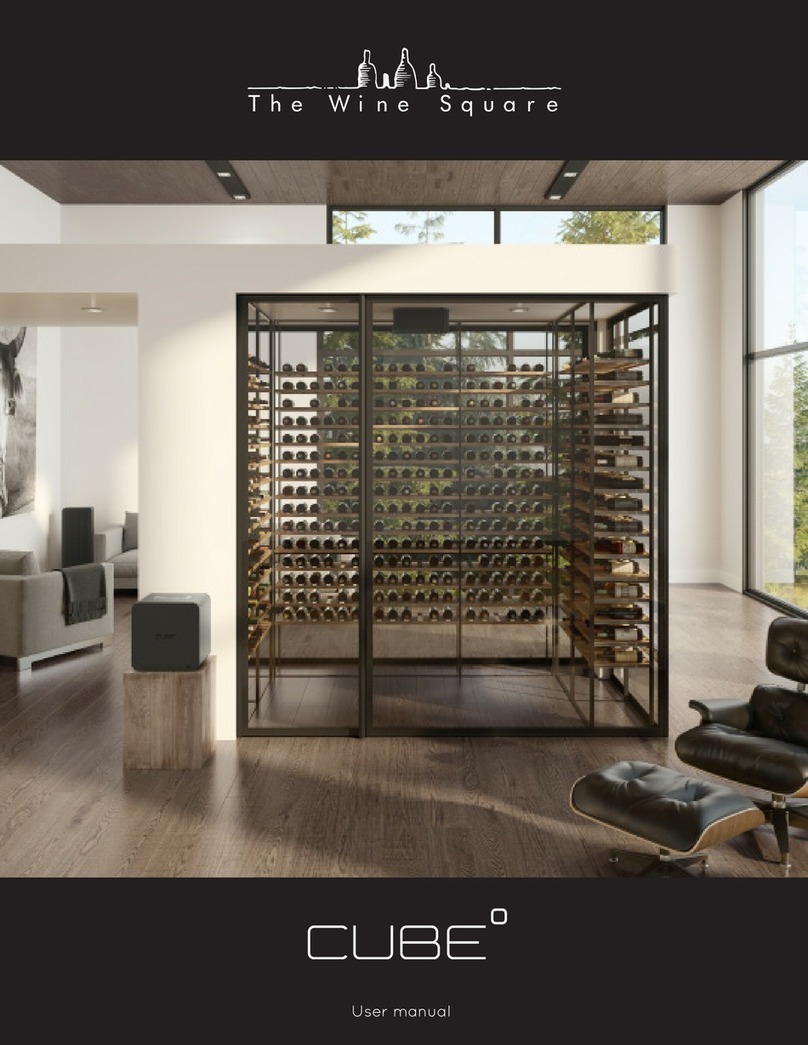

The Wine Square CUBE LT User manual

CUBELT

User Manual

DESIGNED AND MADE IN CANADA

1

TABLE OF CONTENTS

Warning / Caution / Note Definition 2

Introduction 4

Conditions In The Wine Cellar 4

Description of Components 5

Minimum Requirements 9

Location Selection 10

Installation 10

ROUGH-IN 11

FINAL INSTALLATION 15

System Start-Up 24

Use 28

Temperature Adjustment 29

Adjusting the Alarm Sound Level 29

Settings 30

Screen Unlock 32

Control with a Device on the Same Network 32

Remote Connection 33

Maintenance 34

Cleaning the Water Chiller Filter 34

Add Water 35

Water Replacement 37

Troubleshooting 38

Failure identified by a system error code 38

Failure Without System Error Code 46

APPENDICES 50

Wall Pre-Closure Checklist 51

PARTS LIST 53

Control Box CUBELT 54

RC4LT 55

NOTES 56

2

The words WARNING, CAUTION and NOTE have special meanings and should be

carefully reviewed.

WARNING Alerts the reader to a situation which, if not avoided, could result

in death or serious injury. It can also describe potential serious side effects

and their safety risks.

CAUTION Alerts the reader to a potentially hazardous situation which, if not

avoided, may result in minor or moderate injury to the user or damage to

the product or other property. This includes the special precautions neces-

sary for the safe and effective use of the device and the precautions necessary

to avoid damage to a device which may occur as a result of use or misuse.

NOTE : Provides special information to facilitate maintenance or clarify impor-

tant instructions.

WARNING

• DO NOT operate the unit through an electrical outlet and/or wall outlet that is damaged

or improperly secured to the wall. If the supply cord is damaged, it must be replaced by

the manufacturer or an authorized service agent.

• DO NOT cover or obstruct the air intake and exhaust of the CUBELT , Water Cooler and

CUBE-RC4LT while in use.

• This appliance is not intended for use by children. Children should be supervised and

should not play with or around the appliance.

• DO NOT place objects or sit on system modules..

• Always switch off and unplug the appliance when cleaning or servicing.

• DO NOT run power cord under carpet or rug.

• Use caution to avoid tripping over system wires or tubing.

3

• DO NOT use in areas where gasoline, paint or other flammables are stored.

• Basic safety precautions should always be taken when using electrical appliances.

• DO NOT use an extension cord with this appliance.

• Do not insert fingers or other foreign bodies inside the air grilles. This could cause

accidents due to the rotation of the blades.

• To ensure correct operation of the appliance in safe conditions, it is absolutely forbidden

to expose it to atmospheric agents and direct heat sources. The temperature in the

rooms where the appliance is installed must be between 10°C and 38°C (50°F - 100°F).

CAUTION

• If service is required, contact an authorized service agent.

• DO NOT place objects or sit on system modules.

• Install the Water Cooler in a well ventilated area.

• Unplug the appliance when stored or not in use.

• Use caution to avoid tripping over system wires or tubing.

• This appliance has been manufactured for the air conditioning of a wine cellar and must

not be used for any other purpose.

• STRICTLY use the installation hardware provided by The Wine Square. DO NOT attempt

to install or connect this device using any methods other than those provided in this

manual. Improper installation could void any existing warranty.

4

Introduction

This manual will help you operate or maintain the CUBELT wine cellar air con-

ditioning unit. Read this manual carefully before installing, using or servicing this

product.

The CUBELT wine cellar air conditioner is the most advanced compressor system on the

market. Specially designed for shallow glazed wine cellars where the air conditioning unit is

located directly above the bottles. It uses a water loop refrigeration which reduces thermal

shock while preventing air drying. This three-module unit allows for easy and flexible instal-

lation for residential or commercial projects.

Although the air conditioning system has great importance in maintaining adequate condi-

tions for serving or storing wine, it is not the only element to consider. It is very important

to ensure that the wine cellar is adequately insulated and sealed against humidity before

installing the CUBELT .

Conditions In The Wine Cellar

The CUBELT wine cellar cooling system is a system designed to maintain a temperature

in the wine cellar between 54°F-65°F [12°C-18°C]. It does not allow to obtain very cold

temperatures as for the service of champagnes and certain white wines. Its air condition-

ing mechanism is designed to reduce the large temperature differences affecting the wine

between each stop/start of the compressor. It also reduces air drying in the wine cellar that

can cause corks to deteriorate.

Studies show that the temperature of a wine cellar should be between 10°C and 18°C with a

humidity between 50%-80%. The lower the cellar temperature, the slower the wine will age.

A temperature that is too low will block its ageing.

The Wine Square recommends a temperature setpoint of 14°C (57°F) with this device, which

corresponds to both an aging temperature and a tasting temperature for most red wines.

5

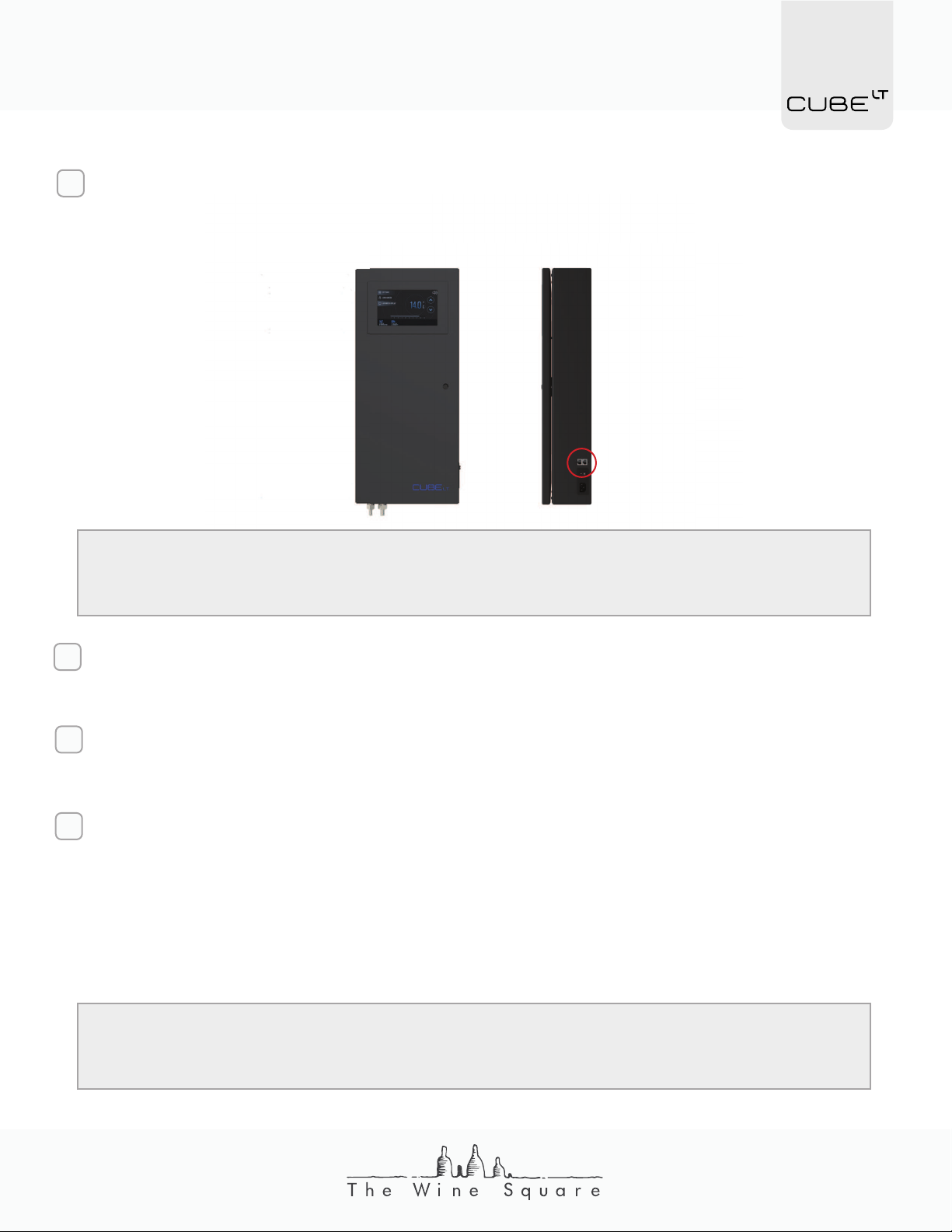

Description of Components

1

2

3

The CUBELT is a “split” cooling system made up of three components. It allows the noisy

element (the compressor) to be placed at a distance from the wine cellar.

1- CUBELT CONTROL BOX

2-CUBELT WATER CHILLER

3-RC4LT DIFFUSER

6

The CUBELT Control Box is the unit managing the system. Equipped with a high-resolution

7” touch screen, it allows the display and simple adjustment of the conditions of the wine

cellar. It provides the electrical power and the chilled water to the RC4-LT module in the

wine cellar by means of a network wire and two 1/2” PEX pipes. The CUBELT Control Box

must be connected to a closed circuit chilled water source coming either from the CUBELT

Water Chiller or from a plate heat exchanger connected to the chilled water of the building.

Very ecological and safe, it uses no refrigerant gas and therefore always recirculates the

same water. It is normally installed in a garage or mechanical room.

CONTROL BOX

Voltage____________________________________________

Amperage_______________________________________

Power_______________________________________________

Plug_________________________________________________

Inlet / Outlet___________________________________

Maximum Water T° ________________________

Minimum Water T°__________________________

Flow Rate________________________________________

Internet Connection________________________

120V 60Hz

0.75 A

90W

NEMA 5-15P

1/2” PEX

48°F (9°C)

32°F (0°C)

20 L/min

RJ45

SPECIFICATIONS

7

The CUBELT Water Chiller provides the chilled water necessary for the proper functioning

of the system. Italian designed, this small, robust and eco-friendly unit uses R290 as refrig-

erant, a non-toxic gas with zero ODP (Ozone Depletion Potential) and very low GWP (Global

Warming Potential). This chiller is installed near the CUBELT Control Box in a mechanical

room or garage usually. Its sound level, similar to that of a dehumidifier, means that it is not

recommended for use in an apartment or condo without a mechanical room.

WATER CHILLER

Voltage____________________________________________

Amperage_______________________________________

Power Consumption_______________________

Cooling Power_________________________________

Plug_________________________________________________

Inlet/Outlet Connection_________________

Weight_____________________________________________

Minimum Water T°__________________________

Refrigerant______________________________________

Ambient Operatoing T°__________________

Certification____________________________________

120V 60Hz

3.6 A

330W

400W

NEMA 5-15P

1/2” PEX

47lb (21.4 kg)

41°F (5°C)

R290

50°F - 100°F (10°C-38°C)

UL / CE

SPECIFICATIONS

8

The RC4LT is the cooling unit of the system positioned at the ceiling of the wine cellar.

It pumps the heat in and carries it to the water cooler. It is equipped with a condensate

pump to evacuate the condensation outside the wine cellar. The RC4LT must be installed

horizontally at the highest point of the wine cellar. For a large wine cellar or a particular

geometry, it may be necessary to install more than one RC4LT, they are then connected

in series on the communication and water supply level.

RC4LT DIFFUSER

Power / Communication_________________

Cooling Power_________________________________

Drain Connection____________________________

Inlet/Outlet Connection_________________

Minimum Clearance

Front (A)_______________________________

Side (B)_________________________________

Back (C)________________________________

Under the device__________________

RJ45

400W

1/2” PEX

1/2” PEX

1.75’’

1”

1’’

8’’

SPECIFICATIONS

A

B

C

Front

Back

9

Minimum Requirements

In order to ensure proper operation of the system as well as to maintain the warranty, it is

important that the wine cellar is built according to the rules of the art. These requirements

remain the same, regardless of the size of the wine cellar.

GENERAL

• Vapor barrier or moisture barrier on all surfaces (walls / floor / ceiling)

• Airtight

WALLS

• Minimum insulation of R15 or U0.06

FLOOR

• Minimum insulation of R7.5 or U0.13

CEILING

• Minimum insulation of R7.5 or U0.13

GLASS

• Minimum insulation of R4.5 or U0.22 with LOW-E protection

CAUTION Insulation under a concrete slab does not count as floor insulation. Unless

the slab of the wine cellar is independent from the rest of the building and has a

thermal break of at least 1”. Otherwise, the thickness of the concrete slab acts as a ther-

mal bridge and injects heat around the entire perimeter of the wine cellar.

In addition to voiding the warranty on the Water Chiller failure to comply with these condi-

tions exposes you to, but is not limited to:

Condensation on wine cellar glasses

Poor humidity control in the wine cellar

Reduced compressor life

Bad conditions for aging wine

Compressor frequent stop/start

A lack of system power to reach the target temperature

10

Installation

The installation of the CUBELT is normally done in two steps, one before the walls are

closed and one when the system is put into operation. The first step is to install the pipes,

communication cable and wood blocking necessary for the system to work properly in the

walls. This installation procedure uses PEX, a flexible and easy to install product to connect

the different units. The system can be installed with other types of piping. Contact The Wine

Square if you would like another type of conduit for installation. Refer to the regulations in

your area/building before using plastic conduit such as PEX.

Location Selection

Before starting the installation of the system, it is important to select the location where the

various components will be installed. Although air conditioning systems push cold air when

they are in use, these devices work more to remove heat, colder air is only a result. The nu-

ance seems small, but it is very important when evaluating the placement of the compo-

nents of the air conditioning system. Indeed, assuming that the system is a heat pump:

THE RC4LT : This unit seeks to remove heat from the wine cellar, so it will need

to be located at the hottest location in the wine cellar, the ceiling. Depending on

the configuration of the room, it can be either in the center or above the door. A

clearance of at least 8’’ must be kept under the appliance to allow the service of

this unit.

THE WATER CHILLER: The compressor system used to produce cold water for the

wine cellar, this is the unit that will reject the heat removed from the wine cellar.

It can be located up to 30 meters (100 feet) from the wine cellar. This unit could

experience reduced power if it is in an overheated room. Heat rejection will then

be more difficult. It is therefore necessary to find a well-ventilated location that will

maintain an annual temperature between 50°F and 100°F (10°C - 38°C). This unit

is not designed for outdoor installation. This unit is also the “noisy” module of the

system. It emits a noise comparable to a window air conditioner. The ideal location

for this module is the mechanical room or the garage.

THE CONTROL BOX: The control box can be located anywhere between the water

chiller and the wine cellar. It is usually installed above the water chiller.

11

PEX 1/2’’ PIPE

2X INSULATED

PEX 1/2’’ PIPE

ETHERNET

RJ45-CAT6

RC4-LT *

CONTROL BOX *

CUBE°LT

WATER CHILLER

CUBE°LT

ETHERNET WALL

PLATE LINKED TO

INTERNET

SOCKET NEMA 5-15R,2P

DEDICATED CIRCUIT

DRAIN

ROUGH-IN

A

B

C

D

E

F

G

12

APosition RC4LT in the wine cellar. It is important to consider the thickness of the insula-

tion, finishing material and glass envelope when locating the final location of the unit.

Check that the clearance necessary for the correct operation of the unit is respected.

B

Minimum Clearance

Front (A)____________________________

Side (B)_________________________________

Back (C)_____________________________

1.75’’

1”

1’’

A

C

Front

Back

Install a wood blocking at least the size of the unit and at least 5/8’’ thick at the loca-

tion of the unit. Provide an opening of maximum 2’’x 10’’ tangent with the middle of the

location of the unit, for the passage of the tubes. Generally two holes of 1-3/4 ‘’ and one

of 0.75 ‘’ are sufficient.

28.5”

[ 724 ]

10.25”

[ 260 ]

Install 2 x 1/2” insulated PEX pipes between the location of the control box (usually locat-

ed in the garage or mechanical room) and the outlet of the RC4LT unit (opening made

in the wood blocking installed previously) .

Put “duct tape” type adhesive tape between the different sections of insulation (joint)

covering the tubes.

B

NOTE : It is preferable to use PEX tube supports rather

than elbows when a 90° is required.

13

Install 1/2” non-insulated PEX pipe between a drain (the drain can be in the garage or

mechanical room since the unit is equipped with a condensate pump) and the outlet of

the RC4LT unit.

Install an elbow at the RC4LT location as in step B’. It is best to connect the other end

of the tube to an open drain (e.g. floor drain) to prevent the risk of odor coming from

the sewers in the wine cellar. Connecting to a drain using a ‘’P-trap’’ principle to prevent

odors is not effective, as the system may never generate condensation if the humidity

in the house is well managed, the ‘’ P-trap’’ would thus end up drying up.

C

2’’-6’’

[50-150]

At the ceiling in the wine cellar, leave between 2” and 6” of tubing hanging from the ceil-

ing and install an elbow on each conduit.

B’

NOTE : It is preferable not to exit all the tubes at the same height to facilitate the

connection of the system during its final installation. It is also possible to hang lon-

ger tubes at this stage and install the elbows only during the final installation of the

RC4LT after the walls are closed.

NOTE : To bring the conduits out of the wall in the mechanical room in an aesthetic

way, it is possible to use a low voltage 2-gang wall bracket.

14

Install an RJ45 network wire with minimum 23AWG wires between the RC4LT and the

control box location. Allow a minimum of 36” of wire to hang in the wine cellar and the

length needed to connect to the right side of the control box.

D

NOTE : It is more prudent at this stage to run a second RJ45 wire away from the

first. In the event that the first is damaged by a nail or screw when closing the

walls, the second can be used.

Install an RJ45 network socket connected to the internet near the device. The CUBELT

uses a wired connection to connect to the internet.

E

Have a professional install a NEMA 5-15R, 2-pole electrical outlet on a dedicated circuit

for powering the control box and the water cooler.

F

Install a nailing backing on the wall at the location of the control box. The nailing bottom

must be at least 36” high and 10” wide. The top of the bottom nailing panel must be

installed 60” above the ground.

G

NOTE : Before closing the walls, take the time to review the “Check List” in the

appendix to make sure that nothing has been forgotten.

15

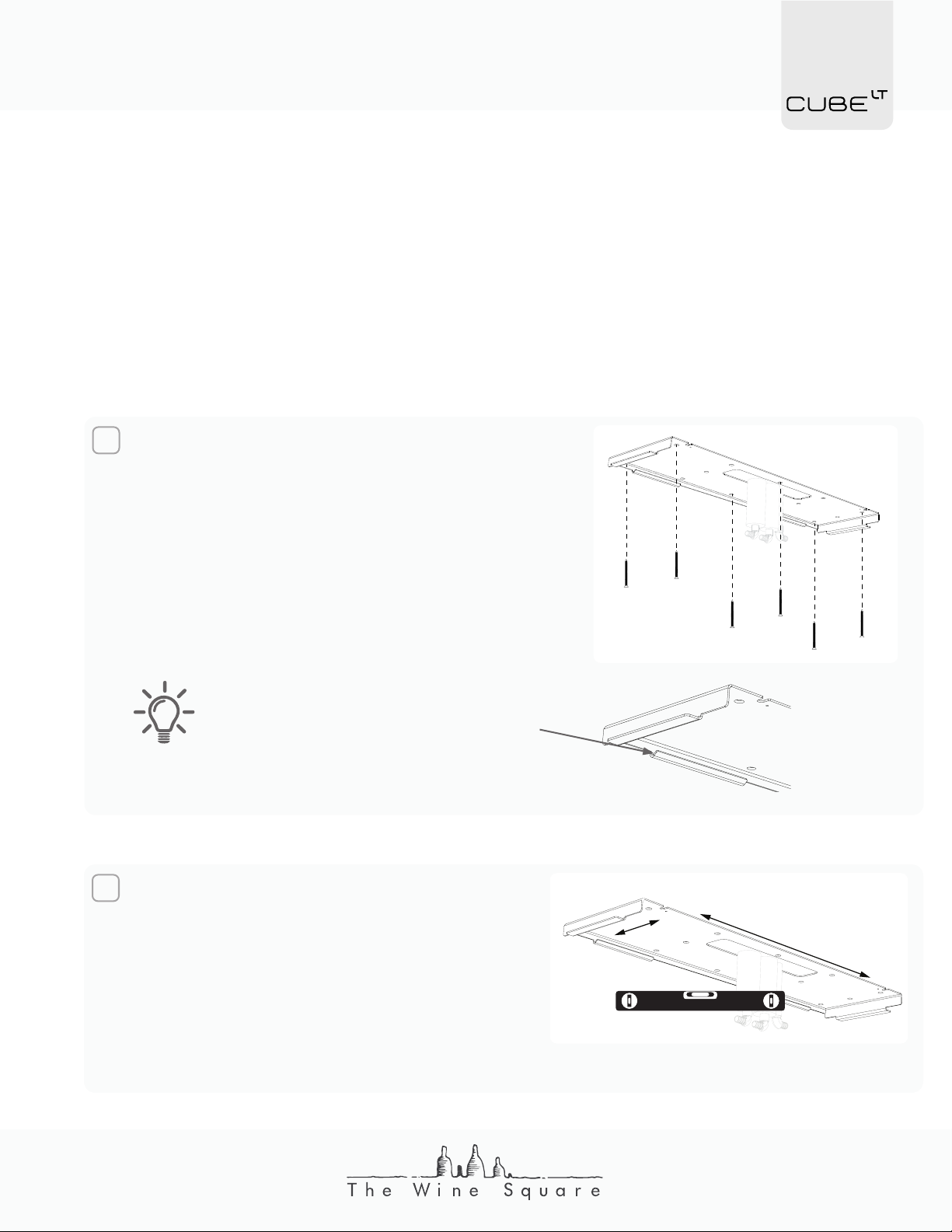

2Check that the backing plate is level in

both axes. If necessary, use shims be-

tween the ceiling and the plate to level

everything. If the support is not level, the

condensation generated by the system

may drip to the floor rather than being

picked up by the condensation pump.

FINAL INSTALLATION

This installation step must be carried out at the very end of the work when there is no lon-

ger any dust production. Otherwise, dust could damage the device and reduce the cool-

ing capacity of the system. In the event that construction steps are required following the

installation of the system, please unplug the device before starting work.

FINAL INSTALLATION RC4LT

1Locate the RC4LT in the wine cellar. Using

# 8 flat-head wood screws, long enough to an-

chor into the nailing base without risking drilling

the PEX tubes installed in the ceiling, secure the

RC4LT backing plate. Take the time to make sure

the plate is parallel with the walls.

The bended edge of the mounting

plate should be the side of the plate

closest to the back wall of the wine

cellar.

16

3Install the radiator module on the support plate. Be careful not to trap the tubes

when rotating the module.

4Secure the radiator in place with two # 8 flat head wood screws long enough to

anchor into the nailing base.

17

5Connect the tubes previously installed in the walls with the radiator module. The

tubes preinstalled on the radiator are connected directly to the PEX fittings without

a crimp ring. The tube is therefore installed on the PEX tip as it will be on a barb

fitting.

Insulated Tube Non-insulated Tube

Make sure that the connection with the tubes is above the condensation

pan. Otherwise, take care to insulate the PEX and fitting to avoid condensa-

tion.

6Install a connector at the end of the RJ45 wire and connect the wire to the RC4LT

electronic board. The wire can be plugged into any of the two connectors on the

board.

CAUTION Be sure to always test your cable with an RJ45 cable tester be-

fore plugging the wire into the device. Reversing two wires when installing

the connector could damage the product electronics.

18

7Install the wooden box over the radiator. Before sliding the casing into place, find

the joint on the wood veneer and orient that surface toward the back of the wine

cellar. When putting the housing back in place, make sure the tubes are not kinked.

Once the wood box is in place, turn the support fins to hold it in position. Make sure

the fins are securely in place and lightly pull on the wood casing to make sure the

part is firmly in place.

Table of contents

Other The Wine Square Wine Cooler manuals