△Coolingsystemfaults.

○Howtodiagnosefaults:

Itshouldtakeapproximate3hourstoreachthelowestsettingtemperatureof5℃foranemptyunit (assuming ambient

tempof32 degreescentigradeandcontinuousoperation).Ifnot,checkthecompressor,coolingfans,controller, and sensors.

Ifallthese are workingnormally, there isprobablya coolingsystem’sfault.

○Howtorepairthedefualt

1.Checkthecompressor

Turnon theunit and checkthereiselectricitycurrentflowingtothecompressorusingacalipertypeAmpmeter,the

currentshouldbewithin0.6to2Amps.Ifthereadingsarenotinthisrange, turnoffand cutoffthepipes (SeeFig.20

showing G) andthesealpliers (See Fig.20showing E.) fromthecompressor,thenturntheunitonagain(inthiscase

onlyrunthecompressorforafewminuets,soastoavoidthecompressorabsorbmoistair)andrecheckthe

currentand ifthereispressureattheoutletpipe. Ifthecurrentreading isstill outofrangespecifiedaboveandno

pressurefromthe compressoroutlet,replacethewholecompressor.

2.Checkthe coolingsystempipework:

Carefullycheckthecoolingsystemafterverifyingthecompressorisworkingnormally.Thenfollowtheprocedure

below.

1>. Thencutoffprocesspipeand checktherefrigerant.Ifthereisnotenoughrefrigerant,thedefualtoftherefrigerant

systemshouldbecausedbythe leaking. If the refrigerantissufficient.,itisprobablyjamedinthecapillary.

2>.If thedefault is concentratedonthecoolingsystem,thecheckingprocedureis as below.

A.Cutofftheventpipeofthecompressor,andinfuse0.8-1MPnitrogenby process pipe,andpleaseputthehandclose

tothecutkerfoftheventpipe. If thereis alittlegas leakformtheterminal, itmeans normal, oritisjamed.

B.Makesurethecapilaryisworking normally,whenthedrainpipeisconnetcedagain,andinfuse0.8-1MPnitrogen

thentesttheleakageifthecoolingsystemofthesolderingpointwiththesoapwater.Checkfromthethesoldering

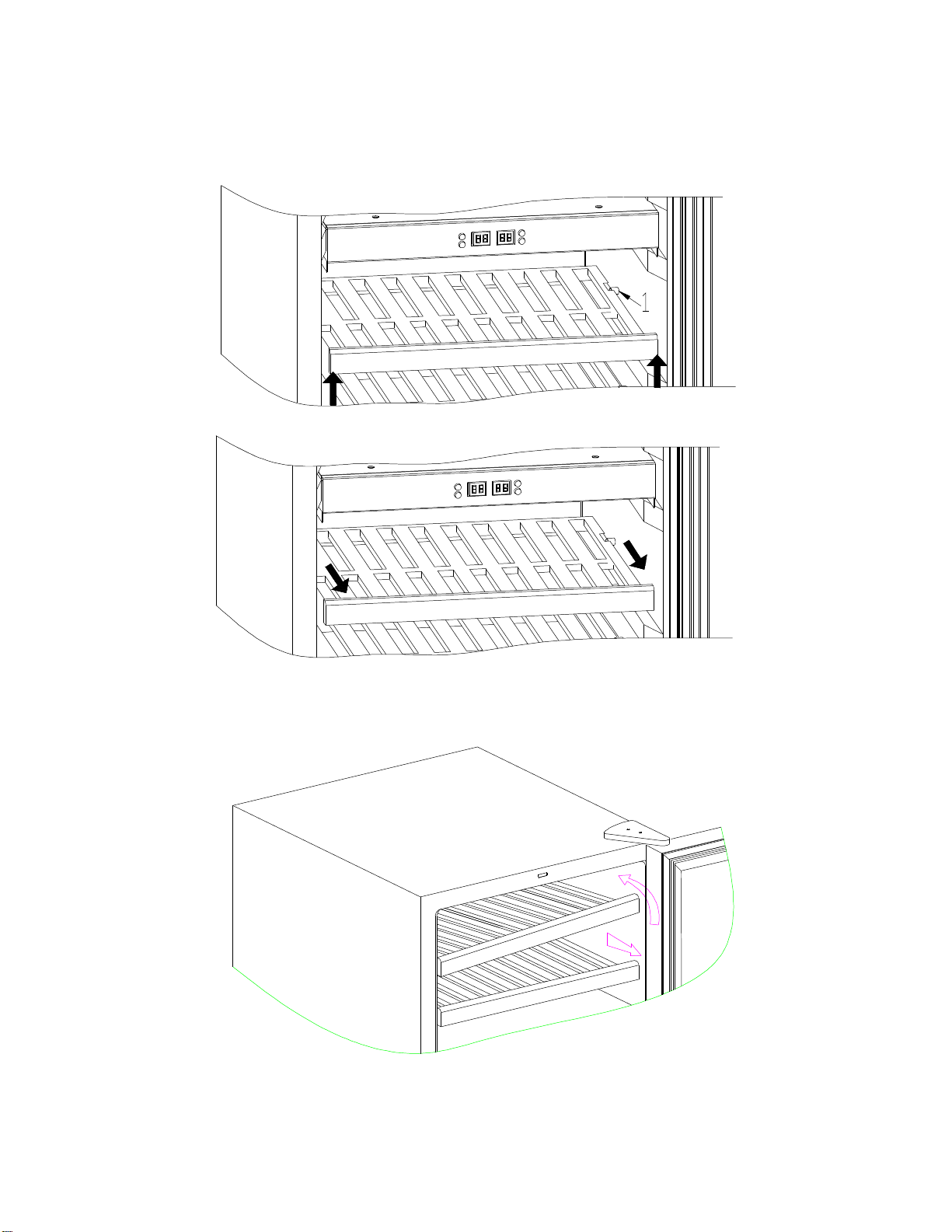

pointarround thecompressor(Fig.20& Fig.21, Fig.21.1),and ifeverythingisok,removetheair-ductboardand

chechthesolderingpointaround evaporator. pleaseseetheremovemethodandtheprocedureas below(→4).

C.Ifall thesolderingpointinBisnotleaking,therearetwopossibility,oneisleakageintheinnercondenser,another

is thedamageontheparts(suchasevaporator,condenserandsoon)inthecoolingsystem.Ifitistheinnerdamage, it

cannotberepaired,andifthedamageontheparts,replacethem.

3>.Makesurethatthereis notleakageinthecoolingsystem,refill therefrigerant.

3. Refill therefrigerant:

1>.Using thevacuumpumpformavacuuminthe system, viathejointofthe low-pressure processpipeonthe compressor,

thehigh-pressurepipelineisontheprocess pipeofthefilter.Applythevacuumpumpforapproximately20 minutes.Until

thevacuumislowerthan100Pa. Thensolderthecompressorprocess pipeofthefilter.Keepthevacuumrunningwhile

soldering thisjoint

2>.FillCoolingsystemwithrefrigerantviatheprocesspipe. (TherefrigerantisR134a.Regardingrefrigerantquantity

Pleaserefertotheinstructionatbacklabelofwinecellar).Thensolderthecompressorprocess pipeafterthesystemis

chargedwithrefrigerant.

4. Runningtest:

Replace allthecomponentsafterthe proceduresabove and turntheunit on.Toverifythe effectiveness ofthe repair, monitor