Therma-tek TEK40 Operating and maintenance manual

Manual Date 05/30/19

PRINTED in USA

LIQUID SHORTENING GAS FRYERS

Model TEK40 - 3 Tube Burners, 40lb Vat ( 90,000 btu/hr)

Model TEK50 - 4 Tube Burners, 50lb Vat (120,000 btu/hr)

Model TEK70 - 5 Tube Burners, 70lb Vat (150,000 btu/hr)

INSTALLATION, MAINTENANCE & OPERATING MANUAL

(covers both Stationary and Mobile Applications)

** Either Natural Gas (NG) or Liquid Propane (LP) can supply the fryers **

Remember that Oil & Water won't mix. Don't attempt to fight an Oil Fire using Water.

In the event that a gas odor is detected, shut off the gas supply at the main shut-off valve and contact the

local gas company or your gas provider/supplier for service!

Thank you for choosing our fryers for your operational requirements. Follow these instructions carefully.

If properly used and maintained, you can expect to enjoy years of reliable, efficient and top quality use.

Note: Product line is subject to ongoing, continuous upgrades and improvements. The specifications defining

each model are subject to change without notice.

Keep this manual for training and as a reference guide when service or maintenance is required.

Keep a copy of your Bill of Sale and final building inspection report for the fryer installation as both will help

establish your appliance's warranty period and the date this coverage started.

1

TABLE OF CONTENTS

WARNING IF A GAS ODOR IS DETECTED – (Precautionary actions to take) COVER PAGE

IMPORTANT FOR YOUR SAFETY 2

INTRODUCTION 3

General

Ordering Parts

Fryer Capacity

Unpacking

INSTALLATION 4

Clearances

Location

Fryer Capacity

Flue Installation

CODES AND STANDARDS 6

ASSEMBLY 6

Flue Exhaust

Gas Connection

Gas Pressure

Testing the Gas Supply Piping Connection

Mobile Fryer Installations

Leveling the Fryer

OPERATION 10

Over-Temperature Shut Down

Before First Use / Cleaning

Filling Tank with Shortening

Lighting the Pilot

Turning On the Fryer

Turning Off the Fryer

Extended Shutdown

BASIC FRYING INSTRUCTIONS 12

Fry Basket Guidelines & Fry Basket Capacity

Extended Shortening Life

Draining the Tank

Daily Filtering

CLEANING

14

Maintenance & Sanitation Calendar < Daily, Monthly, Semi-Annually >

BOIL OUT PROCEDURE 15

FLUE VENT INSPECTION & MAINTENANCE 16

Service in the US and Canada

TROUBLESHOOTING CHART & GUIDE 16

WARRANTY 17

SPECIFICATION and COMMERCIAL DUTY 3RD PARTY APPROVALS 18

DIAGRAMS, EXPLODED VIEWS 19

Exploded View With Replacement/Accessory Part Numbers

Electrical Control Schematic Diagram (Describes Mili-volt System)

Descriptive Drawing of the Fry Tank

SAFETY APPAREL (RECOMMENDED) 24

BENEFITS, FEATURES AND OPTIONS REGARDING THIS FRYER 25

TUNING THE GAS CONTROL SYSTEM COMPONENTS 26

2

IMPORTANT FOR YOUR SAFETY

Proper operation/performance of your liquid shortening gas fryer.

READ THE INSTALLATION, OPERATING AND MAINTENANCE INSTRUCTIONS THOROUGHLY BEFORE INSTALLING,

MAINTAINING, RESETTING, MONITORING, OPERATING OR SERVICING THIS EQUIPMENT. THIS MANUAL HAS BEEN

PREPARED FOR PERSONNEL QUALIFIED TO INSTALL GAS EQUIPMENT. AFTER CAREFULLY REVIEWING AND

FOLLOWING THE INSTRUCTIONS/DIRECTIONS IN THIS MANUAL, ONLY QUALIFIED PERSONNEL THAT HAVE READ THIS

MANUAL SHOULD PERFORM THE INITIAL FIELD START-UP AND EQUIPMENT ADJUSTMENTS .

This fryer is intended and approved for commercial use only- it is not built for residential applications.

IMPROPER INSTALLATION, SERVICE, ADJUSTMENT, ALTERATION, OR MAINTENANCE CAN CAUSE PROPERTY DAMAGE,

PREMATURE PERFORMANCE FAILURES, INJURY OR POSSIBLY DEATH.

WARNING: FAILURE TO COMPLY (EVEN PARTIALLY) WITH THE RULES GIVEN IN THIS MANUAL WILL INVALIDATE

THE PRODUCT WARRANTY AND RELIEVES THE MANUFACTURER OF ANY RESPONSIBILITY.

This instruction booklet must be kept with the fryer for future consultation. If the fryer is sold or transferred to

another user, make sure the booklet always goes with the appliance so that the new owner can have the necessary

information on operation and the relative instructions.

IN A PROMINENT LOCATION, POST INSTRUCTIONS TO BE FOLLOWED IN THE EVENT THE SMELL OF GAS IS DETECTED.

THIS INFORMATION CAN BE OBTAINED FROM THE LOCAL GAS SUPPLIER. If a gas odor is detected, IMMEDIATELY

CLOSE THE MAIN GAS SUPPLY SHUT OFF VALVE WHICH STOPS ALL THE GAS FLOWING TO THIS APPLIANCE.

To maintain the equipment warranty, the installation and service work must be performed by qualified technicians and

factory supplied replacement parts or equipment mounted accessories must be used. Only use factory or distributor

authorized and approved casters or leveling legs to support this fryer. It should stand upright and level in its desired

location before it is turned on with a gas supply line connection to the gas valve feeding the pilot/burners.

Caution: This fryer is built for liquid shortening use only (not solid), Directly adding solid shortening

like

palm oil, coconut oil and tallow to the fryer, when the tube burners are not fully immersed, can damage

this appliance and voids its manufacturer’s warranty. If it is desired to use a solid shortening, pre-melt it

before

carefully and safely pouring the liquid oil into the fry vat. Once the burner tubes are fully covered with

shortening, solid shortening can be directly added to bring the oil level up to the fry vat maximum fill level.

DO NOT ATTEMPT TO LIGHT THE PILOT OR LEAVE THE PILOT LIT WHEN THE FRY VAT IS EMPTY OR IF THE

OIL LEVEL DOES NOT COMPLETELY COVER THE TUBE BURNERS. IGNORING THIS CAUTION VOIDS THE FRYER

WARRANTY. If the pilot and main burners go out, the unit must be shut down for ≥ 5 minutes before the fryer

is lighted again to return it to service.

FOR YOUR SAFETY

DO NOT STORE OR USE GASOLINE OR OTHER FLAMMABLE VAPORS OR LIQUIDS

IN THE VICINITY OF THIS OR ANY OTHER GAS COOKING APPLIANCE.

Keep the area around all gas cooking appliances free and clear of combustible materials!!

CAUTION: Hot oil may splatter or splash out of the appliance at any time creating a potential slip and fall or burn risk.

When working on, monitoring or operating the unit wear proper safety apparel!

3

GENERAL

INTRODUCTION

Our commercial gas fryers are produced with quality workmanship and materials. Proper installation, usage

and maintenance will result in years of satisfactory, cost effective performance producing flavorful, high

quality, delicious fried food for your operation.

This manual is applicable to a model listed on the cover page. Procedures in this manual apply to all models

unless specified. Pictures and illustrations can be of any model unless the picture or illustration needs to be

model specific and is identified as such.

ORDERING PARTS

To speed up your order, provide the model number, serial number, gas type, part needed, item part number

(if known) and quantity needed.

FRYER CAPACITY

MODEL

# of Heat Tubes

BTU / Hour

Width Inch (cm)

Shortening lbs (kg)

3 tube burner N&L

3

90,000

15.5 (39)

35-40 (16-18)

4 tube burner N&L

4

120,000

15.5 (39)

45-50 (21-23)

5 tube burner N&L

5

150,000

21.0 (53)

65-73 (29-33)

UNPACKING

This fryer was carefully inspected before leaving the factory. Upon acceptance of the shipment, the

transportation company assumes full responsibility for its safe delivery. Immediately after unpacking the

fryer, check for possible shipping or concealed damage. If it is damaged, save the packaging material and

contact the carrier within 2 days of delivery.

Check that the following have been included:

w Wire Basket Support Rack (in position this rack rests on top of the tube burners)

w Basket Hanger

w Adjustable Legs (4) {in some case could be 4 casters, 2 of which have brakes}

w Drain Pipe Extension

w Twin Fry Baskets (2)

w Extended exhaust gas flue chimney with deflector plate

w Manual and Warranty Card – Retain manual for future reference, send in filled out card.

Do not use the door or its handle in an attempt to lift the fryer.

NOTE: Some key parts or components may be shipped in separate cartons, in the fry vat, in the fry vat or

even in the fryer principal shipping container or its packaging materials. Be careful not to discard, misplace

or throw out these items which are needed to successfully, safely and efficiently operate this appliance.

Use only factory or distributor approved and authorized fryer support leveling legs or casters for this

appliance to operate it safely and keep its warranty in force.

4

INSTALLATION

Before installing the fryer, verify that the type of gas (natural or liquid propane [LP]) agrees with the

specifications on the fryer data plate. The fryer data plate is located on the inside of the door panel. Make

sure the fryer is configured for the proper elevation (height above sea level) of the facility.

Record the gas fryer model and serial number for future reference in the space provided below. This

information is on the fryer data plate. Also record the installation date.

Fryer Model No: Installation Date: Serial No:

CLEARANCES

• Allow space and accessibility for proper appliance servicing and operation.

• Minimum clearance from combustible construction:

• 6” (15 cm) from the SIDES of the fryer

• 6” (15 cm) from the BACK of the fryer

The fryer may be installed on combustible floors (if factory approved leveling legs or casters are used –

the warranty is voided if any other mounting method is used)

• Minimum clearance from noncombustible construction:

• 0” from the SIDES of the fryer

• 0” from the BACK of the fryer

• Between the fryer and any open-top flame units or unshielded heaters and burners:

• 16” (41 cm) A Flame Guard can be used if allowed by the local codes and officials

LOCATION

• The installation must meet the local building codes and should be approved by authorized building and

fire inspectors before the fryer is started up in operation.

• Install fryer in an area with sufficient air supply for complete tube burner gas combustion.

• Do not obstruct the flow of the appliance’s combustion and ventilation air.

• Provide adequate clearance for air openings into the combustion chamber.

• Do not permit fans to blow directly onto fryer as they can negatively impact the burner or pilot valve

performance possibly even extinguishing the pilot flame.

• Avoid wall-type fans, which create cross-currents within a room. Avoid open windows next to the

fryer’s sides or back. Test the room ventilation air ducts to ensure they aren’t blowing directly on this

appliance as that might create performance issues

• Ensure the floor allows the fryer to sit level and securely when its in position for proper operation,

service and cleaning

• No electrical connection is required for this appliance as the standard control scheme uses mili-volt

components [and possibly a piezo igniter] that don’t use/need a 115/220 v circuit.

• If mobile, an approved quick connect gas supply hose with restraint cable is needed.

• The hook up determines what restraint will prevent tipping over the fryer and avoid the risk of hot

oil splashing, spilling or sloshing out of the unit

• Install the fryer under an approved, operational and properly sized ventilation exhaust hood with the

required 6” minimum overhang surrounding the fryer {a make-up air style is suggested} that comes

with a built in and tested fire protection (i.e. Ansul™) system

• The appliance’s electrical schematic diagram is located on inside of door.

• Do not directly connect the fryer flue or exhaust to the ventilation hood.

• The hood grease filters should be at least 18” above the fryer exhaust flue.

5

FLUE INSTALLATION:

BEFORE USING FRYER INSTALL AND ASSEMBLE THE 10-5/8” FLUE AND DEFLECTOR PLATE

TO THE FRYER.

1. Unpack the flue box and flue wrap

2. Slide the flue box over the flue and secure it with the two self-tapping screws using a 5/16” socket

3. Slide the flue wrap over the flue [Ensure the fryer is properly positioned under the hood with proper

overhang on all sides of the appliance – code requires ≥ a 6” hood overhang distance]

4. Secure it with four self-tapping screws two on the back and one on each side using a 5/16” socket

6

CODES AND STANDARDS

The fryer must be installed in accordance with all applicable national and local codes, regulations and

ordinances. A final building and fire protection inspection should be conducted and the installation approved

prior to putting the new fryer into service.

In the United States:

State and local codes, or in the absence of local codes, comply with:

• National Fuel Gas Code, ANSI-Z223.1/NFPA #54 (latest edition). Copies may be obtained from The

American Gas Association Accredited Standards Committee Z223, @ 400 N. Capital St. NW,

Washington, DC 20001, the Secretary Standards Council, NFPA, 1 Batterymarch Park Quincy, MA

02169-7471 or on-line.

• NFPA Standard #96 Vapor Removal from Cooking Equipment, latest edition, obtain from the National

Fire Protection Association, Battery march Park, Quincy, MA.

• ANSI standards Z 21.69 and Z 21.41 if mounted on casters making it mobile for cleaning and servicing

(ensure the fryer is stable and level in all locations where it will operate or be worked on) If the unit

must be disconnected from its restraint cable for any reason, be sure it is reconnected prior to placing

the appliance back in service.

• In the commonwealth of Massachusetts all gas appliances vented through a ventilation hood or

exhaust system with a damper or with a power means of exhaust shall comply with the

commonwealth’s regulation standard or number 248 CMR.

In Canada:

Comply with all prevailing Local codes

• CAN/CSA-B149.1 Natural Gas and Propane Code Installation (latest edition),available from the

Canadian Gas Association 350 Sparks Street, Ottawa, Ontario Canada K1R 7S8.

• CSA C22.1 Canadian Electric Code L4W 5N6.

• CSA Standards 6.16 and 6.9 if mounted on a manufacturer or distributor approved caster set making it

mobile (see following comments about use of a restraint cable)

ASSEMBLY

The fryer must be properly restrained to prevent tipping and the splashing of hot liquid. The means of

restraint may be the manner of installation, such as connection to a battery of appliances, installing the fryer

in an alcove, or by separate means such as adequate ties or restraining cable if on casters so it’s mobile and

can be rolled into different safe positions..

If the unit must be disconnected from its restraint cable for any reason, be sure it is reconnected prior to

placing the appliance back into service.

FLUE EXHAUST GAS

• Comply with Vapor Removal from Cooking Equipment, ANSI-NFPA Standard #96 (latest edition),

available from the National Fire Protection Association, Batterymarch Park, Quincy, MA 02269.

• Locate the fryer under a hood with adequate connection to an exhaust duct. The hood must extend 6”

(15 cm) beyond fryer on both sides as well as in front of and behind the fryer if mounted in an island

cooking bank set-up, rather than against a back wall.

7

• Clearance above the fryer should be adequate for all combustion byproducts to be removed efficiently

and safely without creating a potential fire hazard.

No structural material on the fryer or its flue chimney including physical alterations should be made so

it can be placed under an approved exhaust hood with fire protection

• An 18” (46 cm) minimum clearance should be maintained between the flue vent and the grease

removal filters of the hood venting system.

• Never make flue connections directly between the fryer and exhaust hood.

• Do not obstruct the flow of the gases from the appliance. Proper air balance should be maintained in

the room. The exhaust system must meet all applicable local air exchange requirements, regulations,

ordinances and building codes.

• Ensure that your ventilation system does not cause a down draft at the fryer’s flue opening, a down

draft will not allow the fryer to exhaust properly and will cause overheating which may cause

permanent damage. Damage caused by down drafts aren’t covered under the equipment warranty.

Never allow anything to obstruct the flue or ventilation exiting from the fryer flue.

• NEVER put anything on top of the flue open area which may impact the exhaust gas flow.

CONNECTION GAS

All gas supply connections and any pipe joint compound must be resistant to the action of

propane gases or any other reasonable corrosion causes or catalysts.

The gas inlet is located on the lower rear of the fryer. Codes require that a gas shutoff valve be installed in the

gas line ahead of the fryer. Installing the fryer and gas plumbing safely in accordance with the local codes and

manufacturer directives including an approved pressure regulator is the purchaser’s (end user’s) responsibility

not the fryer manufacturer or distributor.

The gas supply line must be at least the equivalent of ½” (12.7 mm) iron pipe for single units and 1-1/4” (31.75

mm) for batteries. If using the optional quick-disconnect flex hose, ¾” (19 mm) iron pipe feeding it is

appropriate for single fryer applications.

Each fryer is equipped with a ½” – ¾” coupling that facilitates the proper gas supply line connection using

approved piping and possibly an approved quick disconnect hose with its required restraint cable hook-up to

hold it in position that is required by code if on casters (a mobile appliance set-up).

Make sure the pipes are clean and free of obstructions, dirt, and piping compound. A battery set up may

require one or two connections of appropriate size for the gas requirement to properly supply each gas

cooking appliance in that battery line-up.

Prior to lighting, check all joints in the gas supply line for leaks.

Use soap and water solution. Do not use an open flame.

After piping has been checked for leaks, fully purge gas pipes to remove any trapped air in the line prior to

bringing the fryer on line and into service.

8

GAS PRESSURE (ALL MODELS): Natural Gas, Town Gas or LP {Liquid Propane Gas}

The gas pressure must be set at 4” W.C. (Water Column) (0.8 kPa) for natural gas and 10” W.C. (2.75 kPa) for

gas. If incoming pressure exceeds ½ PSI (3.45 kPa), an additional pressure regulator must be installed.

{Meeting this requirement is the owner’s responsibility} The name plate indicates which form of gas fuel

supply is to be connected to this fryer LP or Natural Gas

All gas piping should be performed by a licensed plumber and approved by an authorized local building code

and fire protection inspector.

TESTING THE GAS SUPPLY PIPING CONNECTION

• When test pressures exceed ½ PSI (3.45 kPa), the fryer and its individual shutoff valve must be

disconnected from the gas supply piping system.

• When test pressures are ½ PSI (3.45 kPa) or less, the fryer must be isolated from the gas supply piping

system by closing its individual shutoff valve.

If any leaks must be repaired, ensure the line is free of any residual gas and then execute the needed remedial

action safely and properly to conform the prevailing codes and ordinances.

MOBILE FRYER INSTALLATION

Approved casters, the quick disconnect supply hose and a secure restraining device aren’t/may

not be supplied with these fryers. A provided set of leveling legs is typical which allows a

stationery safe hook-up with the connection of proper gas piping.

Separate instructions for installing casters are included with each purchased caster kit/set:

• The installation must be made with a connector that complies with the current Standard for

Connectors for Movable Gas Appliances, ANSI Z-21.69 or Connectors for Moveable Gas Appliances,

CAN/CGA-6.16, and a quick-disconnect device that complies with the Standard for Quick-Disconnect

Devices for Use with Gas Fuel, ANSI Z-21.41 or Quick-Disconnect Devices for Use with Gas Fuel, CANI-

6.9.

• When installing a quick disconnect you must also install a means for limiting the movement of the

fryer. This restraining device prevents the gas line or quick disconnect hose from being strained. The

restraining device should be attached to the mounting system/cutout on the fryer’s back panel. {See

illustration for location}

• The manufacturer/distributor offers an approved and proven mobile gas appliance installation kit

consisting or proper strength and size casters (2 with brakes), approved quick disconnect hose and

rated restraining cable. Its use maintains the factory equipment warranty – other set ups may result in

that protection being voided

9

If disconnecting the restraining device is needed for servicing or cleaning the unit, reconnect

the restraining device after the fryer is placed back into its original position.

• The fryer must use with an approved restraint cable and quick disconnect gas supply flexible hose

connector complying with all applicable codes.

• The fryer set up must have a proven restraining means to prevent transmitting strain to the restraining

connector. [See the above illustration for a better understanding of this requirement.]

• The fryer must be installed with the casters provided or approved by its manufacturer.

• If the restraint cable is ever to be disconnected, first turn the gas supply off, reconnect the restraint

cable before returning the appliance into normal operation.

LEVELING THE FRYER

Check if the fryer is level by placing a “level” on top of the fryer after all the gas connections have been made.

Ensure that the fryer is level front-to-back and side-to-side in its final installed position.

If using casters, lock the wheels after unit is level and confirm that the fryer will essentially stay level and

stable as it is moved into the various envisioned locations for operation, cleaning and servicing the unit. (Be

careful if moving a full vat as the oil may splash out)

10

OPERATION

Hot oil and parts can cause burns.

Use care when operating, cleaning and servicing the fryer.

Spilling hot frying compound or boil out solution can cause severe burns.

Do not move the fryer without draining all frying compound and liquid from the tank.

Note: Hot oil can splash, foam or splatter out of the fryer if moved or even stationary

creating a potential burn and slip and fall hazard condition. Use appropriate safety

apparatus and apparel (at least gloves & face shield) when servicing, cleaning,

monitoring or operating the gas fryer.

OVER-TEMPERATURE SHUTDOWN

If the shortening becomes overheated, a high-temperature shutoff safety device will turn the gas valve off and

extinguish the pilot. If the fryer shuts down due to overheating, DO NOT attempt to re-light the pilot until the

shortening temperature is below 300° F (149° C).

If an overheating situation persists, contact the Authorized Service Office. Contact information can be found

on the Cover Page.

BEFORE FIRST USE

Cleaning: New units are wiped down at the factory to remove any visible signs of dirt, oil, grease, etc.

remaining from the manufacturing process. Before any food preparation, thoroughly wash the protective oil

from all surface parts and the tank interior with hot soapy water to remove any film residue and dust or

debris. A fryer boil out with cleaning compound is suggested, this occurs at the factory prior to crating and

shipping through the normal distribution channels.

Do not use chlorine or sulfate/sulfide cleaners. Wash any accessories shipped with unit.

Rinse fryer and accessories thoroughly and drain the fryer. Wipe tank completely dry with a soft,

clean cloth.

FILLING TANK WITH SHORTENING

Solid shortening should NOT be used with these fryers. Directly Melting solid shortening in the fry tank will

damage the tank and void your warranty. If solid shortening is to be used (i.e. palm or coconut oil) it should be

completely melted remotely in another appliance and then carefully and safely poured in the fry vat until all

the tube burners are completely submerged in cooking oil. Any other practice or melting procedure voids

the fryer warranty and could damage the appliance or oil.

If the fryer will be emptied and not immediately refilled with oil, extinguish the gas pilot by shutting off the

gas valve. Do not attempt to re-light the system until the vat is filled with oil. (A lit pilot may damage an empty tank)

Don’t attempt to add liquid shortening to a fry tank that is not completely dry as the water may boil and

bubble as the oil is heated. Hot oil can splatter or slosh out of the vat causing a potential operator burn or

slip and fall hazard in the locale/area/vicinity immediately adjacent to the fryer.

11

1. Close the drain valve.

2. Fill the fryer tank with liquid shortening.

3. Shortening level should be between the min and max lines in the fryer tank.

4. Shortening will expand when heated. Do not fill the fryer tank (vat or pot) past the MAX line. Add

fresh shortening as needed to maintain oil level. DO NOT fill above the maximum fill fine embossed

into the fry vat. If no portion of a tube burner is exposed to air, solid shortening may be added

directly into the fryer, a little at a time to avoid any scorching or shortening of the oil life.

LIGHTING THE PILOT

1. Open the door.

2. Turn the thermostat OFF (see figure, view A). The thermostat is located behind the door.

3. Push the gas control valve knob and turn to OFF. Wait 5 minutes to vent unburned gas.

4. Push and turn gas control valve knob to the “L” in PILOT (see figure below, view B).

5. While still holding the knob in, light the pilot with a suitable flame. Continue to depress the knob until

pilot stays lit when knob is released. If the pilot doesn’t remain lit, repeat steps 3 through 5.

6. Depress and turn gas control knob to ON (See figure below, view C).

7. If gas supply is interrupted, repeat steps 2 through 6.

A lit pilot is needed for proper fryer operation. The pilot is tested at the factory prior to shipping.

12

TURNING ON THE FRYER

1. Set the temperature knob to desired temperature.

2. After the set temperature is reached, the thermostat shuts off the gas flow to the burners.

3. The pilot remains lit. The burners cycle on and off, to maintain the temperature at the set point.

TURNING OFF THE FRYER

1. Turn the thermostat OFF.

2. To keep the pilot lit, turn the gas valve to “L” in Pilot. {only the pilot stays lit in this position}

3. To shut off all gas to the system, including the pilot, turn the gas valve knob to OFF.

EXTENDED SHUTDOWN

1. Turn the thermostat knob to OFF.

2. Push in the pilot knob and turn to OFF.

3. Thoroughly drain the fryer. Refer to DRAINING THE FRYER.

4. Clean the fryer according to CLEANING.

5. Turn off the main gas shutoff valve.

A complete fryer boil-out is suggested after any extended shutdown before bringing it back on-line.

NOTE: If the pilot is extinguished, a control safety sensor (thermopile) cuts off the gas supply to it.

BASIC FRYING INSTRUCTIONS

• Set the desired temperature and allow shortening to heat up to that temperature.

• Fry items should be of similar size to ensure equal doneness.

• Drain or wipe dry raw or wet foods to minimize splatter when lowering into hot oil.

• Add fresh shortening as needed top maintain the shortening level between the recommended

(embossed) minimum and maximum fill level (volume) lines.

FRY BASKET GUIDELINES

• Don’t overfill baskets. (See table for recommended basket capacities below) Carefully lower each

basket into the hot oil to minimize turbulence, splatter and damage to the fry basket itself.

• When frying doughnuts and fritters, turn product only once during frying.

• When cooking French fries or onion rings, shake the basket several times.

• Batter-covered foods should be dropped carefully, one by one, into shortening or basket (If a basket is

used, first dip the basket into the oil to reduce batter-build up on basket surfaces.)

• When frying is completed, remove basket or product. Hang basket on the rear basket hanger allowing

the excess oil to flow back into the fry vat (kettle/pot/tank).

FRY BASKET CAPACITY

• For the 3-tube and 4-tube models: Recommended maximum pounds per basket of frozen French fries

are 1.5 lbs. (0.7 kg). {NEVER put more than 2 lb of frozen fries into any one basket}

• For the 5-tube fryer, its recommended maximum frozen fry load is 3 pounds per basket (1.4 kg).

13

EXTENDING SHORTENING LIFE

Shortening life can be extended by the following guidelines:

o Do not salt foods over the fryer

o Use good-quality shortening

o Filter shortening daily (at a minimum)

o Replace shortening if it becomes poorly flavored

o Keep equipment and surrounding clean

o Set thermostat correctly, lower the temperature to 210°F (99°C) during idle periods

o Remove excess moisture and particles from food products before they’re fried.

o Maintain the proper oil level at all times

o Keep the vat covered minimizing oxidation during idle times and lower the thermostat

o Ensure crumbs and food particles are skimmed away and discarded at least twice daily

(preferably at least once an hour and whenever the facility enters an idle period)

§ Load the baskets with dry ice crystal free product (moisture breaks down the oil)

§ Use a skimmer to remove any floating fried food that is not in a fry basket

§ Remove loose food particles or items immediately before they start to burn. Carbonized food will reduce oil life.

DRAINING THE TANK

1. Turn the thermostat to OFF.

2. Wearing safety apparel (at least face shield and gloves) screw the extended drain pipe into position so

the tank can drain into a safe proper size secondary container

3. To keep the pilot lit, turn the gas valve to PILOT.

4. Direct the drain spout into the container that you want to drain the shortening into.

5. Open the drain valve. The oil will drain into the container. When the container is full or the fryer tank

is empty, close the drain valve. Repeat this step until the vat is empty.

6. If desired, perform the weekly clean-out as described under CLEANING.

7. Once tank is completely empty, add new oil and set thermostat to desired temperature.

Note: It is recommended to conduct a fryer boil out with cleaning compound at least monthly.

Do not leave the fryer unattended during a tank boil out, this boil out solution may foam and over-flow the

vat. If this happens turn the thermostat and gas valve off. Turn the gas valve back on and re-light the fryer,

then resume the boil out after the foam has dissipated.

DAILY FILTERING

Hot oil and hot parts can cause burns.

Use care when operating, cleaning, and servicing the fryer.

• Filter shortening at least once a day. Refer to the instructions provided with your filtering equipment.

• A cold fryer won’t drain properly. Always filter shortening between 250°F and 325°F. The shortening in

the cold zone area may remain hard if the heat is only on for a few minutes. If necessary, use the clean-

out rod to carefully stir the hard shortening to an area above the cold zone where it can melt. Use the

tank brush to help clear sides and tubes of debris. Carefully applying some filtered hot oil with the

brush can aid in better cleaning the vat side walls. Use the crumb scoop to help clean the cold zone

removing any food particles that may accumulate in this area.

• This fryer is designed for efficient filtering of the shortening if a paper cone filter set up, plastic mesh

filter net with handle or a portable power filter system is used as the oil filtering method.

14

CLEANING

Hot oil and hot parts can cause burns.

Use care when operating, cleaning, and servicing the fryer.

Do not use chlorine or sulfate/sulfide cleaners.

GAS FRYER MAINTENANCE & SANITATION CALENDAR

Daily Tasks: Clean your fryer regularly with the tank brush along with a damp cloth, and polish with a soft dry

cloth. If regular cleaning is neglected, grease can burn on and discolorations may form. Fingerprints are

sometimes a problem on highly polished surfaces of stainless steel. They can be minimized by applying a

cleaner that will leave a thin oily or waxy film.

• Clean all exterior surfaces of your fryer at least once daily.

• Use a damp cloth with warm water and a mild soap or detergent.

• Remove discolorations by washing with any detergent or soap and water. Use a self-soaping, non-

metallic scouring pad for particularly stubborn grime and discolored surfaces.

• Always rub with the grain of the stainless steel or other metallic finish.

• Do not use a metallic scoring pad or harsh cleaners.

1. Empty tank into separate approved hot oil storage vessel while filtering the oil at about 275°F (135°C)

2. Clean the crumbs out of the cold zone and off the wall

3. Use brush and clean cloth to clean between the tube burners & remove all debris from the tank walls

4. Carefully refill the fry tank with the oil after testing it using a color tube or strip – use fresh oil when the

testing indicates that it is time to discard the old oil – otherwise the same oil refills the fry vat (top off

with fresh oil as needed.)

5. Clean and sanitize the area around the fryer

6. Wash the basket hanger (if it’s removable) or wipe the basket hanger rods with a cloth if permanent

7. Clean the fry baskets & fryer rack that rests on the tube burner – removing all crumbs & food particles

8. Chart that these event are done nightly & have the shift or general manager evaluate their execution

9. Keep the fryer exterior clean and free of accumulated grease to prevent stubborn stains from forming.

If regular cleaning is neglected, grease will become polymerized as well as get burned on and

discolorations may form.

10. Rinse thoroughly, and then polish with a soft dry cloth. You want the clean tank to be bone dry-

after it’s been cleaned and is dry, refill the tank with oil or wipe it with oil to reduce the risk of

oxidation (rust) occurring even though the vat is made of stainless steel

Weekly Tasks:

1. Clean behind fryer

2. Clean under fryer

3. Clean the sides of the fryer

4. Confirm the fry vat temperature control is accurate and doesn’t need calibration – if it does schedule

this activity with a service technician or QA associate

Monthly Tasks:

1. Perform a fry tank boil out

2. Test fryer warm up time {to be within 2 minutes of the initial warm up time (oil to go from 80° to

275°F)[27°- 135°C]}

3. Check the burner flame for appearance as well as calibration

15

Semi-annual Task:

1. Confirm the high limit safety and pilot thermopile safeties are functional

2. Clean the burner orifices and re-tune

3. Run a burner test- [confirm the gas consumption is with-in 2% of the original value at time of

commissioning]

4. Inspect the burner baffles for overall condition and thickness – replace if worn, thin, deformed or out of

position.

5. Have the unit inspected by a factory trained service technician for over-all state of repair

6. Inspect the safety apparel and other accessories including fry baskets for overall state of repair

• If any issues of excessive wear or performance are found replace that element

• Validate the calibration of the thermometer used to calibrate the thermostat

• Use clean-out rod to clear drain {run a drain time test (should be within 10 seconds of

commissioning value)}

7. Record the measured evaluation test results for future reference and to see deviation over time

8. Confirm the fry time, fry oil temperature after the batch is finished and lifted from the oil and recovery

time to return to 350°F – this should be the same or within 10 seconds for each test

BOIL OUT PROCEDURE

Weekly or as required (a boil out frequency of no less than monthly is strongly suggested):

1. Drain the tank as described under DRAINING THE TANK.

2. Once the shortening has been drained, flush out scraps and sediment with a small amount of warm

shortening, using tank brush. Allow the tank to drain thoroughly.

3. Close the drain valve and fill tank water. Use a low foaming cleaner/degreaser to clean the fry tank.

Follow the instructions on the side of the package. Do not use chlorine or sulfate/sulfide cleaners.

Commercial Fryer Boil Out powder is suggested

4. Add commercial boil-out solution. [Solution height is between the MIN and MAX embossed tank

levels].

5. Set thermostat to the temperature recommended for the solution being used. Do not exceed 210°F.

Allow solution to simmer for about 15 to 20 minutes.

6. Drain the cleaning solution from the tank.

7. Close the drain valve and refill the tank with water. Add 1 cup (1/4 L) of vinegar or mild citric acid

solution to neutralize alkaline left by the cleaner. Solution level must be between the MIN and MAX

level on the fryer tank.

8. Bring the solution to a simmer, turn the thermostat off. Allow to stand for a few minutes.

9. Drain the tank according to DRAINING THE TANK. Rinse thoroughly with clear, hot water. All traces of

cleaner must be removed. Dry the tank thoroughly.

10. Close the drain valve and add shortening. Follow the FILLING TANK WITH SHORTENING procedure in

this manual. The fryer is now ready for use.

While the vat must be dry before refilling it with oil – do not turn the fryer on to help dry it.

Damage to the vat (distortion) can occur and the equipment warranty becomes void.

16

FLUE VENT INSPECTION & MAINTENANCE

Hot oil and hot parts can cause burns.

Use care when operating, cleaning, and servicing the fryer.

Spilling hot oil or fryer boil out solution or compound can cause severe burns.

Do NOT move a fryer without draining all frying compound and liquid from the tank.

CAUTION: A dirty fry vat or clogged tube burner orifice may negatively impact the finished fried food quality,

the fryer performance and its capacity. It’s recommended that in addition to at least monthly fryer

boil outs that the appliance get a complete preventative maintenance tune up and component

cleaning or replacement {if needed} twice a year. Our trained field service technicians can perform

this tune up if asked to do so. This is NOT a warranty service; it must be paid for.

When the fryer is cool, inspect the flue and its connection semi-annually. Check the flue and clear any

obstructions. If anything is loose or worn, tighten the connection and replace the parts as needed.

SERVICE IN THE USA / CANADA:

Contact the Authorized Service Office. Information is on the Cover Page.

TROUBLESHOOTING CHART & GUIDE

PROBLEM

PROBABLY CAUSE

NO HEAT

Thermostat dial is not turned on

Pilot not lit

Gas supply not turned on

Wire connections loose (call service)

Wires connections need cleaning (call service)

Thermopile failure (call service)

Quick disconnect hose not connected

INSUFFICIENT OR TOO MUCH HEAT:

Thermostat dial not set to desired temperature

High limit tripped (call service)

Temperature probe malfunction (call service)

Burner flame not tuned or baffles are burned out

TANK WILL NOT DRAIN:

Shortening too cold to flow- re-heat it to over 275°F (135°C)

Drain pipe clogged with debris- dislodge with cleanout rod

Ball valve handle is jammed or loose so it won’t open

17

TERMS OF SALE

FOB: THERMA-TEK, 115 ROTARY DRIVE, HAZLETON, PA 18202

INSPECTION: Shipments must be inspected promptly upon receipt. No claims for damaged merchandise or missing parts or

other errors will be recognized unless written notice thereof is given to Therma-Tek Commercial Cooking Equipment

Company within 30 days after shipping date.

RETURNED GOODS: Returned goods are subject to a 15% restocking charge along with any reconditioning charges. Any

authorized product return, must be returned in its original unused and undamaged condition, in its original carton, with all

accessories and user manuals included. A Return Materials Authorization Number (RMA) by Therma-Tek must be granted,

and returned goods must be shipped freight prepaid. Custom units built to buyer specifications may not be returned or

cancelled.

SHIPMENTS: All equipment ships under class 85. FOB: Hazleton, PA 18202

PRODUCT REVISIONS: Therma-Tek Commercial Cooking Equipment Company reserves the right without prior notice to make

changes and revisions in product specifications, design and materials at it discretion and without notice.

PRICES: All prices are subject to change without notice. Prices do not include sales or any other local state tax. All prices are

in U.S. Dollars.

TERMS: Net 30 days subject to Therma-Tek credit department approval. All amounts past due are subject to 1 1⁄2% per

month service charge

LIMITED WARRANTY: TWO (2) YEAR PARTS AND LABOR FOR U.S.

THERMA-TEK LIMITED WARRANTY: The Therma-Tek Commercial Cooking Equipment Company warranty applies to all

equipment that has been unaltered, properly installed and maintained in accordance with national and local codes and in

accordance with the Therma-Tek installation manuals.

Therma-Tek products are warranted to the original purchaser to be free from defects in material and workmanship under

normal use and service for a period of (2) two years from the date of original installation. Equipment must be no older than

two (2) years from date of manufacture to carry the one (2) year parts and labor warranty. Equipment is not warranted when

used in a non-commercial location. Porcelain items are excluded from this warranty. Parts wear is not considered a defect.

Faucets, cast iron parts and glass items are warranted for 90 days. This warranty does not apply to equipment damaged,

altered or abused accidentally or intentionally, modified by unqualified service personnel or with missing or altered serial

name plates. Therma-Tek agrees to repair or replace defective parts (with normal shipping charges) due to flaws in material

or workmanship during the warranty period. Labor to repair or replace defective parts shall be warranted when and only

performed by an authorized Therma-Tek service agency. Travel over 50 miles, holiday or overtime labor charges are not

covered.

Any use of any third-party or non Therma-Tek replacement parts will void the warranty

Any Therma-Tek Commercial Cooking Equipment Company product purchased, shipped or installed out of the 48 contiguous

U.S. states is limited to a one (1) year parts only warranty. Replacement parts are F.O.B. Therma-Tek, Hazleton, Pennsylvania

18202.

Proper installation, initial check out, air shutter adjustments, or normal maintenance such as lubrication, adjustment or

calibration of controls is the responsibility of the dealer, owner/user or installing contractor and is not covered by this

warranty.

© 2019 Therma-Tek Commercial Cooking Equipment Company, A Division of TEKMA Corporation, Miami, Florida 33147

18

SPECIFICATION & COMMERCIAL DUTY 3RD PARTY APPROVALS

DIMENSION

Model

Width (in)

Depth (in)

Height (in)

Gas Connection (in)

Total BTU/hr

A

B

C

D

E

F

G

H

I

3 Tube Burner N&L

15.5

14.0

30.3

14.0

47.2

34.7

6.0

7.0

4.2

90,000

4 Tube Burner N&L

15.5

14.0

30.3

14.0

47.2

34.7

6.0

7.0

4.2

120,000

5 Tube Burner N&L

21.0

18.0

30.3

14.0

47.2

34.7

6.0

7.0

4.2

150,000

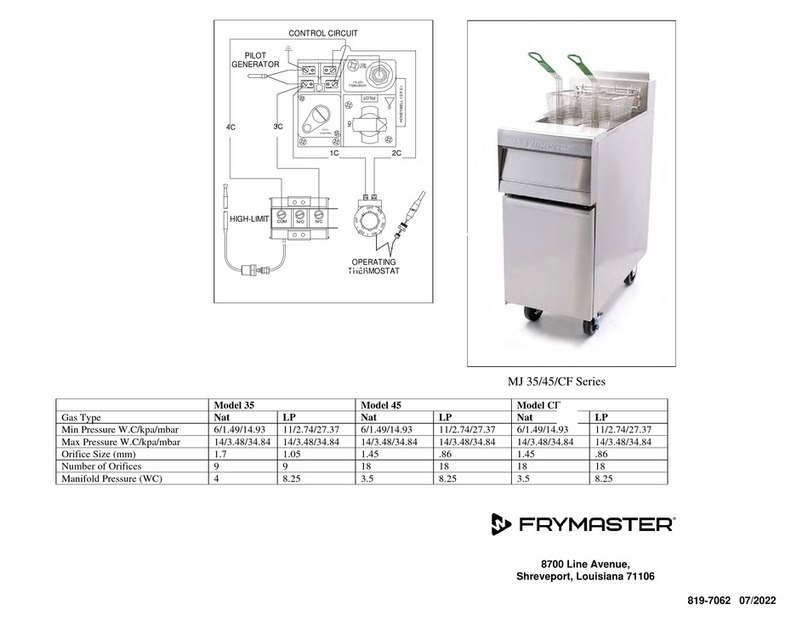

GAS SUPPLY AND BURNER INFORMATION

Supply pressure should be at minimum of 4" W.C. for natural gas or 10" W.C. for propane. The fryer comes with ¾” NPT male

connector on a ½” pipe, allowing you to connect with either ¾” or ½” NPT female connector.

Model

Burners

Gas

Type

Manifold

Pressure

Number

of heat tube

Rate Each

BTUs / Hour

Total Rate

BTUs / Hour

Orifice

Size

3 Tube Burner

Main

Natural

4" W.C.

3

30,000

90,000

#40

Propane

10" W.C.

3

30,000

90,000

#52

4 Tube Burner

Main

Natural

4" W.C.

4

30,000

120,000

#40

Propane

10" W.C.

4

30,000

120,000

#52

5 Tube Burner

Main

Natural

4" W.C.

5

30,000

150,000

#40

Propane

10" W.C.

5

30,000

150,000

#52

* Minimum supply pressure is 4" W.C. for natural gas and 10" W.C. for propane.

** Orifice sizes are for units installed at altitudes between 0 and 2000 feet above sea level.

Note, it is recommended that each burner require its own restricting orifice.

Commercial Duty 3rd Party Approvals:

Conforms to ANSI STD Z83. 11-2016,

Certified to CSA STD 1.8-2016

Conforms to NSF/ANSI Std.4

5004906

5004906

19

DIAGRAMS, EXPLODED VIEWS

EXPLODED VIEW With Replacement/Accessory Part Numbers

1. Gas Parts for Fryer ( 5 tube shown)

Key

Part Number

Qty

Description

1

Part of 14031A

1

Knob, for thermostat

2

16031A

1

Thermostat, High Limit 450 oF Safety,

3

14031A

1

Mili-volt Thermostat for Fryer , Regulates Temperature 200 ~ 400 oF

4

1

Adaptor , 1/2" to 3/4"

5

13031A

1

Safety thermopile 18” for Polit

6

12011A

1

Pilot for Natural Gas

12021A

1

Pilot for Liquid Propane

7

12041A

1

Sylphon Tubing, ¼” for Thermopile

8

11011A

1

Mili-volt Combination valve for Natural Gas

11021A

1

Mili-volt Combination valve for Liquid Propane

9

20031A

ea

Burner, Fryer

10

21011A

ea

Orifice # 40 , for Natural Gas

21021A

ea

Orifice # 52 , for liquid Propane

11

10061A

1

Gas Supply Piping 3 - burner Manifold

10062A

1

Gas Supply Piping 4 - burner Manifold

10063A

1

Gas Supply Piping 5 - burner Manifold

This manual suits for next models

2

Table of contents

Other Therma-tek Fryer manuals

Popular Fryer manuals by other brands

Philips

Philips Cucina HD6151 manual

Midea

Midea MF-TN35D2 instruction manual

Henny Penny

Henny Penny KFC Velocity Series Service manual

BRAYER

BRAYER BR2831 instruction manual

Giles & Posner

Giles & Posner GBF-35 Banked Operation & service manual

Superior

Superior 301HLDS Series Assembly, installation and operation instructions