THERMACUT EX-TRAFIRE 125HD User manual

Plasma Cutting System

Operating Instructions – EX-6-902-001/N-21611 – CE

Revision 1, 15th June, 2023

EN - 2

EX-TRAFIRE®125HD

Table of contents

1 Identification.............................................................. EN-5

1.1 Marking............................................................................................ EN-5

1.2 Identification plate ......................................................................... EN-5

1.3 Signs and symbols used................................................................ EN-5

1.4 Classification of the warnings....................................................... EN-6

2 Safety ......................................................................... EN-6

2.1 Designated use............................................................................... EN-6

2.2 Obligations of the operator.......................................................... EN-7

2.3 Warning and notice signs.............................................................. EN-7

2.4 Product-specific safety instructions.............................................. EN-7

2.5 Safety instructions for the electrical power supply .................... EN-8

2.6 Safety instructions for plasma cutting.......................................... EN-8

2.7 Personal protective equipment .................................................... EN-8

2.8 Emergency information................................................................. EN-8

3 Scope of delivery ....................................................... EN-9

4 Product description..................................................EN-10

4.1 Assembly and use ........................................................................ EN-10

4.2 Technical data............................................................................... EN-11

4.3 Technical data for cutting torches FHT-EX®125TTH and

FHT-EX®125TTM........................................................................... EN-12

5 Transport and positioning........................................EN-14

6 Setting up the power supply ...................................EN-15

6.1 Connecting to the gas supply..................................................... EN-15

6.2 Connecting the work lead........................................................... EN-15

6.3 Connecting the power supply cable ......................................... EN-15

6.4 Connecting the input power plug.............................................. EN-16

6.4.1 Connection to a generator (optional)........................................ EN-16

6.5 Connecting the cutting torch...................................................... EN-17

6.6 Connecting the CNC interface ................................................... EN-17

6.6.1 Setting the DIP switches.............................................................. EN-18

6.6.2 Enabling the external DC coil with an external power supply EN-19

6.6.3 Enabling the external AC coil with an external power supply EN-19

6.6.4 Enabling the industrially insulated module with an

external power supply................................................................. EN-20

6.7 Installing consumables for the hand and machine

cutting torches.............................................................................. EN-20

6.8 Aligning FHT-EX®125TTM machine cutting torch.................... EN-22

7 Operation of the power supply ...............................EN-23

7.1 LCD description............................................................................ EN-24

7.1.1 Setting the parameters................................................................ EN-24

7.1.2 Selecting the cutting mode......................................................... EN-25

7.1.3 Connecting the work lead with the work lead clamp.............. EN-25

7.2 Powering on the machine ........................................................... EN-26

7.3 Manual cutting process ............................................................... EN-26

7.4 Manual grid cutting and gouging process ............................... EN-26

7.5 Cutting........................................................................................... EN-27

7.6 Piercing.......................................................................................... EN-28

7.7 Gouging ........................................................................................ EN-29

EX-TRAFIRE®125HD

EN - 3

7.7.1 Table for FHT-EX®125TT material removal............................... EN-29

7.8 Stopping the cutting process .....................................................EN-30

8 Disconnecting the unit ............................................ EN-30

9 Maintenance and cleaning ...................................... EN-30

9.1 Maintenance and cleaning intervals .......................................... EN-31

10 Faults and troubleshooting ..................................... EN-33

11 Disassembly ............................................................ EN-38

12 Disposal................................................................... EN-39

12.1 Disposal of materials.................................................................... EN-39

12.2 Disposal of consumables ............................................................ EN-39

12.3 Packaging ...................................................................................... EN-39

13 Warranty.................................................................. EN-40

14 Block diagram ......................................................... EN-41

15 Accessories.............................................................. EN-41

16 FHT-EX®125TTH hand cutting torch unit ................. EN-42

17 FHT-EX®125TTH consumables for

hand cutting torch ................................................... EN-43

17.1 FHT-EX®125TTH consumables for hand

cutting torch 45–65 A................................................................... EN-43

17.1.1 Ordering information................................................................... EN-43

17.2 FHT-EX®125TTH consumables for hand

cutting torch 85–125 A................................................................. EN-44

18 FHT-EX®125TTM machine cutting torch unit........... EN-45

18.1 FHT-EX®125TTM machine cutting torch.................................... EN-45

18.2 FHT-EX®125TTSM short machine cutting torch.......................EN-46

19 FHT-EX®125TTM consumables for machine

cutting torch ............................................................ EN-47

19.1 FHT-EX®125TTM consumables for standard machine

cutting torch 45–65 A................................................................... EN-47

19.2 FHT-EX®125TTM consumables for standard

machine cutting torch 85–125 A................................................. EN-48

19.3 FHT-EX®125TTM consumables for SmoothLine

machine cutting torch.................................................................. EN-49

19.3.1 Ordering information................................................................... EN-49

20 Cutting tables for mechanical cutting ..................... EN-51

20.1 45 A cutting, shielded, with compressed air ............................ EN-52

20.2 65 A cutting, shielded, with compressed air ............................ EN-53

20.3 85 A cutting, shielded, with compressed air ............................ EN-54

20.3.1 85 A cutting, shielded, with compressed air ............................ EN-55

20.4 105 A cutting, shielded with compressed air ........................... EN-56

20.4.1 105 A cutting, shielded with compressed air ........................... EN-57

20.5 125 A cutting, shielded, with compressed air .......................... EN-58

EN - 4

EX-TRAFIRE®125HD

20.5.1 125 A cutting, shielded, with compressed air .......................... EN-59

20.6 30–45 A cutting, SmoothLine, shielded, with

compressed air............................................................................. EN-60

20.6.1 30–45 A cutting, SmoothLine, shielded, with

compressed air............................................................................. EN-61

EX-TRAFIRE®125HD 1 Identification

EN - 5

1 Identification

The EX-TRAFIRE®125HD is a portable plasma arc cutting power supply for

mechanized and manual plasma cutting, gouging, and marking. The

EX-TRAFIRE®125HD uses compressed air or nitrogen to cut almost all

conductive metals. The EX-TRAFIRE®125HD may be operated only with

original Thermacut®parts. This documentation describes the

EX-TRAFIRE®125HD cutting power supply only.

When used in this documentation, the term “device” always refers to the

EX-TRAFIRE®125HD cutting power supply.

1.1 Marking

This product fulfills the requirements that apply to the market to which it

has been introduced. Corresponding marking has been affixed to the

product, if required.

1.2 Identification plate

The EX-TRAFIRE®125HD is labeled by means of an identification plate on

the housing located under the machine.

For inquiries, please have at hand the type and number of the

EX-TRAFIRE®125HD per the identification plate.

1.3 Signs and symbols used

The following signs and symbols are used:

Fig. 1 EX-TRAFIRE®125HD identification plate

General instructions.

Action(s) to be carried out in succession.

Lists.

Cross-reference symbol refers to detailed, supplementary or further

information.

Caption, item description.

1

A

EN - 6

2Safety EX-TRAFIRE®125HD

1.4 Classification of the warnings

The warnings are divided into four different categories and are indicated

prior to potentially dangerous work steps. The following signal words are

used depending on the type of hazard:

2Safety

This chapter warns of hazards that should be kept in mind to operate the

product safely. Non-observance of the safety instructions may result in risks

to the life and health of personnel, environmental damage, or material

damage.

Observe the document entitled “Safety Instructions”.

2.1 Designated use

The EX-TRAFIRE®125HD may be used only for the purpose and manner

described. It is used only for the generation and control of the output

current required for plasma cutting, gouging, and marking. Any other use

is considered improper. Unauthorized modifications or changes to

enhance the performance are not permitted.

Do not exceed the maximum load data as defined by the document

supplied. Overloads lead to destruction.

Do not make any modifications or changes to this product.

Do not use the EX-TRAFIRE®125HD to thaw pipes.

Do not use or store the EX-TRAFIRE®125HD outdoors where it is wet.

DANGER

Describes an imminent threatening danger. If not avoided, it may cause

severe injury or death.

WARNING

Describes a potentially dangerous situation. If not avoided, this may

result in serious injury or death.

CAUTION

Describes a potentially harmful situation. If not avoided, this may result in

slight or minor injury.

NOTICE

Describes the risk of impairing work results or material damage and

indicates irreparable damage to the device or equipment.

EX-TRAFIRE®125HD 2Safety

EN - 7

2.2 Obligations of the operator

Ensure that only qualified personnel are permitted to work on the

EX-TRAFIRE®125HD.

Authorized personnel are:

— those who are familiar with the basic regulations on occupational

safety and accident prevention;

— those who have been instructed on how to handle the

EX-TRAFIRE®125HD;

— those who have read and understood these operating instructions;

— those who have been trained accordingly;

— those who are able to recognize possible risks because of their

special training, knowledge and experience.

Keep untrained persons out of the work area.

Each time the EX-TRAFIRE®125HD’s cover plates are opened, have

Thermacut®or another authorized specialist perform a safety inspection

in accordance with DIN IEC 60974 Part 4: “Periodic inspection and

testing”.

The EX-TRAFIRE®125HD can produce electromagnetic fields that could

impact the proper function of cardiac pacemakers and implanted

defibrillators.

Do not use the EX-TRAFIRE®125HD if you have a pacemaker or an

implanted defibrillator.

This Class A cutting device is not intended for use in residential areas with

a public low-voltage power supply system. It can potentially be difficult to

guarantee electromagnetic compatibility in these areas due to both

conducted and emitted interference.

The EX-TRAFIRE®125HD may be used only in industrial zones according

to DIN EN 61000-6-3.

2.3 Warning and notice signs

The following warning, notice and mandatory signs can be found on the

product:

These markings must always be legible. They may not be covered,

obscured, painted over, or removed.

2.4 Product-specific safety instructions

Do not use or store the EX-TRAFIRE®125HD outdoors where it is wet.

Do not operate the EX-TRAFIRE®125HD if the housing is open.

Read and observe the operating instructions.

EN - 8

2Safety EX-TRAFIRE®125HD

2.5 Safety instructions for the electrical power supply

Ensure that the input power cable is not damaged, for example, by

being driven over, crushed, or torn.

Check the input power cable for damage and wear at regular intervals.

If it is necessary to replace the input power cable, only models indicated

by the manufacturer may be used.

Only a qualified electrician should carry out work on the input power

cable and the input power plug.

Water protection and mechanical stability must be ensured when

replacing the input power plug of the input power cable.

2.6 Safety instructions for plasma cutting

Plasma cutting may cause damage to the eyes, skin, and hearing. Note

that other hazards may arise when the EX-TRAFIRE®125HD is used with

other cutting components. Therefore, always wear the prescribed

personal protective equipment as defined by local regulations.

All metal vapors, especially lead, cadmium, copper, and beryllium, are

harmful. Ensure sufficient ventilation or extraction. Do not exceed the

current occupational exposure limits (OELs).

To prevent the formation of phosgene gas, rinse workpieces that have

been degreased with chlorinated solvents using clean water. Do not

place degreasing baths containing chlorine in the vicinity of the cutting

area.

Adhere to the general fire protection regulations and remove

flammable materials from the vicinity of the cutting work area prior to

starting work. Provide appropriate fire extinguishing equipment in the

workplace.

2.7 Personal protective equipment

Wear your personal protective equipment (PPE).

Ensure that others in close proximity are also wearing personal

protective equipment.

Personal protective equipment consists of protective clothing, safety

goggles, face protection, ear protectors, protective gloves, and safety

shoes.

2.8 Emergency information

In the event of an emergency, immediately disconnect the following

supplies:

— Electrical power supply

— Gas supply

EX-TRAFIRE®125HD 3 Scope of delivery

EN - 9

3 Scope of delivery

The following components are included in the scope of supply:

—1×EX-TRAFIRE

®125HD cutting power supply

—1×FHT-EX

®125TTH or FHT-EX®125TTM cutting torch

— 1 × work lead incl. work lead clamp

— 1 × operating instructions

— 1 × “Safety Instructions” document

— 1 × “Warranty” document

— 1 × operating instructions for the cutting torch

— 1 × starter kit

Order the equipment parts and consumables separately.

The order data and ID numbers for the equipment parts and

consumables can be found in the product catalog.

For more information about points of contact, consultation, and orders,

visit

www.thermacut.com

.

Although the items delivered are carefully checked and packaged, it is not

possible to fully rule out the risk of transport damage.

Goods-in inspection

Check for order completeness by checking the delivery note.

Check the delivered goods for damage (visual inspection).

Claim process

If goods are damaged, notify the final carrier.

Keep the packaging for possible inspection by the carrier.

Returns

Use original packaging and packing material for returns.

If you have questions concerning the packaging or how to secure the

device, contact your supplier, carrier, or transport company.

EN - 10

4 Product description EX-TRAFIRE®125HD

4 Product description

4.1 Assembly and use

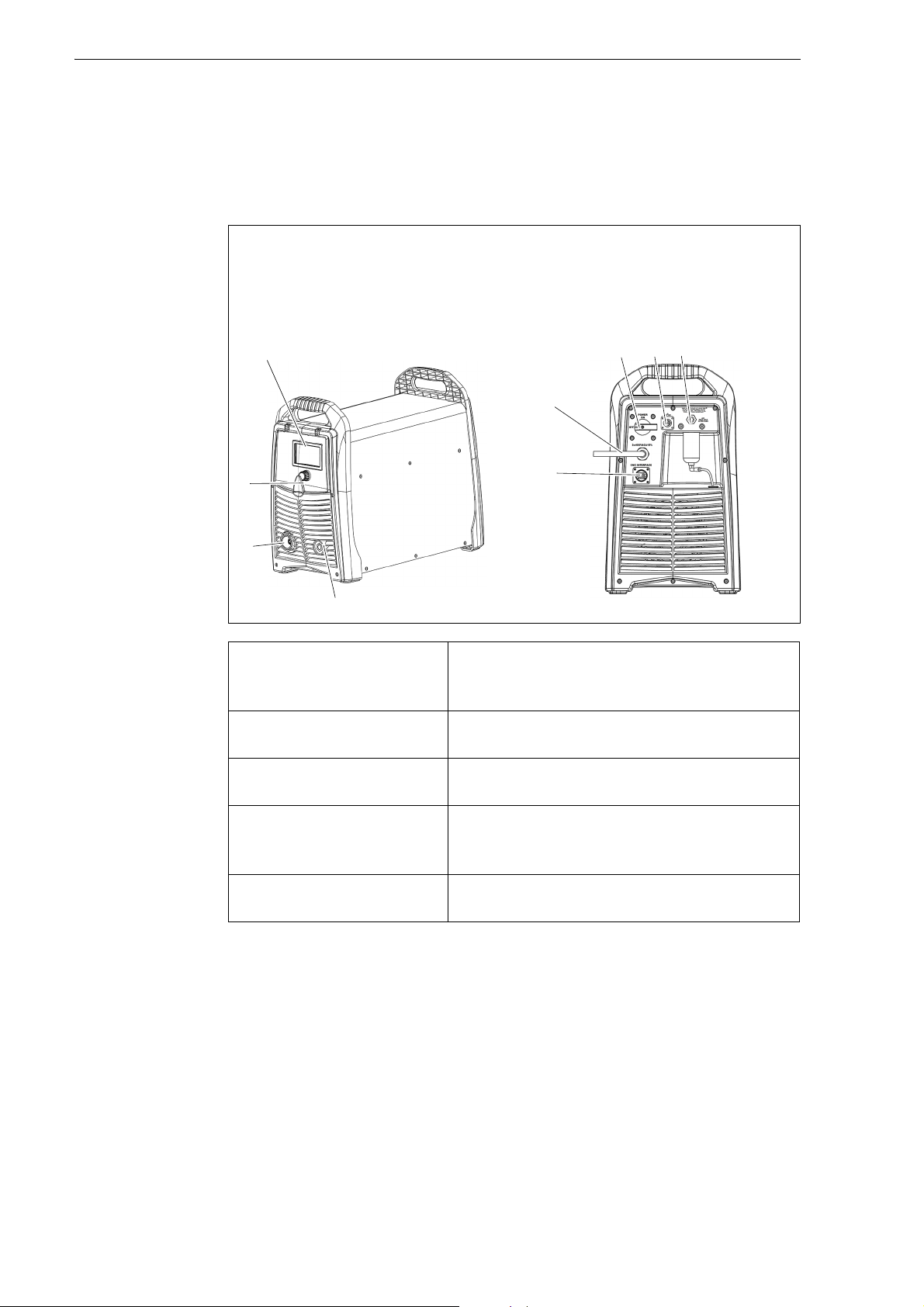

The control elements are located on the control panel. The connections are

on the front and rear of the EX-TRAFIRE®125HD.

Fig. 2 Control elements and connections

ADisplay

B<POWER> switch

COptional BUS interface

DG1/4" gas connection, plug

EOptional CNC interface

FPower cable

GWork lead connection

HTorch connection system (TCS)

IMulti-function button

Digital display (A) Displays the status of the

EX-TRAFIRE®125HD. A fault code is

displayed if an error occurs.

<POWER> switch (B) Used to switch the EX-TRAFIRE®125HD on

and off.

BUS interface (C) For connecting the optional CAN BUS or

RS485/422 BUS.

CNC interface

connection (E)

This optional interface is used to connect the

EX-TRAFIRE®125HD to an optional CNC

cutting table or robot.

Multi-function button (I) For toggling between two menus and

setting the cutting parameters.

D

I

CB

A

F

E

G

H

EX-TRAFIRE®125HD 4 Product description

EN - 11

4.2 Technical data

Table 1 Power supply specifications

CE

Idle voltage (U0)400 V DC

Characteristic curve*

* The curve is defined as output

voltage versus output current

Drooping

Output current (I2)125 A

Nominal output voltage (U2)180 V DC

Output current at 100% duty

cycle (I2)

125 A

Maximum power input 34 kVA

Duty cycle (X*) at 40°C at nominal

conditions (U1, I1, U2, I2)

*X = ton/tbase

ton = time, minutes

tbase = 10 minutes

U1rms

100%

Ambient temperature -10°C to +40°C

Input voltage (U1)400 V AC ±15%

3 PH/50–60 Hz

Rated input current (I1rms) and

effective input current (I1eff) at rated

output power

eff = effective

rms = root mean square

I1rms I1eff

48.9 A 48.9 A

Complies with standards

IEC 60974-1,

IEC 60974-10

Protection type IP23

Tilt angle Up to 15°

Dimensions(L×H×W)[mm]560×400×260

Weight (kg) 35.1

Table 2 Ambient conditions for transport and storage

Ambient temperature -20°C to +55°C

Relative humidity < 50 % at +40°C

< 90 % at +20°C

Table 3 Ambient conditions for operation

Ambient temperature -10°C to +40°C

Relative humidity < 50 % at +40°C

< 90 % at +20°C

Installation above sea level Max. 2000 m

EN - 12

4 Product description EX-TRAFIRE®125HD

4.3 Technical data for cutting torches FHT-EX®125TTH and

FHT-EX®125TTM

FHT-EX®cutting torches are used for manual and mechanical cutting,

gouging, and marking. They use compressed air or nitrogen to cut mild

steels, stainless steels, aluminum, and other electrically conductive metals.

They are connected to the cutting power supply using the Torch

Connection System (TCS).

The values below refer to the torches!

Table 4 Gas data

Permissible gas Compressed air/nitrogen

Max. gas inlet pressure 10 bar

Recommended compressed air

quality

ISO 8573-1 class 1.2.2.

Purity: ≥ 99.99 %

clean, and free from moisture and

oil

Max. flow rate 184 l/min at 5.9 bar

Table 5 Technical data for FHT-EX®125TTH and FHT-EX®125TTM cutting

torches

FHT-EX®125TTH / FHT-EX®125TTM

Recommended cutting

capacity [mm]

40

Max. cutting capacity [mm]60

Separating cut capacity [mm]60

Piercing capacity [mm]25

Permissible ambient

temperature during

operation

-10°C to +40°C

Permissible ambient

temperature during transport

and storage

-25°C to +55°C

Relative humidity < 90 % at +20°C

Sub-menu item Plasma cutting, gouging

Application type Manual and mechanical

Rated current and duty cycle 125 A/100 %

Permissible gas Compressed air/Nitrogen/Argon

Flow rate

85 A/105 A/125 A approx. 175 l/min. at

5.2 bar

65 A approx. 110 l/min. at 4.8 bar

45 A approx. 100 l/min. at 4.8 bar

Flow rate for gouging 65 A–125 A approx. 120 l/min. at 2.7 bar

Maximum inlet pressure 10 bar

(Dynamic) operating pressure 5.2 bar

Gas post-flow period delay ≥ 20 seconds

Type of voltage DC

Protection type for

EX-TRAFIRE®125HD

IP23S (EN 60529)

EX-TRAFIRE®125HD 4 Product description

EN - 13

Connection type TCS (torch connection system) – 13 pin

Standard lengths

(other lengths available upon

request)

5 m/8 m/15 m/23 m

Table 6 Cutting torch weights and cable lengths

Cutting torch Weight and cable lengths

FHT-EX®125TTH

Standard hand cutting torch

5 m / 2.15 kg

8m/3.0kg

15 m /5.0 kg

23 m / 7.1 kg

FHT-EX®125TTM STD-NR

Standard machine cutting torch,

without rack

5 m / 2.35 kg

8m/3.2kg

15 m / 5.2 kg

23 m / 7.3 kg

FHT-EX®125TTSM

Short machine cutting torch

5m/2.0kg

8m/2.9kg

15 m / 4.9 kg

23 m / 7.0 kg

Table 5 Technical data for FHT-EX®125TTH and FHT-EX®125TTM cutting

torches

FHT-EX®125TTH / FHT-EX®125TTM

EN - 14

5 Transport and positioning EX-TRAFIRE®125HD

5 Transport and positioning

WARNING

Risk of injury due to improper transport and installation

Improper transport and installation can cause the EX-TRAFIRE®125HD to

tip or fall over. This may result in serious injury.

• Wear your personal protective equipment.

• Ensure that all supply lines and cables do not encroach into the area in

which employees are working.

•PlacetheEX-TRAFIRE

®125HD on a suitable surface (flat, solid, and dry)

on which it will not topple over, taking into account the max. tilt angle

of 15°.

• Note the weight of the EX-TRAFIRE®125HD when lifting it.

4.2 Technical data on page EN-11

• Use an appropriate lifting tool with load handling equipment for

transporting and installing the EX-TRAFIRE®125HD.

• Avoid abrupt lifting and setting down.

• Do not lift the EX-TRAFIRE®125HD over individuals or other devices.

• Use the attachment points provided.

NOTICE

Risk of material damage due to improper transport and installation

Improper transport or installation can cause the EX-TRAFIRE®125HD to

tip or fall over. This can result in material damage and irreparable

damage.

• Protect the EX-TRAFIRE®125HD against weather conditions, such as

rain and direct sunlight.

• Protect the EX-TRAFIRE®125HD from spatter when cutting.

• Protect the EX-TRAFIRE®125HD from direct exposure to sparks when

grinding.

•UsetheEX-TRAFIRE

®125HD only in dry, clean, and well-ventilated

rooms.

• Maintain a minimum distance of 1 m from the wall when positioning

the EX-TRAFIRE®125HD to ensure that it has sufficient ventilation.

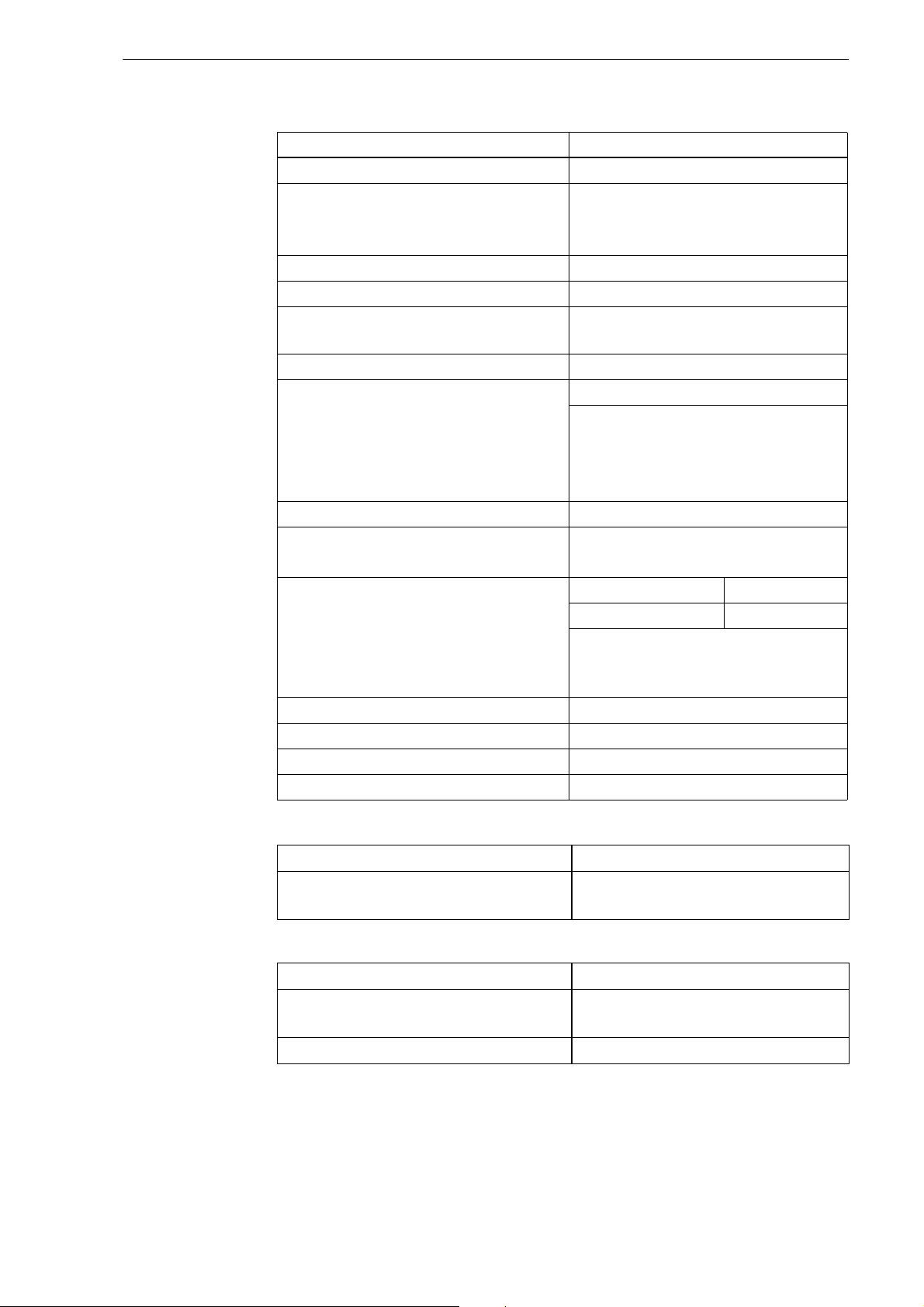

When positioning the

EX-TRAFIRE®125HD, make sure that

the water separator's drain opening

is not covered.

EX-TRAFIRE®125HD 6 Setting up the power supply

EN - 15

6 Setting up the power supply

6.1 Connecting to the gas supply

6.2 Connecting the work lead

6.3 Connecting the power supply cable

Connect the gas hose with an inside

diameter of at least 6 mm to the gas

connection of the

EX-TRAFIRE®125HD.

Connect the work lead to the work

lead connecting socket and secure it

by rotating clockwise.

The power supply should be

connected by a qualified electrician.

L1 -> brown (U)

L2 -> black (V)

L3 -> gray (W)

PE grounding -> green-yellow

Table 7 Recommended cable extensions

Input voltage Wire cross-sections Length

400 V AC/3 phases 6mm

2Up to 15 m

6mm

215–45 m

Brown

Green-yellow

Black

Gray

EN - 16

6 Setting up the power supply EX-TRAFIRE®125HD

6.4 Connecting the input power plug

Note the safety instructions.

2.5 Safety instructions for the electrical power supply on page EN-8

For the input voltage and the fuse protection, please refer to:

4.2 Technical data on page EN-11

If necessary, have a qualified electrician connect the input power cable

extension in accordance with local regulations.

Ensure that the power supply is adequately protected by a safety switch.

Insert the input power plug of the power cable into the corresponding

socket.

6.4.1 Connection to a generator (optional)

Set the generator to three-phase alternating current.

Plug the input power plug into the socket.

Set the motor rating as shown in the following table.

WARNING

Electric shock due to improperly installed electrical power supply

If the electrical power supply and grounding are improperly installed,

fatal electric shock may occur.

• If you want to operate the EX-TRAFIRE®125HD in a very humid

environment or on conductive material, install a ground fault circuit

interrupter (GFCI) in the power supply.

• Use a slow-blow GFCI fuse.

• Protect the power supply line to the EX-TRAFIRE®125HD with suitable

fuses that comply with regulations.

• Ground the EX-TRAFIRE®125HD according to the applicable

regulations.

• Do not ground the EX-TRAFIRE®125HD together with other devices or

machines.

WARNING

Risk of electric shock due to improperly installed or defective cables

Damaged or improperly installed cables can lead to fatal electric shock.

• Check all live cables and connections for proper installation or

damage.

• Damaged, deformed or worn parts should only be replaced by a

qualified electrician.

WARNING

Risk of injury due to fire

Improper use or connection can result in fire. This may result in serious

injury.

Ensure that the operating voltage specified on the identification plate

is suitable for the input voltage.

Table 8 Connection to a generator

Generator motor rating Output current (I2)Arcvoltage

≥ 30 kW 125 A U2= 180 V DC

EX-TRAFIRE®125HD 6 Setting up the power supply

EN - 17

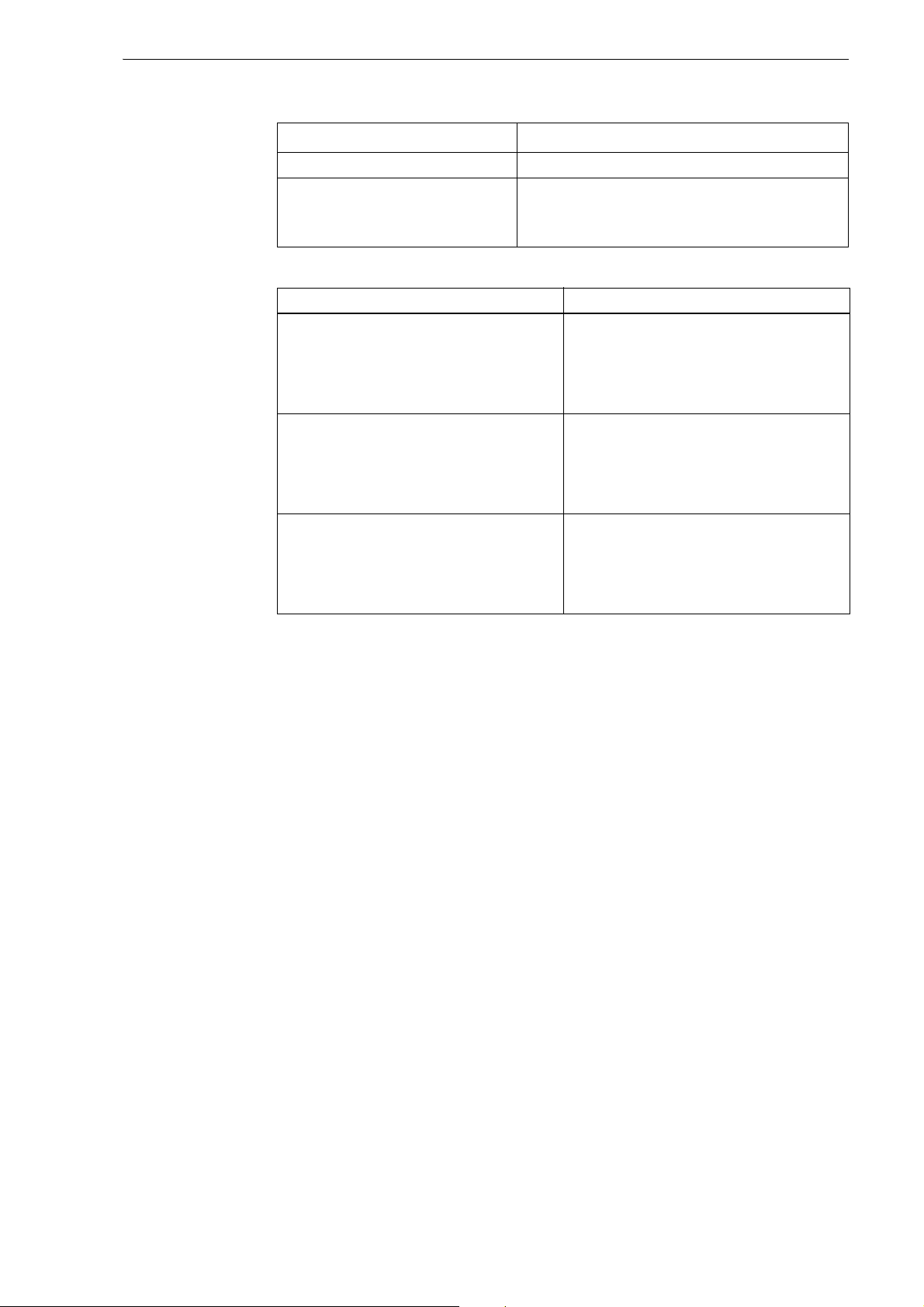

6.5 Connecting the cutting torch

Switch off the power supply.

6.6 Connecting the CNC interface

The CNC interface is on the rear of the EX-TRAFIRE®125HD. Control signals

can be transmitted via the CNC interface. The signal types can be found in

the table. The control elements are located on the control panel. The

connections are on the front and rear of the EX-TRAFIRE®125HD.

4.1 Assembly and use on page EN-10

NOTICE

Risk of material damage if used without TCS Latch with Key

Assembly

The TCS Latch with Key Assembly is important for the proper working of

the machine. If used without, the EX-TRAFIRE®125HD may be irreparably

damaged.

• Do not use the EX-TRAFIRE®125HD without the TCS Latch with Key

assembly installed and properly secured.

1Insert the TCS Latch with Key

Assembly into the TCS socket.

The TCS Latch with Key Assembly

must sit firmly in the TCS socket.

2Push the cutting torch into the TCS

and ensure the Latch with Key

Assembly locks in place.

WARNING

Electric shock due to live parts

Live parts are exposed when the housing is open. This can result in fatal

electric shock.

• Set the <POWER> switch to <OFF> and disconnect the input power

plug before opening the housing.

EN - 18

6 Setting up the power supply EX-TRAFIRE®125HD

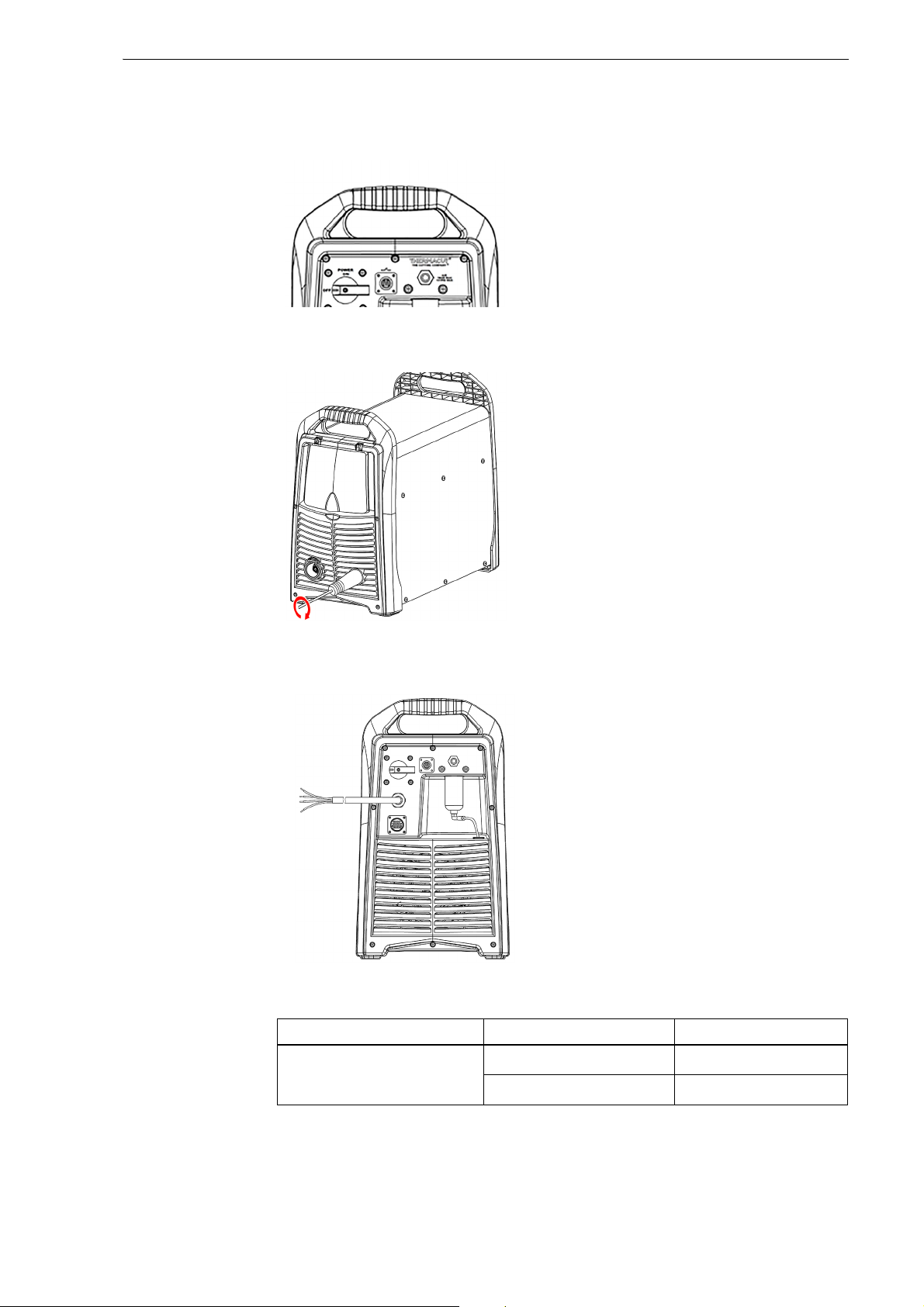

6.6.1 Setting the DIP switches

The DIP switches are preset to 50:1.

1The housing must be opened only by a qualified electrician.

2The DIP switches must be set only by a qualified electrician.

Fig. 4 DIP switch settings on page EN-18

3The housing must be closed only by a qualified electrician.

4Have a safety inspection performed in accordance with DIN IEC 60974

Part 4: “Periodic inspection and testing” by Thermacut®or another

authorized specialist.

Fig. 3 Pin assignment for CNC interface

Table 9 Pin assignment for CNC interface

Signal START

Start plasma

cutting

Arc

Start feeding

PE Voltage divider

Type Input Output PE Output

Notice Open by

default.

Requires

potential-free

contact to

close.

Open by

default.

Potential-free

with max.

capacity of:

120 V AC/1 A

Reduced arc

signal:

20:1

21.1:1

30:1

40:1

50:1

(supplies max.

10 V)

PIN 3, 4 12, 14 13 6 (+), 5 (−)

Internal

cable color

Yellow, yellow White, white Green/

yellow

6 (red), 5 (white)

4

12

6

14

35

13

Fig. 4 DIP switch settings

EX-TRAFIRE®125HD 6 Setting up the power supply

EN - 19

6.6.2 Enabling the external DC coil with an external power supply

For 24 V DC, use a 1N4007 diode.

6.6.3 Enabling the external AC coil with an external power supply

Fig. 5 Enable the external DC coil with an external power supply.

24 V DC

Use diode

1N4007 if the

voltage is

24 V DC.

Fig. 6 Enable the external AC coil with an external power supply.

24 V AC

230 V AC

EN - 20

6 Setting up the power supply EX-TRAFIRE®125HD

6.6.4 Enabling the industrially insulated module with an

external power supply

Industrial insulated user module with 24 V DC power supply.

6.7 Installing consumables for the hand and machine

cutting torches

The procedure shown below applies to both the equipment of hand

and machine cutting torch.

1Switch off the EX-TRAFIRE®125HD.

2Remove the interface cover.

3Connect the interface cable with the

cutting power supply.

Insulated

module

WARNING

Risk of injury due to unexpected ignition of the plasma arc

Hand cutting torch:

When the input powerplug is plugged in, the plasma arc ignites

immediately when the torch trigger is pressed. Individuals can be

seriously injured if the arc ignites unexpectedly.

Machine cutting torch:

When the input power plug is plugged in, the plasma arc ignites

immediately when the CNC start signal is ON. Individuals can be

seriously injured if the arc ignites unexpectedly.

• Hold the tip of the torch away from you.

• Do not hold the workpiece to be cut tightly and keep your hands away

from the cutting surface.

• Do not point the cutting torch at yourself or other individuals.

• Wear your personal protective equipment.

Table of contents

Other THERMACUT Welding System manuals

Popular Welding System manuals by other brands

Telwin

Telwin INVERSPOTTER 13500 SMART instruction manual

Lincoln Electric

Lincoln Electric 12427 Operator's manual

Miller Electric

Miller Electric SCP-200C owner's manual

Telwin

Telwin TECNICA 190 TIG-MMA DC LIFT VRD manual

Paton

Paton PRO-160 Data sheet and operating manual

Sel

Sel WF 230 Classic instruction manual