ThermaFlo OzSaver 4000 User manual

4000

Thermaflo 88-B Industry Ave. Springfield, MA 11 4

8 -8484-CFC

TABLE OF CONTENTS

INTRODUCTION l

READ ME FIRST 2

SAFETY 4

RECOVERY

Liquid and Vapo Recove y Method 5

Push-Pull Liquid and Vapo Recove y Method 7

CHARGING OPERATION WITH HOT VAPOR 9

SELF-EVACUATION 10

SUB-COOL OPERATION 11

PURGING NON-CONDENSABLES (AIR) II

SWITCHING FROM ONE REFRIGERANT TO ANOTHER 11

TROUBLESHOOTING 12

SCHEMATICS 14

ILLUSTRATIONS

Figu e 1 OZsave ™¿¡^Cont ols 3

Figu e 2 Liquid and Vapo Recove y Method 6

Figu e 3 Push-Pull Liquid and Vapo Recove y Method 8

Figu e 4 Cha ging With Hot Vapo 9

UNITED STATES PATENT: 4766733

UNITED STATES PATENT: 4809515

UNITED STATES PATENT: 4981020

Other US and oreign Patents Pending

MODEL 4000

Theimaflo* 3640 Main Street • Springfield, MA 01107

THERMA LG is division of American THERMA LO Corporation Mar 1998

2436A0*

INTRODUCTION

Dea Custome :

THERMAFLO would like to thank you fo selecting the OZsave ™ Recove y & Cha ging Unit.

THERMAFLO is dedicated to designing, p oducing and ma keting the best p oducts in the indust y. We,

p oduce a full line of Recove y/Recycling & Cha ging equipment fo applications in:

• HVAC • appliance • automotive • automotive salvage

• gene al salvage • la ge indust ials • OEMS • mass & p ivate t anspo tation

• ef ige ated t ucks • building maintenance • institutions • packaging & p ocessing

You OZsave ™ unit, like all THERMAFLO p oducts, has gone th ough extensive testing to assu e

the highest deg ee of quality. THERMAFLO backs up this claim of quality with a comp ehensive

se vice p og am and a full wa anty.

The people at THERMAFLO have put a g eat deal of time, effo t and p ide in p oducing this p oduct.

We believe that ou continued diligence will assu e bette p oducts, se vices and satisfied custome s.

Thanks again fo you confidence in THERMAFLO!

Since ely,

m \.

Michael C.D. Fioretti, Jr.

President

2436AI-

READ ME FIRST

THERMAFLO's OZsave Recove y & Cha ging unit is a hyb id pumping system capable of

moving ef ige ant liquid and gas f om:

* ef ige ant system being se viced to a ecove y tank "

* ecove y tank to system being se viced

* new tank to a system being se viced

* one unit to anothe .

The hea t of the OZsave ™/^ unit is a comp esso designed to ope ate without oil in its c ankcase.

Lub ication is a function of the mate ials of const uction and the oil mist associated with the flow of

ef ige ant gas th ough the unit.

The comp esso is a patented di ect d ive open style unit which can ope ate f om 20 inches of HG to 125

psig. of inlet p essu e. The maximum discha ge p essu e switch is set at 425 psig. When 425 psig is

exceeded the unit will shut down.

Since the OZsave ™&/tZ unit has a di ect d ive, oil-less comp esso the e is not a conce n with ove heating

o ha ming the comp esso du ing extended ope ation. In o de to maximize the ecove y p ocess the

OZsave ™li^ l unit will not shut off automatically at a given low p essu e - the technician MUST shut off

the unit. This featu e allows the technician the ability to pull down the system being se viced to the desi ed

vacuum which, as a minimum, should be those equi ed by EPA.

The OZsave ™Ljl unit is App oved toUL 1963 by Unde w ite s Labo ato ies, to ecove ef ige ant

f om any ef ige ant system which uses ef ige ants 12,22,500,502 o 134a.

The OZsave ™jyi unit is Rated in Acco dance with ARI740-91..

Special Featu es

Indicato Lights - You OZsave ™^/, ecove y unit is equipped with High P essu e and Vapo indicating

lights.

The Vapo light indicates whethe the OZsave unit is ecove ing liquid o vapo ef ige ant. If the

OZsave ™^ unit is ecove ing vapo the Vapo light will be illuminated.

The High p essu e light wo ks in conjunction with the high p essu e shutoff. If the discha ge p essu e

eaches 425 psig., the OZsave ™«^ unit will shut off and the High P essu e light will be illuminated.

OZsave ™ LjU Inlet Filte

THERMAFLO equi es that a THERMAFLO filte pa t # ALF-052, standa d 052 o 053 filte d ie ,o

equivalent be used on the inlet side in o de to p otect the OZsave ™/^, unit f om pa ticulate damage.

If, du ing wa anty inspection, it has been dete mined that a filte was not used du ing the ope ation,

the OZsave ™£yW, unit wa anty will be voided.

2

2436A2-

OZsaver "fujll Helpful Hints

• If a se vice manifold is being utilized to access the equipment being se viced, the liquid

must be ecove ed fi st.

• When the OZsave ™ Ljll unit is switching f om liquid to vapo ecove y it will make a

epeated "clicking" sound. This is no mal ope ation.

• If the system being se viced does not equi e valve co e dep esso s in the hose, emove

them to accele ate the ecove y ate.

• P io to use, the ecove y tank should be evacuated to 1000 mic ons, using a vacuum

pump to eliminate non-condensables and to accele ate the ecove y p ocess.

• The OZsave ™,/,^ unit has a comp ession atio of 20 to 1 and can pull vacuums of

10 to 20 inches of Hg on a system even when pumping into a ecove y tank with high

p essu es. Howeve , it is possible to pull even deepe vacuums by eplacing the sto age

tank with a newly evacuated sto age tank at the end of the ecove y p ocess.

• If the ecove y tank is pa tially filled with ef ige ant p io to the ecove y ope ation: it

will be necessa y to sub-cool the ecove y tank (Refe to page 11). If the sub-cooling

ope ation is not pe fo med p io to the ecove y ope ation the ecove y ate will be

slowed down.

The illust ations in Figu e la e used in diag ams th oughout this manual to identify items and

featu es of the OZsave HufiL unit.

3

2436A3-

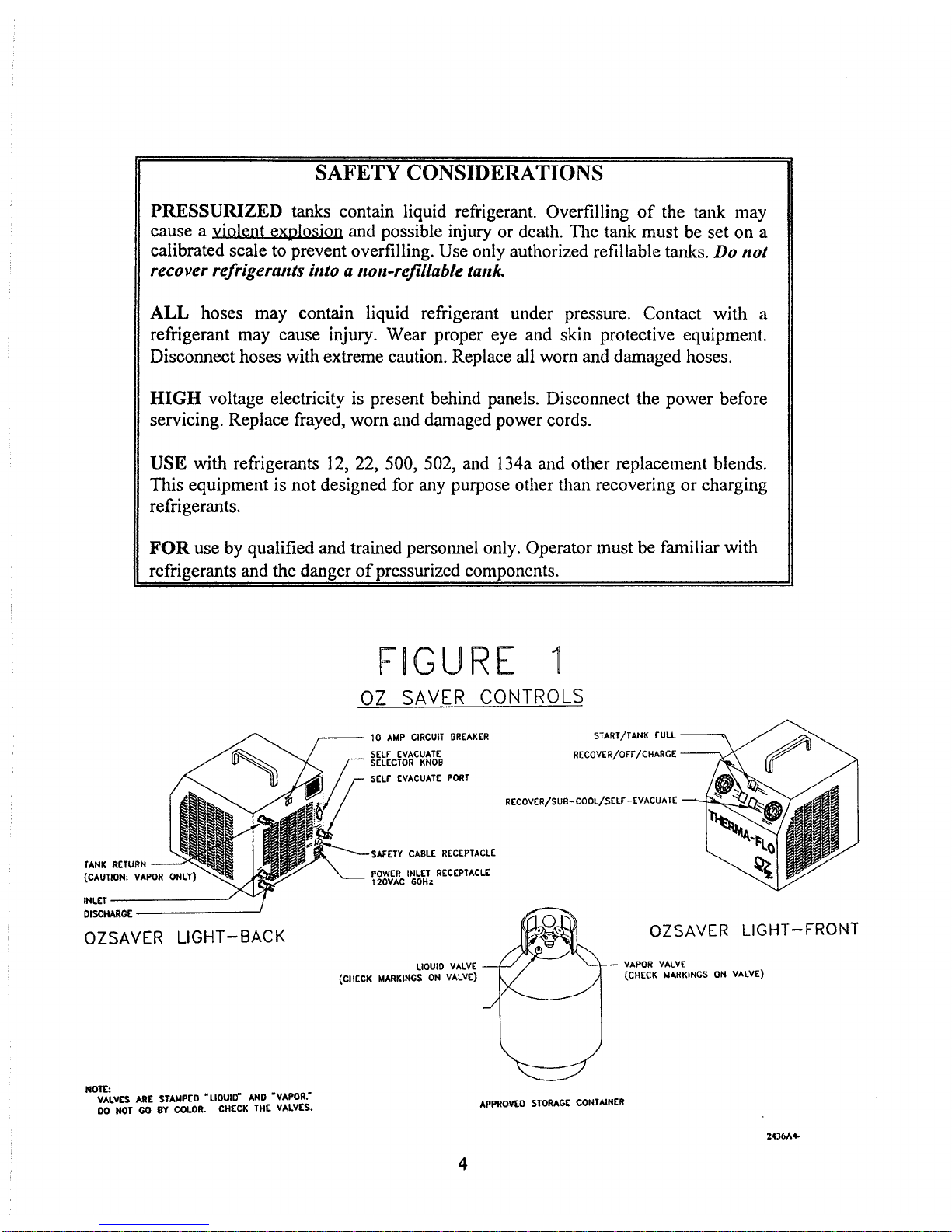

SAFETY CONSIDERATIONS

PRESSURIZED tanks contain liq id refrigerant. Overfilling of the tank may

ca se a violent explosion and possible inj ry or death. The tank m st be set on a

calibrated scale to prevent overfilling. Use only a thorized refiliable tanks. Do not

recover refrigerants into a non refillabte tank.

ALL hoses may contain liq id refrigerant nder press re. Contact with a

refrigerant may ca se inj ry. Wear proper eye and skin protective eq ipment.

Disconnect hoses with extreme ca tion. Replace all worn and damaged hoses.

HIGH voltage electricity is present behind panels. Disconnect the power before

servicing. Replace frayed, worn and damaged power cords.

USE with refrigerants 12, 22, 500, 502, and 134a and other replacement blends.

This eq ipment is not designed for any p rpose other than recovering or charging

refrigerants.

FOR se by q alified and trained personnel only. Operator m st be familiar with

refrigerants and the danger of press rized components.

______________________

TANK RETURN

(CAUTION: VAPOR ONLY)

INLET

DISCHARGE

OZSAVER LIGHT-BACK

NOTE:

VALVES ARE STAMPED "LIQUID" AND “VAPOR.”

DO HOT GO BY COLOR. CHECK THE VALVES.

FIGURE

OZ SAVER CONTROLS

10 AMP CIRCUII BREAKER

SEL EVACUATE

SELECTOR KNOB

SEL EVACUATE PORT

START/TANK FULL

RECOVER/OFF/CHARGE

RECOVER/SUB-COOL/SELF-EVACUATE

SA ETY CABLE RECEPTACLE

POWER INLET RECEPTACLE

120VAC 60Hz

LIQUID VALVE

(CHECK MARKINGS ON VALVE)

OZSAVER LIGHT- RONT

VAPOR VALVE

(CHECK MARKINGS ON VALVE)

APPROVEO STORAGE CONTAINER

24 36 A4«

4

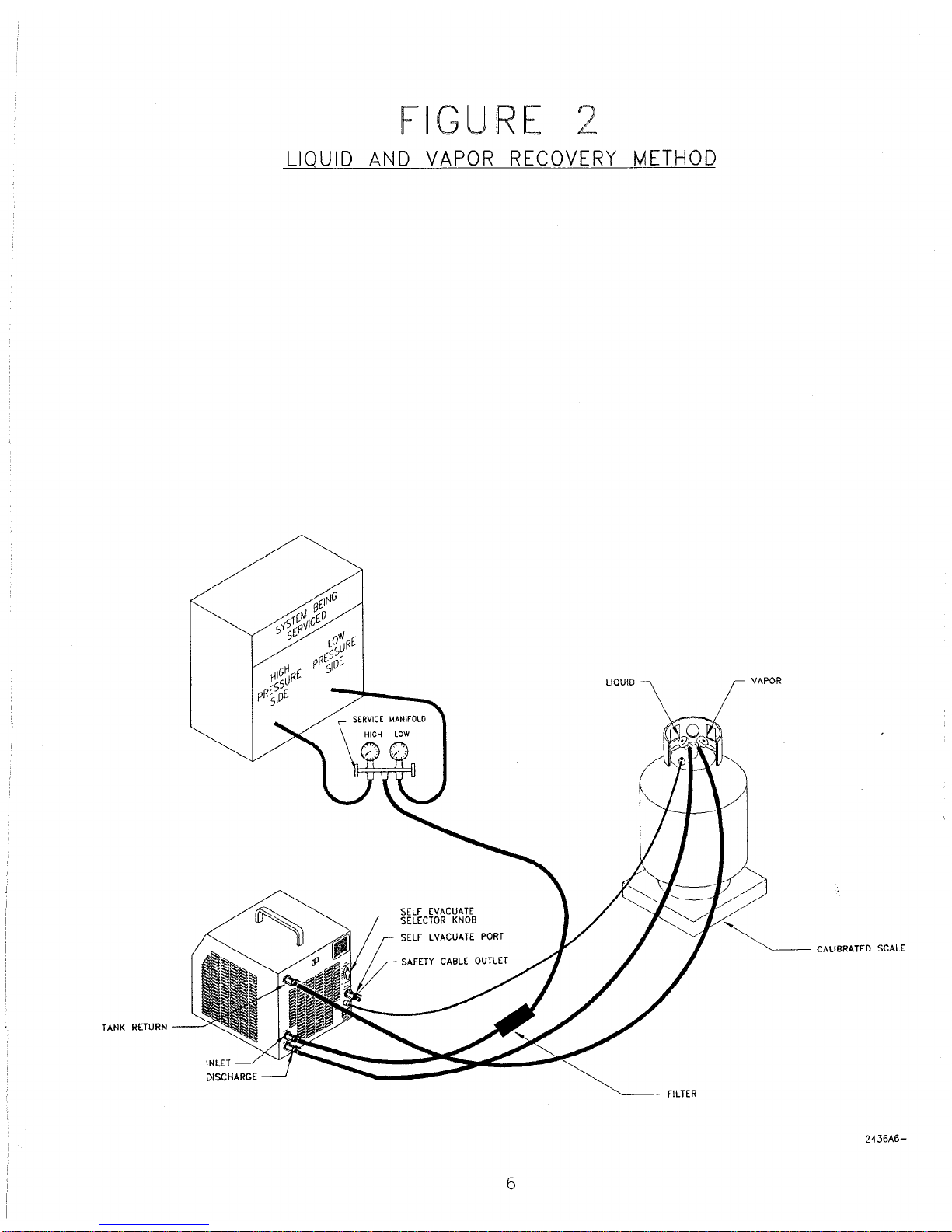

LIQUID AND VAPOR RECOVERY METHOD

SERVICE MANIFOLD REQUIRED

(Refe to Figu e 2)

Before starting this operation, an empty tank m st be located on a calibrated scale. If a partially

filled tank is being sed, a s b-cooling operation m st be performed to improve recovery

performance. See page 11 for s b-cooling instr ctions.

1. PLUG in the power cord to a 110-120 VAC, 15 amp minim m s pply.

2. CONNECT a hose from the INLET port of the OZsaver™ AM nit to the center fitting

of the service manifold. Attention: a filte must be in this line o the wa anty is voided.

3. CONNECT a hose from the HIGH side access port of the system being serviced to the

HIGH side of the service manifold.

4. CONNECT a hose from the LOW side access port of the system being serviced to the

LOW side of the service manifold.

5. CONNECT a hose from the DISCHARGE port of the OZsavei™ JjM nit to the LIQUID

side of the recovery tank.

6. CONNECT a hose from the TANK RETURN port of the OZsaver™ *^ nit to the VAPOR

side of the recovery tank.

7. CONNECT the Safety Cable to the Recovery Tank.

8. OPEN:

HIGH side access valve on the system being serviced,

HIGH side of the service manifold,

DISCHARGE valve on the OZsaver™ nit,

INLET valve on the OZsaver« AM nit,

TANK RETURN valve on the OZsaver™ nit,

LIQUID valve on the tank,

VAPOR valve on the tank.

9. TURN the SELF-EVACUATION selector knob to OZsaver» Jft/ nit to the OFF position.

10. PLACE the RECOVER/SUB-COOL/SELF EVACUATE switch in the RECOVER

position.

11. PLACE the Recover/Charge switch into the Recover position.

12. PRESS the START b tton. The OZsaver™ nit will start r nning.

Once all of the liq id has been recovered from the high side of the system:

13. OPEN:

LOW side access valve on the system being serviced,

LOW side of the service manifold.

Once the recovery process is complete:

14. CLOSE all valves and place the RECOVER/OFF/CHARGE b tton in the OFF position.

15. Use the SELF EVACUATION OPERATION (See Page 10) to self-evac ate the

OZsaver™ nit.

2436A5-

5

FIGURE 2

LIQUID AND VAPOR RECOVERY METHOD

VAPOR

TANK RETURN

FILTER

CALIBRATED SCALE

2436A 6-

6

PUSH-PULL LIQUID AND VAPOR RECOVERY METHOD

(Refe to Figu e 3)

If a partially filled tank is being sed, a s b-cooling operation m st be performed to improve recovery

performance. See page 11 for s b-cooling instr ctions.

1. PLUG in the power cord to a 110-120 VAC 15 amp. minim m s pply.

2. CONNECT a hose from the INLET port of the OZsaver™ A/A nit to the HIGH side access port of

the system being serviced. A filte must be in this line o the wa anty is voided.

3. CONNECT a hose from the SELF EVACUATE port of the OZsaver™ Ay/A nit to the LOW side

access port of the system being serviced.

4. CONNECT a hose from the DISCHARGE port of the OZsaver™ A // nit to the LIQUID side of the

recovery tank.

5. CONNECT a hose from the TANK RETURN port of the OZsaver™ A^A/ nit to the VAPOR side of

the recovery tank.

7. CONNECT the Safety Cable to the Recovery Tank.

8. PLACE the SELF-EVACUATION selector knob in the ON position.

9. OPEN:

HIGH side access valve on the system being serviced,

LOW side access valve on the system being serviced,

SELF EVACUATE valve on the OZsaver™ A /J nit,

TANK RETURN valve on the OZsaver« J f t/ nit,

INLET valve on the OZsaver« .^ nit,

DISCHARGE valve on the OZsaver™ A^J nit,

LIQUID valve on the recovery tank,

VAPOR valve on the recovery tank.

10. PLACE the RECOVER/SUB-COOL/SELF-EVACUATE switch in the RECOVER position.

11. PLACE the RECOVER/OFF/CHARGE switch into the Recover position.

12. PRESS the START b tton.

Once all of the liq id has been recovered:

13. PLACE the SELF EVACUATE selector knob in the OFF position.

The OZsaver™ A ft nit will now be recovering vapor.

Once the vapor recovery process is complete:

14. CLOSE all valves and PLACE the RECOVER/OFF/CHARGE switch into the OFF position.

7

FIGURE 3

PUSH-PULL LIQUID AND VAPOR RECOVERY METHOD

2436A8-

8

CHARGING OPERATION WITH HOT VAPOR

(Refer to Fig re 4)

1. PLUG in the power cord (m st be a 110-120 VAC, 15 amp minim m service).

2. CONNECT a hose from the SELF-EVACUATE port on the OZsaver”Itfi nit to the center port of

the service manifold.

3. CONNECT a hose from the TANK RETURN port on the OZsaver nit to the VAPOR side

of the recovery tank.

4. CONNECT the high side of the service manifold to the high side of the system being serviced.

5. CONNECT the low side of the service manifold to the low side of the system being serviced.

6. TURN the SELF-EVACUATE selector knob to the ON position.

7. OPEN:

HIGH side access valve on the system being serviced,

LOW side access valve on the system being serviced,

LOW side of the service manifold,

SELF-EVACUATE valve on the OZsaver Ml nit,

TANK RETURN valve on the OZsaver Miunit,

VAPOR valve on the recovery tank.

8. CLOSE:

INLET valve on the OZsaver Mi nit,

DISCHARGE valve on the OZsaver Mi nit,

LIQUID valve on the recovery tank,

HIGH side of the service manifold.

9. PLACE the RECOVER/SUB-COOL/SELF-EVACUATE switch into the RECOVER

position.

10. PLACE the RECOVER/OFF/CHARGE switch into the CHARGE position.

11. START the OZsaver™^ nit by pressing the START b tton.

When the charging process is complete:

12. SHUT OFF the OZsaver™^ nit.

13. CLOSE all valves.

FIGURE 4

9

2436A9-

SELF-EVACUATION

1. CLOSE all valves, incl ding tank valves. Make s re safety cable is connected.

If the PUSH-PULL recovery proced re is being sed contin e to step 2 otherwise go

to step 3.

2. REMOVE the hose that is connected between the SELF-EVACUATE port and the

LOW side of the system being serviced.

3. PLACE the RECOVER/SUB-COOL/SELF-EVACUATE switch into the SUB-COOL

position.

4. PLACE the RECOVER/OFF/CHARGE switch into the Recover position.

5. OPEN:

TANK RETURN valve on the OZsa^pr nit,

DISCHARGE valve on the OZsaver SiAl nit,

LIQUID valve on the recovery tank.

6. PRESS the START b tton.

Allow the OZsaver™&i/i nit to r n ntil the s ction press re ga ge reads 10 inches of Hg

or lower, then:

7. CLOSE:

LIQUID VALVE ON THE RECOVERY TANK,

DISCHARGE valve on the OZsaver ¿¡dJ, nit,

TANK RETURN valve on the OZsaver lufl nit.

8. TURN the OZsaver™IjM nit off by placing the RECOVER/OFF/CHARGE switch in

the OFF position.

9. DISCONNECT the tank ret rn hose from the TANK RETURN port and

CONNECT it to the SELF-EVACUATE DISCHARGE port.

10. TURN the SELF-EVACUATE selector knob to the ON position.

11. OPEN:

SELF-EVACUATE valve on the OZsaver nit,

VAPOR side of the recovery tank, TM

DISCHARGE valve on theOZsaver nit.

12. PLACE the RECOVER/SUB-COOL/SELF-EVACUATE switch into the SELF-

EVACUATE position.

13. PLACE the RECOVER/OFF/CHARGE switch into the Recover position.

14. START the OZsaver™iyi nit by pressing the START b tton.

15. ALLOW the OZsaver™/^, nit to r n ntil the s ction press re ga ge reads 10 inches

of Hg or lower.

16. CLOSE all valves.

17. TURN the OZsaver™iWi nit off by placing RECOVER/OFF/CHARGE switch

into the OFF position.

1

2436A10-

SUB-COOL

The S b-cool position on the rocker switch, located on the front of the OZsaver nit

allows the operator to S b-cool the storage tank when the OZsaver nit is connected

per the standard method or when sing a service manifold.

While in the Recovery Mode, move the rocker switch to S b-cool and the OZsaver™

LjkL nit will stop recovering refrigerant from the system being serviced and S b-cool the

storage tank. This is done witho t having to disconnect and reconnect hoses.

When the rocker switch is in the Recover position the OZsaver™JiyU, nit ret rns to the

normal recovery mode. k

The advantages of the S b-cool is that it allows the operator to red ce the press re in the

storage container. This enhances the recovery rates for both liq id and vapor. It also

allows the OZsaver™^ nit to p ll exceptionally low vac ms on the systems being

serviced (15 to 20 inches of Hg or better).

S b-cooling sho ld be done for approximately 5 to 10 min tes or ntil the operator feels

that the press re in the storage tank has been s fficiently red ced.

While the rocker switch is set to S b-cool the s ction press re gage is reading the

press re in the storage container. The longer the OZsaver hfi nit is S b-cooling, the

more the press re will drop. A press re drop of 20 psig. on the gage, from the time the

S b-cool process was beg n, will res lt in a significant increase in the recovery rate.

PURGING NON-CONDENSABLES (AIR)

While in the Recovery mode, se the following proced re to p rge the nit of air:

1. CLOSE the Inlet, Discharge and Tank Ret rn valves.

2. MOVE the rocker switch to Self Evac ate and follow the instr ctions for the Self

Evac ation operation described on page 10 in this man al.

NOTE: If deeper vac ms are req ired, a vac m p mp can be attached to the Self

Evac ate Discharge valve d ring this process.

SWITCHING FROM ONE

REFRIGERANT TO ANOTHER

Whenever the OZsaver nit is sed on two different refrigerants, the Self

Evac ation operation sho ld be sed prior to switching to the new refrigerant. The nit

sho ld then be r n on air in both the Recover and S b-cool modes for 30 seconds each to

p rge any resid al refrigerant. A final Self Evac ation operation sho ld then be

performed to remove the air from the OZsaver L nit.

11 2436AI I-

Model 4000 The maflo OZ Saver

Quick Test

"P eseason Check-out”

Run this test once a yea

O

When the unit seems to un but will not move any ef ige ant.

1. Plug in the powe co d to 110 vac, 15 amp minimum supply.

2. Attach the safety cable to a tank senso o use a The maflo test plug (Pa t # 1997-10).

3. TURN the SELF EVACUATE SELECTOR KNOB to the OFF position.

4. TURN the SELF EVACUATE BALL VALVE to the OFF position,

5. OPEN all (3) othe ball valves.

6. Place both ocke switches into the RECOVER positions and p ess the START button.

7. Unit is now unning.

A. The unit should be sucking in the INLET PORT. YES / NO

CLOSE: Inlet Po t

B. The unit should pull a 28” vacuum on the f ont SUCTION GAUGE. YES / NO

OPEN: Inlet Po t

Place the ocke switch in the SUB-COOL position.

C. The unit should be sucking in the TANK RETURN PORT. YES / NO

CLOSE: Tank Retu n Po t

D. The unit should pull a 28” vacuum on the f ont SUCTION GAUGE. YES / NO

OPEN: Tank Retu n Po t

Place the ocke switch back into the RECOVER position,

E. The unit should be sucking in the INLET PORT again. YES / NO

TURN the unit up-side-down on its handle

F. The unit should be sucking in the TANK RETURN PORT YES / NO

TURN the unit back up ight.

CLOSE: Discha ge Po t

G. The unit should build 150 psi on the f ont DISCHARGE GAUGE

within 30 seconds. YES / NO

Call The maflo custome se vice at 800-848-4232

Fo fu the t ouble-shooting assistiance.

J*.

—0 s

J -0

SrEH-Ow

tow

P8C55URC

SWJCH

I-

»2

i Tank &£

<j>D£q

Solenoid # 1 Solenoid #2 Solenoid #3 Solenoid #4

Liq id Recovery Open at 20

Psigo iess

At Wet

CLOSED OPEN OPEN

Vapor Recovery Same OPEN CLOSED CLOSED

S b-Cool Same CLOSED OPEN CLOSED

Self-Evac OPEN OPEN OPEN OPEN

Table of contents

Popular Test Equipment manuals by other brands

Redtech

Redtech TRAILERteck T05 user manual

Venmar

Venmar AVS Constructo 1.0 HRV user guide

Test Instrument Solutions

Test Instrument Solutions SafetyPAT operating manual

Hanna Instruments

Hanna Instruments HI 38078 instruction manual

Kistler

Kistler 5495C Series instruction manual

Waygate Technologies

Waygate Technologies DM5E Basic quick start guide

StoneL

StoneL DeviceNet CK464002A manual

Seica

Seica RAPID 220 Site preparation guide

Kingfisher

Kingfisher KI7400 Series Training manual

Kurth Electronic

Kurth Electronic CCTS-03 operating manual

SMART

SMART KANAAD SBT XTREME 3G Series user manual

Agilent Technologies

Agilent Technologies BERT Serial Getting started