Thermal Care SF Series User manual

Page1of7

Serial #

The Serial # is located on the top of the

outlet flange or pipe.

1.DONOTEXCEEDTHEMAXIMUMRATEDPRESSUREORTEMPERATUREOFTHESFSTRAINER.Refertodecalslocatedon

thestrainer.

2.Undernocondionsshouldthestrainerlidorpressuregaugesberemovedwhilethestrainerispressurized.

3. Allstrainerswithasideinletandaboomfootringmustbeplacedonafirmsupporngsurface.DONOTsuspendthe

strainerbytheinletandoutletconnecons.Allstrainerswithvercalinletpipingmustbeplumbedintoproperly

supportedpiping.

4. UnitswithdamagedormissingpartsshouldNEVERbeoperated.ContactThermalCarePartsat847‐966‐8560for

replacementparts.

5. Back‐flowprevenondevicesshouldbeinstalledupstreamoftheinletanddownstreamoftheoutletofthestrainerto

preventbackfloworvacuumeffectsthatcanbedamagingtothestrainer.

6. Pressurereliefvalvesofasufficientsizeandvolumeshouldbeinstalledupstreamoftheinletanddownstreamofthe

outletofthestrainer.Theyshouldbesetsothesystemneverexceedsthemaximumratedpressure.Failuretoinstall

reliefvalvescouldleadtopersonalinjuryorproductdamage.

I. SAFETY CONSIDERATIONS

OWNER’S MANUAL

TableofContents

SafetyConsideraons..………………………………………..1

Receiving&Installaon…...…….……………...……………2

StrainerOperaon,Maintenance,&Storage……….2

TorqueRecommendaons…..………………………………3

InformaonConcerningWaterHammer……………..4

SpareParts……………….………………………………………….5

OponalEquipment…………………………………………….6

GENERAL WARNING

Ensureallappropriatepersonnelreadowner’smanualpriortoinstallaonand/oroperaonofstrainer.Failureto

complywithinstruconsandsafetyprecauonscouldleadtopersonalinjuryorproductdamage.Pleasecall

847‐966‐2636andasktospeakwithoneofourcustomerservicerepresentavesifthereareanyquesons.

CAUTION

PersonalProtecveEquipment(PPE)‐eyeprotecon,earprotecon,gloves,andprotecvefootwear‐mustbe

wornwhenoperangandservicingthestrainer.

Page2of7

1.Inspectstrainertoensurethereisnodamagefromtransit.

2.Confirmalldustplugs/flangeprotectors(inlet,outlet,gaugeports,etc.)areremoved.

3.Locateserialnumberontopofoutletflangeorpipe(seediagramsbelow)andrecordintheboxonpage1.

4.Posionthestrainerintothepipingsystemusingtheredarrowstoindicateflowpath.

5.Allstrainerswithasideinletandaboomfootringmustbeplacedonafirmsupporngsurface.DONOTsuspendthestrainerbytheinlet

andoutletconnecons.Allstrainerswithvercalinletpipingmustbeplumbedintoproperlysupportedpiping.

6.Installaonofisolaonvalvesonboththeinletandoutletsidesofthestrainerisrecommendedtoisolatethestrainerduringmaintenance.

7.Installavalveonthedrainageportlocatedattheboomofthestrainerbody(seediagrambelow).Thevalvemustbeplumbedto

atmosphereandtheflushlineshouldnothaveanyelevaonorbepipedtoapressurizedline.Ensureflushlineisplumbedtoprevent

operatorfromcontactwithflushwater.

8.Installpressuregauges(soldseparately)inthegaugeportslocatedonthestrainerbody(seediagrambelow)toallowmonitoringthe

pressuredifferenalacrossthescreen.

9.ReviewallsafetyconsideraonsfromSeconI.todetermineiftheyhaveallbeenaddressed.Reviewproceduresforsafeoperaonspecific

toyourapplicaon.

10.Ensureallstrainerportsareproperlyconnected.

11.Ensurethelidisproperlyinstalled.SeediagrambelowandSeconIV.TorqueRecommendaonsforinstrucons.

12.Thestrainerisnotfreezeprotected.Properfreezeproteconmethodsmustbeulizedtoensurethestrainerwillnotbedamagedifex‐

posedtofreezingcondions.

II. RECEIVING & INSTALLATION

III. STRAINER OPERATION, MAINTENANCE, & STORAGE

StartUp

Openthedownstreamvalve,thenslowlyallowfluidtoflowthroughthestrainerbyopeningtheupstreamvalve.

Flushing

Periodically(dependingonliquidquality)thedebristhatselesattheboomofthestrainerwillneedtobeflushedout.Opentheflushport

valvewhilethestrainerisinoperaontoflushoutdebris.Flowrate,pressure,andamountofdebrisdeterminehowlongthevalveshouldbe

opentoflushthedebrisfromthestrainertank.Itistheuser’sdiscreontodeterminethefrequencythatthevalveshouldbeopened.

Neverallowdebristoaccumulatebeyondthecapacityofthereservoir.

ClampedLidOperangInstrucons:

ToClose‐

Alignvercalslotsinthelidassemblywith

thepinsinsidethehousing.

Lowerthelidassemblyunlitcanbe

rotated.

Rotatethelidassemblyclockwisetostop.

Theheadwilldropintoalockedposion

andshouldbeunabletoberemovedby

pullingstraightup.

InstalltheV‐Bandclamp.

ToOpen‐

RemovetheV‐Bandclamp.

Usingthehandleontopofthehead;pull

upandrotatethelidassemblycounter‐

clockwiseunltheheadisfreefromthe

lockingpins.

Serial # Stamped

On Outlet Pipe

CAUTION

Theinternalpressureofthestrainermustberelievedtozerobeforeremovingtheretainingbolts/clampofthelid.

Page3of7

Cleaning

Apressuredifferenalofapproximately5‐7PSIfromthecleancondionindicatesthatthescreenrequirescleaning.

1.Removestrainerfromservicebyshungoffsystemvalvestoensurenofloworpressure.

2.Checkgaugestoensuretheinternalpressureofthestrainerisrelievedbeforeremovingtheretainingbolts/clampoflid.

3.Openflushportvalvetodrainfluidfromstrainerandrelievestrainerpressure.

4.Openairreliefvalvetobreakvacuumforfasterdrainingandtorelieveanyremainingstrainerpressure.

5.Removethelidofthestrainer.

6.Lithestrainerelement(conicalscreen)outofthestrainerbody.

7.Carefullyscrubdownthestrainerelementwitharigidnylonbrushunlallmaerisloosened.Do not use a steel brush.

8.Washthestrainerelementoffwithcleanwater.Do not use a pressure washer.

9.Rinsegasketsandcleantheinner‐ringwheretheboomofthestrainerelementseals.

10.FittheU‐shapedgasketsecurelytotheboomofthestrainerelement.Posionstrainerelementintothestrainerbody.

11.Fitthestrainerheadgasketontotheupperflangeofthetopofthehousing.Onclampmodels,theO‐ringshouldbe

seatedcompletelyintheheadassembly.FollowinstruconsinTorqueRecommendaons(Sect.IV).

12.Ensureflushportvalveandairreliefvalveareinclosedposionbeforereturningstrainertoservice.

Storage(NotinService)

Forstorageorextendeddownmefollowthesestepstopreventprematuredeterioraonofthestrainerhousingandscreen

Isolatethestrainertoensurenoflowandreleasepressure.

Drainthestrainerbodybyopeningtheflushport.Removetheinternalscreenandgaskets;rinsewithcleanfreshwater.Rinseouttheinside

ofthestrainerbodywithcleanfreshwaterandremoveanyexcesswater.Replaceallcomponentssecurelywhencompletelydry.

BAND CLAMP MODELS:

Theover‐centerlatchclampisusedtosecurethelidtothehousingonthestrainer‐clampmodels.Replacementclampsareshipped

withthelocknutnotpre‐setandmustbeadjusteduponinstallaon.Undernocondionsshouldthestrainerlidorpressuregaugesbe

removedwhilethestrainerispressurized.Clampinstallaoninstrucons:EnsureO‐Ringisproperlyinstalledonthelid.Placethelidonthe

strainerhousing,alignpinswithslotsinthelid,andtwisttolockintoplace.Placetheclamparoundtheflarededgesofthehousingandlid.

LatchtheT‐boltwiththereceiver.Pushthelatchhandle

towardsthestrainerbodyunlthesafetycatchengages.

AdjustthelocknutunltheclampInnerRetainerfits

securelyandisfullyengagedaroundtheflarededgesof

thelidandhousingflange.Theengagementcanbe

inspectedattheseparaongapsoftheInnerRetainer

andshouldhaveaminimumof3/16”overlap(see

diagram).Reclipsafetywarningtagtotheclamp.

BOLTED LID MODELS:

Theboltedlidstrainersrequirethattheaachmentboltsbeghtenedsufficientlytomakeacompletesealwithoutdamagingtheboltsorthe

strainerhead.Bolts,nutsandwashersareusedtoaachtheheadstothesestrainers.Thesizeandrecommendedtorqueoftheboltisdependent

onthestrainersize.Thefollowingtableshowstheboltsizeandtorquerangforeachstrainer.

NEVERoperatethestrainerunlessallboltsareproperlyfastened.Itisimportanttofollowthetorquerecommendaonsasover‐torqueingmay

resultinprematurefailureofthebolt.Tightenandtorqueboltsinanopposingpair“star”paernaccordingtoASMEPCC‐1‐2019Guidelinesfor

PressureBoundaryBoltedFlangeJointAssemblyorMIL‐HDBK‐60ThreadedFastenersTighteningtoProperTension.

IV. TORQUE RECOMMENDATIONS

Domeof

StrainerLid

3/16”

Overlap

BandClamp

Flangeof

StrainerLid

ModelBoltSizeTorque

4”Bolted(3/8”‐16)15to25.lbs.

6”(1/2”‐13)45to55.lbs.

8”(1/2”‐13)45to55.lbs.

10”/12”/14”(5/8”‐11)80to100.lbs.

BoltQuanty

10

10

16

20

Page4of7

WHAT IS WATER HAMMER?

Waterhammerisaphenomenonthatcanoccurinfluidsystemswithlongpipesbetweenthefluidsourceandtheoutlet.Thetermitselfrefersto

thesoundmadewhenwaterhammeroccurswhichresemblesbangingahammeronalongpipe.Waterhammerisarapidchangeofpressure

causedbyarapidchangeinvelocity.Whenthevelocityischangedapressurewavethattravelsatthespeedofsoundisiniatedandtravelsin

theupstreamdireconunlitreachessomestaonaryenergylevel,likeareservoir.Ararefaconwave(atthepressureofthewatersource)

thentravelsdownstreamatthesamespeed.Iftheflowhasbeenshutoffdownstreamthepressurewaveimpactstheblockageandthepressure

intheenresystemisraisedveryquickly.

WHAT CAUSES WATER HAMMER?

Anyaconthatcancausearapidchangeinthevelocityoftheflowcansetoffawaterhammer‐closingadownstreamvalve,pipefracture,pump

stoppage,etc.Thecricalmeforwhichavalvemaybecloseddependsonthelengthofpipingbetweenthevalveandthesourcereservoir.The

longerthedistance,thegreaterthemerequiredtoshutthevalvesafely.Typicallyforshortlengthsofpipe(below500)thecricalmeisless

than1/10second.

WHAT CAN WATER HAMMER DO?

Pressurespikesfromwaterhammercanraisefluidpressurestoveryhighvalues(inexcessof1000PSIdependingonthesituaon).Suchpressure

spikescanresultinmechanicalfailuressuchasbrokenvalves,pipes,strainers,joints,etc.Waterhammerdoesnothavetooccurfullytoraisethe

pressure.Aparalhammercanoccurthatraisesthepressuretoacertainpercentageofthetheorecalmaximum.TheSFStrainerisratedtoan

absolutemaximumpressureof150PSIforboltedlidmodels,125PSIforbandclamplidmodels.Awaterhammerpressurespikethatraisesthe

pressurehigherthanthemaximumratedpressuremayresultinstrainerdamage.

WHAT CAN I DO TO PREVENT WATER HAMMER?

Thereareprecauonsthatcanbetakentopreventordecreasetheeffectofwaterhammer.Apressurereliefvalvethatleadstoasurgetankor

accumulatormayprotectotherkeycomponentsfromwaterhammer.Acloseadherencetooperaonalpolicieswillalsohelppreventvalvesor

pumpsfrombeingaccidentallyshutofftherebycausingawaterhammer.Acloseexaminaonofasystemwillinformyouofpotenalhazards.

V. INFORMATION CONCERNING WATER HAMMER

Page5of7

VI. SPARE PARTS

*Top Head with

Air Relief Port

*O-Ring Gasket

Disc Gasket

Filter Gasket

Replacement Screen

*Gasket Kit

Gaskets also

Available in

BUNA & VITON

*Part No. based on serial No. of

unit. Please have serial No.

available when ordering.

SF Series Strainer - 2” thru 4C”

Fasteners

Top Head with

Air Relief Port

Head Gasket

Disc Gasket

Filter Gasket

Replacement Screen

Gasket Kit

Gaskets also

Available in

BUNA & VITON

Serial No. Location

SF Series Strainer - 4B” thru 14”

Lid Clamp

*O-Ring Gasket

Disc Gasket

Filter Gasket

Replacement Screen

*Gasket Kit

Gaskets also

Available in

BUNA & VITON

*Part No. based on serial No. of

unit. Please have serial No.

available when ordering.

Serial No. Location

Inlet/Outlet Replacement Disc Gasket Top Lid Clamp

Size & Screen (a) Gasket Kit (b) Head or

Type *(EPDM) (EPDM) Fasteners

2" NPT

OR-02-2 GK-02-2 TH-02-2

3" NPT

OR-03-2 GK-03-2 TH-03-2

4" Flanged

P/N:

4S-XXX HG-04 DG-04 GK-04B TH-04B

FASTENERS-04

6" Flanged

P/N:

6S-XXX HG-06 DG-06 GK-06 TH-06

FASTENERS-06

8" Flanged

P/N:

8S-XXX HG-08 DG-08 GK-08 TH-08

FASTENERS-08

10" Flanged

P/N:

10S-XXX HG-10 DG-10 GK-10 TH-10

FASTENERS-10

12" Flanged

P/N:

12S-XXX HG-12 DG-12 GK-12 TH-12

FASTENERS-12

14" Flanged

P/N:

14S-XXX HG-14 DG-14 GK-14 TH-14

FASTENERS-14

Table 1

REPLACEMENT PARTS NOTES:

Select O-Ring, Gasket Kit, and/or Top Head corresponding to serial number stamped on strainer outlet pipe/flange.

(a) Replacement Screen includes: Screen, Filter Gasket

Model Serial No. Serial No.

(U-Gasket, bottom of screen), & Disc Gasket (top of screen). MLS-2 0001-4999 5000 & higher

(b) Gasket Kit includes complete set for Strainer: MLS-3 0001-1999 2000 & higher

(1) Head Gasket or O-Ring, (1) Filter Gasket, & (1) Disc Gasket. MLS-4C 0500-1999 2000 & higher

Complete Filter and Replacement Screen orders must specify mesh or perforated size of screen. See catalog for micron equivalent to mesh.

Screen Mesh Options: Standard Mesh - 16, 20, 30, 40, 50, 60, 80, 100, 120, 150, 200

Heavy-Duty Mesh - 24x110, 30x150, 40x200, 50x250 (Dutch-weave screens: heavier wire gauge, lower open area %)

Perforated Options: 1/4", 1/8", 1/16"

FG-04

OR-02 / GK-02 / TH-02

OR-03 / GK-03 / TH-03

OR-04 / GK-04

Part Number

OR-02-2 / GK-02-2 / TH-02-2

OR-03-2 / GK-03-2 / TH-03-2

OR-04-2 / GK-04-2

Part Number

BAND CLAMP LID

BOLTED LID

GK-04-2

4" Flanged

OR-02

DG-03

DG-04

Select P/N from Table 1

FG-06

GK-02

GK-03

GK-04

FG-08

FG-10

FG-12

FG-14

BC-04

Gasket

(EPDM)

Select P/N from Table 1

OR-03

TH-02

TH-03

Filter

Gasket

(EPDM)

FG-02

FG-03

FG-04 TH-04C

SCREEN OPTIONS: "XXX"

(in above part numbers)

= MESH or PERFORATED SIZE of SCREEN

STRAINER

P/N:

2S-XXX

P/N:

3S-XXX

P/N:

4S-XXX

DG-02

REPLACEMENT PARTS

OR-04

Model

Number

OR-04-2

BC-02

Select from Table 1

Head/O-Ring

BC-03

MLS-02-XXX

MLS-03-XXX

MLS-04C-XXX

MLS-04B-XXX

MLS-06-XXX

MLS-08-XXX

MLS-10-XXX

MLS-12-XXX

MLS-14-XXX

Page6of7

OPTIONAL EQUIPMENT

Please note that the following equipment is not included with the purchase of the strainer. Please contact Thermal Care Sales at

847-966-2260 for information and pricing.

VII. OPTIONAL EQUIPMENT

PressureDifferenalAlarmPackageOverview(PDA2)

Thepressuredifferenalalarmpackageconnuallymonitorsanddisplaysthestrainer’sinletand

outletdifferenalpressure.Whenthestrainerelement(conicalstrainerbasket)becomessignifi‐

cantlyclogged,thepressuredifferenalswitch‐gaugewilltriggeranaudiblesirenandavisualflash‐

ingalarmlight.Thesealarmsareintendedtoalertmaintenancepersonnelthatthestrainerelement

mustberemovedandcleaned(seeyourSFStrainerOwner’sManualforcompletestrainerelement

cleaninginstrucons).

Features

ConnuouslymonitorstheDifferenalPressureacrosstheconicalscreen

AudibleandVisualAlarm

(1)dryoutputcontact

Page7of7

OPTIONAL EQUIPMENT

Please note that the following equipment is not included with the purchase of the strainer. Please contact Thermal Care Sales at

847-966-2260 for information and pricing.

VII. OPTIONAL EQUIPMENT (continued)

AutomacTimerFlushPackage(ATF‐EA‐1.5)

TheATF2isanautomatedflushvalvethatisdesignedforusewiththeSFStrainer.Ithasadigitalmer

thatallowstheoperatortosetthefrequencyandduraonofvalveopeninginordertoallowmoreeffec‐

veandefficientflushingofthecollecteddebrisfromthestrainer.

ControlBox:ThedigitalmerislocatedinsideaNEMA4enclosurethatincludesanAutoandManual

Valvefunconswitch.

BallValve/Actuator:Thevalvebodyhasa316SSballinsideaUVmodified,glass‐filledNylonhousing.The

actuatorhashightorquemotorgearsandsolidstatecomponentsforincreaseddurabilityandmainte‐

nancefreeperformancecontainedinsideaNEMA6Penclosure.

Features

Purgesparclesfromstraineratuser‐definedintervals

Adjustableflushfrequencyandduraon

Manualflushcontrolswitchwithindicator

Stainlesssteelballvalvedesignedfordirtywateruse

Other manuals for SF Series

2

Table of contents

Other Thermal Care Water Filtration System manuals

Popular Water Filtration System manuals by other brands

KineticoPRO

KineticoPRO NSC-120 owner's manual

Pentair

Pentair PRF-RO Installation and maintenance manual

AquaScape

AquaScape Ultraklean 2000 Instructions & maintenance

Wayde King Water Filtration

Wayde King Water Filtration Platinum Series owner's manual

Pond Boss

Pond Boss PonDuett 3000 operating manual

IMI

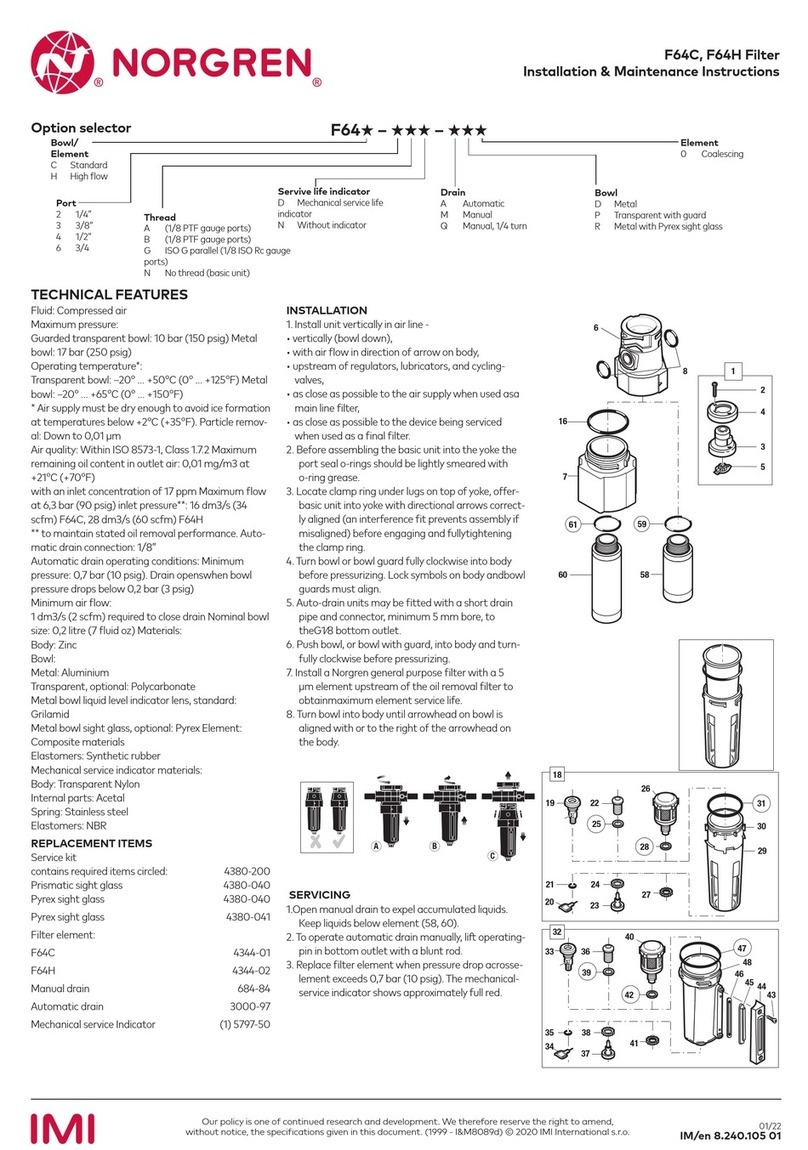

IMI norgren F64C Installation & maintenance instructions