Thermasis HYDRA PLUS User manual

HYDRA PLUS

Installation and

User Manual

2021/R02/Hydra Plus_Micronova

Dear Customer,

Thank you for having chosen our product.

To allow for optimal operation and for you to enjoy the warmth and sense of wellbeing that

the fire can convey in your home, we advise you to read this manual carefully before starting

up the product for the first time.

CARE OF THE MANUAL AND HOW TO CONSULT IT

Take care of this manual and keep it in an easily accessible place.

Should the manual be misplaced or ruined, request a copy from your retailer or directly from

the authorised Technical Assistance Department.

1 INTRODUCTION

HYDRA PLUS is a welded steel hydro-pellet stove with all hydraulic and safety accessories

packed inside the cabinet. Main features and advantages of HYDRA PLUS are as follows:

Automatic ignition

PID control, output regulation

High heat resistant ceramic sightglass with auto cleaning system

Double layer door design with additional tempered glass frontial door

Packed with all accessories suc as;

-Circulation pump with frequency modulation

-7 lt expansion tank

-Safety valve

-Automatic air relief valve

-Water pressure switch for low pressure protection

-Air pressure switch

Safety against back burning

Exhaust fan speed modulation

Burning pot made of special stainless steel

Manually activated cleaning system in smoke pipes

Auto switch-off when there is no fuel

HYDRA PLUS is delivered in one single wooden package with all external cabinets assembed,

no additional assembly is requried

2 WARRANTY CONDITIONS

THE MANUFACTURER guarantees the product, with the exception of elements subject to

normal wear (listed below), for a period of 2 (two) years;

Starting from date of start-up, which is proven by a commissioning document that

contains the name of the seller and the date when the sale / first start-up took place

If there is no service/commissioning report, standard guarantee period starts with

the date when the sale took place.

The term ‘warranty’ refers to the (free-of-charge) replacement or repairs of parts

acknowledged to be faulty due to manufacturing defects.

Furthermore, in order for the guarantee to be valid, the product must be installed and

calibrated by qualified personnel. Installations that do not meet the current standards,

improper use and lack of maintenance as expected by the manufacturer, void the product

warranty. The warranty is valid on the condition that the instructions and warnings

contained in this manual are observed, and therefore the product is used correctly.

The replacement of the entire system or the repair of one of its components does not

extend the warranty period, and the original expiry date remains unchanged.

EXCLUSIONS FROM WARRANTY

Parts subject to normal wear such as gaskets, ceramic glass, cast iron grilles, vermiculite

boards, fire bricks, fire stone burners, handles and electric cables, knobs, all parts which can

be removed from the firebox, are excluded from the warranty

Any part that may be faulty as a result of negligence or careless use, incorrect maintenance

or installation that does not comply with the manufacturer's instructions (see the relative

chapters in user manuals of each product).

The warranty will be rendered null and void in the event of damage caused by tampering,

atmospheric agents, natural disasters, vandalism, electrical discharges, fire, faults/defects in

the electric and/or hydraulic system, and maintenance not being performed at all or as

indicated by the manufacturer instructions

Non-regular electrical supplies, and electrical power cuts off too often, can cause severe

damage on control system, sensors and actuators of the products carrying those

components. We recommend installing 230 V 50 Hz AC voltage regulator for those products.

Also installing a UPS for pumps can protect system from electrical cut-offs causing over

heating of water.

The warranty does not cover malfunctions and/or damage to the appliance that arise due to

the following causes:

Damage caused during internal transportation and/or handling

All parts that develop faults due to negligence or improper use, incorrect

maintenance, installation that does not comply with the manufacturer’s instructions

(always refer to the installation manual provided with the product)

Improper overheating of the equipment, use of fuels not conforming to the types and

quantities indicated in the instructions provided

Further damage caused by incorrect user interventions in an attempt to fix the initial

fault

Worsening of the damage caused by the user continuing to operate the appliance

even after the fault has been noticed.

In case of a boiler/hydro stove, any corrosion, incrustations or breakages caused by

water flow, condensation, lack of water in the system, mud or limescale deposits

Inefficiency of chimneys, flues or parts of the system affecting the appliance.

Failure to have the annual product maintenance performed by an authorised

technician or qualified personnel will result in the loss of the warranty.

Save for the legal or regulatory limits, the warranty does not cover the containment

of atmospheric and acoustic pollution.

THE MANUFACTURER declines all liability for any damage which may be caused, directly or

indirectly, to persons, animals or objects as a consequence of non compliance with any

provision specified in the manual, especially warnings regarding installation, use and

maintenance of the appliance.

SPARE PARTS

Only use original spare parts. The retailer or service centre can provide all necessary

information regarding spare parts. We do not recommend waiting for the parts to get worn

out before having them replaced. It is important to perform regular maintenance.

The Manufacturer declines all liability if the product and any other accessory is used

improperly or modified without authorisation. All parts must be replaced with original spare

parts. Warranty cover is valid if the product is installed and tested by a qualified installer,

according to the detailed instructions provided in the instruction manual supplied with the

product. The term ‘warranty’ refers to the (free-of-charge) replacement or repairs of parts

acknowledged to be faulty due to manufacturing defects.

3 SAFETY WARNINGS

•Installation, electrical connection, functional verification and maintenance must only be

performed by qualified or authorised personnel. Install the product in accordance with

all the local and national laws and standards applicable in the relative region.

•Only use fuel recommended in this manual. Do not put any fuel other than wood pellets

in the hopper. Keep cover of the fuel hopper always closed.

•Do not place laundry on the product to dry. Any clothes or similar objects including the

fuel must be kept at a safe distance from the product.

•Any type of tampering or unauthorised replacement with non-original spare parts could

be hazardous for the operator's safety and relieve the producer/re-seller from any civil

and criminal liability.

•Most of the surfaces of the product are very hot (door, handle, glass, smoke outlet pipes,

etc.). Avoid contact with these parts unless adequate protective clothing is worn or

appropriate means are used, such as heat protective gloves or cold handle type

operating systems. When opening the internal front door, always use the unique

apparatus attached at back side of the product. It is forbidden to operate the product

with the door open or the glass broken.

•THE PRODUCT MUST BE POWERED BY A SYSTEM THAT IS EQUIPPED WITH AN

EFFECTIVE EARTH SYSTEM.

•Switch the product off in the event of a fault or malfunctioning.

•Accumulated unburned pellets in the burner (fire pot) after each "failed start-up" must

be removed before starting up again.

•Do not wash the product with water. The water could get inside the unit and damage the

electrical insulation and cause electric shocks.

•INSTALL THE PRODUCT IN ROOMS THAT ARE ADEQUATELY PROTECTED AGAINST FIRE

AND EQUIPPED WITH ALL THE UTILITIES SUCH AS SUPPLIES (AIR AND ELECTRICITY) AND

SMOKE OUTLETS.

•If a fire breaks out inside the chimney, switch the appliance off, disconnect it from the

mains and do not open the door. Then contact the competent authorities.

•If the ignition system is faulty, do not force ignition with flammable materials.

•Special maintenance must only be performed by authorised and qualified personnel.

DANGER –Risk of electric shock

Switch off the system before performing work on the boiler.

THIS APPLIANCE MUST BE EARTHED !

NOTICE –First operation

•It is quite normal to smell water vapour contained in the special coating of combuston unit

of the product. This smell will be go out through chimney after a few hours of first

opeation, and it should not be considered as a product defect.

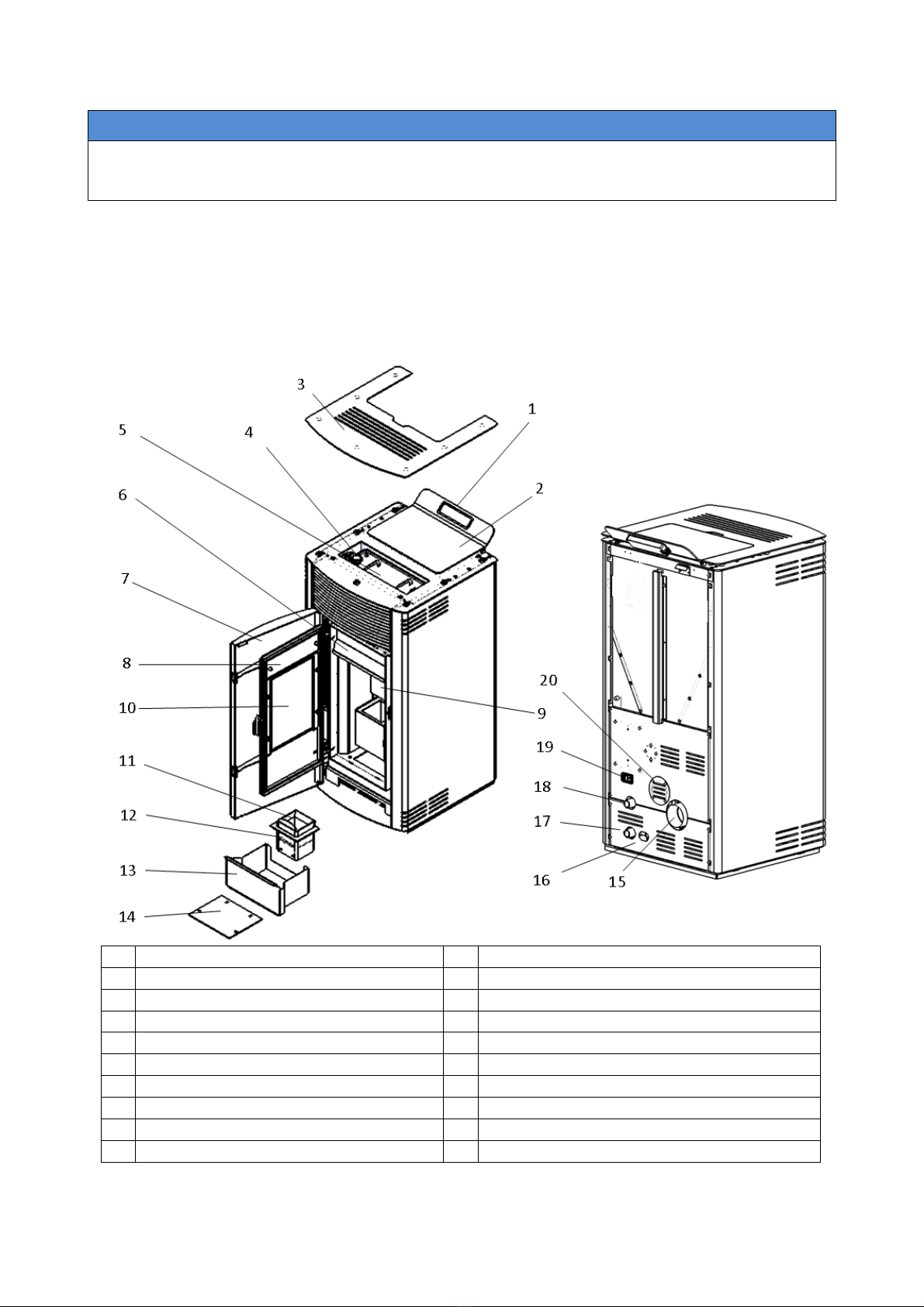

4 MAIN PARTS AND SPECIFICATIONS

For end users:

1

User interface and command display

11

Burning pot upper ring

2

Fuel loading cover

12

Burning pot

3

Top panel

13

Ash tray

4

Smoke pipes cleaning knobs

14

Smoke-hood cleaning cover

5

Combustion unit upper insulation panel

15

Flue outlet

6

Glass cleaning mechanism

16

Safet valve outlet

7

External door

17

Hot water outlet

8

Internal door

18

Cold water inlet

9

Protection panels in combustion unit

19

Main switch of boiler

10

Ceramic glass / inspection window

20

Optional inlet for combustio air (room –seal)

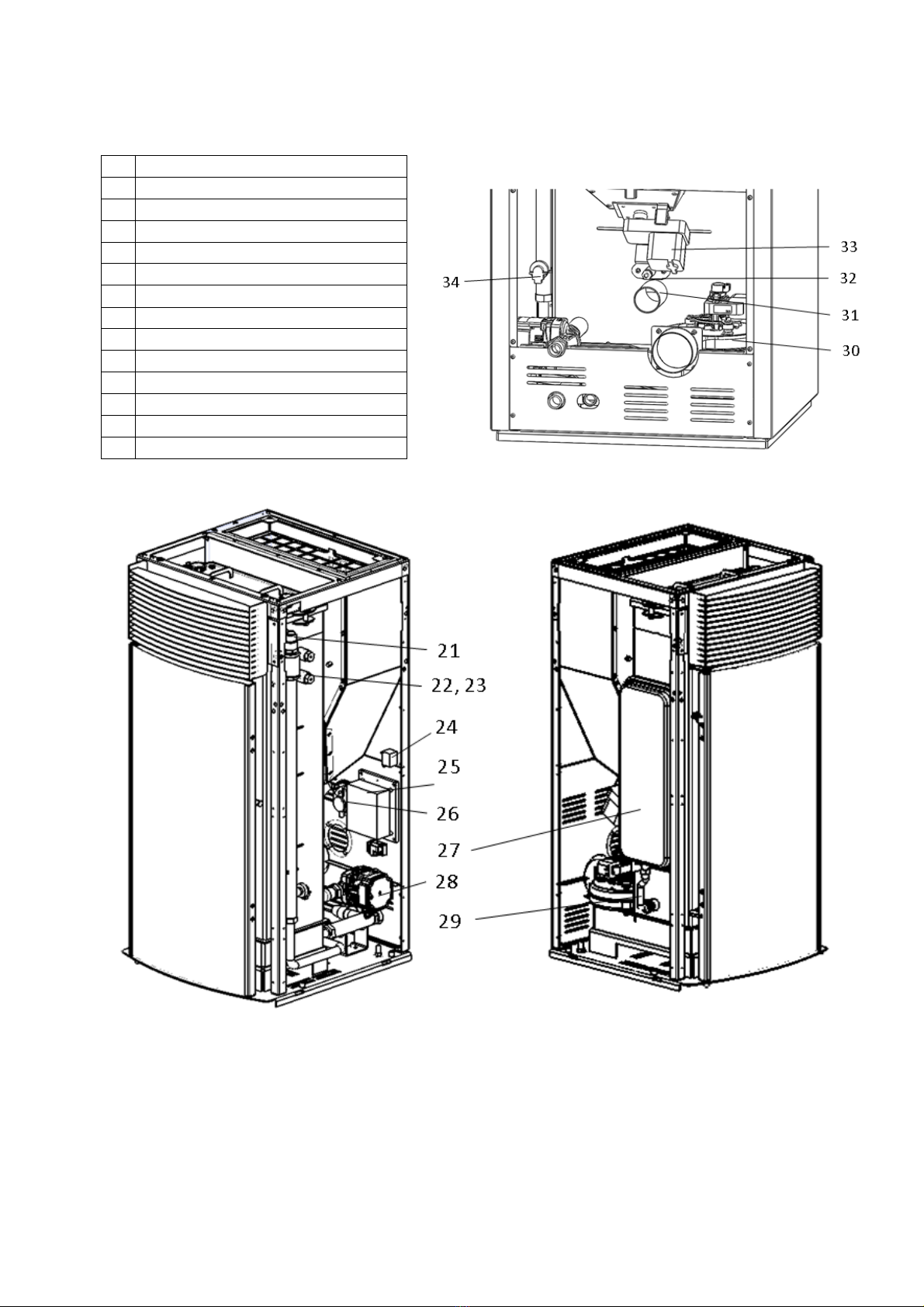

For installers / service staff:

21

Air discharge valve

22

Sensor pocket (boiler thermostat)

23

Sensor pocket (safety limiter)

24

Safety limiter

25

Control board

26

Air pressure switch

27

Expansion tank

28

Circulation pump

29

Flexible connection for exp tank

30

Suction fan

31

Combustion air entrance

32

İgnitor

33

Pellet feeding motor

34

Water pressure switch

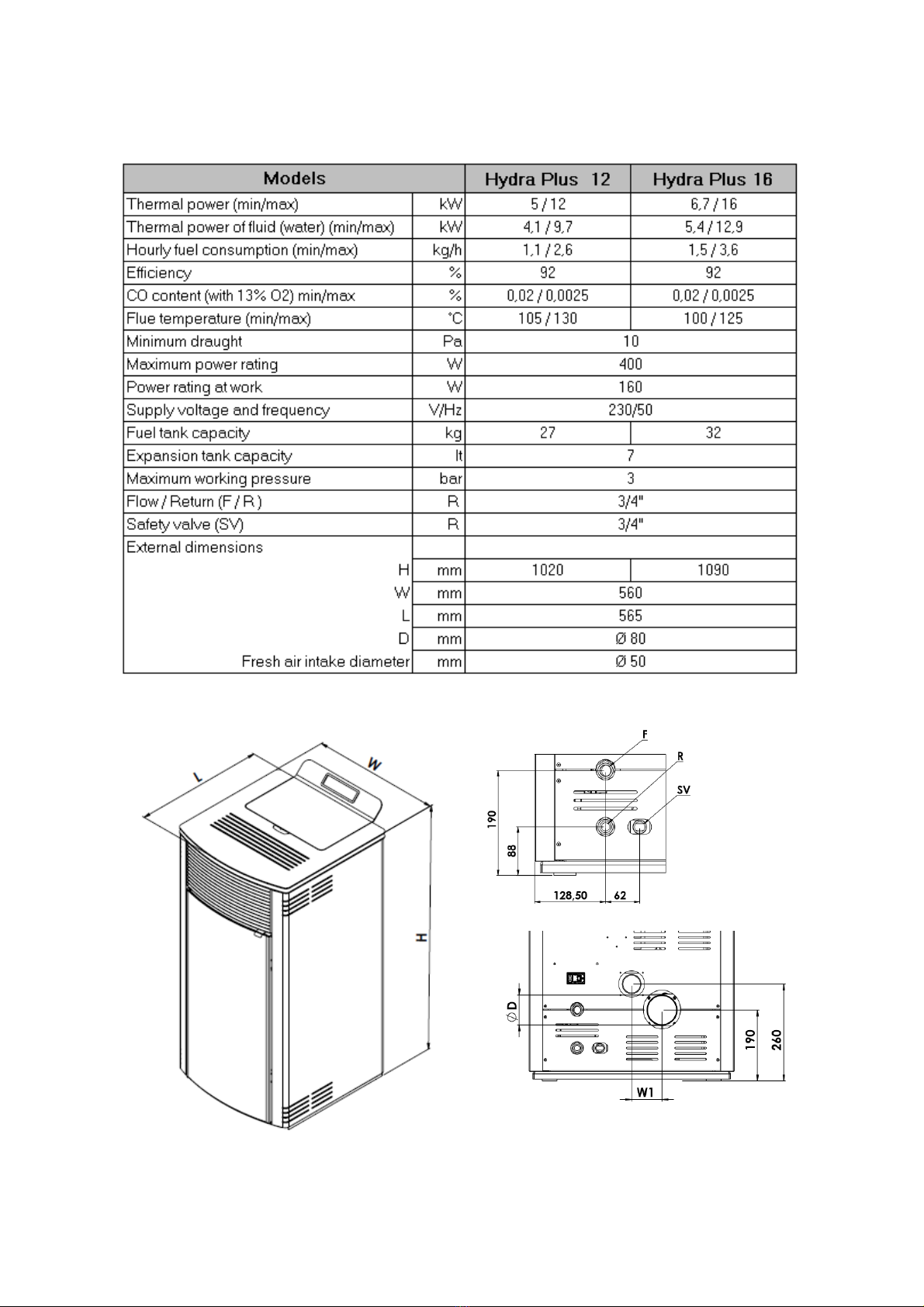

5 BEFORE INSTALLATION

5.1. Fuels

Pellets must comply with Class A1 or A2 according to EN 14961-2

Diameter (mm)

6 ± 1

Length (mm)

Max 40

Moisture (w)

≤ 10%

Ash (w)

≤ 1,5%

Net Calorific Value (kWh/kg)

≥ 4.4

To guarantee combustion without problems, pellets must be kept in a dry place. Poor quality

pellets or others that do not comply with that specified previously compromises the operation

of your product and can therefore render the warranty and product liability null and void.

5.2. Room selection / operating environment

The product must be installed in a suitable place for regularly operation and routine

maintenance. The site must be:

Compliant for proper operation.

Equipped with an adequate smoke expulsion system. The product must be connected to

a chimney or an internal/external vertical duct that complies with the regulations in force.

The product must be positioned in such a way that the electrical socket is accessible.

Equipped with ventilation intake from outside.

Equipped with 230V 50 Hz power supply with an EC compliant earth system.

Operating environment must ensure the following regulations unless any local regulation

in force request different conditions

The volume of the room where the product is installed should be no less than 15 m3. Air

must enter through permanent openings made in the walls (near the product) that reach

outwards with a minimum section of 100 cm2for Vega 12/16, and 150 cm2for Vega 24

without the protective grille. In the case of ducting, up to 3.5 linear meters, increase the

cross-section by about 5%, whereas for longer ducts, increase it by 15%. These openings

(air inlets) must be made in such a way that it is impossible for them to be obstructed in

any way. The opening must be positioned in the lower part of an outer wall, preferably

opposite to that in which the smoke evacuation duct is located.

Air can also be drawn from adjacent rooms to the one that is to be ventilated, provided

they have an external air inlet and are not used as a bedroom or bathroom or where there

is a fire hazard, such as: garages, timber storerooms, warehouses of flammable

materials, observing under all circumstances the the provisions of all the applicable

standards in force.

The adjacent room from which air is

taken must not have a low pressure

compared to the exterior due to a

counter draught caused by the

presence in that room of another

appliance in use or of a suction

device.

NOTICE

The product cannot be installed (except for sealed operation appliances with external ducted

combustion air intake):

•in bedrooms or bathrooms;

•in rooms where there are liquid fuel appliances with continuous or intermittent operation

that draw the combustion air from the room they are installed in;

•in rooms where there are B-type gas heating appliances, with or without domestic hot

water production and interconnecting rooms;

•where another heating appliance is installed without an independent air flow.

It is recommended to install the stove detached from any walls and/or furniture, with a

minimum clearance to allow effective aeration of the appliance and a good distribution of heat

in the room. Observe the distances from flammable or heat-sensitive objects (sofas, furniture,

wood panelling, etc..) as specified below. If particularly delicate objects are present, such as

furniture, curtains or sofas, increase the stove clearance accordingly.

A

B

If the floor is made of combustible material, it is recommended to use protection made of non-

combustible material (steel, glass...) that also protects the front from falling combusted

material during cleaning operations.

The appliance must be installed on a floor with adequate load capacity. If the existing

construction does not meet this requirement, one must take appropriate measures (for

example a load distribution plate).

WARNING

Heat-sensitive or flammable objects cannot be placed near the product. Keep such objects

at a minimum distance of 80 cm from the outermost point of the product.

Leave minimum 80 cm free space in front of the stove for loading, and cleaning of

combustion unit.

REFERENCES

FLAMMABLE OBJECTS

NON-FLAMMABLE

A

200 mm

100 mm

B

200 mm

100 mm

5.3. Connection of the smoke exhaust duct

When making the hole for the passage of the

smoke discharge pipe, one must take into

account the possible presence of flammable

materials. If the hole must be made through a

wooden wall or thermolabile material, the

INSTALLER MUST first of all use the

appropriate wall fitting (minimum diameter 13

cm) and suitably insulate the pipe of the

product that passes through it using adequate

insulating materials (1.3 - 5 cm thick with

minimum thermal conductivity 0.07 W/m°K).

The same minimum distance must be applied

if the pipe of the product must pass through

vertical or horizontal sections near the

thermolabile wall. It is recommended to use an

insulated double-wall pipe in external sections

in order to prevent condensation from forming.

Note that the combustion chamber works in

negative pressure.

WARNING

Always use pipes and fittings with appropriate seals that guarantee tightness.

NOTICE

The following conditions must be complied with when connecting the appliance to the chimney:

The smoke duct must be at least category T200 (or higher if required by the smoke

temperature of the appliance) and P1-type (airtight).

All 90° angles (max. 3) in the smoke exhaust duct must be preferably fitted with the

relative T-fittings with inspection hole.

It is strictly forbidden to fit a mesh at the end of the exhaust pipe as it could cause the

product to malfunction (due to clogging).

It is forbidden to use counter-sloping pipes.

The horizontal section of the smoke duct must not be longer than 2-3 m.

It is also recommended not to exceed 6 metres in length with the pipe Ø 80 mm.

The smoke duct must not cross rooms in which it is forbidden to install combustion

appliances.

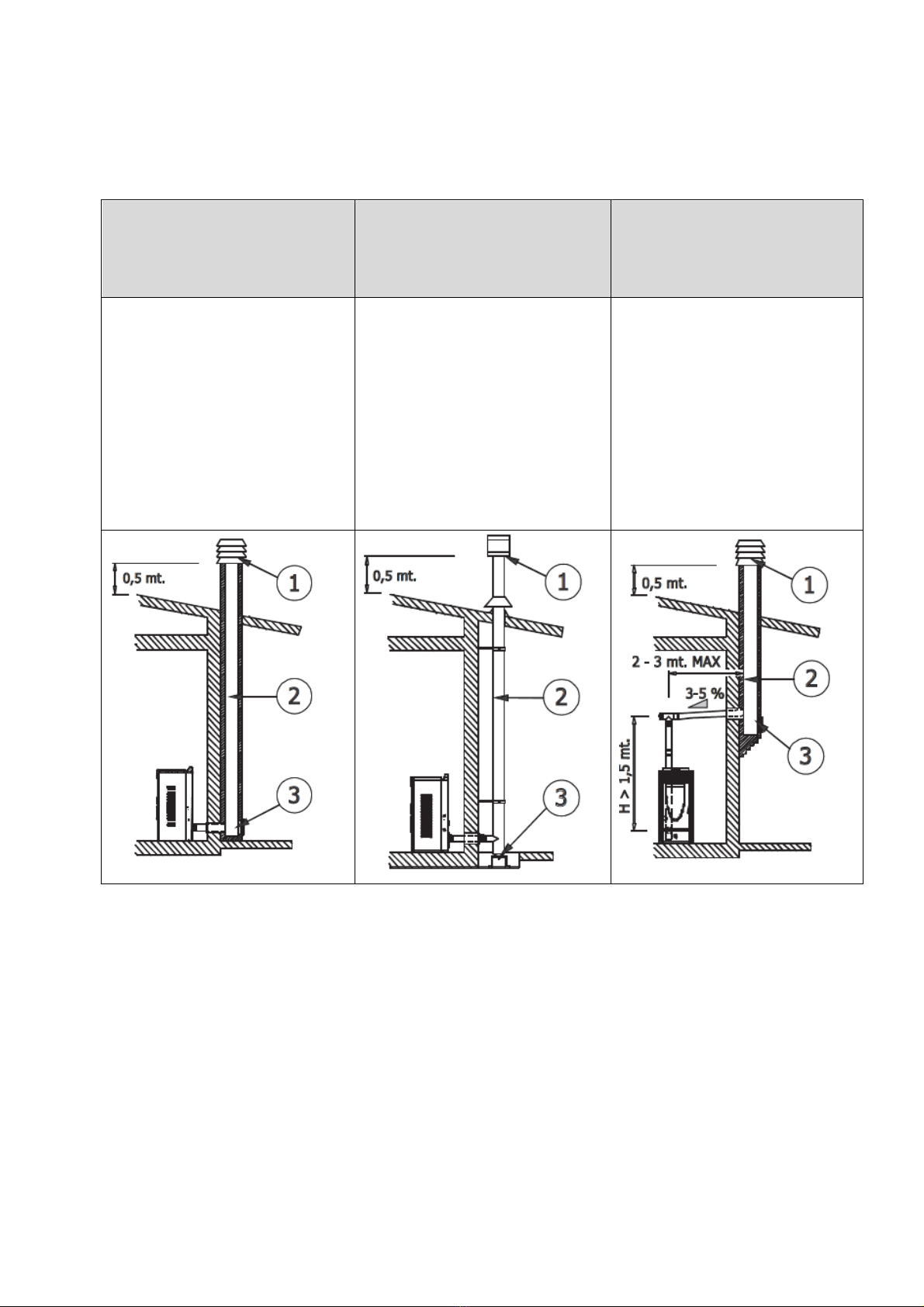

5.4. Connection to the chimney

The chimney must comply with the following requirements:

• Be waterproof and thermally insulated.

• Be made of suitable materials that resist mechanical stress over time, heat, the effects of the

combustion products and any possible condensation.

• Have a vertical set-up with deviations from the axis of no more than 45° and free of

bottlenecks.

• Must be suitable for the specific operating conditions of the product and have the CE marking

(EN1856-1, EN1443).

• Must be adequately sized for the draught/smoke expulsion requirements that are necessary for

the product to operate correctly (EN13384-1).

• The internal section is preferably circular.

• In the case of a pre-existing product that has been used, it must be cleaned.

• The chimney must not be shared with other appliances.

1) Windproof chimney pot, 2) Chimney 3) Inspection hole

CONNECTION TO THE

CHIMNEY

CONNECTION TO AN

EXTERNAL DUCT WITH AN

INSULATED OR DOUBLE-

WALL PIPE

CONNECTION TO THE

CHIMNEY

The chimney's internal

dimensions must not exceed

20x20 cm or 20 cm diameter;

in the event of bigger sizes or

bad chimney conditions (e.g.

cracks, poor insulation, etc.), it

is advisable to fit a stainless

steel pipe of suitable diameter

throughout the length of the

chimney right to the top.

The minimum internal

dimensions of the external duct

must be 10x10 cm or 10 cm

in diameter and must not

exceed 20x20 cm or 20 cm in

diameter. Only stainless steel

insulated (double-wall) pipes

must be used, which are

smooth on the inside and fixed

to the wall. Flexible stainless

steel pipes must not be used.

The connection between the

product and the chimney or the

smoke duct must not have an

inclination that is less than 3%

in the horizontal sections,

which must have a maximum

overall length of 2/3 m. The

vertical section between one

T-fitting and another (angle)

must not be less than 1.5 m.

5.4. Chimney stack

The chimney stack is a device fitted on the top of

the chimney that is designed to aid dispersion of

the products of combustion in the atmosphere.

Chimney stack must comply with the following

requirements:

it must have an internal section and shape the

same as the flue (A);

it must have a useful outlet section (B) of not

less than twice that of the flue (A);

the part of the chimney that emerges from

the roof or remains in contact with the outside

(e.g. in the case of a flat roof), must be

covered with brick or tile elements and in any

case well insulated;

it must be built in such a way as to prevent

the penetration of rain, snow and foreign

matter into the flue and to ensure that in the

event of winds from all directions and angle,

discharge of the combustion products is

assured (chimney stack with down-draught

cowl).

6 INSTALLATION AND PLUMBING

6.1. Unpacking

The stove is supplied complete with all its electrical and mechanical components and factory-

tested. Open the package and cut the strip that fastens the stove to the pallet.

If possible, unpack the stove near the chosen place of installation. Set the stove in the pre-

selected place, making sure this complies with the requirements. The stove body or unit must

always be kept in a vertical position when handled and moved by using carts only. Pay

particular attention that its door and its glass are protected from knocks that might

compromise their integrity. There are four rubber bases supplied with the stove. Screw them

into nuts fitted bottom level of the stove, and balance the stove by adjusting those rubber

bases up and down.

The materials that make up the packaging are neither toxic nor harmful, and so require no

particular disposal measures. After removing the packaging make sure that the stove is

complete and not damaged. If in doubt contact the dealer.

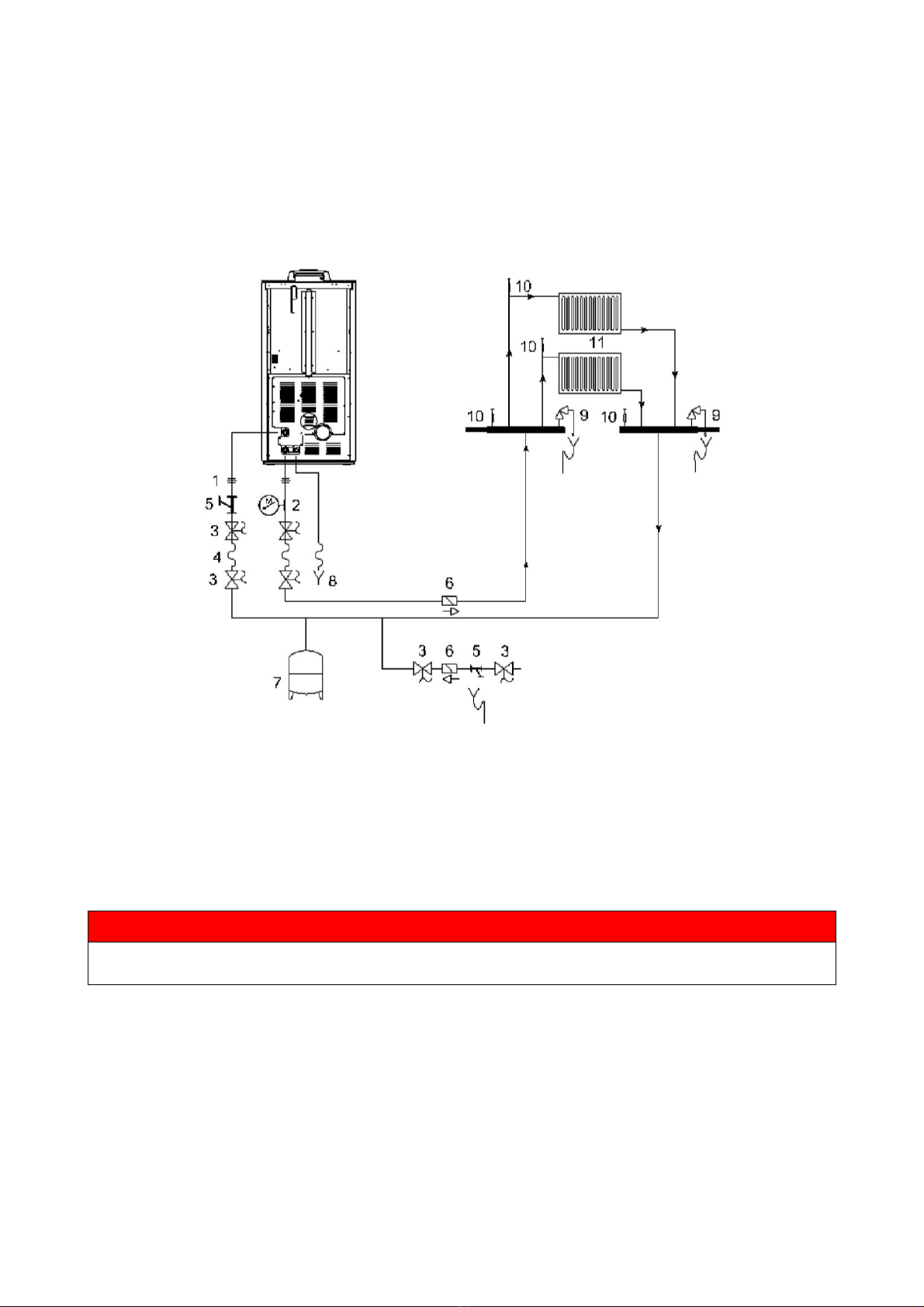

6.2. Hydraulic connections

This appliance has been designed to heat not only the immediate surrounding environment,

but also water for a hot-water type heating system. When the appliance is operating regularly

it produces hot water at a temperature that is necessarily below boiling point and a heating

system must therefore be designed that is suited to the characteristics of the appliance.

The installer must connect the appliance to the water system as shown in following diagram.

This set-up allows:

an instant check of filling or operating pressure of the system (MANOMETER WITH

SCALE 0 ÷ 6 BAR) (2)

the stove to be moved slightly for maintenance or cleaning purposes, without

disconnecting it from the water system (HOSES) (4)

The original system filling water and any topping-up water must always be filtered (using

synthetic or metal mesh filters with a filtration rating of no less than 50 microns) to prevent

sludge from forming and triggering deposit induced corrosion (STRAINER/FILTER) (5)

the stove to be disconnected from the water system without having to empty either the

stove boiler or the actual system (BALL VALVES) (3)

the appliance to be disconnected quickly without subjecting the connecting pipes to

stress (3-PIECE PIPE UNION) (1)

The safety valve must be connected using a hose without shut-off devices, which could

obstruct the free flow of fluid under pressure.Check that any kinks in the hoses will not allow

air locks or pockets to form or obstruct the free flow of water.

NOTICE

Before connecting the appliance, flush the heating system through to eliminate any residues (oil,

swarf, drops of weld material, hemp, rust) inside the pipework, which could otherwise damage

the appliance or cause malfunction. Insulate the connecting pipework adequately to prevent

heat loss and the formation of condensation. Under no circumstances light the appliance unless

the water circuit is completely filled with water.

The expansion tank installed inside the appliance is only sufficient to compensate the water in

the appliance and up to a MAX. of 20 lt of water in the system; the part of the system

corresponding to this quantity must be near the appliance and run relatively straight.

Installation of a suitably sized additional expansion tank is however recommended to

compensate for the quantity of water present in the heating system. The correct size of the

expansion tank must be calculated by a qualified heating plumber. As an example, the design

calculations for an expansion tank are given below, taking into consideration the following:

cold temperature of fluid 15°C

maximum working temperature of fluid 90°C

difference in level between additional expansion tank and relief valve (3 bar) equal to

or less than 1.5 m

pre-filling pressure of the expansion tank 2 bar.

The capacity of the closed expansion tank required by a heating system with such characteristics

can be calculated with the following formula:

Vv= Vox 0.16

Vv= volume of the expansion tank in l

Vo= water content of the system in l

1

Three piece pipe union

7

Expansion tank

2

Manometer

8

Drain

3

Ball valve

9

Safety valve

4

Hose

10

Air relief valve

5

Strainer (filter)

11

Radiator

6

Check valve

6.3. System filling

Fill the water heating system when the appliance is shut down. Under no circumstances light

the appliance if the boiler is not full of water. Filling must be carried out slowly so that air

bubbles can get out via the purposely placed outlets on the heating system. In closed circuit

heating systems the loading pressure of the system when cold and the expansion tank

preloading pressure must be the same.

WARNING

Do not mix the heating water with antifreeze or anticorrosion substances in the wrong

concentrations! It can damage the seals and cause the onset of noise during operation.

To fill the system, the boiler is fitted with a tap, with a check valve, to load the heating system

manually. During this operation, any air in the system is released via the air valve located in

the upper part of the boiler.

Open the radiator, and boiler air discharge valves;

Gradually open the system filling tap making sure that any automatic air valves

installed on the system work properly;

Close the radiator air valves as soon as water starts to come out;

On the system pressure gauge check that the pressure reaches a value of

approximately 1 bar;

Close the system loading tap and then bleed air again via the radiator air valves; and

check tightness of all connections;

After having started the boiler for the first time and heated up the system, stop the

pumps and repeat the air bleeding operations;

Let the system cool down and if needed take the water pressure back to 1 bar. The

water pressure in the heating system - when the system is cold - must be no less than

1 bar; if under this value, act on the system filling tap. The operation must be carried

out when the system is cold. The system pressure gauge enables to monitor the

pressure in the circuit.

Auto air discharge valve of the stove is reached after removing top and of right hand

side panel:

6.4. Electrical connection

Electrical safety of the system is ensured only when it is properly connected to an efficient

earthing system made in compliance with the safety standards in force. Gas, water or heating

systems pipes are not suitable as earth connections. Check if the electrical system is suitable

for the maximum power absorbed by the heating system, ensuring in particular that the

diameter of cables is appropriate for the power absorbed by the loads. The use of any

component that is powered by electricity entails compliance with some basic rules such as:

• do not touch the appliance with wet and/or damp body parts and/or bare feet;

• do not pull the electric cables;

• do not leave the appliance exposed to weathering (rain, sun, etc.);

• do not allow the appliance to be used by children or inexperienced persons.

Installation of the boiler accessory electrical components requires electrical

connection to a 230 V –50 Hz mains.

NOTICE

Electrical installation must be carried out by a qualified technician only.

Before performing connections or any operation on the electrical parts, always disconnect the

power supply and make sure it cannot be accidentally reconnected.

Please note that the boiler electrical power line must be fitted with a bipolar switch with a

contact gap greater than 3 mm, easy to access, in order to make any maintenance

operations quick and safe.

The power cable must be replaced by authorised technical personnel.

If the supply cord is damaged, it must be replaced by a special cord or assembly available

from the manufacturer or its service agent.

First connect the power cable to the stove and then

to a wall socket. The main switch at the side must

only be activated to switch the stove on; otherwise,

it is advisable to keep it off.

WARNING

It is recommended to disconnect the power cable when the stove is not used.

6.5. External room thermostat

The external thermostat can be used

to turn the combustion system on

and off. In this case the controller

ignores all internal temperature

thresholds and is operating

exclusively with the thermostat input.

To configure this option; connect

room thermostat wires into the ports

of green connector on board as seen

below

7 INITIAL START-UP

7.1. Before start-up

Check that the fire pot and its ring above are positioned correctly and rests properly on the

base. Fire pot ring fits into fire pot by its sides. Fire pot ring ensures all pellets will enter the

fire pot, protects burning pellets from moving out from the pot. So, it is very important to keep

that ring during stove operation.

Once the power cable is connected in the rear part of the stove, turn the switch to position (I).

To switch the stove on or off press ON/OFF button (4) on the control panel.

7.2. Loading the pellets

Fuel is loaded by lifting the cover on the upper part of the product. Slowly pour the pellets into

the hopper. Be careful as the cover could become very hot. No other type of fuel other than

pellets, in compliance with above-mentioned specifications, is to be inserted into the hopper.

WARNING

Do not allow sawdust to accumulate on the bottom of the hopper.

Do not leave leftover pellets on top of the stove –they could catch fire!

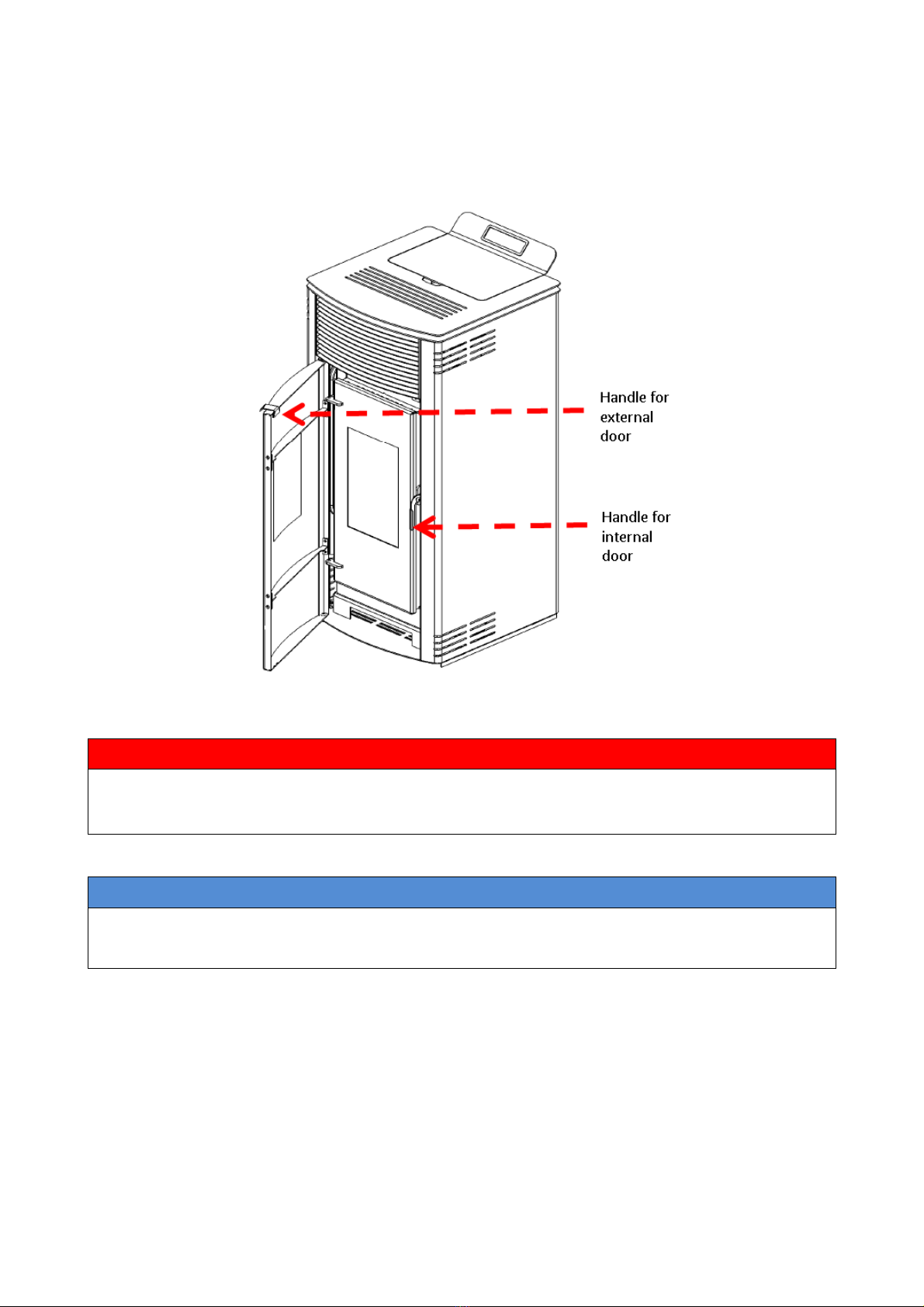

7.3. Opening and closing the door

First open external door via the handle on top right corner. Then, unhook the lock on the

internal door of the stove, as shown in the figure

WARNING

Internal door must be closed properly for the stove to work correctly.

Use suitable Personal Protective Equipment (e.g. gloves) to open the stove door.

NOTICE

Stove is equipped with a water pressure switch that protects the boiler from operation without

water inside. The minimum setting of pressure switch is 0,2 bars. That is why, your stove will

not be in operation, unless water pressure inside the hydraulic circuit is above 0,2 bars.

Table of contents

Popular Stove manuals by other brands

ROBENS

ROBENS FIREFLY instruction manual

Dean

Dean Hembury Slimline operating instructions

Harrie Leenders

Harrie Leenders HL2 Manual and installation instructions

EverHot

EverHot ElectricStove owner's manual

Harman Stove Company

Harman Stove Company P61A-2 owner's manual

Flame King

Flame King VT-505 Care, use and safety instructions

VARDE OVNE

VARDE OVNE Fuego 1 Installation and user guide

Brunton

Brunton Crux user manual

BRULA

BRULA CITY GRUNDI Maxi Assembly and operating instructions

Harman Stove Company

Harman Stove Company Accentra owner's guide

RIKA

RIKA LOOK Assembly manual

Vilpra Sauna

Vilpra Sauna Fornax VPR-14 Installation and operation manual