thermastor Phoenix Aquadry TX 80 User manual

11

Phoenix’s new hydronic fan coils, the Phoenix Aquadry

TX 80 and TX 200 set a new standard for heat drying

technology. The Phoenix Aquadry fan coils, when coupled

to a glycol central heat system, deliver safe, efficient, and

even heat to your restoration job.

The Phoenix Aquadry TX 80 provides 80,000 BTU/hr and

950 CFM. The Phoenix Aquadry hydronic fan coils are

engineered to be the most efficient, most rugged, and

most portable hydronic heat exchangers made.

Unlike direct-fired heaters, Phoenix Aquadry fan coils

completely isolate the heat source from combustion

byproducts. This not only provides a safer heat source

on the job, but also eliminates the need for outside air

ventilation. By doing so, the Phoenix Aquadry hydronic

fan coils give restoration professionals higher efficiency,

more flexibility in job setup, and a larger number of drying

opportunities.

Phoenix Aquadry fan coils are thermostatically controlled,

allowing the user to set the optimal temperature for

each job. Both units use a motorized impeller and high

efficiency coil to ensure the most efficient heat transfer

and even heat distribution throughout the structure.

Owner’s Manual — Phoenix Aquadry TX 80

Installation, Operation & Service Instructions

Read and Save These Instructions

www.UsePhoenix.com • [email protected]Toll-Free 1-800-533-7533

Specifications subject to change without notice.

TS-613b

04/10

The Phoenix Aquadry TX 80

Hydronic Heat Exchanger

• 80,000BTUs

• 950CFM

• ETLCertiedtoANSI/UL1995andCSA

C22.2No.236

• Thermostaticallycontrolled

• Multipleairlteroptions

• Multipleductingoptions

16”intake,14”supply

• Stainlesssteelcabinet

• Operatesbothverticallyandhorizontally

The Phoenix Aquadry TX 80, like the TX 200, can be

transported and operated upright or on its back. This

flexibility, along with multiple ducting options, allows the

restoration professional to maneuver into tight or low-

clearance spaces and direct the heat precisely where it is

needed.

The Phoenix Aquadry fan coils feature compact designs,

sturdy handles, and chamfered cabinets. Their light

weight, large recessed wheels, and high-impact skid

plates help negotiate curbs and stairs easily. The units’

balanced designs and integral lift hooks further enhance

maneuverability on the job site, while stainless steel

cabinets ensure years of service without corrosion or the

need for repainting.

4201 Lien Rd. • Madison, WI 53704

2

www.UsePhoenix.com • [email protected]Toll-Free 1-800-533-7533

Read the installation, operation and maintenance

instructions carefully before installing and operating

this device. Proper adherence to these instructions is

essential to obtain maximum benefit from your Phoenix

Aquadry TX 80.

Table of Contents

SafetyPrecautions .........................................2

1.Specications ............................................3

2. Operation

2.1 Transporting .......................................3

2.2ElectricalRequirements .......................3

2.3PowerSwitch .......................................3

2.4GlycolConnections ...............................3

2.5 Ducting................................................3

3. Maintenance

3.1AirFilter...............................................3

4. Service

4.1TechnicalDescription............................4

4.2Troubleshooting...................................4

5. OptionsandAccessories...........................4

6. WiringDiagram.........................................4

7. ServiceParts ...........................................5

8. Warranty ..................................................6

9.GlycolMSDS ..............................................7

SerialNo.__________________________________

PurchaseDate______________________________

Dealer’sName______________________________

Unit Intended for INDOOR USE ONLY; DO NOT USE

OUTDOORS

• DeviceisHOTwheninuse.Topreventburns,avoid

skin contact with hot surfaces.

• Use handle when moving device.

• Extremecautionisnecessarywhendeviceisused

by or near children or invalids and whenever device

is left operating unattended.

• Always unplug unit when not in use.

• DONOTOPERATEwithdamagedcord,inlet

receptacle, or after unit malfunctions, has been

droppedordamagedinanymanner.Returnto

authorized service facility for adjustment or repair.

• Device not intended for use directly in an area

where it may fall into a bathtub or other water

container.

• DONOTruncordundercarpetingorotheroor

covering. Arrange cord away from traffic area and

where it will not present a trip hazard.

• To disconnect device, turn controls off, then

remove user-supplied cord from inlet receptacle.

• ConnectONLYtoproperlygroundedoutlets.

• DONOTinsertorallowforeignobjectstoenter

any inlet or supply openings as this may cause

anELECTRICSHOCKorFIRE,ordamagetothe

heater.

• To prevent a possible fire, do not block air inlet

or supply openings in any manner. Do not use on

soft surfaces, like a bed, where openings may

become blocked.

• Device is not explosion proof. Do not use in areas

where gasoline, paint, or flammable liquids are

used or stored.

• Use device only as described in this manual. Any

other use not recommended by the manufacturer

may cause fire, electric shock, or injury to

persons.

• Ensurethattheuser-suppliedcordissized

appropriately to the current of this device.

3

www.UsePhoenix.com • [email protected]Toll-Free 1-800-533-7533

1. Specifications

Part Number: 4029410

Power: 1.8fullloadamps,120V/60Hz

Blower: 950 CFM

Temperature

Set Point Range:40ºFto180ºF

Filter Box

(Option): FilterSize:16”X16”X2”

Hydronic

Connections: 3/4”ISO7241SeriesBcouplings

Duct Inlet:16”Flex-Duct

Connections: Supply:14”LayFlat-Duct

Warranty: 1YearPartsandLabor

Dimensions:

Unit Shipping

Width 20.25” 24”

Height 40” 45.25”

Depth 21.375” 25.5”

Weight 85lb 110lb

2. Operation

2.1 Transporting

The Phoenix Aquadry TX 80 may be transported and

operated upright or on its back. The unit features a high-

impact plastic skid plate which protects the unit while

navigating obstacles such as curbs, stairways, and while

loading into vehicles.

2.2 Electrical Requirements

ThePhoenixAquadryTX80requires120VACandfeatures

astandard120VACinletreceptaclewithground.When

properly connected to a grounded outlet, it provides a

ground connection through the user-supplied cord in order

protecttheoperatorfromelectricshock.Ensurethatthe

supply cord used is a 2-conductor with ground and that it

has no nicks or cuts in the insulation. The electrical inlet

isdesignedtoacceptaNEMA5-15R(receptacle-15amp,

2 pole + ground).

2.3 Power Switch and Thermostat

MasterPOWERSwitch:Themasterpowerswitchlocated

on the side of the Phoenix Aquadry TX 80 can be used to

turntheunitON,OFF.

WhensettoON,thePhoenixAquadryTX80willenergize

the blower. Temperature set point can be set by

using a flat-bladed screwdriver. The thermostat will

control only the blower motor - not the glycol fluid -

so the unit may be hot even when the blower is not

energized. The blower will cycle on and off as needed to

maintain the selected temperature.

2.4 Glycol Line Connections

Hydronic(hotwater/propyleneglycol)connectionsare

madeusing3/4inchcouplingsthatcomplywiththeISO

7241SeriesBstandard.Thesecouplersminimizethe

fluid loss on disconnection – but there is a small amount

lost(~1tablespoon/16cc).ThePhoenixAquadryTX80

has been designed to direct this loss away from the fan

inlet.

Ensurethatthehydronicpumpisoffbeforeattempting

connection of the hydronic couplers.

Heat transfer fluid temperatures can approach 200°F

(93C).Usegloveswhenhandlinghotcouplersandworking

around the unit’s hot surfaces.

2.4 Ducting

The Phoenix Aquadry TX 80 can be ducted at the

inlet, the outlet or both. The Phoenix Aquadry TX 80

comes equipped with a snap ring on the outlet that

accommodates14”lay-atduct.Byaddingtheoptional

ductablelterboxassembly,16”exductcanbeused

ontheinlet.WhenductingtheTX80,caremustbetaken

to ensure airflow is not choked off due to kinks or sharp

bends in the duct.

3 Maintenance

3.1 Cleaning

Coils should be checked periodically to ensure they are

freeofdirtanddebris.Removedebrisfromcoilwith

compressedair(preferredmethod).Ifcoilsbecome

contaminated, they can be washed down with water and

blown dry with compressed air.

IfthePhoenixAquadryTX80isoperatedindirty

environments, the optional air filter kit should be installed

on the intake of the machine.

4

www.UsePhoenix.com • [email protected]Toll-Free 1-800-533-7533

4 Service

Servicing the Aquadry TX 80 with its high voltage

circuitry presents a health hazard which could result in

death, serious bodily injury, and/or property damage.

Only qualified service people should service this unit.

Do not operate the unit without all panels in place.

4.1 Technical Description

The Phoenix Aquadry TX 80 uses a high efficiency heat

transfer coil and high volume impeller to transfer and

deliver heat to the structure. The system is designed to

operate with hydronic heating module that use a low-

pressure, open fluid loop distribution system with an

atmospherically vented fluid reservoir. A hydronic heating

module warms the heat transfer fluid. This heated fluid

is pumped through a distribution system loop, passing

through heat exchangers in remote locations. By providing

a clean heat source, the system eliminates the need to

draw in outside air, minimizing energy costs.

4.2 Troubleshooting

Blower not running

1.Unitunplugged,nopowertoinletreceptacle

2. Power switch not working or thermostat not calling for

heat

3.Wiringfaultinsidedevice

4.Defectiveblowermotororcapacitor

Blower running but no heat

1.Airowrestrictedatinlet,outletorfouledcoil

2. Heating source not operating

5 Options and Accessories

Accessory Part Description

4029876 DUCTABLEFILTERBOXKIT

4021799 16”x16”x2”MERV-8

4028363 16”X25’HEAVYDUTYFLEXDUCT

4024936 14”X250’LAYFLATDUCT

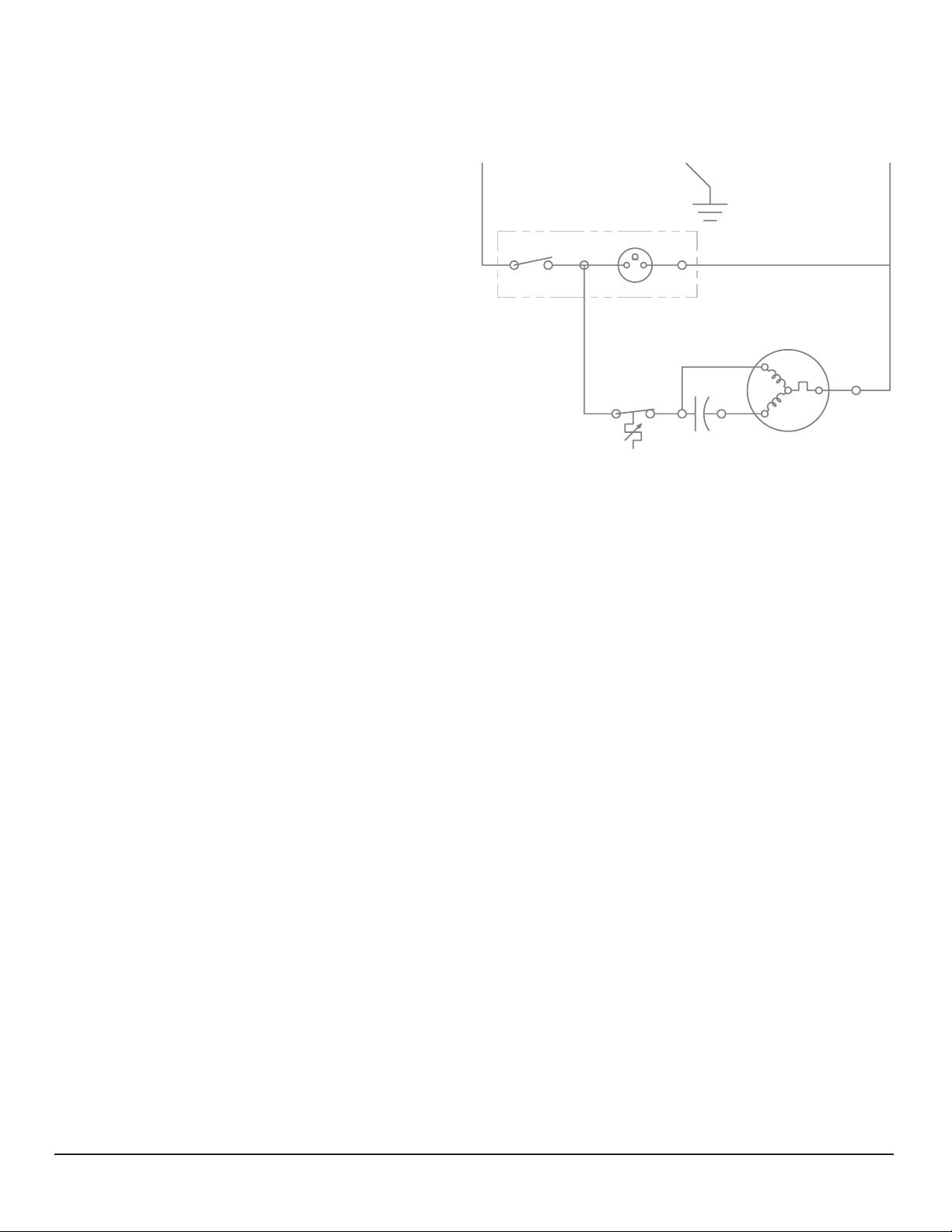

6 Wiring Diagram

3.50

3.50

4029457

A

4201 Lien Rd., Madison, WI 53704

1-800-533-7533

BLU

BLK

BLK

BLK

WHT

WHT

WHT

BRN

MOTOR

POWER

SWITCH

LIGHT

MAIN

POWER

SWITCH

T-STAT

ADJ

CAPACITOR

115 VAC, 60 HZ, 1 PH

NOTES:

1. MATL: VINYL FILM PER SES 182

2. CAMERA READY ARTWORK TO BE SUPPLIED BY

TS MARKETING DEPT

3. PROOFS TO BE APPROVED BY TS ENGRG DEPT

4. COLORS: BLACK LINES & LETTERS

ON WHITE BACKGROUND

5. SHEETS WITH SPLIT LINER OR ROLLS

6. MARK PACKAGING CLEARLY WITH DATE OF

MANUFACTURE, TS P/N, REV LETTER & PKG QTY

DWG. NO.

SHEET

REV.

TITLE:

DRAWN BY

CHECKED BY

SIGNATURES / DATE

SCALE

A

1 OF 1

INCHES METRIC [MM]

.X

.030 X.

1

.XX

.010 X.X

0.5

.XXX

.005 X.XX

0.25

ANGULAR TOL.

1

FRACTIONAL TOL.

1/64

1 INCH = 25.4 MM

DIMENSIONS ARE TOLERANCED

AS FOLLOWED:

THIRD ANGLE PROJECTION

MAT'L

Therma-Stor

LLC

P.O. Box 8050, Madison, WI 53708

REL ECO

REV ECO

REV ESA

MCN

DO NOT SCALE DRAWING. DIMENSIONS

AND TOLERANCES PER ANSI Y14.5-1793.

ALL DIMENSIONS ARE BEFORE PLATING.

DEBURR HOLES AND SHARP EDGES .005/.015.

MACHINED SURFACES 125 RMS.

THIS DRAWING IS CONFIDENTIAL AND

PROPRIETARY TO THERMA-STOR LLC. IT IS

LOANED STRICTLY ON CONDITION THAT THE

INFORMATION WILL NOT BE USED FOR THE

BENEFIT OF ANY OTHER ENTITY

4029457

A

SDB

7-15-09

EC

7-15-09

76776

NOTED

1:1

WIRING DIAG,

QUEST DRY HTC

REV APPROVAL

SIZE

5

www.UsePhoenix.com • [email protected]Toll-Free 1-800-533-7533

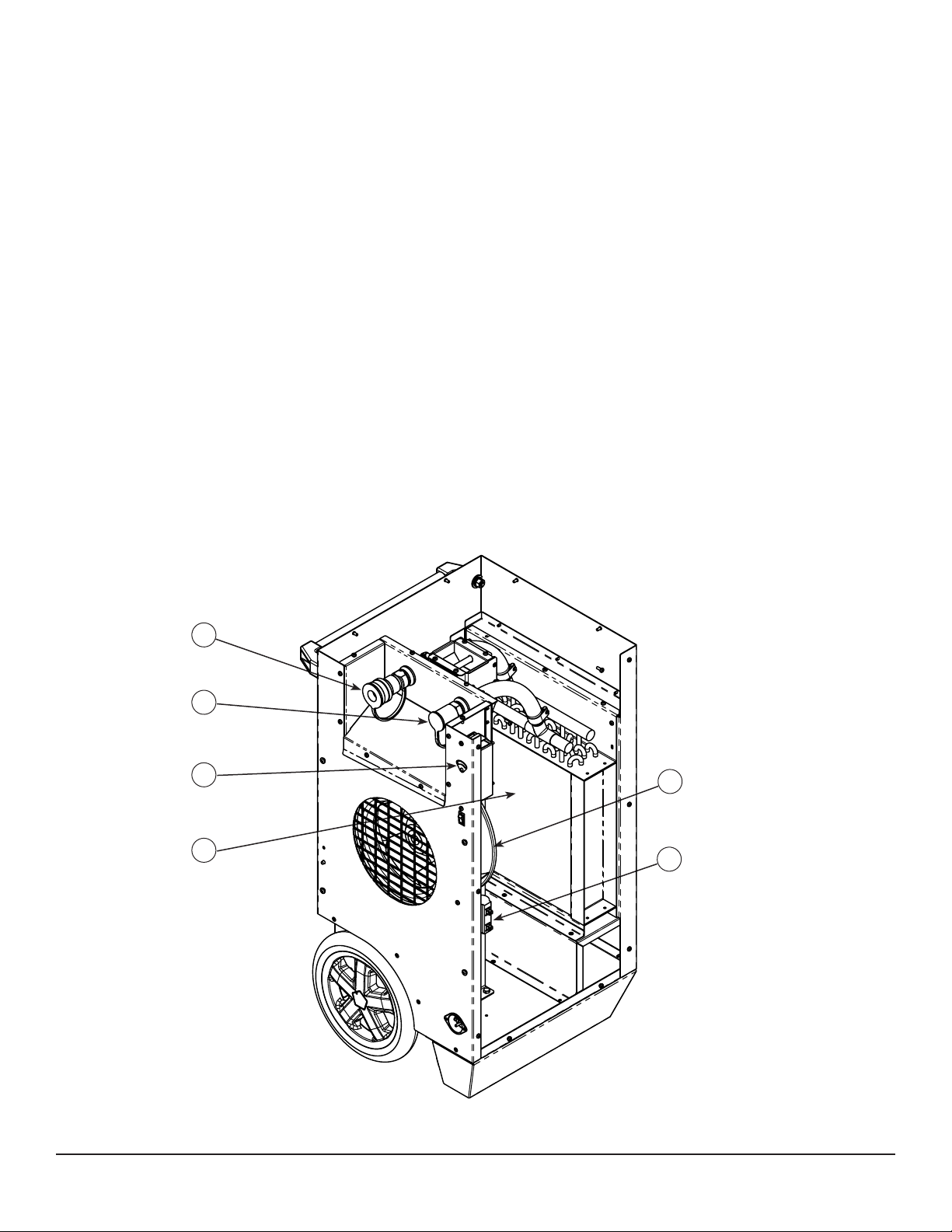

7 Service Parts

Item Description Service Part Qty

1 CAPACITOR15MFD 4025043 1

2 HOSECLAMP 4029411 4

3 DUSTCAP 4029781 1

4 DUSTPLUG 4029782 1

5 COUPLINGMALE,3/4”x3/4”FNPT 4029783 1

6 COUPLING,FEMALE,3/4”x3/4”NPT 4029784 1

7 THERMOSTAT 4030411 1

8 NUTJAM1.25-12UNF2B,ZP 4029418 2

9 HOSE 4029419 9.5”

10 HYDRONICCOIL 4029441 1

11 FAN,MOTORIZEDIMPELLER 4029455 1

12 BULKHEADFITTING 4029785 2

13 14”SNAPRING 4029877 1

6

5

7

10

11

1

Table of contents