3ENGLISH

GENERAL INFORMATION

GENERAL INFORMATION

b

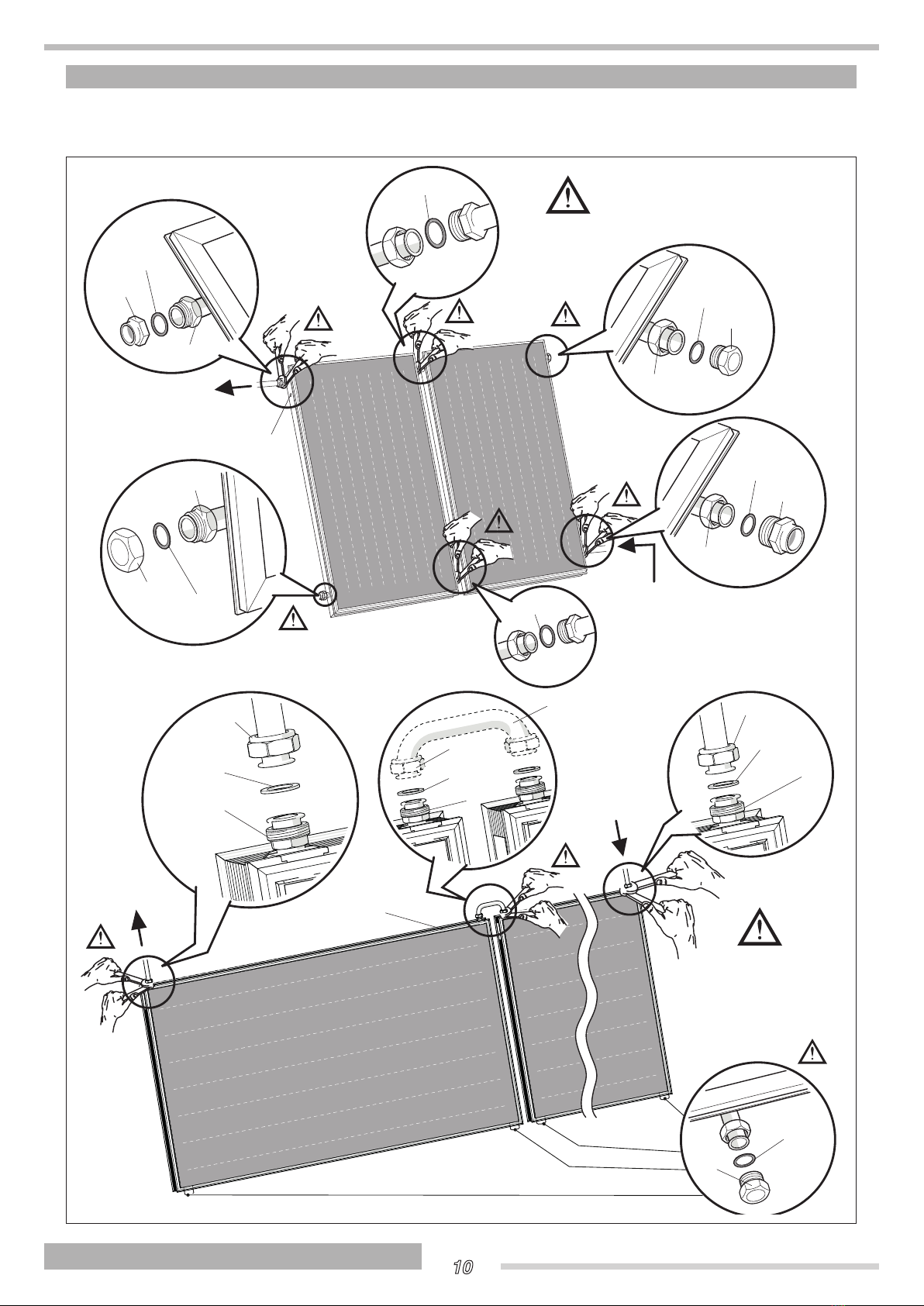

The system must be installed by specialist personnel.

Use only the assembly material supplied with the solar

collector. The supporting framework and all masonry or

brickwork fixing points must be checked by a person ex-

pert in static loading, and must be suitable for the nature

of the installation site.

b

The solar collector must only be installed on roofs or

frames that are strong enough to support its weight. The

strength of the roof or frame must be verified on site by a

person expert in static loading before the solar collector

is installed. During this process, it is important to verify

the suitability of the supporting frame to hold the screw

fasteners that fix the solar collector in place. An expert

in static loading must verify that the entire frame com-

plies with relevant standards, especially in areas liable

to snow and areas exposed to high winds. Conditions

(gusts of wind, formation of wind vortices, etc.) at the

point where the solar collector is to be installed must be

carefully considered since these can increase the loads

on the supporting structure.

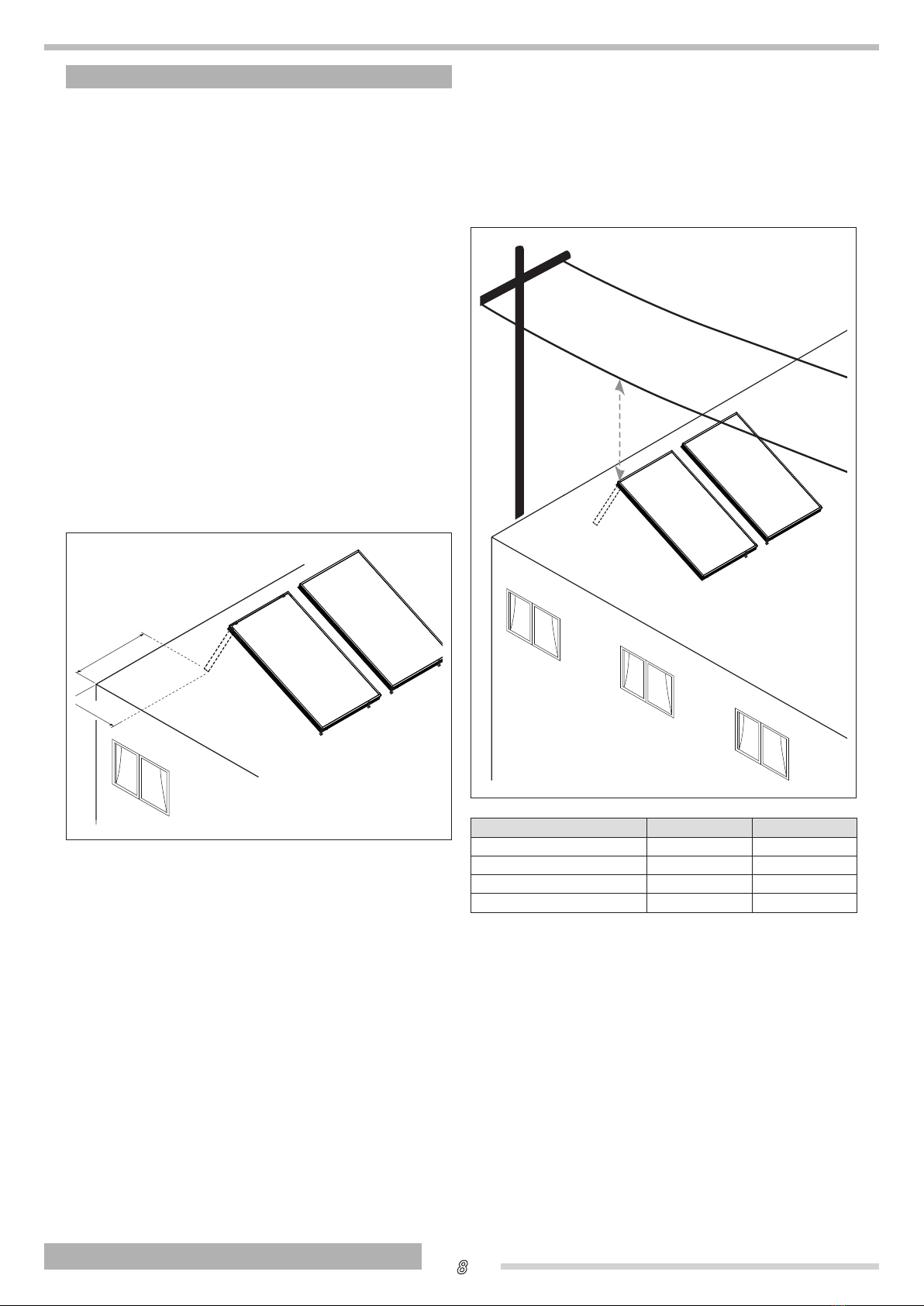

b

Solar collector pipes must be connected through a (yel-

low-green) connector of at least 16 mm2Cu (H07 V-U o

R) to the potential compensation main bar. If a lighting

rod is already installed, collectors can be integrated in

the existing system. If this is not the case, it is possible

to carry out earthing with a buried earth cable. The earth

duct must be laid outside the house. Furthermore, the

earth cable must be connected to the compensation bar

through a duct having the same diameter.

b

All pipes in the water circuit must be insulated in con-

formity to relevant standards. Lagging and insulation

must be protected against damage by the weather and

birds and animals.

b

The collector is suitable for a minimum inclination of 15°,

up to a maximum of 75°.

b

This instruction manual is an integral part of the prod-

uct. It must be kept safe and must ALWAYS accompany

the product, even if it is sold to another owner or trans-

ferred to another user or to another installation. If you

lose this manual, order a replacement immediately. Keep

the product purchase documents to be presented to the

Tauthorised Technical Assistance Centre to

request a service call under warranty.

b

Size the solar expansion tank so as to ensure complete

absorption of the expansion of the fluid contained within

the system, with reference to the prevailing regulations

on the matter. In particular, consider fluid characteris-

tics, considerable fluctuation of service temperature and

vapour that might be generated during solar collector

stagnation stage. Proper size of expansion tank ensures

setting off of all volume changes of the heat transfer fluid,

avoiding excessive pressure increase. Limited pressure

changes avoid reaching safety valve opening pressure

and the consequent fluid drainage.

PRECAUTIONS

b

Always wear safety goggles when drilling. Always wear

safety shoes, cut-proof protective gloves and a safety

helmet when performing installation work.

b

Before beginning installation work on roofs, install the

necessary fall prevention and fall arrest devices and en-

sure that all applicable safety standards are applied. Use

only tools and materials that conform to the safety stand-

ards that are applicable in the place of work.

b

Use only overalls with harness (with lacing or restraining

belt, connection ropes or bands, fall dampeners, heat

sinks) certified for the risk detected according to the type

of covering and allowing operating in complete safety.

b

The use of ladders leaned against walls can lead to se-

rious falls if the ladder slips, slides of falls. When using

ladders, always ensure that they are stable, and that suit-

able ladder stops are present. If possible secure the lad-

der with hooks. Make sure that there are no live electrical

wires near the ladder.

a

Never attempt to install the system without using suitable

personal protection equipment and without following all

applicable occupational safety standards.

a

Do not touch the product when barefoot or wet if it has

any electrical accessories installed in it.

a

Never clean or service the storage cylinder without first

turning the mains power switch OFF to disconnect all

electrical accessories (if fitted) from the mains electricity

supply.

a

If solar plant pressure decreases, it is forbidden to top

up with only water as there is a danger of freezing and

overheating.

a

Do not dispose of packaging material into the environ-

ment, or leave it within the reach of children, since it can

become a potential hazard. Dispose of packaging mate-

rial in compliance with applicable legislation.