Thermo King SG 3500 Series User manual

Revision A

April 2022 TTKK 6611991144--44--MMMM--EENN

Container Edition

SG 3500 Series

Maintenance Manual

©2022 Trane Technologies TK 61914-4-MM-EN

Introduction

This manual is published for informa ional purposes only. Thermo King®makes no represen a ions warran ies express

or implied, wi h respec o he informa ion recommenda ions and descrip ions con ained herein. Informa ion provided

should no be regarded as all-inclusive or covering all con ingencies. If fur her informa ion is required, Thermo King

Corpora ion Service Depar men should be consul ed.

TThheerrmmoo KKiinngg’’ss wwaarrrraann yy sshhaallll nnoo aappppllyy oo aannyy eeqquuiippmmeenn wwhhiicchh hhaass bbeeeenn ““ssoo iinnss aalllleedd,, mmaaiinn aaiinneedd,, rreeppaaiirreedd

oorr aall eerreedd aass,, iinn hhee mmaannuuffaacc uurreerr’’ss jjuuddggmmeenn ,, oo aaffffeecc ii ss iinn eeggrrii yy..””

MMaannuuffaaccttuurreerr sshhaallll hhaavvee nnoo lliiaabbiilliittyy ttoo aannyy ppeerrssoonn oorr eennttiittyy ffoorr aannyy ppeerrssoonnaall iinnjjuurryy,, pprrooppeerrttyy ddaammaaggee oorr aannyy

ootthheerr ddiirreecctt,, iinnddiirreecctt,, ssppeecciiaall,, oorr ccoonnsseeqquueennttiiaall ddaammaaggeess wwhhaattssooeevveerr,, aarriissiinngg oouutt ooff tthhee uussee ooff tthhiiss mmaannuuaall oorr

aannyy iinnffoorrmmaattiioonn,, rreeccoommmmeennddaattiioonnss oorr ddeessccrriippttiioonnss ccoonnttaaiinneedd hheerreeiinn.. TThhee pprroocceedduurreess ddeessccrriibbeedd hheerreeiinn sshhoouulldd

oonnllyy bbee uunnddeerrttaakkeenn bbyy ssuuiittaabbllyy qquuaalliiffiieedd ppeerrssoonnnneell.. FFaaiilluurree ttoo iimmpplleemmeenntt tthheessee pprroocceedduurreess ccoorrrreeccttllyy mmaayy ccaauussee

ddaammaaggee ttoo tthhee TThheerrmmoo KKiinngg uunniitt oorr ootthheerr pprrooppeerrttyy oorr ppeerrssoonnaall iinnjjuurryy..

General Information

The maintenance information in this manual covers unit models:

SGCO 3500 System Number 904281M

SGUM 3500 System Number 904282M

SGCO 3500 System Number - Wujiang 904636M

SGUM 3500 System Number - Wujiang 904637M

For further information, refer to:

SGCO 3500 Parts Manual TK 61935

SGUM 3500 Parts Manual TK 61936

Yanmar TK486VEGS5 Engine Troubleshooting Manual TK 61757

Tool Catalog TK 5955

The information in this manual is provided to assist owners, operators and service people in the proper upkeep and maintenance of Thermo

King units.

Model Nomenclature CO: Clip-On unit frame

UM: Undermount unit frame

Tools

TOOL - ECU Diagnostic, YSAD (Dealer Version) 2041969

TOOL - ECU Diagnostic, YSAD (Customer Version) 2041970

Revision History

Revision A (04/2022) New Manual.

TK 61914-4-MM-EN 3

Customer Satisfaction Survey

Le your voice be heard!

Your feedback will help improve our manuals. The survey is accessible hrough any in erne -connec ed device wi h a

web browser.

Scan he Quick Response (QR) code or click Technical Publica ions EMEA Feedback

Serial Number Location

•EEnnggiinnee:: Engine iden ifica ion pla e is loca ed on he engine valve cover.

•GGeenneerraa oorr:: The genera or namepla e is a ached o he genera or housing. The serial number is loca ed on his

namepla e.

•SSGGUUMM UUnnii ss:: The uni serial number namepla e is a ached o he uni frame near he rear moun ing bracke or on

he air cleaner bracke .

•SSGGCCOO UUnnii ss:: The uni serial number namepla e is on curb side of ank by lower moun ing bol area.

•CCoonn rroolllleerr::The con roller serial number namepla e is on he back of he con roller.

IInn rroodduucc iioonn

4TK 61914-4-MM-EN

SSaaffee yy PPrreeccaauu iioonnss ............................................................................................................................................................ 99

Danger, Warning, Cau ion, and No ice . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

General Prac ices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Elec rical Hazards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

High Vol age . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

LowVol age ............................................................................... 11

Ba ery Ins alla ion and Cable Rou ing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Ba ery Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Elec ros a ic Discharge Precau ions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Elec ros a ic Discharge and he Con roller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Con roller / Microprocessor Service Precau ions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Welding on Refrigera ion Uni s or Con ainers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

High Pressure Fuel Hazards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Firs Aid....................................................................................... 13

SSppeecciiffiiccaa iioonnss .. .. ........ ........ .. ...... .. .. .... .. ........ .. ........ ........ .. ...... .. ...... .. ........ .. .... .. .. ...... .. ........ .. ...... .. ...... .. .. .... .. ........ .. ........ .... 1155

Genera or..................................................................................... 15

Elec rical Con rol Sys em . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Engine ....................................................................................... 16

Bel Tension................................................................................... 17

SG 3500 Series Uni Weigh . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

MMaaiinn eennaannccee IInnssppeecc iioonn SScchheedduullee .... .. .. ...... .. ...... .. ...... .. .. .... .. ........ .. ...... .. .. .... .. ........ .. ...... .. ...... .. .. .... .. ........ .. ...... .. .. 1188

UUnnii DDeessccrriipp iioonn .. .. ...... .. .... .. ...... .. .... .. ...... .. .... .. ...... .. .... .. ........ .. .... .. ...... ...... .. ...... .. .... .. ...... .. ...... .. ...... ...... .. .... .. ...... .. .... .. ...... 1199

General Descrip ion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

EMI3000...................................................................................... 20

Microprocessor Con roller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Uni Pro ec ion Devices. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Vol age Op ion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

PPhhoo ooss,, IIlllluuss rraa iioonnss,, aanndd MMeeaassuurreemmeenn ss .... .. ........ .. ...... .. ...... .. .. .... .. ........ .. ........ .. ...... .. ...... .. ...... .. ........ .. .... .. .. .... 2222

SGCO 3500 Fron View . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

SGCO 3500 Fron View (Covers Removed) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

SGCO 3500 Con rol Box (Ex ernal). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

SGCO 3500 Pins and Clamps (Op ion) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

SGCO 3500 Telema ics Fuel Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

SGCO 3500 Cus omer asse ID decal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

SGCO 3500 Mechanical fuel gauge (Op ion) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Con rol Box SGCO Inside view . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

able of Contents

TK 61914-4-MM-EN 5

SGUM 3500 Fron View. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

SGUM 3500 Fron View (Covers Removed). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

SGUM 3500 Arms Moun ing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

SGUM 3500 Telema ics Fuel Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

SGCO 3500 Con rol Box (Ex ernal). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Con rol Box SGUM Inside view . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

SGUM 3500 Ins alla ion Decal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

GGeennssee MMooddeell FFeeaa uurreess ...... ........ .. ...... .. ...... .. ........ .. .... .. .. ...... .. ........ ........ .. ...... .. .. .... .. ........ .. ........ ........ .. ...... .. ...... .. ........ 3344

CCoonn rroolllleerr aanndd OOppeerraa iinngg IInnss rruucc iioonnss ................................................................................................................ 3355

Con roller Descrip ion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Con roller Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Miscellaneous Con roller Fea ures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Naviga ing he Con roller Menus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Ho keys................................................................................... 36

Direc ional and Confirma ion Keys. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Opera ing Ins ruc ions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Pre rip Inspec ion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

VViissuuaall IInnssppeecc iioonn ......................................................................... 37

Con roller In erac ion and Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Uni PowerToggleSwich .................................................................. 38

ConrollerDisplay.......................................................................... 38

Flashloading he con roller. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Con roller Display Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Saus ................................................................................... 41

Engine................................................................................... 41

Generaor ................................................................................ 41

Alarms................................................................................... 42

AciveECUDTC’sMenu..................................................................... 42

Even Log ................................................................................ 42

SerialPor Menu........................................................................... 42

Gense Da a Menu and Config De ails . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

PLCInsrumenaion ....................................................................... 42

Abou.................................................................................... 42

Gense S ar -up and Ini ial Run ime . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Uni S ar Sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

CoundownTimer ......................................................................... 44

Buzzer................................................................................... 44

EngineSar Sequence ..................................................................... 44

EngineResar Sequence.................................................................... 44

Pos Sar................................................................................. 45

PreandPos Hea .......................................................................... 45

Engine Opera ion and Speed Con rol . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

EngineSall................................................................................ 46

Uni Alarm Moni oring. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Gense Service and Pre- rip Tes ing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

TTaabbllee ooff CCoonn eenn ss

6TK 61914-4-MM-EN

Pre- rip Tes ing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Manual Speed Con rol . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

ServiceMode.............................................................................. 46

Even logging . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

AlarmsLis .................................................................................... 47

Warning Alarms. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Shu down Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

AlarmCodes............................................................................... 48

EElleecc rriiccaall MMaaiinn eennaannccee.... .. .. ...... .. ........ .. ...... .. ...... .. .. .... .. ........ .. ........ ...... .. .. ...... .. ...... .. ........ .. .... .. .. ...... .. ........ .. ...... .. ...... .. 5500

Ba ery........................................................................................ 50

Gense Ba ery Charger Specifica ion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

I/O Descrip ions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

ACInpu ................................................................................. 50

Ba eryChargeCurren ..................................................................... 50

Ba eryChargeVolage..................................................................... 50

Ba erycharger............................................................................ 51

Ba erycharge ............................................................................ 51

Microprocessor Con roller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Fuses......................................................................................... 52

Uni Wiring.................................................................................... 53

Wire Harness Rou ing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Engine Oil Sensors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Engine Low Oil Pressure Swi ch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Engine Oil Level Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

EEnnggiinnee MMaaiinn eennaannccee .. .. ........ ........ .. ...... .. .. .... .. ........ .. ...... .. ...... .. ........ ........ .. ...... .. .. .... .. ........ .. ........ ........ .. ...... .. .. .... .. ........ 5555

EMI3000...................................................................................... 55

Engine Lubrica ion Sys em . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Engine Oil Change . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Oil Fil er Change . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Low Oil Pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Engine Cooling Sys em. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Ex ended Life Coolan (ELC). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

An ifreeze Main enance Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Checking heAnifreeze..................................................................... 59

Changing heAnifreeze .................................................................... 59

Bleeding Air from he Cooling Sys em . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Engine Thermos a . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Coolan Level Swi ch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Tes ing he Coolan Level Swi ch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Checking heFloa ......................................................................... 60

Replacing he Coolan Level Swi ch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Engine Fuel Sys em . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Opera ion ................................................................................. 62

TTaabbllee ooff CCoonn eenn ss

TK 61914-4-MM-EN 7

Fuel Line Rou ing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Fuel Sys em Fi ings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Main enance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Fuel Re urn Line Replacemen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Bleeding he Fuel Sys em . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

SG3500Series............................................................................ 64

Draining Wa er from Fuel Tank . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Fuel Fil er/Wa er Separa or. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Fuel Fil er and Wa er Separa or Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

FilerIconIdenificaion..................................................................... 65

Injec ion Pump and Engine Speed Con rol. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Injec ion Pump Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Injec ion Pump Reins alla ion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Download Procedure for Injec ion Pump Replacemen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Engine Valve Clearance Adjus men . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

Crankcase Brea her . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

EMI 3000 Air Cleaner . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

Bel s.......................................................................................... 87

Wa er Pump Bel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

Radia or and Fan Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

Radia or................................................................................... 89

Radia or Cooling Fan . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

Fan and Shroud Adjus men . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

YYaannmmaarr YYSSAADD DDiiaaggnnooss iicc EEnnggiinnee SSeerrvviiccee.... .. .. ...... .. ...... .. ...... .. .. .... .. ........ .. ........ .. .... .. .. ...... .. ...... .. ...... .. .. .... .. ...... 9911

Yanmar Diagnos ic Trouble Codes (DTC) and Associa ed Thermo King Alarm Codes . . . . . . . . . . . . . . . . 91

Clearing Yanmar DTC Codes and Associa ed Thermo King Alarm Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

Connec ing and Using he Yanmar Engine Diagnos ic Tool . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

Sof ware Download for Flash o Replacemen ECU . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

Uploading Informa ion o Yanmar. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

Upda ing ECU Sof ware From Yanmar Core Da abase . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

ECU Recovery/Failures During Flash Load Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

ECU Programming or ECU Upda ing of Sof ware Failure During Flash . . . . . . . . . . . . . . . . . . . . . . . . . 105

Communica ion In errup ion During Flashing Process . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

Abnormali y Occurrence During Flashing Process. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

Accessing and Downloading YSAD Troubleshoo ing Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

AAll eerrnnaa oorr OOppeerraa iioonn aanndd DDiiaaggnnoossiiss ..................................................................................................................111122

Megohmme er . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

Main enance Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

General Inspec ion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

Insula ion.................................................................................112

Field Coils, S a or Windings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

Genera or Housing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

TTaabbllee ooff CCoonn eenn ss

8TK 61914-4-MM-EN

Genera or Bearing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

Impeller Fan . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

Coupling .................................................................................113

General Descrip ion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

Al erna or Func ion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

S ar ing Exci a ion. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

Running Exci a ion and Con rol. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

Overload .................................................................................116

Overload Shu down . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

Al erna or Diagnosis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

Preliminary Checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

Tes Ins rumen s . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

Al erna or Troubleshoo ing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

Tes 1 - De ermine if problem is wi h he DSR or he Al erna or. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

Tes 2 - Al erna or Exci er Field Tes ing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

Tes 3 - Al erna or S a or Tes ing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

Tes 4- Exci er and Diode Tes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

Al erna or Replacemen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

Al erna or Removal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

Al erna or Ins alla ion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 124

SS rruucc uurraall//AAcccceessssoorryy MMaaiinn eennaannccee......................................................................................................................112266

Uni Inspec ion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 126

Moun ing Bol s . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 126

SGCO Clip-on Corner Clamp Uni Ins alla ion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 127

SGCO Clip-on Corner Header Pin Uni Ins alla ion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 130

TTeelleemmaa iiccss IInnffoorrmmaa iioonn ..............................................................................................................................................113311

Telema ics General Descrip ion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 131

Telema ics Componen Loca ions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 132

Telema ics Module Cycle Iden ifica ion (LED Flash) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 132

Telema ics Diagnos ic Informa ion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 135

Telema ics Fuel Level Sensor (op ional). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 138

Telema ics An enna . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 140

Pairing Telema ics Module o SG Uni . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 142

Ins all of Telema ics in he SGUM-3500 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 149

MMeecchhaanniiccaall DDiiaaggnnoossiiss..................................................................................................................................................115511

DDiiaaggrraamm IInnddeexx..................................................................................................................................................................115533

TTaabbllee ooff CCoonn eenn ss

TK 61914-4-MM-EN 9

Safety Precautions

Danger, Warning, Caution, and Notice

Thermo King®recommends ha all service be performed by a Thermo King dealer and o be aware of several general

safe y prac ices.

Safe y advisories appear hroughou his manual as required. Your personal safe y and he proper opera ion of his uni

depend upon he s ric observance of hese precau ions. The four ypes of advisories are defined as follows:

DDAANNGGEERR

HHaazzaarrdd!!

IInnddiiccaa eess aann iimmmmiinneenn llyy hhaazzaarrddoouuss ssii uuaa iioonn wwhhiicchh,, iiff nnoo aavvooiiddeedd,, wwiillll rreessuull iinn ddeeaa hh oorr sseerriioouuss iinnjjuurryy..

WWAARRNNIINNGG

HHaazzaarrdd!!

IInnddiiccaa eess aa ppoo eenn iiaallllyy hhaazzaarrddoouuss ssii uuaa iioonn wwhhiicchh,, iiff nnoo aavvooiiddeedd,, ccoouulldd rreessuull iinn ddeeaa hh oorr sseerriioouuss iinnjjuurryy..

CCAAUUTTIIOONN

HHaazzaarrdd!!

IInnddiiccaa eess aa ppoo eenn iiaallllyy hhaazzaarrddoouuss ssii uuaa iioonn wwhhiicchh,, iiff nnoo aavvooiiddeedd,, ccoouulldd rreessuull iinn mmiinnoorr oorr mmooddeerraa ee iinnjjuurryy aanndd

uunnssaaffee pprraacc iicceess..

NN TTIICCEE

HHaazzaarrdd!!

IInnddiiccaa eess aa ssii uuaa iioonn hhaa ccoouulldd rreessuull iinn eeqquuiippmmeenn oorr pprrooppeerr yy--ddaammaaggee oonnllyy aacccciiddeenn ss..

General Practices

WWAARRNNIINNGG

PPeerrssoonnaall PPrroo eecc iivvee EEqquuiippmmeenn ((PPPPEE)) RReeqquuiirreedd!!

AAllwwaayyss wweeaarr ggoogggglleess oorr ssaaffee yy ggllaasssseess aanndd pprrooppeerr PPPPEE wwhheenn wwoorrkkiinngg oonn aa uunnii .. RReeffrriiggeerraann lliiqquuiidd,, ooiill,, aanndd

bbaa eerryy aacciidd ccaann ppeerrmmaanneenn llyy ddaammaaggee yyoouurr eeyyeess.. WWhheenn wwoorrkkiinngg wwii hh oorr aarroouunndd hhaazzaarrddoouuss cchheemmiiccaallss,,

AALLWWAAYYSS rreeffeerr oo aapppprroopprriiaa ee MMaa eerriiaall DDaa aa SSaaffee yy SShheeee ss ((MMSSDDSS)) aanndd OOSSHHAA//GGHHSS ((GGlloobbaall HHaarrmmoonniizzeedd SSyyss eemm

ooff CCllaassssiiffiiccaa iioonn aanndd LLaabbeelllliinngg ooff CChheemmiiccaallss)) gguuiiddeelliinneess ffoorr iinnffoorrmmaa iioonn oonn aalllloowwaabbllee ppeerrssoonnaall eexxppoossuurree

lleevveellss,, pprrooppeerr rreessppiirraa oorryy pprroo eecc iioonn,, aanndd hhaannddlliinngg iinnss rruucc iioonnss..

WWAARRNNIINNGG

EEqquuiippmmeenn DDaammaaggee aanndd RRiisskk ooff IInnjjuurryy!!

NNeevveerr ddrriillll hhoolleess iinn oo hhee uunnii uunnlleessss iinnss rruucc eedd bbyy TThheerrmmoo KKiinngg.. HHoolleess ddrriilllleedd iinn oo hhiigghh vvooll aaggee ccaabblleess ccoouulldd

ccaauussee aann eelleecc rriiccaall ffiirree,, sseevveerree ppeerrssoonnaall iinnjjuurryy,, oorr eevveenn ddeeaa hh..

WWAARRNNIINNGG

RRiisskk ooff IInnjjuurryy!!

WWhheenn uussiinngg llaaddddeerrss oo iinnss aallll oorr sseerrvviiccee rreeffrriiggeerraa iioonn ssyyss eemmss,, aallwwaayyss oobbsseerrvvee hhee llaaddddeerr mmaannuuffaacc uurreerr’’ss

ssaaffee yy llaabbeellss aanndd wwaarrnniinnggss.. AA wwoorrkk ppllaa ffoorrmm oorr ssccaaffffoollddiinngg iiss hhee rreeccoommmmeennddeedd mmee hhoodd ffoorr iinnss aallllaa iioonnss aanndd

sseerrvviicciinngg..

10 TK 61914-4-MM-EN

NN TTIICCEE

EEqquuiippmmeenn DDaammaaggee!!

AAllll uunnii mmoouunn iinngg bbooll ss mmuuss bbee iinnss aalllleedd,, bbee hhee ccoorrrreecc lleenngg hh ffoorr hheeiirr aapppplliiccaa iioonn,, aanndd oorrqquueedd oo

ssppeecciiffiiccaa iioonnss.. MMiissssiinngg bbooll ss,, iinnccoorrrreecc bbooll lleenngg hhss aanndd iimmpprrooppeerr oorrqquuee ssppeecciiffiiccaa iioonnss ccaann ddaammaaggee

eeqquuiippmmeenn aanndd vvooiidd hhee wwaarrrraann yy..

Electrical Hazards

EElleecc rriiccaall PPrreeccaauu iioonnss

• The possibili y of serious or fa al injury from elec rical shock exis s when servicing a Gense uni . Ex reme care mus

be used when working wi h a refrigera ion uni ha is connec ed o i s power source.

• Ex reme care mus be used even if he uni is no running. Le hal vol age po en ials can exis a he uni power cord,

inside he con rol box, inside any high vol age junc ion box, a he mo ors and wi hin he wiring harnesses.

• In general, disconnec he uni ba ery and disconnec any power cords before repairing or changing any Gense

componen s.

• Even hough he con roller is urned off, one of he phases is s ill live and represen s a po en ial danger of

elec rocu ion.

High Voltage

DDAANNGGEERR

HHaazzaarrddoouuss VVooll aaggee!!

HHiigghh VVooll aaggee iiss pprreesseenn wwhheenn eennggiinnee iiss rruunnnniinngg!! DDiissccoonnnneecc mmaaiinn bbaa eerryy ccaabblleess oo eennssuurree hhee uunnii ccaannnnoo bbee

ss aarr eedd!!

DDAANNGGEERR

HHaazzaarrddoouuss VVooll aaggee!!

LLee hhaall aammoouunn ss ooff vvooll aaggee aarree pprreesseenn iinn ssoommee eelleecc rriiccaall cciirrccuuii ss.. UUssee eexx rreemmee ccaarree wwhheenn wwoorrkkiinngg oonn aann

ooppeerraa iinngg uunnii .. IIff hheerree iiss aa rriisskk ooff eenneerrggiizzeedd eelleecc rriiccaall ccoonn aacc ,, aarrcc,, oorr ffllaasshh,, eecchhnniicciiaannss MMUUSSTT ppuu oonn aallll PPPPEE iinn

aaccccoorrddaannccee wwii hh OOSSHHAA,, NNFFPPAA 7700EE,, oorr oo hheerr llooccaall,, ss aa ee,, oorr ccoouunn rryy--ssppeecciiffiicc rreeqquuiirreemmeenn ss ffoorr aarrcc ffllaasshh

pprroo eecc iioonn PPRRIIOORR oo sseerrvviicciinngg hhee uunnii .. NNEEVVEERR PPEERRFFOORRMM AANNYY SSWWIITTCCHHIINNGG,, DDIISSCCOONNNNEECCTTIINNGG,, OORR VVOOLLTTAAGGEE

TTEESSTTIINNGG WWIITTHHOOUUTT PPRROOPPEERR EELLEECCTTRRIICCAALL PPPPEE AANNDD AARRCC FFLLAASSHHIINNGG CCLLOOTTHHIINNGG.. EELLEECCTTRRIICCAALL MMEETTEERRSS AANNDD

EEQQUUIIPPMMEENNTT MMUUSSTT BBEE PPRROOPPEERRLLYY RRAATTEEDD FFOORR IINNTTEENNDDEEDD VVOOLLTTAAGGEE..

WWAARRNNIINNGG

HHaazzaarrddoouuss VVooll aaggee!!

TTrreeaa aallll wwiirreess aanndd ccoonnnneecc iioonnss aass iiff hheeyy wweerree hhiigghh vvooll aaggee uunn iill aa mmee eerr aanndd wwiirriinngg ddiiaaggrraamm iinnddiiccaa ee

oo hheerrwwiissee.. OOnnllyy uussee oooollss wwii hh iinnssuullaa eedd hhaannddlleess.. NNeevveerr hhoolldd uunniinnssuullaa eedd mmee aall oooollss nneeaarr eexxppoosseedd,, eenneerrggiizzeedd

ccoonndduucc oorrss.. IIff hheerree iiss aa rriisskk ooff eenneerrggiizzeedd eelleecc rriiccaall ccoonn aacc ,, aarrcc,, oorr ffllaasshh,, eecchhnniicciiaannss MMUUSSTT ppuu oonn aallll PPPPEE iinn

aaccccoorrddaannccee wwii hh OOSSHHAA,, NNFFPPAA 7700EE,, oorr oo hheerr llooccaall,, ss aa ee,, oorr ccoouunn rryy--ssppeecciiffiicc rreeqquuiirreemmeenn ss ffoorr aarrcc ffllaasshh

pprroo eecc iioonn PPRRIIOORR oo sseerrvviicciinngg hhee uunnii .. NNEEVVEERR PPEERRFFOORRMM AANNYY SSWWIITTCCHHIINNGG,, DDIISSCCOONNNNEECCTTIINNGG,, OORR VVOOLLTTAAGGEE

TTEESSTTIINNGG WWIITTHHOOUUTT PPRROOPPEERR EELLEECCTTRRIICCAALL PPPPEE AANNDD AARRCC FFLLAASSHHIINNGG CCLLOOTTHHIINNGG.. EELLEECCTTRRIICCAALL MMEETTEERRSS AANNDD

EEQQUUIIPPMMEENNTT MMUUSSTT BBEE PPRROOPPEERRLLYY RRAATTEEDD FFOORR IINNTTEENNDDEEDD VVOOLLTTAAGGEE..

WWAARRNNIINNGG

HHaazzaarrddoouuss VVooll aaggee!!

NNeevveerr wwoorrkk aalloonnee oonn hhiigghh vvooll aaggee cciirrccuuii ss iinn hhee uunnii .. AAnnoo hheerr ppeerrssoonn sshhoouulldd bbee nneeaarrbbyy oo sshhuu ooffff hhee uunnii aanndd

pprroovviiddee aaiidd iinn hhee eevveenn ooff aann aacccciiddeenn .. IIff hheerree iiss aa rriisskk ooff eenneerrggiizzeedd eelleecc rriiccaall ccoonn aacc ,, aarrcc,, oorr ffllaasshh,, eecchhnniicciiaannss

MMUUSSTT ppuu oonn aallll PPPPEE iinn aaccccoorrddaannccee wwii hh OOSSHHAA,, NNFFPPAA 7700EE,, oorr oo hheerr llooccaall,, ss aa ee,, oorr ccoouunn rryy--ssppeecciiffiicc

rreeqquuiirreemmeenn ss ffoorr aarrcc ffllaasshh pprroo eecc iioonn PPRRIIOORR oo sseerrvviicciinngg hhee uunnii .. NNEEVVEERR PPEERRFFOORRMM AANNYY SSWWIITTCCHHIINNGG,,

DDIISSCCOONNNNEECCTTIINNGG,, OORR VVOOLLTTAAGGEE TTEESSTTIINNGG WWIITTHHOOUUTT PPRROOPPEERR EELLEECCTTRRIICCAALL PPPPEE AANNDD AARRCC FFLLAASSHHIINNGG

CCLLOOTTHHIINNGG.. EELLEECCTTRRIICCAALL MMEETTEERRSS AANNDD EEQQUUIIPPMMEENNTT MMUUSSTT BBEE PPRROOPPEERRLLYY RRAATTEEDD FFOORR IINNTTEENNDDEEDD VVOOLLTTAAGGEE..

SSaaffee yy PPrreeccaauu iioonnss

TK 61914-4-MM-EN 11

WWAARRNNIINNGG

PPeerrssoonnaall PPrroo eecc iivvee EEqquuiippmmeenn ((PPPPEE)) RReeqquuiirreedd!!

IInn hhee eevveenn ooff aann eelleecc rriiccaall aacccciiddeenn ,, aallll rreeqquuiirreedd PPPPEE sshhoouulldd bbee nneeaarr hhee wwoorrkk aarreeaa iinn aaccccoorrddaannccee wwii hh OOSSHHAA,,

NNFFPPEE 7700EE,, oorr oo hheerr llooccaall,, ss aa ee,, oorr ccoouunn rryy--ssppeecciiffiicc rreeqquuiirreemmeenn ss ffoorr aa CCaa eeggoorryy 22 rriisskk..

WWAARRNNIINNGG

HHaazzaarrddoouuss VVooll aaggee!!

TThhee uunnii OOnn//OOffff sswwii cchh mmuuss bbee uurrnneedd OOffff bbeeffoorree ccoonnnneecc iinngg oorr ddiissccoonnnneecc iinngg hhee ss aannddbbyy ppoowweerr pplluugg.. NNeevveerr

aa eemmpp oo ss oopp hhee uunnii bbyy ddiissccoonnnneecc iinngg hhee ppoowweerr pplluugg..

WWAARRNNIINNGG

RRiisskk ooff IInnjjuurryy!!

TThhee uunnii ppoowweerr pplluugg mmuuss bbee cclleeaann aanndd ddrryy bbeeffoorree ccoonnnneecc iinngg ii oo aa ppoowweerr ssoouurrccee..

WWAARRNNIINNGG

RRiisskk ooff IInnjjuurryy!!

DDoo nnoo mmaakkee rraappiidd mmoovveess wwhheenn wwoorrkkiinngg oonn hhiigghh vvooll aaggee cciirrccuuii ss iinn hhee uunnii .. DDoo nnoo ggrraabb ffoorr ffaalllliinngg oooollss

bbeeccaauussee yyoouu mmiigghh aacccciiddeenn aallllyy oouucchh aa hhiigghh vvooll aaggee ssoouurrccee..

Low Voltage

WWAARRNNIINNGG

LLiivvee EElleecc rriiccaall CCoommppoonneenn ss!!

CCoonn rrooll cciirrccuuii ss aarree llooww vvooll aaggee ((2244 VVaacc aanndd 1122 VVddcc)).. TThhiiss vvooll aaggee ppoo eenn iiaall iiss nnoo ccoonnssiiddeerreedd ddaannggeerroouuss.. LLaarrggee

aammoouunn ooff ccuurrrreenn aavvaaiillaabbllee ((oovveerr 3300 aammppeerreess)) ccaann ccaauussee sseevveerree bbuurrnnss iiff sshhoorr eedd oo ggrroouunndd.. DDoo nnoo wweeaarr

jjeewweellrryy,, wwaa cchh oorr rriinnggss.. TThheessee ii eemmss ccaann sshhoorr ccuu eelleecc rriiccaall cciirrccuuii ss aanndd ccaauussee sseevveerree bbuurrnnss oo hhee wweeaarreerr..

Battery Installation and Cable Routing

WWAARRNNIINNGG

HHaazzaarrdd ooff EExxpplloossiioonn!!

AAnn iimmpprrooppeerrllyy iinnss aalllleedd bbaa eerryy ccoouulldd rreessuull iinn aa ffiirree,, eexxpplloossiioonn,, oorr iinnjjuurryy.. AA TThheerrmmoo KKiinngg aapppprroovveedd bbaa eerryy

mmuuss bbee iinnss aalllleedd aanndd pprrooppeerrllyy sseeccuurreedd oo hhee bbaa eerryy rraayy..

WWAARRNNIINNGG

HHaazzaarrdd ooff EExxpplloossiioonn!!

IImmpprrooppeerrllyy iinnss aalllleedd bbaa eerryy ccaabblleess ccoouulldd rreessuull iinn aa ffiirree,, eexxpplloossiioonn,, oorr iinnjjuurryy.. BBaa eerryy ccaabblleess mmuuss bbee iinnss aalllleedd,,

rroouu eedd,, aanndd sseeccuurreedd pprrooppeerrllyy oo pprreevveenn hheemm ffrroomm rruubbbbiinngg,, cchhaaffffiinngg,, oorr mmaakkiinngg ccoonn aacc wwii hh hhoo ,, sshhaarrpp,, oorr

rroo aa iinngg ccoommppoonneenn ss..

WWAARRNNIINNGG

FFiirree HHaazzaarrdd!!

DDoo nnoo aa aacchh ffuueell lliinneess oo bbaa eerryy ccaabblleess oorr eelleecc rriiccaall hhaarrnneesssseess.. TThhiiss hhaass hhee ppoo eenn iiaall oo ccaauussee aa ffiirree aanndd

ccoouulldd ccaauussee sseerriioouuss iinnjjuurryy oorr ddeeaa hh..

SSaaffee yy PPrreeccaauu iioonnss

12 TK 61914-4-MM-EN

WWAARRNNIINNGG

HHaazzaarrdd ooff EExxpplloossiioonn!!

AAllwwaayyss ccoovveerr bbaa eerryy eerrmmiinnaallss oo pprreevveenn hheemm ffrroomm mmaakkiinngg ccoonn aacc wwii hh mmee aall ccoommppoonneenn ss dduurriinngg bbaa eerryy

iinnss aallllaa iioonn.. BBaa eerryy eerrmmiinnaallss ggrroouunnddiinngg aaggaaiinnss mmee aall ccoouulldd ccaauussee hhee bbaa eerryy oo eexxppllooddee..

CCAAUUTTIIOONN

HHaazzaarrddoouuss SSeerrvviiccee PPrroocceedduurreess!!

SSee aallll uunnii eelleecc rriiccaall ccoonn rroollss oo hhee OOFFFF ppoossii iioonn bbeeffoorree ccoonnnneecc iinngg bbaa eerryy ccaabblleess oo hhee bbaa eerryy oo pprreevveenn

uunnii ffrroomm ss aarr iinngg uunneexxppeecc eeddllyy aanndd ccaauussiinngg ppeerrssoonnaall iinnjjuurryy..

NN TTIICCEE

EEqquuiippmmeenn DDaammaaggee!!

DDoo nnoo ccoonnnneecc oo hheerr mmaannuuffaacc uurreerr’’ss eeqquuiippmmeenn oorr aacccceessssoorriieess oo hhee uunnii oorr oo hhee TTKK BBaa eerriieess uunnlleessss

aapppprroovveedd bbyy TThheerrmmoo KKiinngg.. FFaaiilluurree oo ddoo ssoo ccaann rreessuull iinn sseevveerree ddaammaaggee oo eeqquuiippmmeenn aanndd vvooiidd hhee wwaarrrraann yy..

Battery Removal

WWAARRNNIINNGG

HHaazzaarrdd ooff EExxpplloossiioonn!!

WWhheenn rreemmoovviinngg bbaa eerryy ccaabblleess,, AALLWWAAYYSS ddiissccoonnnneecc hhee nneeggaa iivvee bbaa eerryy eerrmmiinnaall ffiirrss .. TThheenn rreemmoovvee hhee

ppoossii iivvee eerrmmiinnaall.. WWhheenn rreeccoonnnneecc iinngg hhee bbaa eerryy eerrmmiinnaallss,, ccoonnnneecc hhee ppoossii iivvee eerrmmiinnaall ((++)) ffiirrss ,, aanndd

ccoonnnneecc hhee nneeggaa iivvee ((--)) eerrmmiinnaall llaass ..

This order is impor an because he frame is grounded o he nega ive ba ery erminal. If he nega ive erminal is s ill

connec ed, a comple e circui exis s from he posi ive erminal of he ba ery o he frame. Me al objec s con ac ing he

posi ive side and he frame simul aneously will cause sparks or arcing. If here are sufficien hydrogen gases emi ed

from he ba ery, an explosion migh occur, causing equipmen damage, serious injury, even dea h.

Electrostatic Discharge Precautions

Precau ions mus be aken o preven elec ros a ic discharge while servicing he microprocessor con roller and rela ed

componen s. The risk of significan damage o he elec ronic componen s of he uni is possible if hese precau ionary

measures are no followed. The primary risk po en ial resul s from he failure o wear adequa e elec ros a ic discharge

preven ive equipmen when handling and servicing he con roller. The second cause resul s from elec ric welding on

he uni and con ainer chassis wi hou aking precau ionary s eps.

Electrostatic Discharge and the Controller

You mus avoid elec ros a ic discharges when servicing he con roller. Solid-s a e in egra ed circui componen s can be

severely damaged or des royed wi h less han a small spark from a finger o me al objec . You mus rigidly adhere o

he following s a emen s when servicing hese uni s. This will avoid con roller damage or des ruc ion.

• Disconnec all power o he uni .

• Avoid wearing clo hing ha genera es s a ic elec rici y (wool, nylon, polyes er, e c.).

• Do wear a s a ic discharge wris s rap (refer o Tool Ca alog) wi h he lead end connec ed o he con roller's ground

erminal. These s raps are available a mos elec ronic equipmen dis ribu ors. Do not wear hese s raps wi h power

applied o he uni .

• Avoid con ac ing he elec ronic componen s on he circui boards of he uni being serviced.

• Leave he circui boards in heir s a ic proof packing ma erials un il ready for ins alla ion.

• Re urn a defec ive con roller for repair in he same s a ic pro ec ive packing ma erials from which he replacemen

componen was removed.

• Check he wiring af er servicing he uni for possible errors. Comple e his ask before res oring power.

SSaaffee yy PPrreeccaauu iioonnss

TK 61914-4-MM-EN 13

Controller / Microprocessor Service Precautions

Take precau ions o preven elec ros a ic discharge when servicing he con roller or microprocessor and i s rela ed

componen s. Even iny amoun s of curren can severely damage or des roy elec ronic componen s.

Observe he following precau ions when servicing a con roller or microprocessor con rol sys em o avoid damaging

elec ronic componen s. Refer o he appropria e uni , con roller, or microprocessor diagnos ic manual for more

informa ion.

• If he uni has a service or microprocessor ON/OFF swi ch, urn i OFF before connec ing or disconnec ing he

ba ery.

• Disconnec power o he uni .

• Avoid wearing clo hing ha genera es s a ic elec rici y (wool, nylon, polyes er, e c.).

• Wear a wris s rap (P/N 204-622 or equivalen ) wi h he lead end connec ed o he microprocessor or uni ground

erminal (if equipped). These s raps are available from mos elec ronic equipmen dis ribu ors. DO NOT wear hese

s raps wi h power applied o he uni .

• Avoid unnecessary con ac wi h he elec ronic componen s.

• S ore and ship elec ronic componen s in an is a ic bags and pro ec ive packaging.

• Leave elec ronic componen s in heir an is a ic packing ma erials un il you’re ready o use hem.

• Af er servicing any elec ronic componen s, check he wiring for possible errors before res oring power o he uni .

• Never use a ba ery and a ligh bulb o es circui s on any con roller or microprocessor-based equipmen .

Welding on Refrigeration Units or Containers

Elec ric welding can cause serious damage o elec ronic circui s when performed on any por ion of he refrigera ion

uni , gense , con ainer, or con ainer chassis wi h he refrigera ion uni a ached. I is necessary o verify ha welding

curren s are no allowed o flow hrough he elec ronic circui s of he uni . The procedures below MUST be s ric ly

followed when servicing uni s o avoid damage or des ruc ion of he microprocessor.

1. Disconnec he ba ery connec ions (if equipped) and lock ou - ag ou he uni according o local regula ions.

2. Disconnec all power o or from he refrigera ion uni or gense .

3. Disconnec all quick-disconnec wire harnesses from he back of he con roller.

4. Disconnec all wire harnesses from he Remo e Moni or Modem (RMM) or Telema ics, if equipped.

5. Swi ch all of he elec rical circui breakers in he con rol box o he Off posi ion.

6. When s eps 1 hrough 5 are comple e, weld he uni and/or con ainer using normal welding procedures. Keep

ground re urn elec rode as close o he area o be welded as prac ical. This will reduce he likelihood of s ray

welding curren s passing hrough any elec rical or elec ronic circui s.

7. When welding is comple e, res ore he uni power cables, wiring, and circui breakers o heir normal condi ion.

High Pressure Fuel Hazards

WWAARRNNIINNGG

HHaazzaarrddoouuss PPrreessssuurreess!!

AAff eerr hhee eennggiinnee hhaass ss ooppppeedd,, wwaaii 1100 oo 1155 mmiinnuu eess bbeeffoorree ooppeenniinngg hhee hhiigghh pprreessssuurree ssiiddee ooff hhee ffuueell ssyyss eemm..

WWAARRNNIINNGG

RRiisskk ooff IInnjjuurryy!!

DDoo nnoo uussee yyoouurr ffiinnggeerrss oo cchheecckk hhiigghh pprreessssuurree jjooiinn ss ffoorr lleeaakkss.. UUssee aa ppiieeccee ooff ppaappeerr oorr ccaarrddbbooaarrdd..

First Aid

EENNGGIINNEE CCOOOOLLAANNTT

•EEyyeess:: Immedia ely flush wi h large amoun s of wa er for a leas 15 minu es. Ge promp medical a en ion.

SSaaffee yy PPrreeccaauu iioonnss

14 TK 61914-4-MM-EN

•SSkkiinn:: Remove con amina ed clo hing. Wash horoughly wi h soap and wa er. Ge medical a en ion if irri a ion

persis s.

•IInnggeess iioonn:: Do no induce vomi ing. Immedia ely con ac local poison con rol cen er or physician.

BBAATTTTEERRYY AACCIIDD

•EEyyeess:: Immedia ely flush wi h large amoun s of wa er for a leas 15 minu es. Ge promp medical a en ion. Wash

skin wi h soap and wa er.

EELLEECCTTRRIICCAALL SSHHOOCCKK

Take IMMEDIATE ac ion af er a person has received an elec rical shock. Ge quick medical assis ance, if possible.

The source of he shock mus be quickly s opped, by ei her shu ing off he power or removing he vic im. If he power

canno be shu off, he wire should be cu wi h an non-conduc ive ool, such as a wood-handle axe or hickly insula ed

cable cu ers. Rescuers should wear insula ed gloves and safe y glasses, and avoid looking a wires being cu . The

ensuing flash can cause burns and blindness.

If he vic im mus be removed from a live circui , pull he vic im away wi h a non-conduc ive ma erial. Use wood, rope,

a bel or coa o pull or push he vic im away from he curren . DO NOT TOUCH he vic im. You will receive a shock from

curren flowing hrough he vic im’s body. Af er separa ing he vic im from power source, immedia ely check for signs

of a pulse and respira ion. If no pulse is presen , s ar Cardio Pulmonary Resusci a ion (CPR). If a pulse is presen ,

respira ion migh be res ored by using mou h- o-mou h resusci a ion. Call for emergency medical assis ance.

AASSPPHHYYXXIIAATTIIOONN

Move vic im o fresh air and use Cardio Pulmonary Resusci a ion (CPR) or mou h- o-mou h resusci a ion o res ore

brea hing, if necessary. S ay wi h vic im un il emergency personnel arrive.

SSaaffee yy PPrreeccaauu iioonnss

TK 61914-4-MM-EN 15

Specifications

Generator

Type 460/230 Vac, 3 Phase, 60/50 Hz

Output Power 15 kW

Kilovolt-Amperes 18.75 kVA

RPM 1800 RPM

Electrical Control System

Controls SG–3500 Controller

Voltage 12.5 Vdc (nominal)

Battery 12 Volts, Group 31, 925 / 950 CCA @ -18 C (0 F)

Fuse FS1 (Located in Control Box) 10 Amp - Battery Post to Main Relay

Fuse FS2 (Located in Control Box) 40 Amp - Battery Post trough ON/OFF switch to SW Post

Fuse FS3 (Located in Control Box) 60 Amp - Starter Fuse

Fuse FS4 (Located in Control Box) 80 Amp - Air Heater Fuse

Fuse FS5 (Located in Control Box) 2 Amp - Battery Post to Telematics

Fuse FS6 (Located in Control Box) 2 Amp - SW Post to Telematics

Electrical Components

NOTE: Disconnect components from unit circuit to check resistance.

Current Draw (Amps) at 12.5

Vdc

Resistance — Cold (Ohms)

Starter Motor 350-475*

* On-the-engine cranking check. Bench test is approximately 140 amps.

16 TK 61914-4-MM-EN

Engine

SG 3500

Model Thermo King TK486VGE1 (EPA Tier IV and 2016/1628 EU

regulation (or NRMM Stage V) compliant)

Fuel Type Diesel fuel must conform to EN590

Oil Capacity Dry fill: 13.2 liters (14 quart)

Wet fill: 12 liters (12.7 quart)

Oil Type API CK4 grade or better

Use multi-weight oils appropriate for the ambient

temperature (delivered with 10W30 oil)

Oil Viscosity -30 °C to +0 °C: SAE 5W-30

-25 °C to +30 °C: SAE 10W-30

-25 °C to +40 °C: SAE 10W-40

-15 °C to +40 °C (or -10 °C to +50 °C): SAE 15W-40

Nominal Engine RPM

NN TTIICCEE

EEqquuiippmmeenn DDaammaaggee!!

DDoo NNOOTT ooppeerraa ee hhee eennggiinnee

iinn AANNYY uunnii mmoorree hhaann 110000

RRPPMM oovveerr hhee hhiigghh ssppeeeedd

ssee iinngg sshhoowwnn oo aavvooiidd

ddaammaaggee oo hhee aacc iivvee

rreecc iiffiieerr..

SG-3500 High Speed : 1800 RPM

Low Speed : 1500 RPM

Engine Oil Pressure 2.1 to 5.5 bar (30 to 80 psi)

Intake Valve Clearance 0.15 to 0.25 mm

Exhaust Valve Clearance 0.15 to 0.25 mm

Valve Setting Temperature 21 °C

Timing Injection Pump 12° +/– 1° BTDC (timed on No. 1 cylinder, flywheel side)

Low Oil Pressure Switch (Normally Closed) 0.55 to 0.83 bar (8 to 12 psi)

High Coolant Temperature Switch Sensor - 101.7 to 107.2 °C or higher (Shutdown)

Engine Coolant Thermostat 71 °C

Engine Coolant Type

NN TTIICCEE

SSyyss eemm CCoonn aammiinnaa iioonn!!

OOnnllyy OOAATT eexx eennddeedd lliiffee ccoooollaann ss ((CChheevvrroonn DDeelloo®® XXLLCC oorr

eeqquuiivvaalleenn )) sshhoouulldd bbee aaddddeedd oo TThheerrmmoo KKiinngg ssyyss eemmss..

CCoonnvveenn iioonnaall ccoooollaann ss sshhoouulldd nnoo bbee uusseedd ((TTyyppiiccaallllyy

iiddeenn iiffiieedd bbyy ggrreeeenn oorr bblluuee--ggrreeeenn ccoolloorr)).. IIff aa ccoonnvveenn iioonnaall

ccoooollaann iiss ccoommbbiinneedd wwii hh hhee TThheerrmmoo KKiinngg ffaacc oorryy ffiillll uupp oo

2255%% bbyy vvoolluummee,, hhee ccoooollaann mmuuss bbee cchhaannggeedd aa hhee nneexx

sseerrvviiccee ooppppoorr uunnii yy.. AAbboovvee 2255%%,, hhee ccoooollaann mmuuss bbee

cchhaannggeedd iimmmmeeddiiaa eellyy.. CCoonnvveenn iioonnaall ccoooollaann ss ddiilluu ee//iinn eerraacc

wwii hh hhee aaddddii iivvee ppaacckkaaggeess ooff eexx eennddeedd lliiffee ccoooollaann wwhhiicchh

ssiiggnniiffiiccaann llyy rreedduucceess hhee sseerrvviiccee lliiffee ooff hhee ccoooollaann ..

ELC (Extended Life Coolant), which is “RED”

Factory filled with Chevron Delo® XLC extended life

coolant (ELC), 50/50 glycol/water concentration. Freeze

protection of -34°F/ -37°C

Compatible coolants:

• Chevron Delo® XLC

• Havoline Delo® XLC (Europe)

• Caltex Delo® XLC (Asia)

OR

Meets the performance requirements of both ASTM D6210

and ASTM D3306

OAT extended life coolant, nitrite free

Coolant System Capacity 6.7 liters/litres (7.08 quarts)

Radiator Cap Pressure 0.83 bar (12 psi) (88 kPa)

SSppeecciiffiiccaa iioonnss

TK 61914-4-MM-EN 17

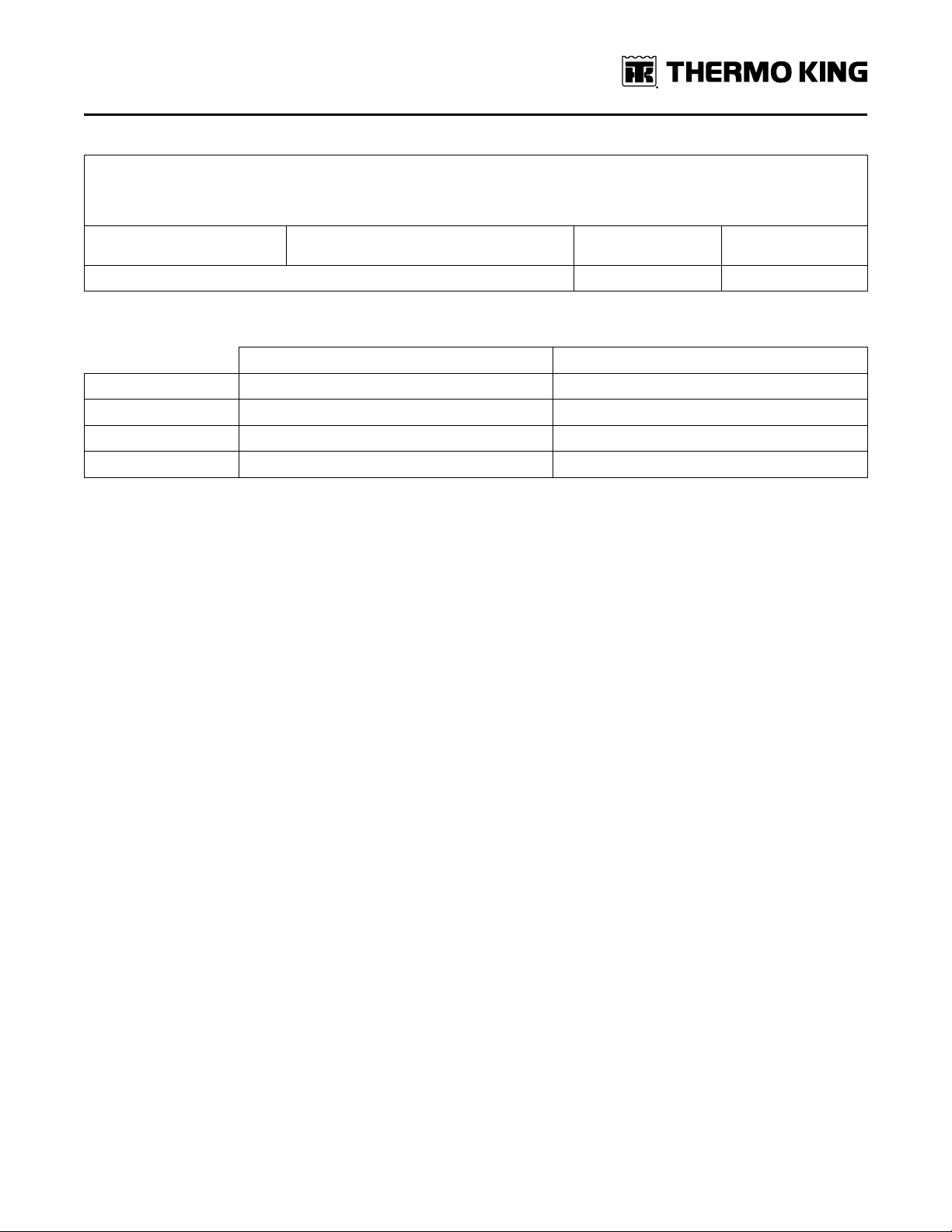

Belt ension

Notes:

1. All Belt Tension Values indicated are at room temperature

2. Belt Tension to be measured at longer span.

Use of Frequency Gauge to measure frequency

(Hz) is recommended.

New Belt Field Reset

(used belt)

Water Pump Belt 126 Hz (40 lbs) 118 Hz (32 lbs)

SG 3500 Series Unit Weight

Max weight Tare weight

SGCO-3500 1234 kg (2719.38 lbs.) 852 kg (1879 lbs.)

SGUM-3500 30Gal 764 kg (1684 lbs.) 669 kg (1474 lbs.)

SGUM-3500 50Gal 846 kg (1864 lbs.) 673 kg (1484 lbs.)

SGUM-3500 80Gal 852 kg (1879 lbs.) 680 kg (1499 lbs.)

SSppeecciiffiiccaa iioonnss

18 TK 61914-4-MM-EN

Maintenance Inspection Schedule

Pretrip Every

1,500

Hours

Every

3,000

Hours*

Inspect/Service These Items

Microprocessor:

•Run Pretrip Test (see “Performing a Pretrip Test”).

Engine:

•Check fuel supply.

•Check engine oil level.

• • • Listen for unusual noises, vibrations, etc.

• • • Inspect belt for condition and proper tension.

• • • Check engine oil pressure hot, on high speed (should display “OK”).

• • • Check engine coolant level and antifreeze protection (-30 F [-40 C]).

• • • Drain water from the Primary fuel filter bowl.

• • Drain water from fuel tank and check vent.

• • Inspect/clean screen in banjo fitting on hand fuel pump.

•Check engine mounts for wear.

•Replace EMI 3000 air cleaner element (see “EMI 3000 Air Cleaner”) at 3,000

hours or two years (whichever occurs first). See note.

•Replace EMI 3000 fuel filter/water separator. See note.

•

Change engine oil and oil filter (hot). Requires oil with API Classification CJ-4 or

CK-4. See Note*.NOTE: For high biodiesel use (B20) the engine oil and

filter should be changed every 1500 hours.

•Adjust engine valve clearance.

Change ELC (red) engine coolant every 5 years or 12,000 hours. Units

equipped with ELC have an ELC nameplate on the expansion tank (see “Engine

Cooling System”).

Electrical:

• • Inspect battery terminals and electrolyte level.

• • Inspect wire harness for damaged wires or connections.

• • Inspect AC generator wire connections for tightness.

Structural:

• • • Visually inspect unit for fluid leaks.

• • • Visually inspect unit for damaged, loose, or broken parts.

• • Clean entire unit including radiator coil.

• • Check all unit and fuel tank mounting bolts, brackets, lines, hoses, etc.

*3000 hours or one year, whichever occurs firs .

TK 61914-4-MM-EN 19

Unit Description

General Description

Thermo King genera or se s (clip-on and under-moun ) are self-con ained fully-au oma ic, diesel powered uni s. The

genera or se s supply 230 or 460 Vac elec rical power for con ainer refrigera ion uni s. Enclosed wi hin he uni frame

are he engine, dual vol age al erna or, genera or ba ery compar men , ba ery charging regula or and con rol panel.

CCAAUUTTIIOONN

RRiisskk ooff IInnjjuurryy!!

DDOO NNOOTT aa eemmpp oo ooppeerraa ee oorr mmaaiinn aaiinn hhee ggeenneerraa oorr uunn iill yyoouu hhaavvee ccoommppllee eellyy ffaammiilliiaarriizzeedd yyoouurrsseellff wwii hh hhee

eeqquuiippmmeenn ..

This uni uses an engine called TK486VGE1 (EPA Tier IV and 2016/1628 EU regula ion (or NRMM S age V) complian ).

This is a 4-cylinder, wa er cooled, direc injec ion diesel engine. An ECU (Engine Con rol Uni ) moni ors and con rols

engine opera ion. The uni con roller indirec ly moni ors and con rols he engine hrough he ECU.

Each uni fea ures a welded, heavy-gauge s eel frame wi h special sea-going finish; non-corrosive fi ings, all s ainless

s eel ex ernal hardware, brazed aluminum radia or, and poly-vinyl coa ing on he engine and genera or.

Fuel anks are provided as an in egral par of each uni . Fuel capaci ies are: 454 li er (120 gal.) on SGCO clip-on models;

303 li er (80 gal.), 189 li er (50 gal.) or 114 li er (30 gal.) on SGUM under moun models.

The al erna or is a brushless, ro a ing field ac genera or. A rec ified exci er arma ure ou pu provides dc power for he

field. The exci er field ob ains i s power from he full wave rec ified ou pu of he main genera or. The al erna or

supplies 230 or 460 Vac, 3 phase, 4 wire, 60 Hz power a 1800 RPM.

This equipmen develops normal ou pu vol ages (below 600 vol s) whenever he engine is running. All ou pu vol ages

normally reach 460 vol s. Under malfunc ion condi ions, 575 vol s may be produced. Any elec ric po en ial more han

50 vol s is hazardous. Exercise cau ion and discre ion in he opera ion and main enance of he equipmen .

20 TK 61914-4-MM-EN

EMI 3000

These uni s are equipped wi h an EMI 3000 Ex ended Main enance In erval package. The EMI 3000 package will resul in

lower o al uni life cycle cos , because main enance in ervals have an impor an impac on uni opera ing cos s.

The EMI 3000 package consis s of he following key componen s:

• EMI 3000-Hour Cyclonic Air Cleaner Assembly and Air Cleaner Elemen

• EMI 3000-Hour 5-Micron Primary Fuel Fil er / Wa er Separa or

• EMI 3000-Hour Dual Elemen Oil Fil er (blue wi h whi e le ering)

• API Classifica ion CJ-4 or CK-4 Oil

• Five Year or 12,000 Hour Ex ended Life Coolan (ELC)

The EMI package allows s andard main enance in ervals o be ex ended o 3,000 hours, or 2 years, whichever occurs

firs .

EMI 3000 equipped uni s are iden ified by a “ELC” decal ag on he coolan expansion ank, and blue and whi e colored

oil fil ers. The EMI 3000 package allows s andard gense main enance in ervals o be ex ended o 3000 hours. However,

please no e ha uni s equipped wi h he EMI 3000 package s ill require regular inspec ion in accordance wi h Thermo

King pre rip inspec ion and main enance recommenda ions (see he Main enance Inspec ion Schedule chap er in his

manual).

UUnnii DDeessccrriipp iioonn

This manual suits for next models

2

Table of contents

Popular Laboratory Equipment manuals by other brands

Roth

Roth Rotilabo M 3 instruction manual

Xylem

Xylem WTW Turb 750 IR/T operating manual

Pacific Image Electronics

Pacific Image Electronics RapidScan One user manual

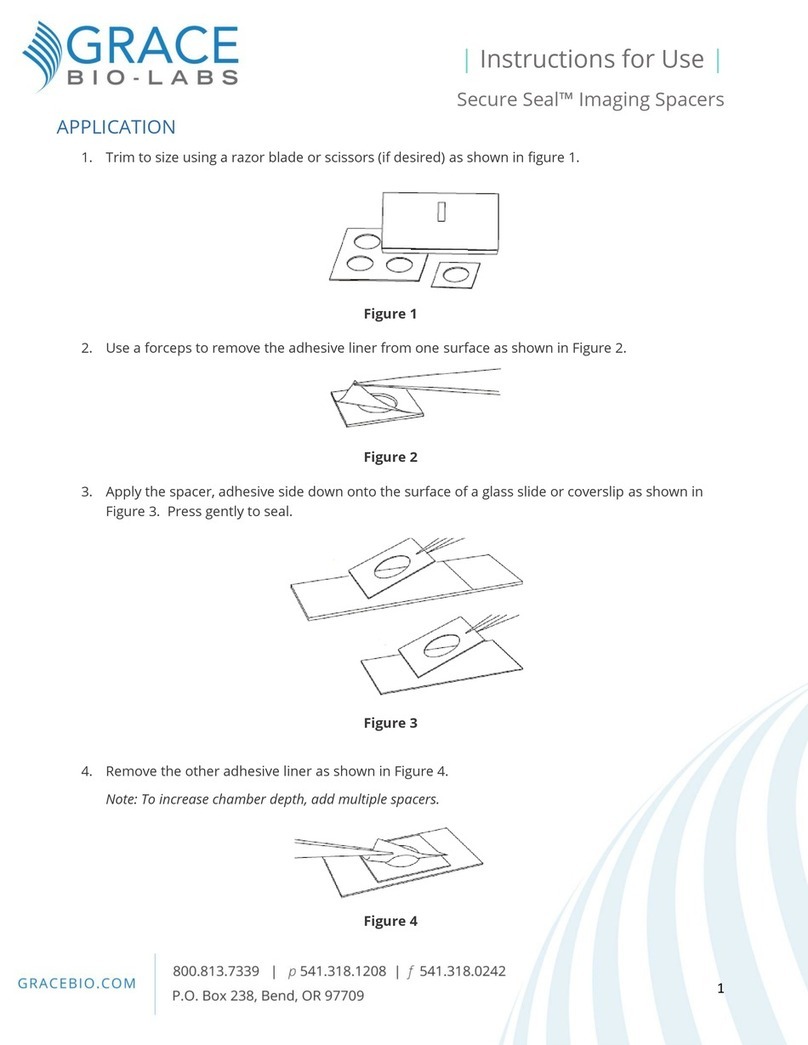

Grace Bio-Labs

Grace Bio-Labs Secure Seal Instructions for use

Heidolph

Heidolph REAX top instruction manual

EUTHANEX

EUTHANEX SMARTBOX EA-34004C Setup and user's manual