MR05 Undercounter Laboratory Refrigerators Installation, Operation and Maintenance

3

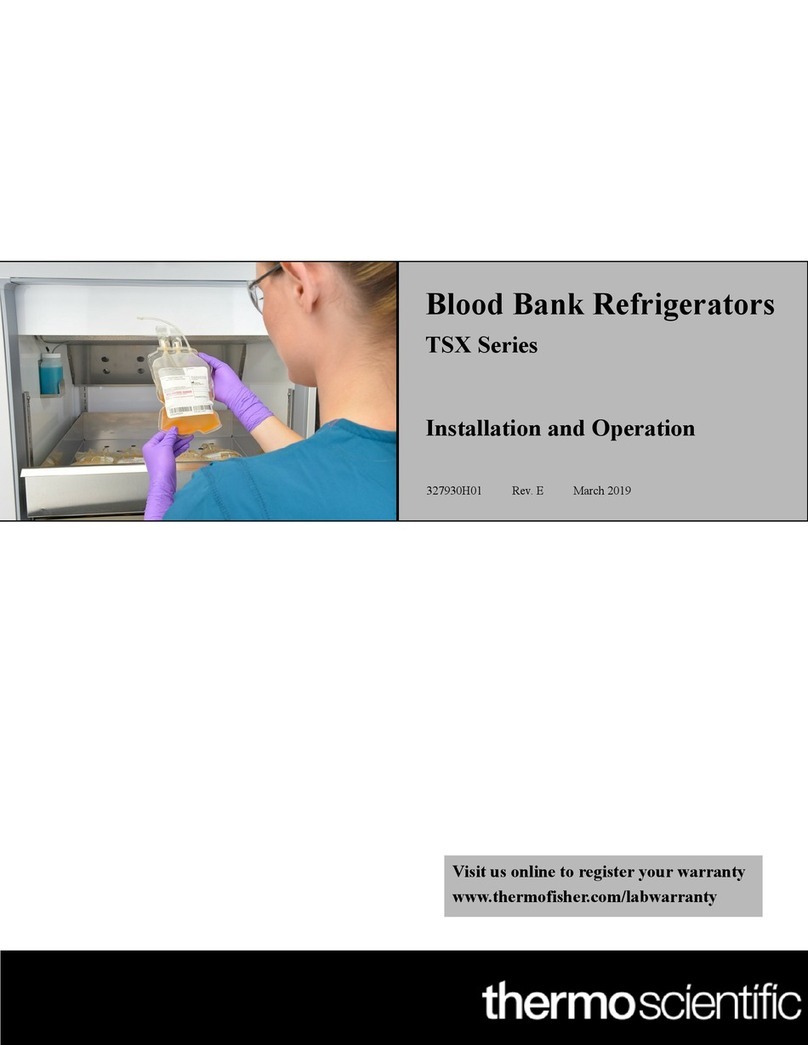

3 Introduction

This manual provide

s installation, operation and maintenance

instructions for MR05 General purpose laboratory refrigerator

models.

The control system, standard on all models, includes:

•Preset temperature setpoint (+4°C), unless optional +5C

setpoint is ordered.

•Digital temperature display with 1°C resolution.

Other standard features include:

•Keyed door locks

•CFC-free refrigerant

•CFC-free foamed in-place urethane insulation

•Quiet, hermetically sealed refrigeration compressors.

4 Inspection for Damage

At delivery, examine the exterior for physical damage while the

carrier’s representative is present.

If there is no exterior damage, unpack and inspect the equipment

within five days of delivery. If you find any damage, keep the

packing materials and immediately report the damage to the carrier.

Do not return goods without written authorization. When

submitting a claim for shipping damage, request that the carrier

inspect the shipping container and equipment.

5 Installation Instruction

This product is a complete packaged unit ready to operate when

plugged into an electrical source. Read all the instructions before

proceeding with installation.

1. The cabinet will pass through a standard 30” door opening.

2. Move the cabinet into the desired location. Make sure the

bottom of the cabinet is evenly supported. Thin shims under

the points of rest can be used to equalize the distribution of

weight. If the cabinet sets on an uneven floor, a slight rocking or

vibration might result when the condensing unit is set in

operation.

3. Make certain the cabinet is located so the front grill is

unobstructed.

4. The unit is shipped in ready to operate condition. Adjustment

of operating temperatures or setpoint is not necessary and may

adversely effect unit performance.

5. Use of electrical supply, other than that specified on the serial

plate will cause permanent damage to the product.

6. Operate the unit for several hours to allow the cabinet to reach

normal operating temperatures before storing product.

7. Do not install temperature sensing cables using the front door

gasket. Instead, use the rear access ports.

6 Operating Instructions

6.1 Temperature Control

The temperature control system is preset by the factory to maintain

a cabinet temperature of 4°C. Adjustment of operating values are

possible, but may change unit performance. Consult a qualified

service technician if you have questions about settings.

An optional 5C factory setpoint can be ordered using part number

7508TA at time of purchase.

6.2 Automatic Defrost

The defrosting process on all models is primarily accomplished by

air circulated during off-cycle periods.

Under normal conditions, the temperature warm-up during defrost is

virtually unnoticeable. However, an occasional 2°C warm-up is

possible if usage is heavy and ambient conditions are extreme.

7 Maintenance Instructions

1. The cabinet interior should be cleaned frequently. Any spilled

liquid should be wiped off immediately. A mild detergent and

lukewarm water or a solution of bicarbonate of soda (1

tablespoon per gallon of water) is recommended for cleaning

the interior and exterior of the cabinet. All surfaces should be

rinsed and thoroughly dried.

2. Shelves and/or drawers should be removed from the cabinet

and thoroughly scrubbed. Clean door gasket periodically with

water.

3. The unit cooler fan operates continuously when the door is

closed and requires no lubrication. These models require no

manual defrosting. The cooling coil automatically defrosts

when the condensing unit is on the off cycle.

4. The condensing unit needs no oil or other lubrication. The

finned condenser can become clogged with lint or dust. The

openings between the fins should be kept clean. A vacuum

cleaner or small test tube brush works well for this purpose.

This should be accomplished on an annual basis. Failure to

keep the condenser fins free of dirt and lint will hamper

operation and may damage the refrigeration system.

5. Annual inspection of the mechanical refrigeration equipment

by a qualified service provider or factory direct technician is

recommended.

6. The refrigeration system is charged with refrigerant. If the

system is opened for any reason, extreme care should be taken

to prevent the entry of moisture-bearing air. A new drier should

be installed in the lines when the system is closed.

7. The condensate evaporator pan is located behind the

compressor fan, which is behind the base grill. This pan should

be cleaned at least once a year.

Intended Use of the MR05 Series Undercounter Laboratory

Refrigerator:

The MR05 series undercounter laboratory refrigerator described

in this manual is not intended for use as a medical device and is

not intended for in vitro diagnostic cases. This unit is intended

store non-flammable general laboratory products.