Thermo-Star Denta-Star S1 User manual

Original instruction manual

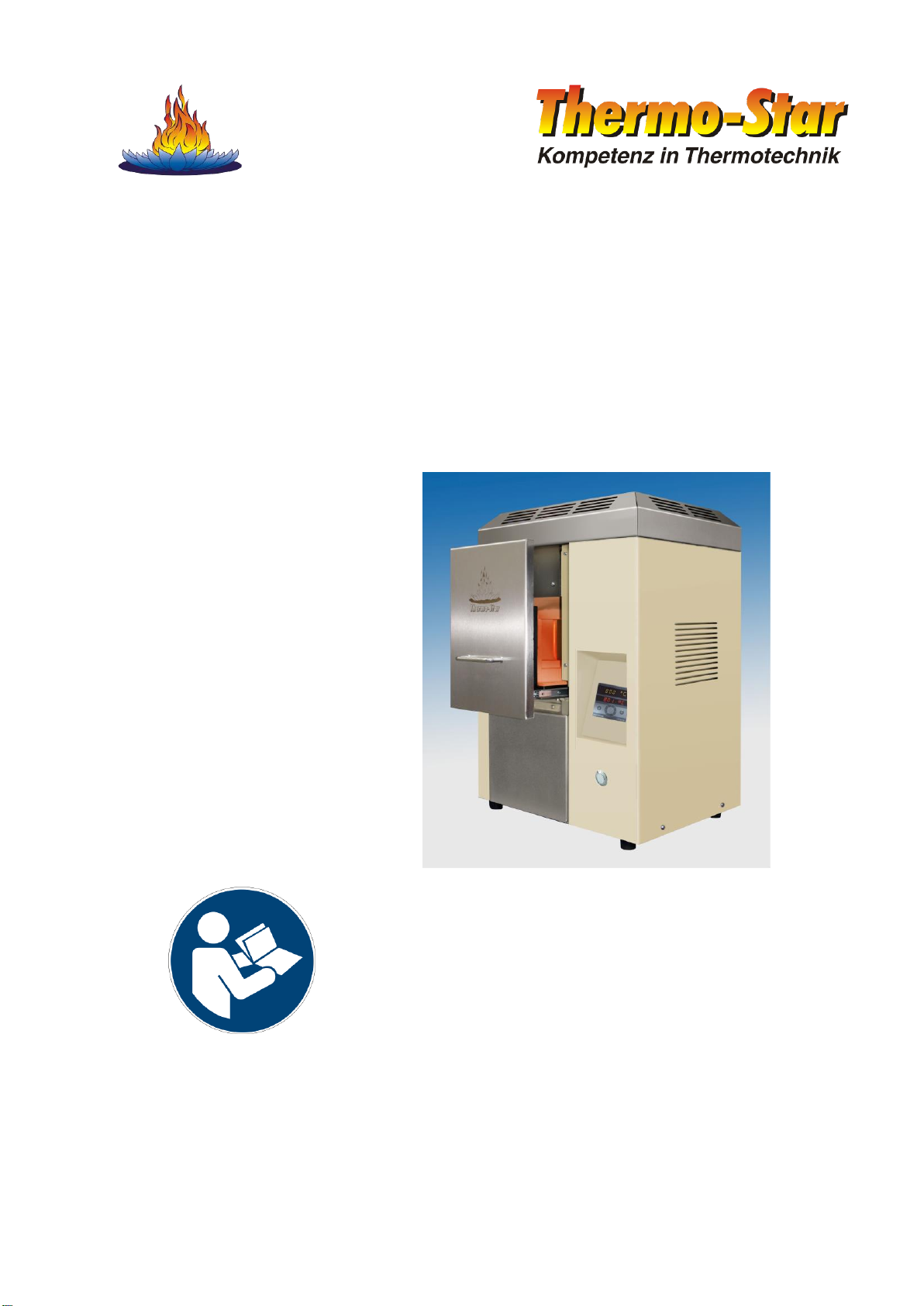

Denta-Star S1

Atmospheric sintering furnace for

sintering of oxide ceramics

Please read this instruction manual carefully and if

necessary other documents related to the product to ensure

safe and proper application.

The manual must be given to the end user who should keep

it throughout the service life until disposal.

- 2 -

WELCOME

Thermo-Star GmbH (hereafter referred to as Thermo-Star) appreciates your

confidence and delivers to you a sintering furnace (hereafter referred to as

furnace).

The furnace was subjected to a complete functional test prior to dispatch and the

packaging content was checked for completeness.

The figures and illustrations used in this document contribute to basic understanding

and may be different from the product design.

You can find a list of tables and illustrations in the Appendix.

2. edition, status January 2018

Thermo-Star GmbH

Krantzstr. 7 / Geb. 37

52070 Aachen, Germany

Phone: +49 241 60845-0

Fax: +49 241 60845-100

www.thermo-star.de

- 3 -

TABLE OF CONTENTS

1INTRODUCTION............................................................................................................. 5

1.1 SERVICE ................................................................................................................................... 5

1.2 STATUTORY DEFECTS LIABILITY............................................................................................... 5

1.3 SYMBOLS USED IN THIS INSTRUCTION MANUAL..................................................................... 5

2SAFETY INFORMATION .................................................................................................. 6

2.1 INTENDED USE......................................................................................................................... 6

2.1.1 SCOPE...................................................................................................................................... 6

2.1.2 IMPROPER USE........................................................................................................................ 6

2.2 QUALIFIED PERSONS ............................................................................................................... 7

2.3 PERSONAL PROTECTIVE EQUIPMENT...................................................................................... 8

2.4 DEPICTION OF WARNINGS ...................................................................................................... 9

2.5 UNAUTHORIZED PARTS........................................................................................................... 9

2.6 GENERAL HAZARDOUS POTENTIAL ....................................................................................... 10

2.6.1 THERMAL HAZARD ................................................................................................................ 10

2.7 ELECTROMAGNETIC COMPATIBILITY .................................................................................... 10

2.8 RESPONSIBILITY OF THE OWNER........................................................................................... 11

3TRANSPORT AND STORAGE ......................................................................................... 12

3.1 SAFE TRANSPORT AND STORAGE .......................................................................................... 12

3.2 TRANSPORT........................................................................................................................... 13

3.3 STORAGE ............................................................................................................................... 13

4DESCRIPTION OF THE PRODUCT................................................................................... 14

4.1 SCOPE OF SUPPLY.................................................................................................................. 14

4.2 PRODUCT CHARACTERISTICS................................................................................................. 15

4.2.1 SHORT DESCRIPTION OF THE FURNACE................................................................................ 15

4.2.2 CHARACTERISTICS AND TECHNICAL DATA............................................................................ 15

4.3 COMPONENTS....................................................................................................................... 16

4.4 FUNCTIONALITY .................................................................................................................... 17

4.5 TYPE PLATE............................................................................................................................ 17

4.6 ACCESSORIES......................................................................................................................... 17

5INSTALLATION............................................................................................................. 18

5.1 SAFE INSTALLATION .............................................................................................................. 18

5.2 INSTALLING THE FURNACE .................................................................................................... 19

5.2.1 LOCATION.............................................................................................................................. 19

5.2.2 SETTING UP THE FURNACE.................................................................................................... 19

5.2.3 MOUNTING HEATING ELEMENTS ......................................................................................... 20

5.2.4 ELECTRICAL CONNECTION..................................................................................................... 21

6FIRST PUTTING INTO SERVICE AND USE........................................................................ 22

6.1 SAFE FIRST PUTTING INTO SERVICE AND USE........................................................................ 22

6.2 PUTTING INTO SERVICE......................................................................................................... 22

6.2.1 OPERATIONAL CONDITION ................................................................................................... 22

6.2.2 FIRST LOADING THE FURNACE.............................................................................................. 23

6.2.3 UNLOADING THE FURNACE................................................................................................... 24

6.2.4 RELOADING THE FURNACE.................................................................................................... 24

6.2.5 FURNACE EMERGENCY STOP ................................................................................................ 24

- 4 -

7OPERATION................................................................................................................. 25

7.1 GENERAL FURNACE OPERATION ........................................................................................... 25

7.1.1 OPENING AND CLOSING THE FURNACE ................................................................................ 25

7.1.2 CONTROLLER COMPONENTS ................................................................................................ 26

7.1.3 SELECTING A PROGRAM........................................................................................................ 26

7.1.4 SEGMENT FUNCTIONS .......................................................................................................... 27

7.2 PROGRAMMING THE CONTROLLER ...................................................................................... 28

7.2.1 PROGRAMMING SEGMENTS................................................................................................. 28

7.2.2 SEGMENT FUNCTIONS .......................................................................................................... 28

7.2.3 EXAMPLE PROGRAMMING ................................................................................................... 30

8MAINTENANCE............................................................................................................ 32

8.1 SAFE MAINTENANCE ............................................................................................................. 32

8.2 FURNACE MANUAL ............................................................................................................... 33

8.3 MAINTENANCE WORK FOR THE USER................................................................................... 33

8.3.1 DAILY CONTROLS................................................................................................................... 33

8.3.2 MAINTENANCE WORK AS NEEDED ....................................................................................... 33

8.3.3 REGULAR MAINTENANCE WORK .......................................................................................... 33

9TROUBLESHOOTING .................................................................................................... 34

9.1 SAFE TROUBLESHOOTING ..................................................................................................... 34

9.2 FAULT FINDING...................................................................................................................... 34

10 REPAIR........................................................................................................................ 35

10.1 SAFE REPAIR .......................................................................................................................... 35

10.2 REPLACING HEATING ELEMENTS........................................................................................... 35

10.3 OTHER REPAIRS &SPARE PARTS............................................................................................ 35

11 TAKING OUT OF SERVICE & DISPOSAL .......................................................................... 36

11.1 SAFE TAKING OUT OF SERVICE .............................................................................................. 36

11.2 TAKING OUT OF SERVICE....................................................................................................... 37

11.3 SHUTDOWN .......................................................................................................................... 37

11.4 DISPOSAL............................................................................................................................... 37

12 DECLARATION OF CONFORMITY .................................................................................. 38

13 APPENDIX ................................................................................................................... 39

13.1 INDEX OF TABLES................................................................................................................... 39

13.2 INDEX OF ILLUSTRATIONS ..................................................................................................... 39

14 NOTES......................................................................................................................... 40

- 5 -

1INTRODUCTION

This instruction manual for furnace type “Denta-Star S1” was put together with

greatest care and includes important information to ensure a safe, long-term

operation.

Please let us have your feedback if any information is incomplete or missing.

1.1 SERVICE

If you have any questions regarding the furnace, components from the scope of

supply or this instruction manual, please contact our customer service at

Thermo-Star GmbH

Krantzstr. 7 / Geb. 37

52070 Aachen, Germany

Phone: +49 241 60845-0

Fax: +49 241 60845-100

info@thermo-star.de

1.2 STATUTORY DEFECTS LIABILITY

For more information about statutory defects liability, please see our General

Terms and Conditions.

http://www.thermo-star.de/tl_files/docs/Thermo-Star/AGB%20Thermo-Star%20GmbH.pdf

1.3 SYMBOLS USED IN THIS INSTRUCTION MANUAL

The symbols below are used to identify different types of information:

Depiction of warnings

Chapter 2.4 “DEPICTION OF WARNINGS”

Refers to information in this instruction manual

Refers to information in other documents

- 6 -

2SAFETY INFORMATION

Please read the safety notes before installing and putting the furnace into service

to prevent personal injury and property damage.

2.1 INTENDED USE

2.1.1 SCOPE

This furnace is used for sintering of oxide ceramics with normal atmosphere.

Areas of application:

Dental laboratories

Research institutes / universities

Ceramic processing factories

Modifications to the status of delivery or other areas of application or utilization

are not permitted or may only be carried out after consulting the manufacturer.

2.1.2 IMPROPER USE

Improper use is for example:

Drying of all kinds of materials

Sintering of chemically treated ceramics

Non-compliance with these instructions or other product-related documents

Use in potentially explosive areas

Use of defective components (deferred maintenance)

Never use gaseous, liquid or slightly volatile substances in the furnace.

This refers particularly to:

Salts

Oils

Greases

Acids and alkaline solutions

Fuels

Resins

Plastics

- 7 -

2.2 QUALIFIED PERSONS

All activities on the furnace may only be carried out by qualified personnel who

have several years’ professional experience and certified knowledge as listed in the

table below:

Table 01: Qualification of personnel

Activities

Persons

Knowledge

Design

Operational changes

Engineer, designer

Knowledge of high-

temperature technology

Evaluation of substance

properties and reactions

exposed to effects of

temperature

Transport

Storage

Forwarding agents,

traders, repairers

Proof of instruction in

freight securing

Safe handling of lifting

aids and accessories

Knowledge about

handling of hazardous

substances

Installation

Supplier, owner, user

Knowledge of electrical

supply lines and ambient

conditions

Use

Owner, user

Knowledge of

information in this

instruction manual

Simple maintenance

Owner, user

Knowledge of

information in this

instruction manual

Basic knowledge of

measuring devices for

electrical measurements

Major servicing, repair and

maintenance work

Qualified personnel

Proof of electrical or

mechanical technical

training

Disposal

Qualified personnel

Knowledge of

dismantling of

mechanical and

electrical components

Knowledge of

professional disposal

Knowledge of recycling

of raw materials

- 8 -

2.3 PERSONAL PROTECTIVE EQUIPMENT

Appropriate personal protective equipment must be worn in accordance with the

operating location and activities being carried out on the furnace.

The employer must provide personal protective equipment for personnel and

supervisors must ensure that the equipment is used.

Table 02: Personal protective equipment

Symbol

Meaning

Explanation

Use foot

protection

Safety shoes offer slip resistance on slippery floors,

puncture resistance and protection from falling

objects.

Use eye

protection

Protective goggles protect the eyes from dust and

other particles or small objects.

Use hand

protection

Protective gloves protect the hands from bruises, cuts,

chemical burns and hot surfaces.

Use

protective

mask

A mask protects against inhalation of fine dust that is

not filtered out and prevents respiratory complaints.

- 9 -

2.4 DEPICTION OF WARNINGS

To make it easier to identify hazardous risks, these are marked in the instruction

manual with the following warning symbols and signal words:

Table 03: Risk classifications

Symbol

Signal word

Meaning

DANGER

This symbol indicates a hazardous situation

presenting an immediate threat of death or

serious injury to persons and life.

DANGER

Danger from electrical voltage.

This symbol indicates danger from

electrical voltage.

DANGER

Danger from hot surfaces.

This symbol indicates risks of burning on

hot surfaces.

DANGER

Danger from hand injuries.

Sections marked with this symbol indicate

hazardous situations presenting danger

from hand crushing.

NOTICE

Refers to a situation that, if not avoided,

could result in damage to the furnace, its

components or objects in its environment.

Warning example:

SIGNAL WORD (Warning)

Cause

Effects

Protective measure(s)

2.5 UNAUTHORIZED PARTS

Before market launch, the furnace was subjected to extensive tests and quality

controls. All components were tested under the highest load levels. Mounting

unauthorized parts affects safety and will exclude all statutory defects liability by

Thermo-Star. Use only original spare parts or spare parts approved by Thermo-Star

when replacing parts.

- 10 -

2.6 GENERAL HAZARDOUS POTENTIAL

This chapter specifies general hazards resulting from the furnace.

2.6.1 THERMAL HAZARD

The furnace operates in cycles. Thermal hazards arise from the furnace door during

operation. Because of its design, the furnace door will not cool down completely.

Please note the safety notes on the furnace.

2.7 ELECTROMAGNETIC COMPATIBILITY

The device does not cause any electromagnetic emission levels or faults in other

devices.

- 11 -

2.8 RESPONSIBILITY OF THE OWNER

The owner and/or user is responsible for ensuring compliance with the following:

Operate the furnace only in accordance with its intended purpose and in

proper condition.

Chapter 2.1 “INTENDED USE”

The functionality of protective devices may not be affected.

Comply with maintenance intervals and eliminate faults immediately.

Eliminate faults yourself only when the required measures

are indicated in this instruction manual.

Thermo-Star or a qualified service company is responsible for implementing

all other measures.

Check that the furnace type plate is complete and legible.

Chapter 4.5 “TYPE PLATE”.

Provide sufficient personal protective equipment and ensure that it is worn.

Chapter 2.3 “PERSONAL PROTECTIVE EQUIPMENT”

Provide the full instruction manual on-site and instruct personnel

accordingly.

First aid: we refer to local and internal corporate provisions when dealing

with accidents. Ensure that sufficient staff are trained in first aid.

The operator must provide suitable fire-fighting equipment and make sure

that the location and handling of fire extinguishers are known. If unsuitable

fire-fighting equipment is used, harmful fumes or hazards from electric shock

may occur.

Danger of injuries or death from electric shock.

Never use water to extinguish electrical equipment. Risk of electric

shocks.

Employ only authorized and adequately qualified personnel.

Chapter 2.2 “QUALIFIED PERSONS”

- 12 -

3TRANSPORT AND STORAGE

This chapter provides information about proper transport and storage of the

furnace.

The furnace and all loose parts and accessories (packed in cardboard or transport tube)

are delivered in a stackable transport packaging made of wood.

Chapter 4.1 “SCOPE OF SUPPLY”

Chapter 4.2.2 “CHARACTERISTICS AND TECHNICAL DATA”

3.1 SAFE TRANSPORT AND STORAGE

During transport and storage, the following hazards must be expected:

WARNING

Read the following safety notes carefully before transport or storage.

Misuse can cause serious injuries.

Make sure that transport and storage personnel are qualified as required.

Chapter 2.2 “QUALIFIED PERSONS”

Transport of the furnace by persons

Physical injuries because of too heavy weight

2 persons are required for transport.

Chapter 3.2 “TRANSPORT”

Chapter 4.2.2 “CHARACTERISTICS AND TECHNICAL DATA”

Transport using truck or industrial truck

Serious crushing, impacts and accidents as a result of inappropriate handling

Wear personal protective equipment.

Chapter 2.3 “PERSONAL PROTECTIVE EQUIPMENT”

Transport the furnace as it was delivered (packed in transport box).

Make sure that the freight is properly secured.

Check that the lifting accessories are suitable and undamaged.

Transport using a loading crane

Serious crushing and impact injuries from swinging or falling loads

Wear personal protective equipment.

Chapter 2.3 “PERSONAL PROTECTIVE EQUIPMENT”

Comply with the maximum load of the crane system and lifting accessories.

Never stand under swinging loads.

Keep other persons out of the danger zone.

Avoid swinging movements.

- 13 -

3.2 TRANSPORT

Please refer to the notes concerning correct transportation of the unit given below.

Red points indicate the respective lifting points.

Table 04: Types of transport

Type of transport

Permitted lifting

points

3.3 STORAGE

Inappropriate storage might damage the furnace.

Make sure you meet or exceed these requirements:

If possible store the furnace in the transport packaging

Avoid dusty or corrosive atmospheres

Temperature: -20°C < TStorage < 60°C

Humidity: < 80%rH, non-condensing

- 14 -

4DESCRIPTION OF THE PRODUCT

This chapter provides information about the scope of supply, characteristics,

accessories and functionality.

4.1 SCOPE OF SUPPLY

When unpacking check that the supplied product is undamaged and complete (see

the table below). There may be differences in the scope of supply as the furnace is

subject to prior sale. Please note the vendor’s delivery notes.

Table 05: Scope of supply of the furnace

Amount /

component

Description

Figure

Packing

1 x furnace

Denta-Star S1

Transport box

1 x mains cable

Mains cable

1.8m, 1.5mm²

IEC 320 <-> C19

Plastic-wrapped

1 x sintering beads

Sintering beads

200g

PET bottle

1 x protective cover

Protective cover

100x70x30mm

Cardboard

4 x spacers

Spacer

h: 20mm

Cardboard

1 x setter

Setter

100x70x2mm

Cardboard

1 x base plate

Base plate

100x70x8mm

Cardboard

3 x heating

elements

Heating element

Transport sleeve

“TwistPack”, if

not pre-

assembled

2 x connecting strip

Connecting strip

EE100 used to

connect the heating

elements

Cardboard, if not

pre-assembled

1 x display

protective foil

Display protective

foil

Self-adhesive

--

Cardboard

1 x documentation

Instruction manual

--

Cardboard

Each sintering aid is suitable for temperatures

T ≤ 1,550°C & Δ T/t ≤ 800°C/h

- 15 -

4.2 PRODUCT CHARACTERISTICS

This chapter describes the main characteristics of the furnace.

4.2.1 SHORT DESCRIPTION OF THE FURNACE

A double fiber-insulated chamber is heated electrically. The required cooling is

carried out using a second wall and ventilators.

The load (sintering aids and ware to be sintered) is placed in the furnace chamber

using a tray in the furnace door. They are subjected to thermal treatment with

normal atmosphere.

An electronic PID control with storage capacity for several temperature-time

profiles is available.

The furnace is operated using an industrial controller positioned on the front of the

furnace. A door switch located below can be used for extended operation.

The main switch and the supply connections for power are located on the back of

the furnace.

4.2.2 CHARACTERISTICS AND TECHNICAL DATA

Table 06: Characteristics and technical data

General

Alumina fiber insulation (Al2O3)

3 molybdenum disilicide heating elements (MoSi2)

Housing made of powder-coated steel sheet and stainless steel

Bolted cover and back wall for easy maintenance

4 rubber feet

Separate cooling air outlet (upwards and to the side, backwards)

Mechanical

Size: 450/390/660 mm (W/D/H)

Weight: 62kg (Net)

Electrical

Voltage: 220-240 V

Supply: ≤ 16 A

Power: ≤ 2,500 W

Temperature: ≤ 1,550°C

- 16 -

4.3 COMPONENTS

The figure below shows the assembly and location of each component. They will

allow the descriptions given in the following chapters to be assigned to the

individual components.

Figure 01: Furnace overview

01

Cooling air outlet, top

04

Setter

02

Cooling air outlet, side

05

Controller

03

Furnace door

06

Door opener

07

Connection to power supply & main switch

(back of the furnace)

01

03

04

02

05

07

06

- 17 -

4.4 FUNCTIONALITY

The furnace is a high-temperature furnace with direct, electrical resistance heating.

Temperature is measured using a thermocouple type S (Pt-PtRh10%; platinum

against platinum-rhodium 10%) placed in the center of the furnace chamber side

wall. The load is assembled on the firing support placed in the furnace door and

the ceramic ware to be sintered is positioned on ceramic sintering aids. The

thermal treatment starts after the furnace has been loaded. Select one of the

stored programs with temperature-time profile to start the process. The

temperature inside the furnace chamber is controlled electronically and modified

in accordance with the selected program. The furnace passes into an automated

cooling phase after ending a process i.e. when the end segment in the active

program has been reached. You can open the furnace at temperatures <300°C to

remove sintered products. The furnace can now be reloaded and is ready for the

next sintering procedure.

4.5 TYPE PLATE

A type plate is attached to the furnace housing. Please find the following

information and keep it at hand for inquiries of any kind:

Figure 02: Example type plate

Serial number

Power supply

Year of construction

4.6 ACCESSORIES

For information about suitable accessories, please see Chapter 1.1 “SERVICE”

- 18 -

5INSTALLATION

This chapter describes how to install the furnace.

Table 07: Requirements for installation

Connections, objects, tools, installation material

Cutter knife

Screwdriver, TX20, PH1

Open-end wrench SW7

Allen key SW3.0

All components Chapter 4.1 “SCOPE OF SUPPLY”

Ambient conditions Chapter 5.2.1 “LOCATION”

5.1 SAFE INSTALLATION

DANGER

Read the following safety notes carefully before installing the furnace.

Misuse can cause serious injuries.

Make sure that installation personnel are qualified as required.

Chapter 2.2 “QUALIFIED PERSONS”

Mechanical hazards

Physical injuries because of too heavy weight

2 persons are required for transport.

Chapter 3.2 “TRANSPORT”

Chapter 4.2.2 “CHARACTERISTICS AND TECHNICAL DATA”

Serious crushing due to falling components such as furnace, gas bottle etc.

Wear personal protective equipment.

Chapter 2.3 “PERSONAL PROTECTIVE EQUIPMENT”

Electrical hazards

Serious injuries or death through contact with live parts

Disconnect power plug before opening the furnace.

Open the furnace only when required for maintenance purposes.

Check electrical installation before installing the furnace.

Never carry out modifications.

- 19 -

5.2 INSTALLING THE FURNACE

Inappropriate positioning might damage the furnace or surrounding parts.

5.2.1 LOCATION

Requirements imposed on the operating location:

Humidity < 85%rH, non-condensing

Ambient temperature > 5°C and < 25°C

Even surfaces

Load-bearing capacity > 100kg

Temperature resistance > 60°C

Air quality of the ambient air should generally correspond to that of the

outside air

Components that are not permitted:

Grinding dusts (independent from material), spray oils, oil vapors, corrosive

gases or vapors and other chemical auxiliary materials i.e. scanner sprays,

separating agents etc.

The distance to the walls, ceilings or other devices should be > 5cm on each

side

The distance to flammable objects should be > 50cm on each side

The distance to hot objects should be > 50cm on each side

(monitor and check to exclude potential interactions)

Socket with grounding contact and separate electric circuit

Fuse preferably with automatic cut-out line protection switch D16A or

fusible cut-out

5.2.2 SETTING UP THE FURNACE

Step 1

Open the transport packaging on each side and remove. The

transport box can be stored and reused.

Screwdriver TX20

Step 2

Remove protective foils and accessories cardboard box and

dispose of them correctly.

Cutter knife

Step 3

Lift furnace and place it on the stand / table

Step 4

Mount the heating elements, if not pre-assembled

Chapter 5.2.3 “MOUNTING HEATING ELEMENTS”

Allen key SW3.0

Open-end wrench SW7

Step 5

Connect to power supply

Chapter 5.2.4 “ELECTRICAL CONNECTION”

Step 6

Connect to network (optional)

Chapter 5.2.5 “NETWORK CONNECTION”

- 20 -

5.2.3 MOUNTING HEATING ELEMENTS

Figure 03: Replacing heating elements

Remove cover screws on both sides

left and right

Lift cover

Remove heating elements from the

transport sleeves and insert

carefully into the holding fixtures

Chapter 4.1 “SCOPE OF SUPPLY” / Table 05

Contact heating elements

Connect pre-installed connecting strips P2E-150

and P2E-200 to the ends of 2 nearest heating

elements. Connect all heating elements using 5

connecting strips E2E-100.

Torque: 3 Nm

Fit cover and insert cover screws at

front and back and screw on tightly

This manual suits for next models

1

Table of contents