Thermon Ruffneck RGE Series Installation instructions

ISO 9001

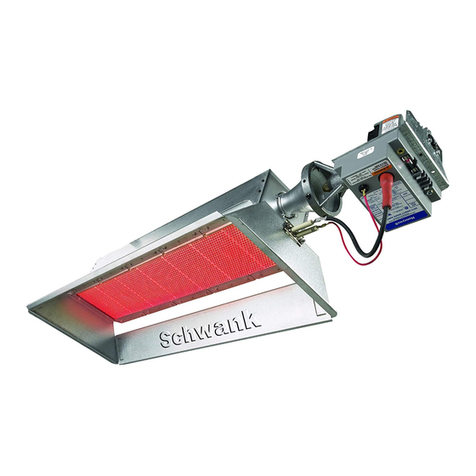

RGE heater with optional disconnect

Part No.MI280.Rev.4.02 March 2022 Printed in Canada

Regular Duty Forced Air Unit Heaters

RGE 20 3 C T - D

Model

Series

Kilowatts

02 - 2 kW

03 - 3 kW

04 - 4 kW

05 - 5 kW

07 - 7.5 kW

10 - 10 kW

15 - 15 kW

20 - 20 kW

25 - 25 kW

30 - 30 kW

Voltage

2 - 208

3 - 240

5 - 347

6 - 416

7 - 480

8 - 600

Contactor

(Optional)

Thermostat

(Optional)

Other Options

B - Epoxy painted fan blade and motor

D - Disconnect switch

F - Fan switch

K - Fused control circuit

L - Energy Management Controller

M - Manual reset high limit

N ‑ Low voltage relay (24V)

V ‑ 120V control voltage (240V is standard)

Model Coding

C US

®

Ruffneck™ is a registered trademark of Thermon.

Copyright© 2022. All rights reserved.

Installation & Operation Instructions

RGE Series

IMPORTANT INSTRUCTIONS - SAVE THESE INSTRUCTIONS

Read all instructions before installing or using the heater. Please adhere to instructions

published in this manual. Failure to do so may be dangerous and may void certain

provisions of your warranty.

TABLE OF CONTENTS

A. Important Notices 3

B. Installation 3

B.1 Location..................................................................................................................................................................3

B.2 Mounting ................................................................................................................................................ .............4

B.3 Electrical.................................................................................................................................................. .............5

B.4 Sample Wiring Schematics RGE Series Heaters ......................................................................5

C. Operation 8

C.1 General ....................................................................................................................................................................8

D. Repair & Replacement 8

D.1 Heating Elements............................................................................................................................................8

D.2 Fan ............................................................................................................................................................................8

D.3 Thermal Cut-Out.............................................................................................................................................8

E. Parts List 9

F. Troubleshooting Tips 11

F.1 Heater is not operating................................................................................................................................ 11

F.2 Contactor is chattering............................................................................................................................... 11

F.3 Contactor is burned or welded............................................................................................................. 11

F.4 Heater cycles on high limit...................................................................................................................... 11

F.5 Heater is operating but no heat is present................................................................................... 11

F.6 Heater fan does not operate but the heating elements operate................................. 11

F.7 The Ground Fault Interrupter (GFI) trips on the main panel, or heater blows

fuses......................................................................................................................................................................... 11

F.8 The fan is turning but very little air comes from the front of the heater................. 11

G. Technical Data 12

H. General Specifications 13

I. Heater Maintenance Checklist 14

I.1 Periodic (before and as required during heating season) ................................. ............14

I.2 Annual (before heating season).......................................................................................... ............14

3

Important Notices

A. IMPORTANT NOTICES

CAUTION

CAUTION. This symbol indicates a potentially hazardous

situation, which, if not avoided, may result in personal

injury or damage to the equipment.

WARNING

WARNING. This symbol indicates an imminently

hazardous situation, which, if not avoided, can result in

serious injury or damage to the equipment.

WARNING

WARNING. Read and adhere to the following. Failure to

do so may result in a risk of re, electrical shock, and

severe or fatal injury. Warranty will be void.

1. Read and follow all instructions in this manual.

2. This heater is intended to be used for commercial and

industrial indoor space heating applications.

WARNING

WARNING. Heater is not to be used in hazardous

atmospheres where ammable vapors, gases, liquids or

other combustible atmospheres are present.

3. Heater is to be connected and serviced only by a qualied

electrician.

4. Installation and wiring of the heater must adhere to all

applicable codes.

5. Disconnect heater from power supply at disconnect or

fuse box before opening enclosures or servicing heater. IF

DISCONNECT IS BEING SERVICED, verify power has been

disconnected at fuse box or main panel. Lock the switch

in the “OFF” (open) position and tag the switch to prevent

unexpected power application.

6. Do not operate heater in wet and humid environments.

WARNING

WARNING. Elements get hot during operation.

Contact can cause burns.

7. Install and maintain clearances as per this manual.

8. Do not operate the heater in corrosive atmospheres.

9. Use factory replacement parts only.

10. Maximum ambient operating temperature is 40°C (104°F).

11. Do not operate the heater with the louvers deformed

or damaged.

12. If there are any questions or concerns regarding the

heater, please refer to contact information on the back

page of this manual.

13. Follow the recommended maintenance procedures under

Section I. Heater Maintenance Instructions, page 16.

B. INSTALLATION

All applicable codes must be adhered to. For optimum

performance, the heater should be installed as follows:

B.1 Location

1. Ensure there are no obstructions that may impede

the heater’s air inlet or discharge. Refer to Figure 1 and

Figure2, page4, for minimum clearances.

2. Ensure the air discharge is not directed at a thermostat.

3. Ensure the air discharge is not directed towards areas of

heat loss, such as windows.

4. Ensure the air discharge is directed along and at a slight

angle toward exterior walls.

5. If equipment freeze protection is important, direct air

discharge at equipment while maintaining minimum

clearances.

4

Installation

WALL MOUNT

WITH CLEARANCES

FRONT VIEW

REAR VIEW

2¼"

B

A

HEATING ELEMENTS

MOTOR

1/2" x 3/4" MULTIPLE

CONDUIT ENTRY

1" x 1-1/4" MULTIPLE

CONDUIT ENTRY

6"

MIN. INLET

WALL MOUNT

BRACKET HOLE

PATTERN

CLEARANCE

6 FT C

MOUNTING ARM

S

T

U

MIN.

DISCHARGE

DISTANCE

'R' HOLE

CEILING MOUNT

WITH CLEARANCES

'W' HOLE

6" MIN.

CEILING

CLEARANCE

WALL MOUNT

WITH CLEARANCES

FRONT VIEW

REAR VIEW

2¼"

B

A

HEATING ELEMENTS

MOTOR

1/2" x 3/4" MULTIPLE

CONDUIT ENTRY

1" x 1-1/4" MULTIPLE

CONDUIT ENTRY

6"

MIN. INLET

WALL MOUNT

BRACKET HOLE

PATTERN

CLEARANCE

6 FT C

MOUNTING ARM

S

T

U

MIN.

DISCHARGE

DISTANCE

'R' HOLE

CEILING MOUNT

WITH CLEARANCES

'W' HOLE

6" MIN.

CEILING

CLEARANCE

Table1 – Heater & Bracket Dimensions

Dim. 2-10 kW 15 – 30 kW

in. mm in. mm

A17 432 24 610

B 14 356 19 1/2 495

C (Depth) 15 1/2 394 22 559

R (Hole dia.) 1/2 13 5/8 16

S 12 1/2 318 17 1/2 445

T 4 1/2 114 6 152

U 4 1/2 114 6 152

W (Hole dia.) 3/4 19 3/4 19

Figure 1

Figure2 – Mounting Clearance

FRONT VIEW REAR VIEW

2¼"

B

A

HEATING ELEMENTS

MOTOR

1/2" x 3/4" MULTIPLE

CONDUIT ENTRY

1" x 1-1/4" MULTIPLE

CONDUIT ENTRY

WALL MOUNT

BRACKET HOLE

PATTERN

T

U

'D' HOLE

CEILING MOUNT

WITH CLEARANCES

'W' HOLE

6” (152mm) MIN.

CEILING

CLEARNACE

WALL MOUNT

WITH CLEARANCES

3.5" (89 mm) for 2 to 10 kW

6.0” (152 mm) for 15 to 30 kW

MINIMUM WALL CLEARANCE

72”

(1830 mm)

DISCHARGE

DISTANCE

C

MOUNTING ARM

S

72”

(1830 mm)

MINIMUM

WALL MOUNT

WITH CLEARANCES

FRONT VIEW REAR VIEW

2¼"

B

A

HEATING ELEMENTS

MOTOR

1/2" x 3/4" MULTIPLE

CONDUIT ENTRY

1" x 1-1/4" MULTIPLE

CONDUIT ENTRY

6"

MIN. INLET

WALL MOUNT

BRACKET HOLE

PATTERN

CLEARANCE

6 FT C

MOUNTING ARM

S

T

U

MIN.

DISCHARGE

DISTANCE

'R' HOLE

CEILING MOUNT

WITH CLEARANCES

'W' HOLE

6" MIN.

CEILING

CLEARANCE

FRONT VIEW REAR VIEW

2¼"

B

A

HEATING ELEMENTS

MOTOR

1/2" x 3/4" MULTIPLE

CONDUIT ENTRY

1" x 1-1/4" MULTIPLE

CONDUIT ENTRY

WALL MOUNT

BRACKET HOLE

PATTERN

T

U

'D' HOLE

CEILING MOUNT

WITH CLEARANCES

'W' HOLE

6” (152mm) MIN.

CEILING

CLEARNACE

WALL MOUNT

WITH CLEARANCES

3.5" (89 mm) for 2 to 10 kW

6.0” (152 mm) for 15 to 30 kW

MINIMUM WALL CLEARANCE

72”

(1830 mm)

DISCHARGE

DISTANCE

C

MOUNTING ARM

S

72”

(1830 mm)

MINIMUM

B

A

B.2 Mounting

1. The heater must be permanently mounted to a xed

location onto a wall or ceiling.

2. The mounting surface must be strong enough to:

–Support the heater’s weight.

–Provide sufcient stiffness to prevent excessive

vibration.

3. The single bolt mounting is not designed for high dynamic

loads that can occur during transportation. For heaters

that are to be installed prior to transportation, it is

recommended that temporary blocking or strapping be

used to limit movement of the heater with respect to the

mounting structure. Inspection of the mounting bolt for

correct tensioning is also recommended after arrival at site

to ensure no loosening has occurred in transportation. The

mounting bolt/nut should be torqued to 65 – 75ft‑lbs, refer

to Table5, page11.

4. Install the bracket on the heater with hardware provided.

4.1 Orient the heater to its nal position before

tightening all hardware.

4.2 In higher vibration installations use of a removable

thread locking compound such as Loctite® 243™

Blue Threadlocker is recommended.

4.3 Correct tensioning of the mounting bolt will include

full compression of the split lock washer and

inspection for correct thread engagement. The

mounting bolt/nut should be torqued to 65 – 75ft‑lbs,

refer to Table5, page11.

5. The discharge air louvers are individually adjustable.

(57 mm)

72”

(1830 mm)

MINIMUM

Table2 – Installation Height & Heater Weight

kW Recommended Mounting

Height - ft (m)

Heater Weight

lbs (kg)

2 – 1 0 6 to 8 (1.8 to 2.4) 53 (24)

15 – 30 8 to 12 (2.4 to 3.6) 104 (47)

WARNING

WARNING. Install heater with suffcient clearance to walls

and ceiling as indicated in gure 2 on page 4. Mount with

bottom of heater no less than 6 ft (1830 mm) above oor

or grade.

5

Installation

B.3 Electrical

WARNING

WARNING. Disconnect heater from power supply at

disconnect or fuse box before opening enclosures or

servicing heater.

Lock the switch in the “OFF” (open) position and tag the

switch to prevent unexpected power application.

This heater should only be serviced by qualied personnel

with electrical heating equipment experience.

Install and use the heater in accordance with local codes

and this manual.

1. General

1.1 Use only approved copper conductors for

installation. Refer to Section G. Technical Data, page

12 and heater data plate for heater rating.

1.2 The power supply may be single or three phase as

shown on the nameplate. Wiring diagrams are on

the inside of the terminal compartment cover (or

refer to B.3.7, page5). Connection box volume:

2 to 10kW: 9,893 cm³, 15 to 30 kW: 32,333 cm³.

2. Field Wiring

Heater is supplied with an enclosure that has standard

trade size conduit openings to accommodate the line

conductors or external thermostat connection. Two 1/2" or

3/4" conduit knockouts are located on the 2 to 10 kW units.

Two 1/2", 3/4", 1" or 1-1/4" conduit knockouts are located on

the 15 to 30 kW units.

3. Heater may be supplied with a factory-installed built-in

room thermostat. On heaters not supplied with this option,

a remote thermostat is required. Connect the remote

thermostat conductors to the terminal block, refer to

Section 7. Sample Wiring Schematics - RGE Series Heater,

page 5 – 7. Remote thermostats are available from

the factory. Any thermostat used with this heater must be:

3.1 UL listed or CSA approved

3.2 Rated for 240 volts minimum and 5 amps minimum.

4. Grounding: a copper compression terminal is located

beside the terminal block. Ensure the unit is properly

grounded before energizing.

5. Models without a built-in contactor should have the limit switch

wired in the control circuit of an external contactor, and for

three phase supply, this control circuit should be connected

to L2 and L3 which feed the centre heating element,

refer to

Figure3E, page 7.

The limit switch is rated 600 volts, 10

amps

resistive.

6. Final Inspection

Before application of electrical power:

6.1 Check that all connections are secured and comply

with the applicable code requirements.

6.2 Conrm supply voltage is compatible with the data

plate specications.

6.3 Remove any foreign objects from the heater.

6.4 Ensure all external ttings and enclosure covers are

secured.

6.5 Ensure fan rotates freely.

6.6 If equipped, ensure manual reset thermal cut‑out

has been reset.

7. Sample Wiring Schematics - RGE Series Heater

If the wiring schematics of Figures 3A – 3G, page5 –7,

do not match your conguration, check the inside

access panel of the unit for specic wiring schematic.

Alternatively, all wiring schematics are available online at:

www.thermon.com.

B.4 Sample Wiring Schematics RGE Series Heaters

Figure 3A – RGE Series 2 – 10 kW wiring schematic with hi-limit option. 208V and 240V models.

6

Installation

Figure 3B – RGE Series 2 – 10 kW wiring schematic with hi-limit and fused control circuit options. 208/240/480/600V models.

Figure 3C – RGE Series 2 – 10 kW wiring schematic with hi-limit, contactor, built-in thermostat, fan only switch options. 208 - 240V models.

Figure 3D – RGE Series 2 – 10 kW wiring schematic with hi-limit, contactor, built-in thermostat, fan only switch, transformer and fused control

circuit options. 208 – 600V models.

B.4 Sample Wiring Schematics RGE Series Heaters (cont’d)

If the wiring schematics of Figures 3A – 3G, page5 – 7, do not match your conguration, check the inside access panel of the

unit for specic wiring schematic.

7

Installation

B.4 Sample Wiring Schematics RGE Series Heaters (cont’d)

Figure3E - RGE Series 15 – 30 kW wiring schematic with hi-limit option. 208 – 600V models.

Figure 3F - RGE Series 15 – 30 kW wiring schematic with hi-limit and contactor options. 208 – 240V models.

Figure 3G - RGE Series 15 – 30 kW wiring schematic with hi-limit, contactor, transformer and fused control circuit options. 208 – 600V models.

8

Operation, Repair & Replacement

C. OPERATION

C.1 General

1. To operate heater, ensure power supply is properly

connected as specied in the wiring schematic (refer to

Figures 3A – 3G, page5 –7).

2. If the heater is setup to operate on a thermostat, ensure

the temperature set point is set high enough to turn on

the heater

3. During normal operation, the thermal cut-out control should

not cycle the heater ON and OFF. If cycling occurs, check to

see if there is an airow blockage. If there are no obstructions,

the heater must be examined by qualied personnel to

determine the cause of the thermal cut-out cycling.

4. Operate the unit for a minimum of 10 minutes to allow the

heating elements to reach a steady state. If no warm air

is discharged from the heater, shut off the unit and see

Section F. Troubleshooting Tips, page 11.

D. REPAIR & REPLACEMENT

WARNING

WARNING. Disconnect heater from power supply at

disconnect or fuse box before opening enclosures or

servicing heater.

Lock the switch in the “OFF” (open) position and tag the

switch to prevent unexpected power application.

This heater should only be serviced by qualied personnel

with electrical heating equipment experience.

Install and use the heater in accordance with local codes

and this manual.

Note*: ONLY USE FACTORY SUPPLIED REPLACEMENT PARTS OF THE

SAME SPECIFICATION. REFER TO TABLE3, PAGE10 FOR

COMPLETE LISTING OF AVAILABLE PARTS.

D.1 Heating Elements

1. Disconnect all wires connected to the heating element

terminals. Remove louver assembly from heater. Remove

heating elements, noting their proper placement.

2. Install factory-supplied replacement heating element (see

Table3, page10 for Parts List).

2.1 Ensure heating element attaching screws are in

good condition.

2.2 Re-attach heating element mounting screws and

tighten.

2.3 Check heating elements are not in contact with the

cabinet or each other.

3. Reinstall all wires with hardware provided. Torque the

element terminal hardware to the torque specications,

refer to Table4, page11.

4. Reinstall the louvers.

D.2 Fan

1. Remove the rear grille. Remove the motor mount

assembly. Remove the screw securing the fan to the fan

hub attached to the motor.

2. Replace fan with factory-supplied fan. Install the fan such

that the mounting hub collar of the fan faces the inside of

the heater, i.e. facing towards the elements. Ensure motor

shaft end is ush to hub collar.

D.3 Thermal Cut-Out

1. Disconnect all wires connected to thermal cut-out.

2. Remove two mounting screws.

3. Remove thermal cut-out switch from the enclosure.

4. Replace thermal cut-out with factory-supplied

replacement thermal cut-out.

5. Reinstall thermal cut-out switch in the control enclosure.

6. Re-attach thermal cut-out mounting screws.

7. Reconnect all wires to thermal cut-out.

HEATER

CABINET

PANEL

ELEMENT

TERMINAL

HARDWARE

ELEMENT

MOUNTING

HARDWARE

HEATING ELEMENT

Figure4 – Heating Element Assembly

9

Parts List

7

3

11

12

10

6

13

4

5

15

8

1

14

16

9

BILL OF MATERIAL

ITEMDESCRIPTION

1 CABINET BOX ASSEMBLY

2LOUVER ASSEMBLY

3 MOTOR MOUNT

4MOTOR

5FAN BLADE

6COVER PANEL

7REAR GRILLE

8 NON-FINNED (2-10 KW), FINNED ELEMENT (15-40 KW)

9THERMOSTAT - SPST

10 THERMOSTAT KNOB

11 TRANSFORMER

12 THERMAL CUT-OUT

13 TERMINAL BLOCK, 6 POLE

14 TERMINAL BLOCK, 3 POLE

15 CONTACTOR, 3POLE

16 GROUND CONNECTOR

17 FUSE

18 HEATER COWL BAFFLE (GEA40 ONLY)

17

2

E. PARTS LIST

Item Description

1 Cabinet box assembly

2Louver assembly

3Motor mount

4Motor

5Fan blade

6Cover panel

7Rear grille

8Non‑nned (2–10 kW),

Finned element (15–30 kW)

9 Thermostat - SPST

10 Thermostat knob

Figure5 – Parts Assembly Diagram & Chart

11 Transformer

12 Thermal cut-out

13 Terminal block, 6 pole

14 Terminal block, 3 pole

15 Contactor, 3 pole

16 Ground connector

17 Fuse

10

Parts List

Item Description VkW Part Number

1Cabinet box

assembly Contact Factory

2Louver assembly —2 – 1 0 B11022-01

15 – 30 B11022-02

3Motor mounting

Bracket —2 – 10 B11026-01

15 – 30 B11027-01

4Motor

208 2 – 10 B11041-02

15 – 30 B11059-02

240 2 – 10 B11041-02

15 – 30 B11059-02

480 2 – 10 B11041-02

15 – 30 B11059-03

600 2 – 1 0 B11041-02

15 – 30 B11059-04

5Fan blade —

2 – 5 C11028-02

7.5 C11028-03

10 C11028-04

15 C11028-05

20 C11028-06

25 – 3 0 C11028-07

6Cover panel —2 – 1 0 A11050-01

15 – 30 All049-01

7Rear grille —2 – 10 B11024-01

15-30 B11023-01

8

Heating Elements

Non‑nned

(2–10 kW)

Finned element

(15–30 kW)

208

2IXS11011-01

3IXS11011-05

4IXS11011-09

5IXS11011-13

7.5 IXS11011-18

10 IXS11011-23

15 KXF11008-81

20 KXF11008-84

25 KXF11008-33

240

2IXS11011-02

3IXS11011-06

4IXS11011-05

5IXS11011-14

7.5 IXS11011-19

10 IXS11011-24

15 KXF11008-82

20 KXF11008-85

480

4IXS11006-37

5IXS11006-16

7.5 IXS11006-21

10 IXS11006-26

15 KXF11008-64

20 KXF11008-62

25 KXF11008-35

30 KXF11008-61

600

4IXS11006-38

5IXS11006-17

7.5 IXS11006-22

10 IXS11006-27

15 KXF11008-83

20 KXF11008-86

25 KXF11008-36

30 KXF11008-65

Item Description VkW Part Number

9 Thermostat - SPST — 2 – 10 FAT 8

15 – 30

10 Thermostat knob —2 – 1 0 B11037-01

15-30

11 Transformer

240

2 – 1 0

TSK4114-32

480 B11033-02

600 B11033-03

480 15 B11033-04

600 B11033-05

12 Thermal cut-out —2 – 1 0 B11035-03

15 -30

13 Terminal block, 6

pole

Contact factory.

14 Terminal block, 3

pole

15 Contactor, 3 pole

16 Ground connector

17 Fuse

240

2 – 1 0

ATQR 1.4

480 ATQR 0.75

600 ATQR 0.75

208

15 – 30 ATQR 0.25

240

480

600

*Ceiling Bracket —— A11034-01

*Wall Bracket —2 – 10 WB 210

15 – 30 WB 1540

Note*: *Not shown in Figure 5

Table3 – Parts List

11

Troubleshooting Tips

F. TROUBLESHOOTING TIPS

F.1 Heater is not operating.

1. Check all fuses.

2. Check disconnect switch.

3. Check voltage supplied to the heater – refer to the

heater data plate for voltage requirements.

4. Check control voltage if transformer is installed.

5. Check thermostat by turning it and check continuity.

6. Check the condition of the disconnect switch if the

heater is so equipped. Measure continuity through the

disconnect by engaging the switch.

7. Verify that there is a jumper wire present between the

terminals as per the wiring schematics (refer to Figures

3A – 3F, page5 – 7.

8. If problem still exists, contact factory.

F.2 Contactor is chattering.

1. Check supply voltage.

2. Check control voltage if transformer is installed.

3. Check wiring connections. Tighten all loose electrical

connections.

4. Check thermostat for continuity. If thermostat does not

break continuity replace thermostat.

5. Check for excessive heater vibration.

6. Do not operate if problem persists. Contact factory.

F.3 Contactor is burned or welded

1. Check the contactor for burn marks and blackening. If

present, replace the contactor.

2. Check incoming power to the heater to ensure there are

no voltage uctuations.

3. Check heating element for continuity.

4. Check motor for continuity.

5. Check thermostat for continuity. If thermostat does not

break continuity replace thermostat.

6. Do not operate if problem persists. Contact factory.

F.4 Heater cycles on high limit.

1. Check the inlet and discharge louvers for air blockage.

2. Check for heating element fouling.

3. Ensure motor is functioning and fan is rotating counter

clockwise when viewed from the rear .

4. Do not operate if problem persists. Contact factory.

F.5 Heater is operating but no heat is present.

1. Check the control voltage to the contactor coil, if unit is

equipped with a contactor and transformer. If voltage is

not within specication replace the transformer.

2. Measure and record all element resistances. Contact

factory to verify if elements are within specications. If

not within specication replace heating element(s).

3. If problem persists, contact factory.

F.6 Heater fan does not operate but the heating

elements operate.

1. Ensure fan blade spins freely to check motor bearings.

Replace motor as required.

2. Do not operate unit. Contact factory.

F.7 The Ground Fault Interrupter (GFI) trips on the main

panel, or heater blows fuses.

1. Check that you have a fuse of the proper amperage

rating.

2. Check for loose or frayed wiring.

3. If condition is not observable, send heater in for repair.

F.8 The fan is turning but very little air comes from the

front of the heater.

1. Check fan rotation and ensure fan turns clockwise as

seen from the front of the heater. Refer to Section B.

Installation, page 3.

2. Check fan blade set screws to ensure fan blade is not

loose on the motor shaft.

3. Do not operate unit. Contact factory.

Table4 – Recommended Torque Specications

Item Description Inch Pounds

Heating Elements without bus bars 16

with bus bars 30

Contactor —18–22

Mounting Bolt/Nut 65–75 (ft‑lbs)

12

Technical Data

G. TECHNICAL DATA

Table5 – Technical Data

kW

Voltage

Phase

Air Flow Temp. Rise

Motor

Voltage

Basic Unit

Basic Unit with: Amps

(Btu/hr) CFM m³/min ºF ºC Contactor Thermostat

(1 Ph only)

Contactor &

Thermostat Ph 1 Ph 3

2

(6824)

208 1 or 3 460 13 14 8 208/240 RGE022 RGE022C RGE022T RGE022CT 11.1 6.8

240 1RGE023 RGE023C RGE023T RGE023CT 9.8 –

3

(10236)

208 1 or 3

465 13 21 12 208/240

RGE032 RGE032C RGE032T RGE032CT 16.1 9.8

240 1RGE033 RGE033C RGE033T RGE033CT 14.1 –

600 1 or 3 RGE038 RGE038C RGE038T RGE038CT 6.2 3.9

4

(13648)

208 1 or 3

475 14 28 16 208/240

RGE042 RGE042C RGE042T RGE042CT 21.2 12.7

240 1RGE043 RGE043C RGE043T RGE043CT 18.5 –

480 1 or 3 RGE047 RGE047C RGE047T RGE047CT 9.9 6.2

600 1 or 3 RGE048 RGE048C RGE048T RGE048CT 7.9 4.9

5

(17060)

208 1 or 3

480 14 40 22 208/240

RGE052 RGE052C RGE052T RGE052CT 26.2 15.6

240 1RGE053 RGE053C RGE053T RGE053CT 22.9 –

480 1 or 3 RGE057 RGE057C RGE057T RGE057CT 12.0 7.4

600 1 or 3 RGE058 RGE058C RGE058T RGE058CT 9.6 6.0

5

(17060)

208 1550 16 35 20 208/240 – – RGE052T/RGX* –26.2 –

240 – – RGE053T/RGX* –22.9 –

7.5

(25590)

208

1 or 3 590 17 43 24 208/240

RGE072 RGE072C

–

RGE072CT 38.9 22.9

240 RGE073 RGE073C RGE073CT 33.8 20.0

480 RGE077 RGE077C RGE077CT 17.5 10.6

600 RGE078 RGE078C RGE078CT 14.0 8.5

10

(34120)

208

1 or 3 760 22 45 25 208/240

RGE102 RGE102C RGE102CT 51.5 30.2

240 RGE103 RGE103C RGE103CT 44.8 26.3

480 RGE107 RGE107C RGE107CT 23.0 13.7

600 RGE108 RGE108C RGE108CT 18.4 11.0

15

(51180)

208

1 or 3 1040 29 50 28

208 RGE152 RGE152C RGE152CT 78.7 46.8

240 240 RGE153 RGE153C RGE153CT 68.2 40.5

480 480 RGE157 RGE157C RGE157CT 34.1 20.3

600 600 RGE158 RGE158C RGE158CT 27.5 16.4

20

(68240)

208

1 or 3 1260 37 55 31

208 RGE202 RGE202C RGE202CT 104.0 61.4

240 240 RGE203 RGE203C RGE203CT 90.1 53.2

480 480 RGE207 RGE207C RGE207CT 45.1 26.6

600 600 RGE208 RGE208C RGE208CT 36.2 21.4

25

(85300)

208

1 or 3 1500 43 61 34

208 RGE252 RGE252C RGE252CT 129.2 75.9

240 240 RGE253 RGE253C RGE253CT 112.0 65.8

480 480 RGE257 RGE257C RGE257CT 56.0 32.9

600 600 RGE258 RGE258C RGE258CT 45.0 26.5

30

(102360)

480 1 or 3 1500 43 70 39 480 RGE307 RGE307C RGE307CT 66.9 39.2

600 600 RGE308 RGE308C RGE308CT 53.7 31.5

Note*: Barn Heaters: Approved by Manitoba Hydro for use in buildings housing livestock: c/w low watt density

13

General Specications

H. GENERAL SPECIFICATIONS

Table6 – General Specications

Nominal kW

2 3 4 5 7.5 10 15 20 25 30

Fan Diameter in. 10 14

mm 254 356

Air Delivery CFM 460 465 475 480 590 760 1040 1260 1500 1500

m³/min 13 13 14 14 17 17 29 37 43 43

Horizontal Throw ft. 20 47

m 6 14.3

Normal Mounting Height*

(to underside)

ft. 6.0 to 8.0 8.0 to 12.0

m 1.8 to 2.4 2.4 to 3.6

Shipping Weight lbs 59 104

kg 24 47

Note*: *Recommended mounting height to ensure warm air reaches the oor.

14

Heater Maintenance Instructions

I. HEATER MAINTENANCE CHECKLIST

Heater Model

Serial Number

Comments

Date of Maintenance

Maintenance Done By

I.1 Periodic (before and as required during heating season)

• Clean - Use compressed air only.

Heating Elements

Louvers

Motor

Inlet Grille

Fan

• Mounting & Motor Check

All mounting hardware condition and

tightness

Motor for smooth, quiet operation

I.2 Annual (before heating season)

• Electrical Check

All terminal connections and conductors.

Tighten loose connections. Conductors with

damaged insulation must be replaced.

Electrical resistance on all load side legs.

Reading should be balanced (± 5%).

WARNING

WARNING. Disconnect heater from power supply at

integral disconnect or fuse box before opening enclosures

or servicing heater.

Lock the switch in the “OFF” (open) position and tag the

switch to prevent unexpected power application.

This heater should only be serviced by qualied personnel

with electrical heating equipment experience.

WARNING

WARNING. Use this heater only as described in this

manual. Any other use not recommended by the

manufacturer may cause re, electric shock, or injury

topersons.

• Mechanical Check

Check heating elements for corrosion and

debris buildup. Clean as required.

Check motor shaft bearing play. Replace

motor if play is excessive, or if motor does

not run quietly and smoothly. Bearings are

permanently lubricated.

Check fan. Replace immediately if cracked,

damaged, or out of balance.

Check tightness of all hardware. All fasteners

must be tight.

Turn heater on for a minimum of ve minutes.

Check for warm air exiting heater through

discharge louvers.

PLEASE ADHERE TO INSTRUCTIONS IN THIS MANUAL

Failure to do so may be dangerous and may void certain

provisions of your warranty.

For further assistance, please call 24hr hotline: 1-800-661-8529 (U.S.A. and Canada)

Please have model and serial numbers available before calling.

WARRANTY: Under normal use the Company warrants

to the purchaser that defects in material or workmanship

will be repaired or replaced without charge for a period

of 18 months from date of shipment, or 12 months from

the start date of operation, whichever expires rst. Any

claim for warranty must be reported to the sales of ce

where the product was purchased for authorized repair or

replacement within the terms of this warranty.

Subject to State or Provincial law to the contrary, the

Company will not be responsible for any expense for

installation, removal from service, transportation, or

damages of any type whatsoever, including damages

arising from lack of use, business interruptions, or

incidental or consequential damages.

The Company cannot anticipate or control the conditions

of product usage and therefore accepts no responsibility

for the safe application and suitability of its products when

used alone or in combination with other products. Tests

for the safe application and suitability of the products are

the sole responsibility of the user.

This warranty will be void if, in the judgment of the

Company, the damage, failure or defect is the result of:

• Vibration, radiation, erosion, corrosion, process

contamination, abnormal process conditions,

temperature and pressures, unusual surges or pulsation,

fouling, ordinary wear and tear, lack of maintenance,

incorrectly applied utilities such as voltage, air, gas, water,

and others or any combination of the aforementioned

causes not speci cally allowed for in the design

conditions or,

• Any act or omission by the Purchaser, its agents,

servants or independent contractors which for greater

certainty, but not so as to limit the generality of the

foregoing, includes physical, chemical or mechanical

abuse, accident, improper installation of the product,

improper storage and handling of the product, improper

application or the misalignment of parts.

No warranty applies to paint nishes except for manufacturing

defects apparent within 30 days from the date of installation.

The Company neither assumes nor authorizes any person to

assume for it any other obligation or liability in connection

with the product(s).

The Purchaser agrees that all warranty work required after

the initial commissioning of the product will be provided

only if the Company has been paid by the Purchaser in full

accordance with the terms and conditions of the contract.

The Purchaser agrees that the Company makes no warranty

or guarantee, express, implied or statutory, (including any

warranty of merchantability or warranty of tness for a

particular purpose) written or oral, of the Article or incidental

labour, except as is expressed or contained in the agreement

herein.

LIABILITY: Technical data contained in the catalog or

on the website is subject to change without notice. The

Company reserves the right to make dimensional and other

design changes as required. The Purchaser acknowledges

the Company shall not be obligated to modify those articles

manufactured before the formulation of the changes in

design or improvements of the products by the Company.

The Company shall not be liable to compensate or indemnify

the Purchaser, end user or any other party against any actions,

claims, liabilities, injury, loss, loss of use, loss of business,

damages, indirect or consequential damages, demands,

penalties, nes, expenses (including legal expenses), costs,

obligations and causes of action of any kind arising wholly or

partly from negligence or omission of the user or the misuse,

incorrect application, unsafe application, incorrect storage

and handling, incorrect installation, lack of maintenance,

improper maintenance or improper operation of products

furnished by the Company.

Oakville

1-800-410-3131

1-905-829-4422

F 905-829-4430

Orillia

1-877-325-3473

1-705-325-3473

F 705-325-2106

Edmonton

1-780-466-3178

F 780-468-5904

5918 Roper Road

Alberta, Canada T6B 3E1

Houston

1-800-654-2583

1-713-433-2600

F 713-433-4541

Denver

1-855-244-3128

1-303-979-7339

F 303-979-7350

ISO 9001

Radiateur RGE avec commutateur de débranchement en option

RGE 20 3 C T - D

Série du

modèle

Kilowatts

02 - 2 kW

03 - 3 kW

04 - 4 kW

05 - 5 kW

07 - 7.5 kW

10 - 10 kW

15 - 15 kW

20 - 20 kW

25 - 25 kW

30 - 30 kW

Voltage

2 - 208

3 - 240

5 - 347

6 - 416

7 - 480

8 - 600

Contacteur

(en option)

Thermostat

(en option)

Auteur options

B - Pales de ventilateur et moteur peints à l’époxy

D - Commutateur de débranchement

F - Commutateur pour le ventilateur seulement

K - Circuit de commande avec fusible

L - Contrôleur de gestion de l’énergie

M - Limite haute pour la réinitialisation manuelle

N ‑ Relais faible tension (24V)

V - Tension de commande 120 V

(240 est standard)

Code du modèle

Part No.MI280.Rev.4.02 mars 2022 Imprimé au Canada

Série RGE

Aérothermes à usage régulier

Pour l’installation, l’utilisation,

l’entretien, la réparation et les

pièces de rechange

C US

®

INSTRUCTIONS IMPORTANTES - CONSERVEZ CES INSTRUCTIONS

Lisez toutes les consignes avant d’installer ou d’utiliser le chauffage. Veuillez suivre à la lettre toutes les consignes

publiées dans ce manuel. Le non-respect des consignes peut être dangereux et peut annuler certaines dispositions

de votre garantie.

RuffneckMC est une marque déposée de Thermon

Droit d’auteur © 2022 Tous droits réservés.

RGE 20 3 C T - D

Série du

modèle

Kilowatts

02 - 2 kW

03 - 3 kW

04 - 4 kW

05 - 5 kW

07 - 7.5 kW

10 - 10 kW

15 - 15 kW

20 - 20 kW

25 - 25 kW

30 - 30 kW

Voltage

2 - 208

3 - 240

5 - 347

6 - 416

7 - 480

8 - 600

Contacteur

(en option)

Thermostat

(en option)

Auteur options

B - Pales de ventilateur et moteur peints à l’époxy

D - Commutateur de débranchement

F - Commutateur pour le ventilateur seulement

K - Circuit de commande avec fusible

L - Contrôleur de gestion de l’énergie

M - Limite haute pour la réinitialisation manuelle

N ‑ Relais faible tension (24V)

V - Tension de commande 120 V

(240 est standard)

Code du modèle

A. Avis importants 18

B. Installation 18

B.1 Emplacement.....................................................................................................................................................18

B.2 Montage................................................................................................................................................. .............19

B.3 Électricité.............................................................................................................................................................20

B.4 Schémas de raccordement des appareils de chauffage de la série RGE ..............20

C. Fonctionnement 23

C.1 Généralités...........................................................................................................................................................23

D. Réparation et rechange 23

D.1 Éléments chauffants....................................................................................................................................23

D.2 Ventilateur ..........................................................................................................................................................23

D.3 Protecteur thermique ................................................................................................................................23

E. Liste des pièces 24

F. Conseils de dépannage 26

F.1 L’appareil de chauffage ne fonctionne pas. ..................................................................................26

F.2 Le contacteur fait du bruit. ......................................................................................................................26

F.3 Le contacteur est brûlé ou soudé.......................................................................................................26

F.4 Les cycles de l’appareil se font à limite élevée...........................................................................26

F.5 L’appareil de chauffage fonctionne, mais ne produit pas de chaleur........................26

F.6 Le ventilateur de l’appareil de chauffage ne fonctionne pas, mais les éléments

chauffants fonctionnent............................................................................................................................26

F.7 Le disjoncteur différentiel de fuite à la terre (DDFT) se déclenche sur le

panneau principal ou l’appareil de chauffage brûle les fusibles...................................26

F.8 Le ventilateur tourne, mais très peu d’air sort du devant de l’appareil de

chauffage. ............................................................................................................................................................26

H. Spécifications générales 28

I. Liste de contrôle pour la maintenance de l’appareil de chauffage 29

I.1 Périodique (avant la saison de chauffage, ainsi qu’au besoin pendant la saison

de chauffage)....................................................................................................................................... ............29

I.2 Annuel (avant la saisonde chauffage)................................................................................. ............29

TABLE DES MATIÈRES

18

Avis importants

A. AVIS IMPORTANTS

ATTENTION

ATTENTION. Ce symbole indique une situation

potentiellement dangereuse qui, si elle n’est pas

évitée, pourrait causer des blessures corporelles ou

endommager l’équipement.

AVERTISSEMENT

Avertissement. Ce symbole indique une situation

très dangereuse qui, si elle n’est pas évitée, pourrait

causer des blessures graves ou endommager

gravement l’équipement.

AVERTISSEMENT

Avertissement. Lire et respecter les consignes

suivantes. Le non-respect de ces consignes pourrait

entraîner des risques d’incendie ou d’électrocution et

causer des blessures graves ou mortelles. La garantie

sera nulle.

1. Lire et suivre toutes les instructions de ce manuel.

2. Cet appareil de chauffage est destiné à une utilisation

commerciale et industrielle dans un espace intérieur.

AVERTISSEMENT

AVERTISSEMENT. L’appareil de chauffage ne doit

pas être utilisé dans une atmosphère dangereuse

contenant des vapeurs, des gaz, des liquides ou

d’autres combustibles.

3. L’appareil de chauffage doit être branché et entretenu

uniquement par un électricien qualié.

4. L’installation et le câblage de l’appareil de chauffage

doivent respecter tous les codes applicables.

5. Débrancher l’appareil de chauffage de la source de

courant au disjoncteur ou à la boîte à fusibles avant

d’ouvrir les boîtiers ou de procéder à son entretien.

SI UN ENTRETIEN EST EFFECTUÉ AU SYSTÈME DE

DÉCONEXXION, s’assurer que le courant a été coupé

à la boîte à fusibles ou au panneau principal. Bloquer

le commutateur à la position d’arrêt (OFF), étiqueter

le commutateur pour éviter une mise sous tension

inattendue.

AVERTISSEMENT

AVERTISSEMENT. Les éléments deviennent chauds

pendant le fonctionnement. Tout contact peut causer

des brûlures.

6. Ne pas utiliser l’appareil de chauffage dans un

environnement mouillé ou humide.

7. Procéder à l’installation et assurer un dégagement

conforme aux instructions de ce manuel.

8. Ne pas utiliser l’appareil de chauffage dans un milieu où

l’atmosphère est corrosive.

9. Utiliser uniquement des pièces de rechange d’origine.

10. La température ambiante maximale de fonctionnement

est de 40 ºC (104 ºF).

11. Ne pas utiliser l’appareil de chauffage si les grilles

d’aération sont déformées ou endommagées.

12. Pour toute question ou préoccupation au sujet de

l’appareil de chauffage, veuillez utiliser les coordonnées

de contact à la dernière page de ce manuel.

13. Suivre les procédures de maintenance recommandées à

la section I. Instructions de maintenance de l’appareil de

chauffage, à la page 31.

B. INSTALLATION

Tous les codes applicables doivent être respectés. Pour une

efcacité maximale, l’appareil de chauffage doit être installé de la

façon suivante :

B.1 Emplacement

1. S’assurer que rien n’obstrue l’entrée d’air ou l’évacuation

de l’appareil de chauffage. Se reporter à la Figure 1 et à la

Figure 2, à la page 20, pour connaître les dégagements

minimaux.

2. S’assurer que l’évacuation d’air n’est pas dirigée vers un

thermostat.

3. S’assurer que l’évacuation d’air n’est pas dirigée vers une

zone de perte de chaleur, comme des fenêtres.

4. S’assurer que l’évacuation d’air est dirigée le long des

murs extérieurs avec un léger angle.

5. S’il est important de protéger l’équipement contre le gel,

diriger l’évacuation vers l’équipement tout en maintenant

les dégagements minimaux.

19

Installation

Tableau1 – Dimensions de l’aérotherme et du

support éléments chauffants

Dim. 2-10 kW 15 – 30 kW

in. mm in. mm

A17 432 24 610

B 14 356 19 1/2 495

C (Depth) 15 1/2 394 22 559

R (Hole dia.) 1/2 13 5/8 16

S 12 1/2 318 17 1/2 445

T 4 1/2 114 6 152

U 4 1/2 114 6 152

W (Hole dia.) 3/4 19 3/4 19

Figure 1

WALL MOUNT

WITH CLEARANCES

FRONT VIEW REAR VIEW

2¼"

B

A

HEATING ELEMENTS

MOTOR

1/2" x 3/4" MULTIPLE

CONDUIT ENTRY

1" x 1-1/4" MULTIPLE

CONDUIT ENTRY

6"

MIN. INLET

WALL MOUNT

BRACKET HOLE

PATTERN

CLEARANCE

6 FT C

MOUNTING ARM

S

T

U

MIN.

DISCHARGE

DISTANCE

'R' HOLE

CEILING MOUNT

WITH CLEARANCES

'W' HOLE

6" MIN.

CEILING

CLEARANCE

WALL MOUNT

WITH CLEARANCES

FRONT VIEW

REAR VIEW

2¼"

B

A

HEATING ELEMENTS

MOTOR

1/2" x 3/4" MULTIPLE

CONDUIT ENTRY

1" x 1-1/4" MULTIPLE

CONDUIT ENTRY

6"

MIN. INLET

WALL MOUNT

BRACKET HOLE

PATTERN

CLEARANCE

6 FT C

MOUNTING ARM

S

T

U

MIN.

DISCHARGE

DISTANCE

'R' HOLE

CEILING MOUNT

WITH CLEARANCES

'W' HOLE

6" MIN.

CEILING

CLEARANCE

ÉLÉMENTS CHAUFFANTS

1/2" x 3/4" Entrée de

câblage multiple

1" x 1-1/4" Entrée de

câblage multiple

‘W’ trou

Figure2 – Dégagement d’installation

Moteur

VUE DE FACE VUE ARRIÈRE

B.2 Montage

1. L’appareil de chauffage impératif être monté en permanence

à un emplacement xe sur un mur ou un plafond.

2. La surface de montage doit être assez solide pour :

–Offrir sufsamment de rigidité pour empêcher

la vibration.

–Offrir sufsamment de rigidité pour empêcher

la vibration.

3. Le montage à un boulon n’est pas conçu pour les

charges dynamiques élevées qui peuvent se produire

pendant le transport. Lorsque l’appareil de chauffage est

installé avant le transport, il est recommandé d’utiliser

un dispositif de blocage ou des sangles pour limiter le

mouvement de l’appareil et protéger la structure de

montage. Il est aussi recommandé d’examiner le boulon

de montage à l’arrivée sur le site pour s’assurer qu’il ne

s’est pas desserré pendant le transport. Le boulon/écrou

de montage doit être serré à un couple de 65 à 75 lb-pi. Se

reporter au Tableau 4, à la page 26.

4. 4. Installer le support sur l’appareil de chauffage à l’aide de

la quincaillerie fournie.

4.1 Orienter l’appareil de chauffage dans sa position

nale avant de serrer la quincaillerie.

4.2 Si l’appareil est exposé à la vibration, il est

recommandé d’utiliser un adhésif frein‑let tel que

Loctite® 243™ Blue Threadlocker.

4.3 Il y a tension adéquate du boulon de montage

lorsque la rondelle de frein élastique est bien

comprimée et que le letage est bien engagé. Le

boulon/écrou de montage doit être serré à un

couple de 65 à 75 lb-pi. Se reporter au Tableau 4, à la

page 28.

5. Les grilles d’aération sont réglables individuellement.

AVERTISSEMENT

AVERTISSEMENT. Installer l’appareil de chauffage

en assurant un dégagement sufsant avec les

murs et les plafonds, comme indiqué à la Figure 2,

à la page 20. Monter de façon à ce que le dessous

de l’appareil de chauffage soit à au moins 6 pi

(1830 mm) au-dessus du plancher ou du niveau du

sol.

FRONT VIEW REAR VIEW

2¼"

B

A

HEATING ELEMENTS

MOTOR

1/2" x 3/4" MULTIPLE

CONDUIT ENTRY

1" x 1-1/4" MULTIPLE

CONDUIT ENTRY

WALL MOUNT

BRACKET HOLE

PATTERN

T

U

'D' HOLE

CEILING MOUNT

WITH CLEARANCES

'W' HOLE

6” (152mm) MIN.

CEILING

CLEARNACE

WALL MOUNT

WITH CLEARANCES

3.5" (89 mm) for 2 to 10 kW

6.0” (152 mm) for 15 to 30 kW

MINIMUM WALL CLEARANCE

72”

(1830 mm)

DISCHARGE

DISTANCE

C

MOUNTING ARM

S

72”

(1830 mm)

MINIMUM

WALL MOUNT

WITH CLEARANCES

FRONT VIEW REAR VIEW

2¼"

B

A

HEATING ELEMENTS

MOTOR

1/2" x 3/4" MULTIPLE

CONDUIT ENTRY

1" x 1-1/4" MULTIPLE

CONDUIT ENTRY

6"

MIN. INLET

WALL MOUNT

BRACKET HOLE

PATTERN

CLEARANCE

6 FT C

MOUNTING ARM

S

T

U

MIN.

DISCHARGE

DISTANCE

'R' HOLE

CEILING MOUNT

WITH CLEARANCES

'W' HOLE

6" MIN.

CEILING

CLEARANCE

FRONT VIEW REAR VIEW

2¼"

B

A

HEATING ELEMENTS

MOTOR

1/2" x 3/4" MULTIPLE

CONDUIT ENTRY

1" x 1-1/4" MULTIPLE

CONDUIT ENTRY

WALL MOUNT

BRACKET HOLE

PATTERN

T

U

'D' HOLE

CEILING MOUNT

WITH CLEARANCES

'W' HOLE

6” (152mm) MIN.

CEILING

CLEARNACE

WALL MOUNT

WITH CLEARANCES

3.5" (89 mm) for 2 to 10 kW

6.0” (152 mm) for 15 to 30 kW

MINIMUM WALL CLEARANCE

72”

(1830 mm)

DISCHARGE

DISTANCE

C

MOUNTING ARM

S

72”

(1830 mm)

MINIMUM

B

A

VUE DE FACE

72”

(1830 mm)

Distance

D’évacuation

3.5” (89 MM) for 2 to 10 KW

6.0 (152 MM) for 15 to 30 kW

Dégagement minimal du mur

72”

(1830 mm)

MINIMUM

Montage Mural Avec Dégagements

motif du trou

du support

de montage

mural

‘R’ trou

Bras de

Montage

Dégagement Minimal

du plafond

6” (152 mm) MIN.

dégagement du

plafond

Tableau2 – Hauteur d’installation et poids du radiateur

kW Conseillé Montage Hauteur - ft

(m)

Poids du radiateur

lbs (kg)

2 – 1 0 6 - 8 (1.8 - 2.4) 53 (24)

15 – 30 8 - 12 (2.4 - 3.0) 104 (47)

20

Installation

B.4 Schémas de raccordement des appareils de chauffage de la série RGE

Figure 3A – Schéma de raccordement des appareils de la série RGE de 2 à 10 kW avec option de limite élevée. Modèles de 208 V et 210 V.

B.3 Électricité

AVERTISSEMENT

AVERTISSEMENT. Débrancher l’appareil de chauffage

de la source de courant au disjoncteur ou à la boîte à

fusibles avant d’ouvrir les boîtiers ou de procéder à son

entretien.

Bloquer le commutateur à la position d’arrêt (OFF),

étiqueter le commutateur pour éviter une mise sous

tension inattendue.

Cet appareil de chauffage doit être entretenu

uniquement par un technicien qualié possédant de

l’expérience avec les équipements de chauffage.

Installer et utiliser l’appareil de chauffage

conformément aux codes locaux et à ce manuel.

1. Généralités

1.1 N’utiliser que des conducteurs en cuivre approuvés

pour l’installation. Se reporter à la section G,

Données techniques, à la page 29, et à la plaque

signalétique pour connaître les caractéristiques

nominales des conducteurs.

1.2 La source de courant peut être monophasée ou

triphasée, comme indiqué sur la plaque signalétique.

Les schémas électriques se trouvent à l’intérieur

du couvercle du compartiment à bornes (ou se

reporter à V.3.7, à la page <OV>). Volume du boîtier

de connexions : 2 à 10 kW : 9 893 cm³, 15 à 30 kW : 32

333 cm³.

2. Câblage sur place

L’appareil de chauffage est livré avec un boîtier muni

d’ouvertures pour câbles de format standard an

de permettre le branchement de conducteurs de

lignes ou d’un thermostat externe. Les appareils de

2 à 10 kW sont munis de deux entrées défonçables

de 1/2 po ou de 3/4 po. Les appareils de 15 à 30 kW

sont munis de deux entrées défonçables de 1/2 po,

de 3/4 po, de 1 po ou de 1 1/4 po.

3. L’appareil de chauffage peut être livré avec un thermostat

d’ambiance intégré installé en usine. Les appareils de

chauffage qui ne sont pas livrés avec cette option doivent

être équipés d’un thermostat à distance. Brancher

les conducteurs du thermostat à distance au bornier

de connexion. Se reporter à la section 7. Schémas de

raccordement – appareil de chauffage de la série RGE,

page 21-24. Des thermostats à distance sont offerts

par l’usine. Le thermostat utilisé avec cet appareil de

chauffage doit avoir les spécications suivantes :

3.1 Homologation UL ou approbation CSA

3.2 Calibré pour 240 volts au minimum et 5 ampères au

minimum.

4. Mise à la terre : une borne de compression se trouve à

côté du bornier de connexion. S’assurer que l’appareil est

adéquatement mis à la terre avant de mettre sous tension.

5. L’interrupteur de n de course des modèles sans

contacteur intégré doit être câblé dans le circuit

de commande d’un contacteur externe et, pour

l’alimentation triphasée, ce circuit de commande doit être

raccordé à L2 et L3 qui alimentent l’élément chauffant

central. Se reporter aux Figures 3E et 3G, aux pages 23.

L’interrupteur de n de course a une tension nominale de

600 volts, 10 ampères résistifs.

6. Inspection nale

Avant d’appliquer l’alimentation électrique :

6.1 S’assurer que tous les raccordements sont bien

solides et qu’ils respectent les exigences des codes

applicables.

6.2 Vérier si la tension d’alimentation est compatible

avec les données de la plaque signalétique.

6.3 Enlever tout corps étranger de l’appareil de

chauffage.

6.4 S’assurer que tous les raccords externes et les

couvercles de boîtiers sont bien en place.

6.5 S’assurer que le ventilateur tourne librement.

6.6 Si l’appareil en est équipé, s’assurer que le

mécanisme de coupure thermique manuel a été

réenclenché.

7. Schémas de raccordement – appareil de chauffage de la

série RGE

Si les schémas de raccordement des Figures 3A à 3G, aux

pages 20 à 22, ne correspondent pas à votre conguration,

consulter le schéma de raccordement propre à l’appareil

qui se trouve à l’intérieur du panneau d’accès. Sinon, tous

les schémas de raccordement sont accessibles en ligne à

l’adresse www.thermon.com.

CÂBLAGE D’USINE CÂBLAGE SUR PLACE

3 Phase 1 Phase

Raccordez au circuit de bobine de l’interrupteur

externe.

Table of contents

Languages:

Other Thermon Heater manuals

Thermon

Thermon Norseman XB Series Guide

Thermon

Thermon HELLFIRE 400 Guide

Thermon

Thermon Caloritech Thermon Quantum TruFlow Heater Guide

Thermon

Thermon Norseman XB Series Guide

Thermon

Thermon Caloritech GE Series Installation instructions

Thermon

Thermon Caloritech EX Series Guide

Thermon

Thermon Ruffneck Assembly instructions

Thermon

Thermon Fastrax FEB Series Manual

Thermon

Thermon HELLFIRE 905 User manual

Thermon

Thermon Caloritech CX Series Guide