5.3 ON/OFF PROGRAMMING.5.3 ON/OFF PROGRAMMING.

5.3 ON/OFF PROGRAMMING.5.3 ON/OFF PROGRAMMING.

5.3 ON/OFF PROGRAMMING.

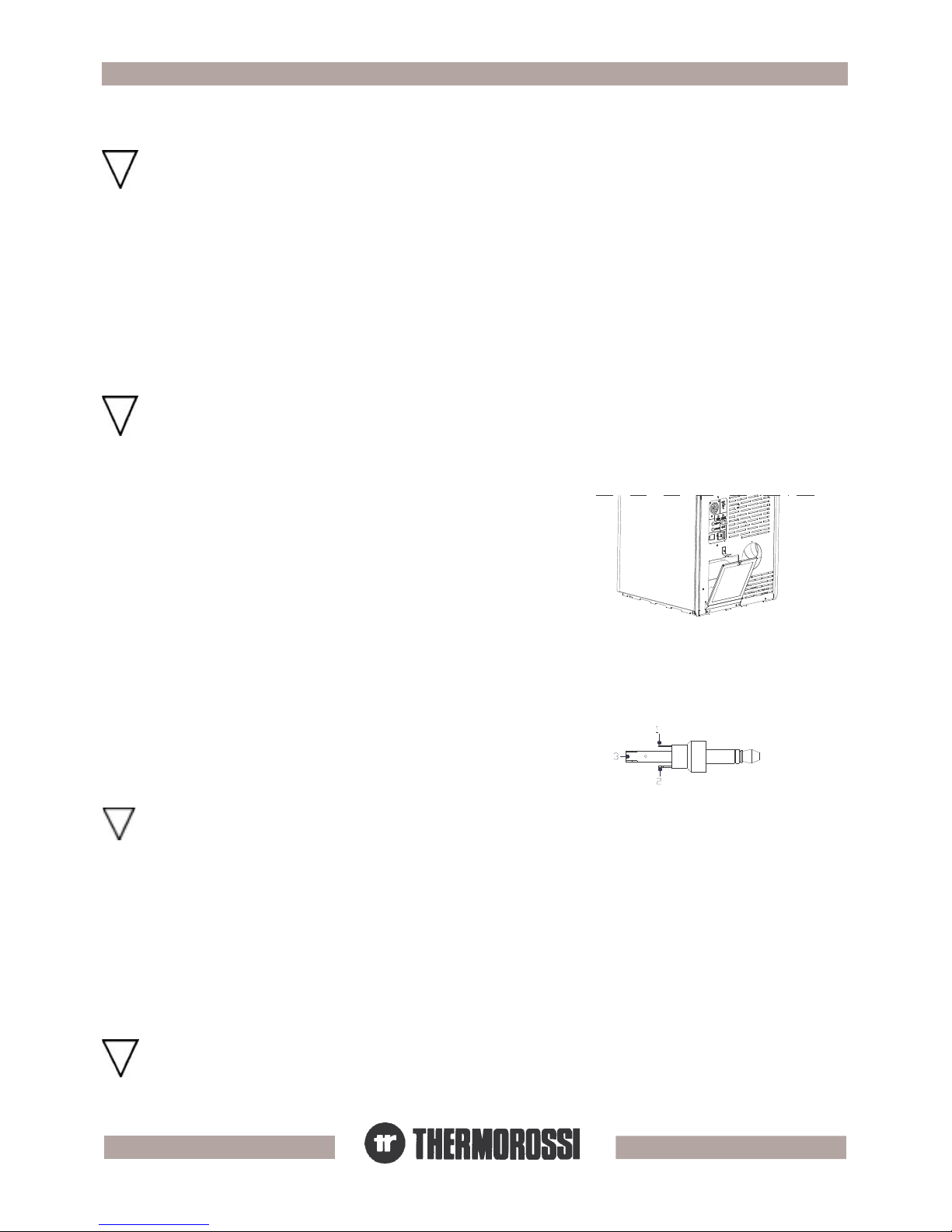

The heater must be energised and the switch at the back in position “1”.

The weekly programming can be executed with the help of the handheld radio

control. It is possible to set up to 3 on-off cycles for each day from Monday to

Sunday. To access the programming mode press the button (19) on the back of the

radio control repeatedly until the word CRONO appears.

Press button (3) or (4) to enable/disable the program setting ( symbol (14) present /

absent) : this function is useful if you wish to disable the established weekly

program setting. To program the heater you need to access the chronothermostat

function by pressing the button (2):

the LED (12) comes on (this indicates that Monday, the first day of the week, is

being programmed). The text ON1 of the indicator (15) comes on and the word

HOURS appears on the display. Press button (3) and/or (4) to enter the hour of the

first cycle start time. To confirm the selection press the button (1). The word

MINUTES will appear on the display . Press button (3) and/or (4) to enter the

minutes of the first cycle start time. To confirm the selection press the button (1).

Next the text OFF1 (indicator (16)) will appear on the display. Proceed using buttons

(3), (4) and (1) as indicated above to set HOURS and MINUTES for the cycle end

time. At this point the first on-off cycle for Monday has been entered. It is then

possible to set the second on-off cycle for Monday (indicated by the texts ON2 and

OFF2) and the third on-off cycle for Monday (indicated by the texts ON3 and OFF3)

. Now program the on-off cycles for the remaining days of the week up to and including Sunday. When the programming mode is active

(symbol present) the minimum operating value at cycle on (combustion power - ventilation speed ) is the same minimum operating value

that was set before the last cycle off.

If the second on-off cycle is not required simply set the ON2 time as 00:00 and the OFF2 time as 00:00 .

In the event of a programmed cycle on always ensure that the brazier is clean and seated correctly in its lodging: failure to keep the

brazier clean can reduce the life of the spark plug.

5.45.4

5.45.4

5.4 VV

VV

VOICE INFORMAOICE INFORMA

OICE INFORMAOICE INFORMA

OICE INFORMATIONTION

TIONTION

TION VV

VV

VOLOL

OLOL

OLUME CONTRUME CONTR

UME CONTRUME CONTR

UME CONTROLOL

OLOL

OL

The heater must be energised and the switch at the back turned to position “1”.

Your heater informs you on its operating status and on any problems that could arise by means of voice messages . Select the volume level

for the voice messages by carrying out the following procedure. When the heater is in the POWER OFF, POWER ON or RUNNING status

simply press the button (19) until the word VOLUME appears on the display (10). Press button (2) and the word SELECT appears on the

display: the introductory music plays. Press button (4) repeatedly and the + symbol appears (to increase the volume) .

Press button (3) repeatedly and the - symbol appears (to lower the volume) . To confirm the volume selection press the button (1). The

heater then returns to its previous POWER ON or RUNNING or POWER OFF status.

5.5 OPERA5.5 OPERA

5.5 OPERA5.5 OPERA

5.5 OPERATING LEVEL SETTINGTING LEVEL SETTING

TING LEVEL SETTINGTING LEVEL SETTING

TING LEVEL SETTING

The heater must be energised and the switch at the back turned to position “1”.

Your appliance is delivered with an excellent program installed that favours combustion yield; the program is called Level 1.

If you are using pellets with a higher than normal incidence of residues after combustion in the brazier, alternative levels may be selected:

Level 2 : this program increases the smoke suction unit speed acceleration.

Level 3 : this program increases the suction unit speed to a greater degree than level 2.

Level 0 : when using lightly-compressed pellets and/or flue outlets with very high vacuum, over 2 mm water column.

The pellet consumption value is not affected by the operating level settings.

Select the required level by acting as follows:

Press the (19) button on the back of the radio control repeatedly until the text indicating the preset heater level appears on the display.

(Level 1 or Level 2 or Level 3 or Level 0). Press the button (2) and the word SELECT appears on the display (10). To change the

operating level hold down button (3) and press button (4).

By holding down button (3) and pressing button (4) repeatedly the level changes in the following sequence: Level 2... Level 3...Level

0...Level 1..

The level selection can be made with the heater OFF or ON. If the change is made while the heater is running the

difference in the flame will be apparent. It is mandatory to pay particular care when selecting the most appropriate

operating cycle for your installation. After the selection of the operating cycle a thorough cleaning of the brazier is

mandatory.

5.6 LANGU5.6 LANGU

5.6 LANGU5.6 LANGU

5.6 LANGUAA

AA

AGE SELECTIONGE SELECTION

GE SELECTIONGE SELECTION

GE SELECTION

The heater must be energised and the switch at the back turned to position “1”.

Press the MENU’ button (19) repeatedly until the word ITALIAN appears on the display (10) . To change the display language proceed as

follows: Press button (2) and the SELECT ITALIAN text appears on the display. Press the button (4) repeatedly to select German, English,

French, Spanish. Once you have selected the desired language press button (1) : ALADINO carries out a data analysis, that is, an update of

the new language.