1 –INTRODUCTION

1.1 SAFETY GUIDELINES

This installation, use and maintenance manual is an integral and essential part of the product and must be kept by the user. Before

commencing with the installation, use and maintenance of the product, carefully read this guide. All local, national and European

regulations regarding the installation and use of the appliance must be met. The Manufacturer recommends carrying out all the

maintenance operations described in this manual.

This appliance must only be used as intended by the manufacturer. Any other use is considered incorrect and therefore hazardous;

consequently, the user shall be totally liable for the product if used improperly. Installation, maintenance and repairs must be carried

out by professionally qualified personnel, certified according to Decree no. 37 of 22 January 2008 and in compliance with current

regulations. In case of repairs only original spare parts supplied by the manufacturer must be used. Incorrect installation or poor

maintenance can injure or damage people, animals or things; in this case the manufacturer shall be relieved of all responsibility.

Before beginning any cleaning or maintenance operation switch off the appliance by means of the 0/I main switch and disconnect

the plug from the electrical power socket. The product must be installed in suitable locations and furnished with all the services

(power and outlets) which the appliance requires for a correct and safe operation. Any repairs or actions carried out on any

systems, components or internal parts of the appliance, or on any of the accessories supplied with it, that are not specifically

authorised by Thermorossi S.p.A, will automatically void the warranty and the manufacturer's responsibility, pursuant to Italian

Decree no. 224 of the President of the Republic of 24/05/1988, art. 6/b.

It is recommended to keep this manual in a safe place that is easily accessible to all users; if the manual is lost or deteriorated

contact the manufacturer for a replacement copy. If the appliance is sold or transferred to another user ensure that the manual is

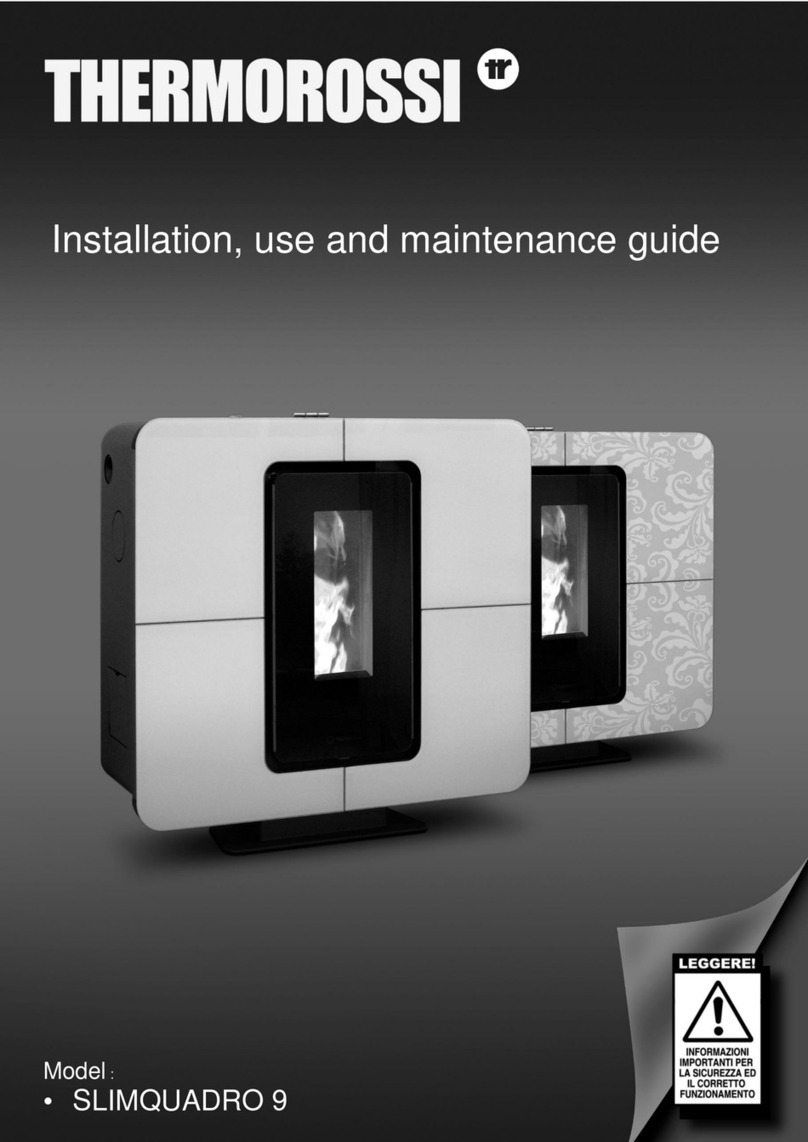

handed over with it. The images and figures featured in this manual are purely illustrative and may differ from the actual product.

Furthermore, Thermorossi reserves the right to apply changes to the content of this manual anytime and without notice.

Thermorossi S.p.A. retains copyright on this manual. These instructions may not be reproduced or communicated to third parties or

used in any other way without the necessary authorisation.

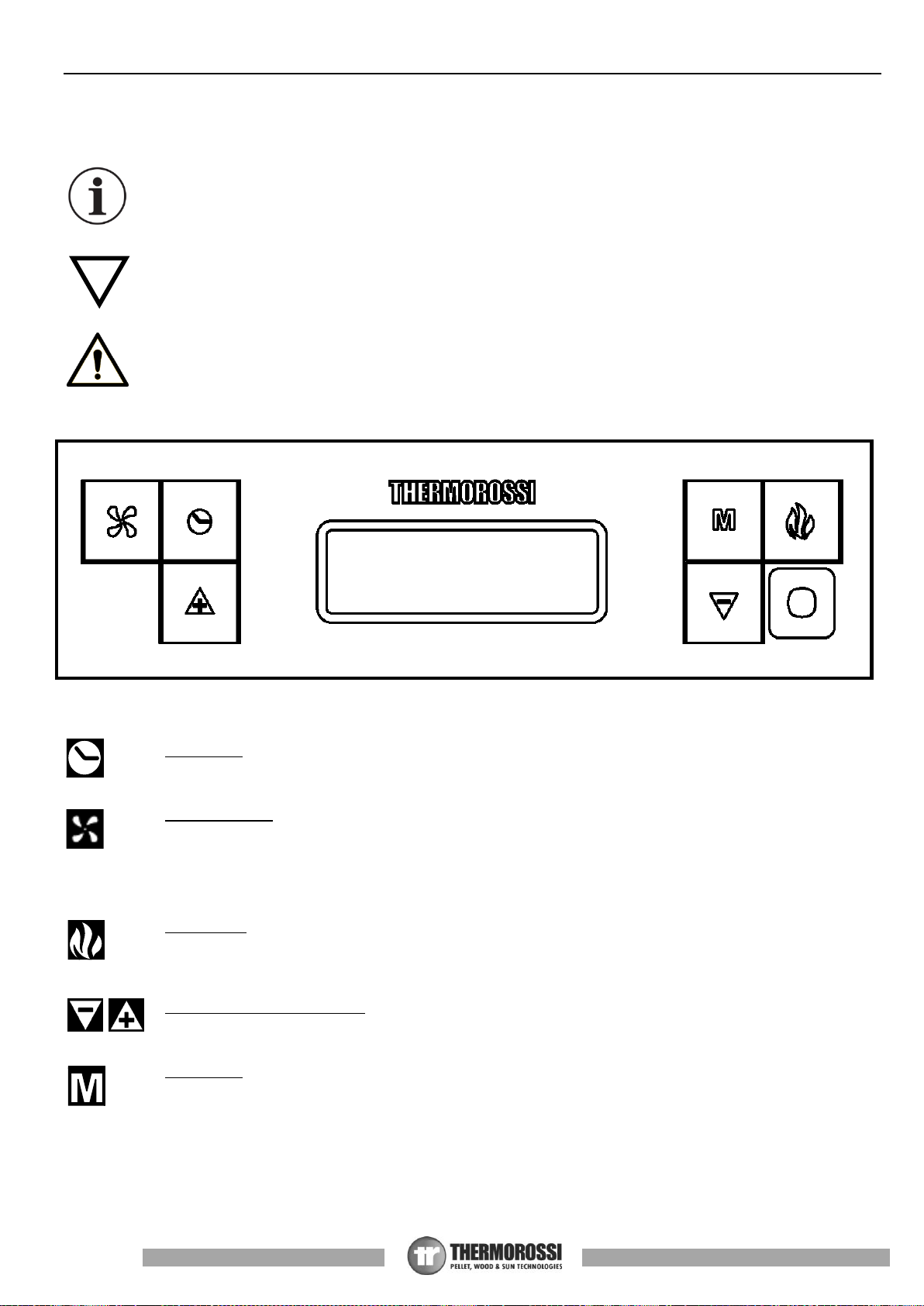

1.2 SAFETY STANDARDS

PERSONAL INJURY

This safety symbol identifies important messages throughout the manual. Read the information

marked by this symbol carefully as non-observance of this message can cause serious injury to

persons using the appliance.

DAMAGE TO PROPERTY

This safety symbol identifies messages or instructions that are fundamental for the appliance and

system to function well. To avoid serious damage to the appliance adhere strictly to these

instructions.

INFORMATION

This symbol indicates important instructions for good functioning of the appliance. If this information

is not correctly observed, the performance of the appliance will not be satisfactory.

1.3 RECOMMENDATIONS

Read this entire use and maintenance manual carefully before using the appliance as familiarity with the information

and instructions contained in it are essential for the correct use of the appliance.

No responsibility will be accepted for damages, even to third parties, if the instructions for installation, use and

maintenance of the appliance are not followed scrupulously. Modifications made to the appliance by the user or on

his behalf, must be considered to be under his complete responsibility. The user is responsible for all the operations

required for the maintenance of the appliance before and during its use.

1.4 GENERAL GUIDELINES

Attention: the appliance must be connected to a system provided with a PE conductor (in compliance with the

specifications concerning low voltage equipment). Before installing the appliance check the efficiency of the earth

circuit of the power supply system.

Attention: the power supply line must have a section which is suitable for the power of the equipment. The cable section must in any

case be no less than 1.5 mm². The appliance requires powering with a voltage of 230V and 50 Hz. Voltage variations greater than

10% of the nominal value can cause irregular operation or damage the electrical device. Position the appliance so that the electric

power outlet in the room is easily accessible. Ensure that a suitable differential switch is installed upstream from the equipment.

Position the power supply cable in order to prevent any contact of the latter with the smoke exhaust pipe or hot parts of the

appliance. If the power cord is damaged it must be replaced by the manufacturer or by an authorised technical assistance service in

order to avoid risks.

Your appliance has obtained the CE marking and has been made to run for 1 hour to check that it functions correctly.

The product must not be used by children under the age of 8 years, by persons with physical, mental or sensorial impairments, or

by persons who are not familiar with the instructions for use and maintenance of the product (the instructions are found in this

booklet). Children must not play with the appliance.