Owner's Manual for Thern Model FVC-1000 Winchespage 12

A8018B-1210

3.4.4 Instructions for Periodic Inspection

a OPEN THE FIRE VENT to release tension from the winch and wire rope by

following the procedure for testing the fire vent.

b VISUALLY INSPECT the winch and all other equipment.

• Check the finish for wear, flaking, or other damage.

• Check all equipment for cracks, dents, bending, rust, wear, corrosion

and other damage. If the winch was overloaded, or if you notice cracks

or other signs of overloading and damage, consider using magnetic or

chemical crack detecting procedures. DO NOT CONTINUE TO USE

DAMAGED OR OVERLOADED EQUIPMENT OR WIRE ROPE.

• Check all fasteners for stripped threads, wear, bending, and other damage.

• Check the foundation for cracks, corrosion or other damage.

• Make sure the winch is lubricated properly.

• Make sure all labels and plates are readable, firmly attached, free of dam-

age and clean. Replacements are available from the factory.

• Check the entire length of wire rope for bent wires, crushed areas, broken

or cut wires, corrosion, and other damage. Carefully inspect areas that

pass over sheaves or through roller guides.

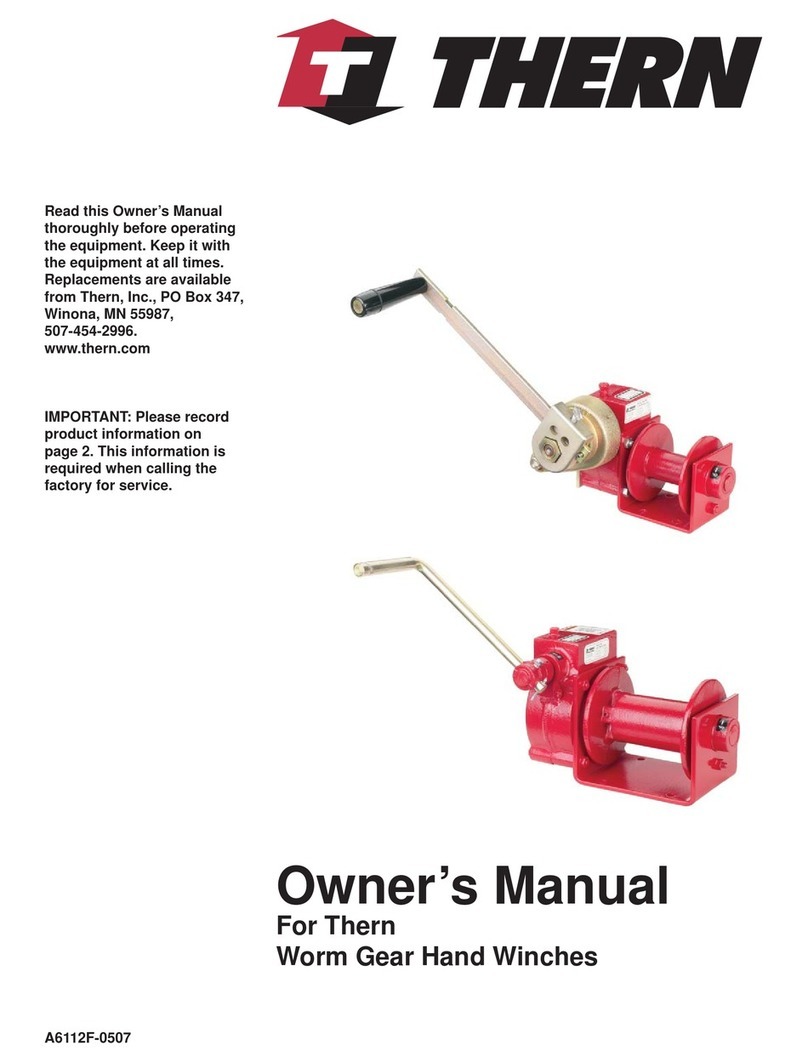

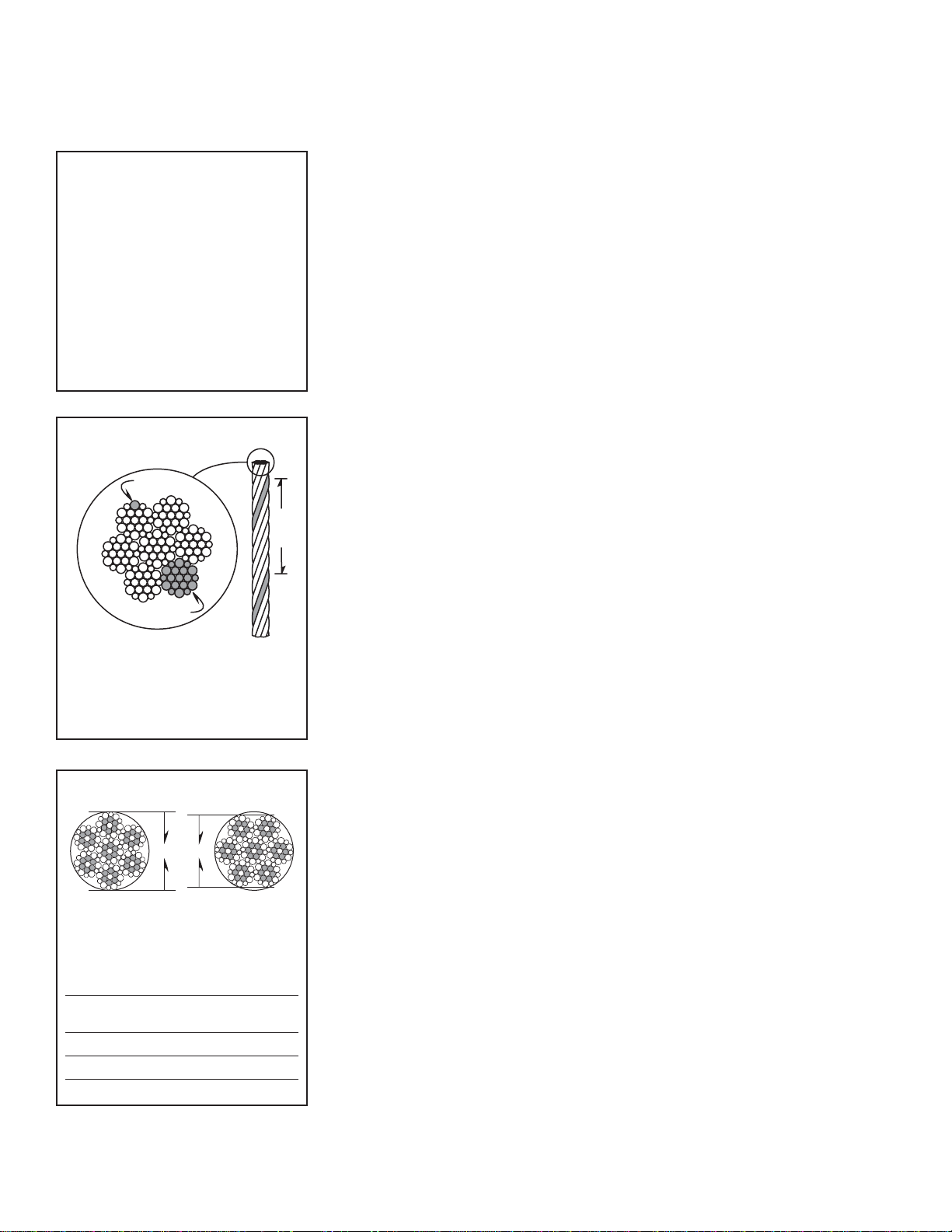

• Note the location and concentration of broken wires. Replace wire rope if

more than 6 wires are broken in one lay, or more than 3 wires are broken

in one strand in one lay. See Figure 4.

• Make sure connecting devices are securely attached to the wire rope, and

the wire rope where they are attached is not frayed, corroded, broken, or

otherwise damaged.

• Make sure the wire rope is securely anchored to the drum and inspect the

flange clip for signs of wear or distortion.

• Make sure the ratchet engages and disengages completely.

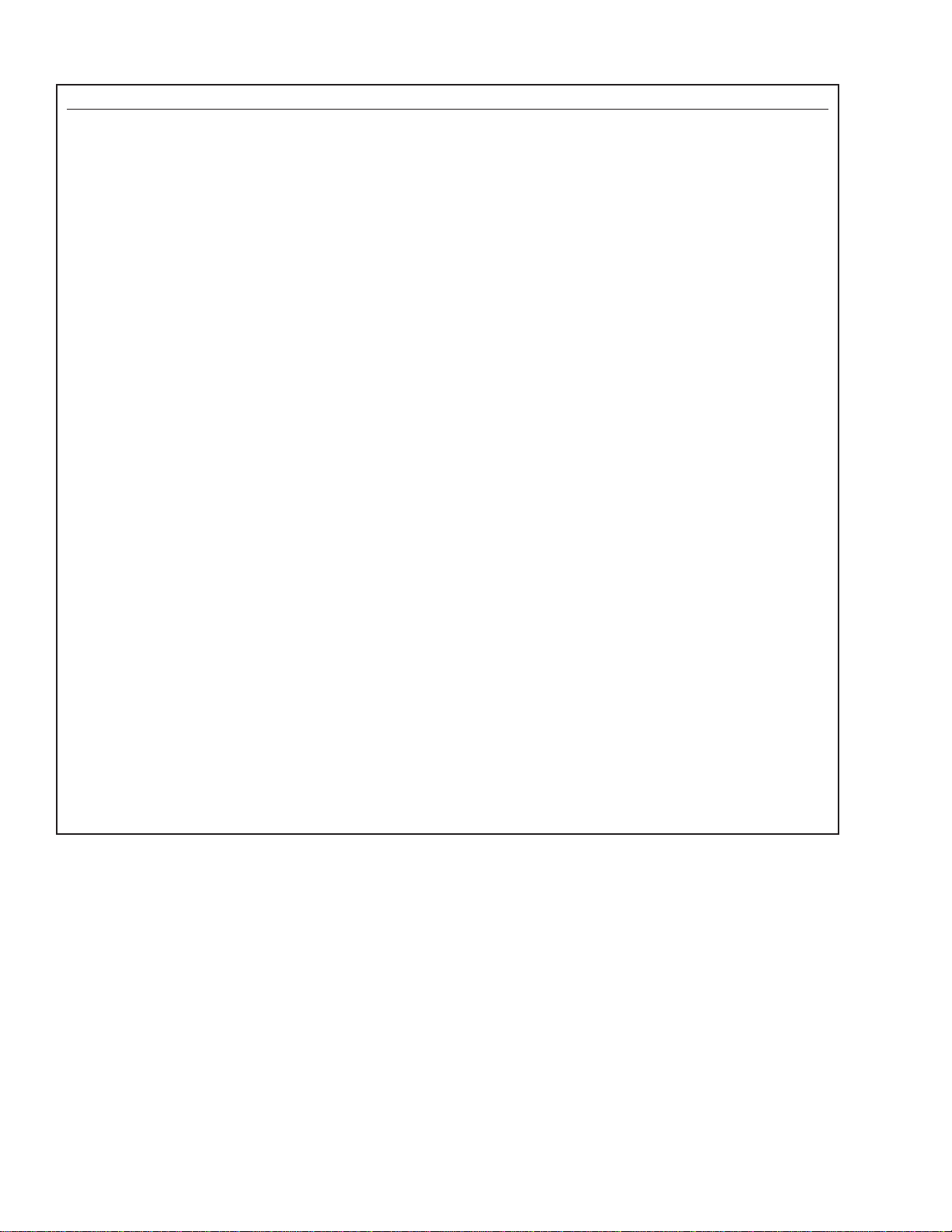

• Measure the diameter of the wire rope, especially in areas where wear

is noticeable. Replace the wire rope if the diameter measures below the

minimum diameter at any point. See Figure 5.

• Check for excessive drum movement indicating worn or loose gears,

bearings, or shafts.

• Disassemble the winch if necessary. Inspect gears, bearings, spring pins,

and shafts for wear, corrosion, distortion, and other damage.

c MONITOR WINCH PERFORMANCE as winch is operated.

• Listen for unusual noises, and look for signs of damage as you operate the winch.

• Make sure the wire rope winds evenly and tightly onto the drum. If it is

loose or uneven, rewind it before continuing.

• Observe the rotating drum; look for signs of loose or misaligned bearings.

Completely correct all problems before continuing. Use the troubleshooting

chart to help determine the cause of certain problems. See Table 2.

Perform periodic inspections:

• Every 6 months.

• Whenever you return the winch

to service from storage.

• Whenever you notice damage

or poor operation in a frequent

inspection.

• Whenever you have, or think you

may have, overloaded or shock

loaded the winch.

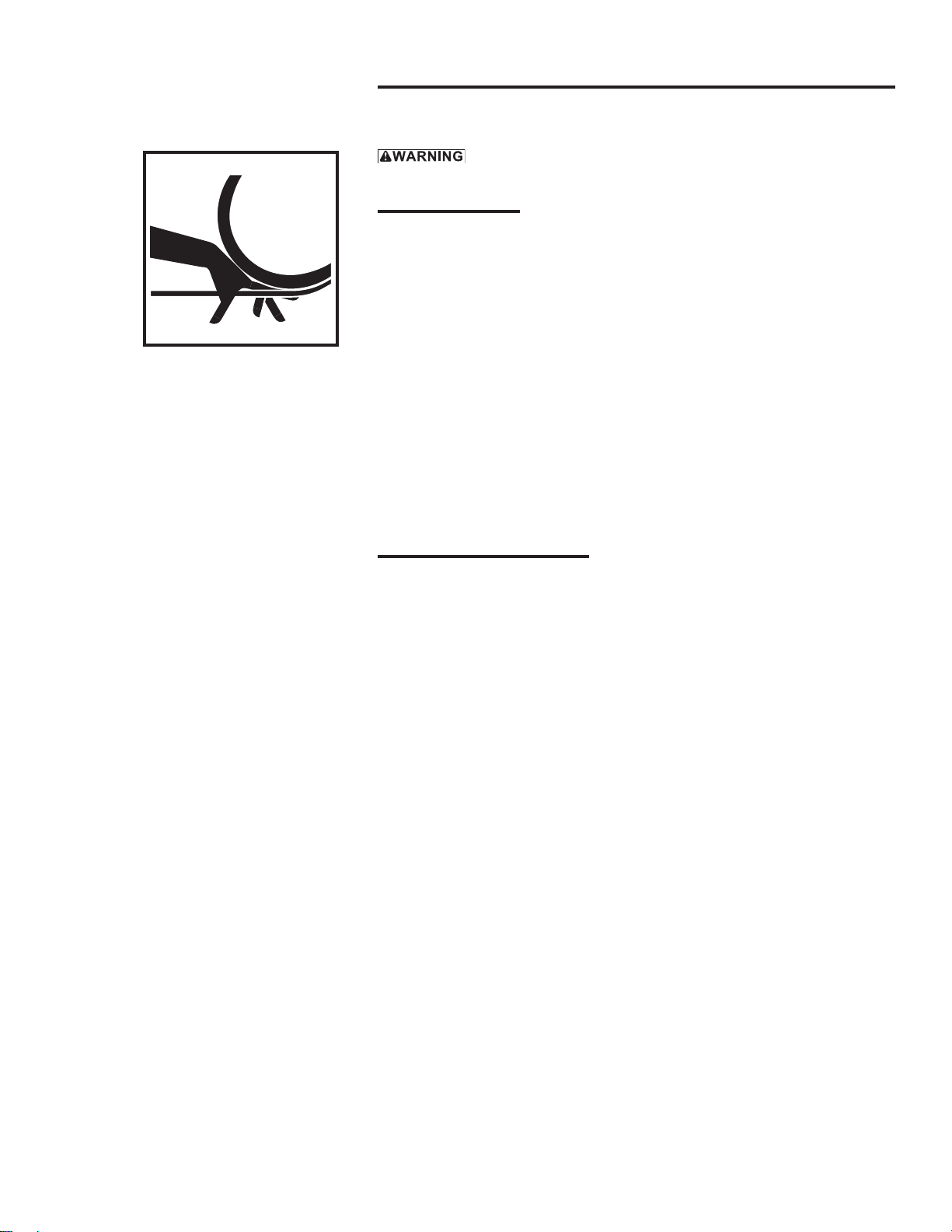

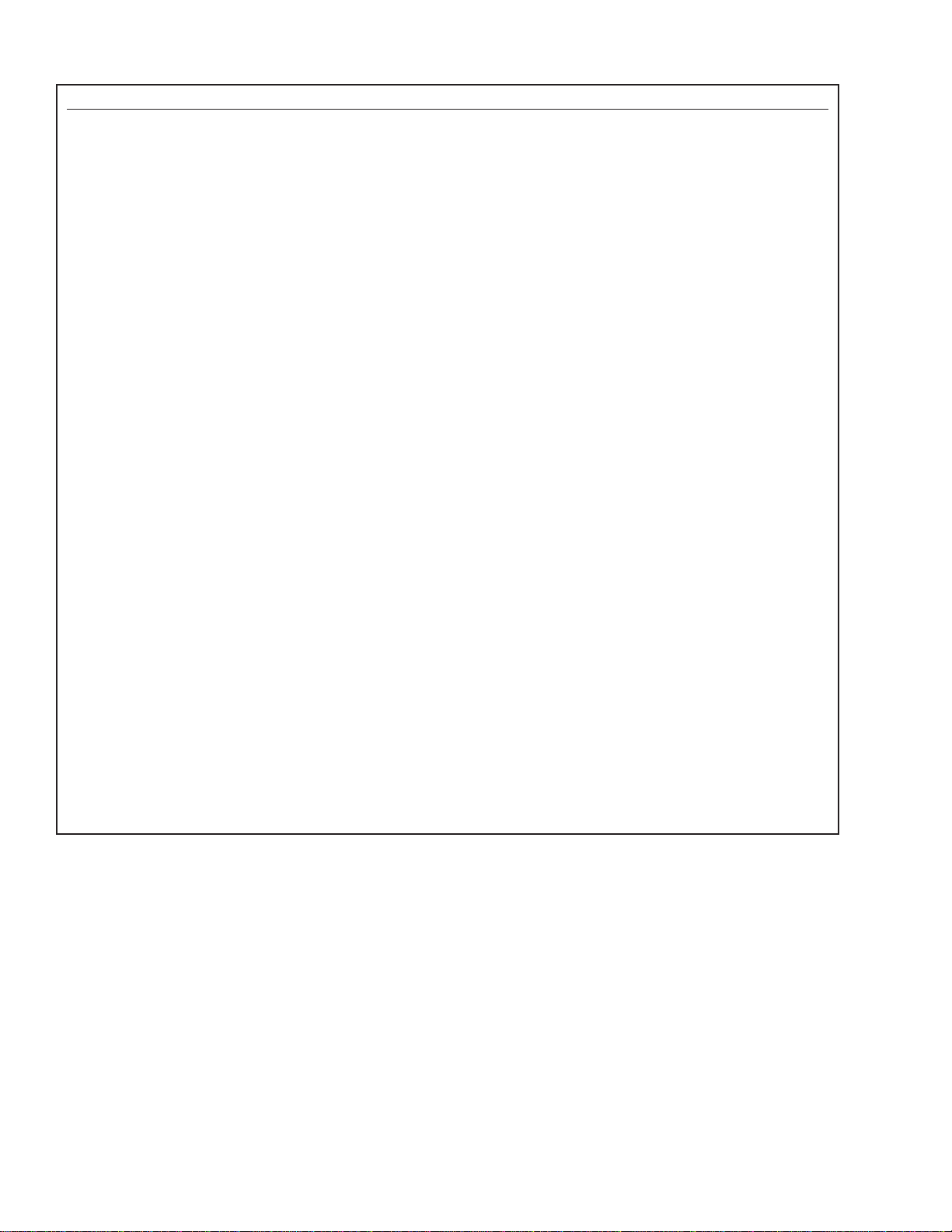

wire

strand

one

lay

Figure 4 – Broken Wires

Wire rope assembly must be re-

placed if more than 6 wires are

broken in one lay, or if more than

3 wires are broken in one strand

in one lay.

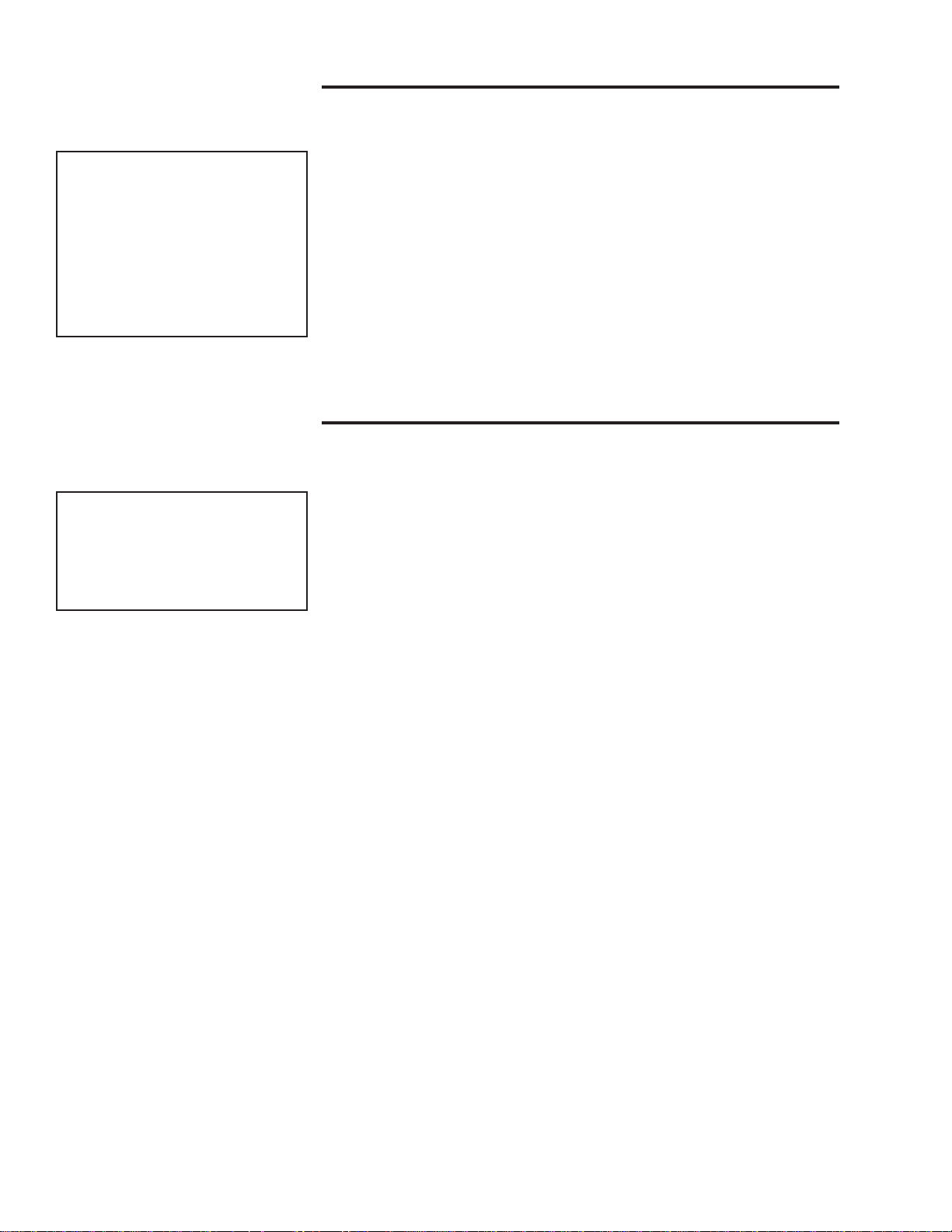

diameter

correct incorrect

Figure 5 – Rope Diameter

The wire rope assembly must be

replaced if the diameter measures

less than the minimum diameter at

any point.

wire rope

diameter minimum diameter

1/8 in 7/64 in (.1094 in)

3/16 in 11/64 in (.1719 in)

1/4 in 15/64 in (.2344 in)