Owner's Manual for Thern TSSBW Spur Gear Hand Winchespage 12

A10191-0309

3.3.4 Instructions for Periodic Inspection, see table 1.

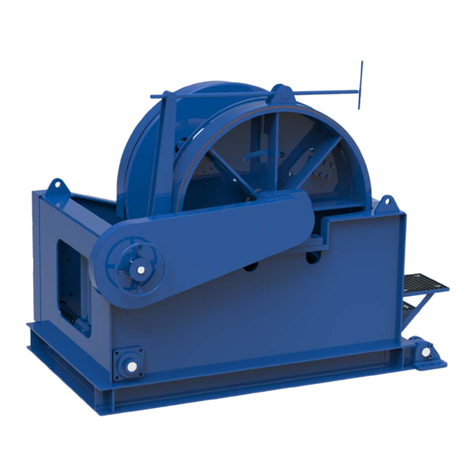

a VISUALLY INSPECT the winch and all other equipment.

• Disassembly may be required in order to properly inspect individual com-

ponents. Contact factory for assembly/disassembly instructions. Disassem-

bly of the winch or brake before contacting Thern, Inc. voids all warranties.

• Check the finish for wear, flaking, or other damage.

• Check all equipment, including wire rope for cracks, dents, bending, rust,

wear, corrosion and other damage. If the winch was overloaded, or if

you notice cracks and other signs of overloading and damage promptly

remove equipment from use and have it repaired or replaced. DO NOT

CONTINUE TO USE DAMAGED OR OVERLOADED EQUIP-

MENT OR WIRE ROPE.

• Check all fasteners for stripped threads, wear, bending, and other damage.

• Check the foundation for cracks, corrosion, and other damage.

• Make sure the winch and brake are properly lubricated.

• Make sure all labels and plates are readable, firmly attached, free of dam-

age and clean. Replacements are available from the factory.

b REMOVE THE WIRE ROPE entirely from the drum.

• Always wear protective clothing when handling wire rope.

• Check the entire length of wire rope for bent wires, crushed areas, broken

or cut wires, corrosion, and other damage. Carefully inspect areas that

pass over sheaves or through roller guides.

• Note the location and concentration of broken wires. Replace wire rope if

more than 6 wires are broken in one lay, or more than 3 wires are broken

in one strand in one lay. See figure 6.

• Make sure the load hook or other device is securely attached to the wire

rope, and the wire rope where it is attached is not frayed, corroded, bro-

ken, or otherwise damaged.

• Measure the throat opening, thickness, and twist of the hook. Replace the

hook if it shows signs of damage. See figure 7.

• Make sure hook latch opens without binding and closes when released.

• Check the anchor holes in the drum flange for signs of wear or distortion.

c PLACE enough weight to keep the wire rope straight and tightly drawn.

• Measure the diameter of the wire rope, especially in areas where wear

is noticeable. Replace the wire rope if the diameter measures below the

minimum diameter at any point. See figure 8.

d REMOVE THE WINCH from the foundation.

• Check fasteners for stripped threads, wear, bends, and other damage.

• Check the frame for bending, distortion, cracks and other damage. A bent

frame is caused by overloading, and is a sign that your application may

require a winch with a larger load rating.

e MOVE THE DRUM with your hands.

• Check for excessive movement indicating worn or loose gears, bearings,

or shafts.

f FASTEN THE WINCH securely to the foundation.

Perform periodic inspections:

• Every 6 months.

• Whenever you return the winch

to service from storage.

• Whenever you notice damage

or poor operation in a frequent

inspection.

• Whenever you have, or think you

may have, overloaded or shock

loaded the winch.

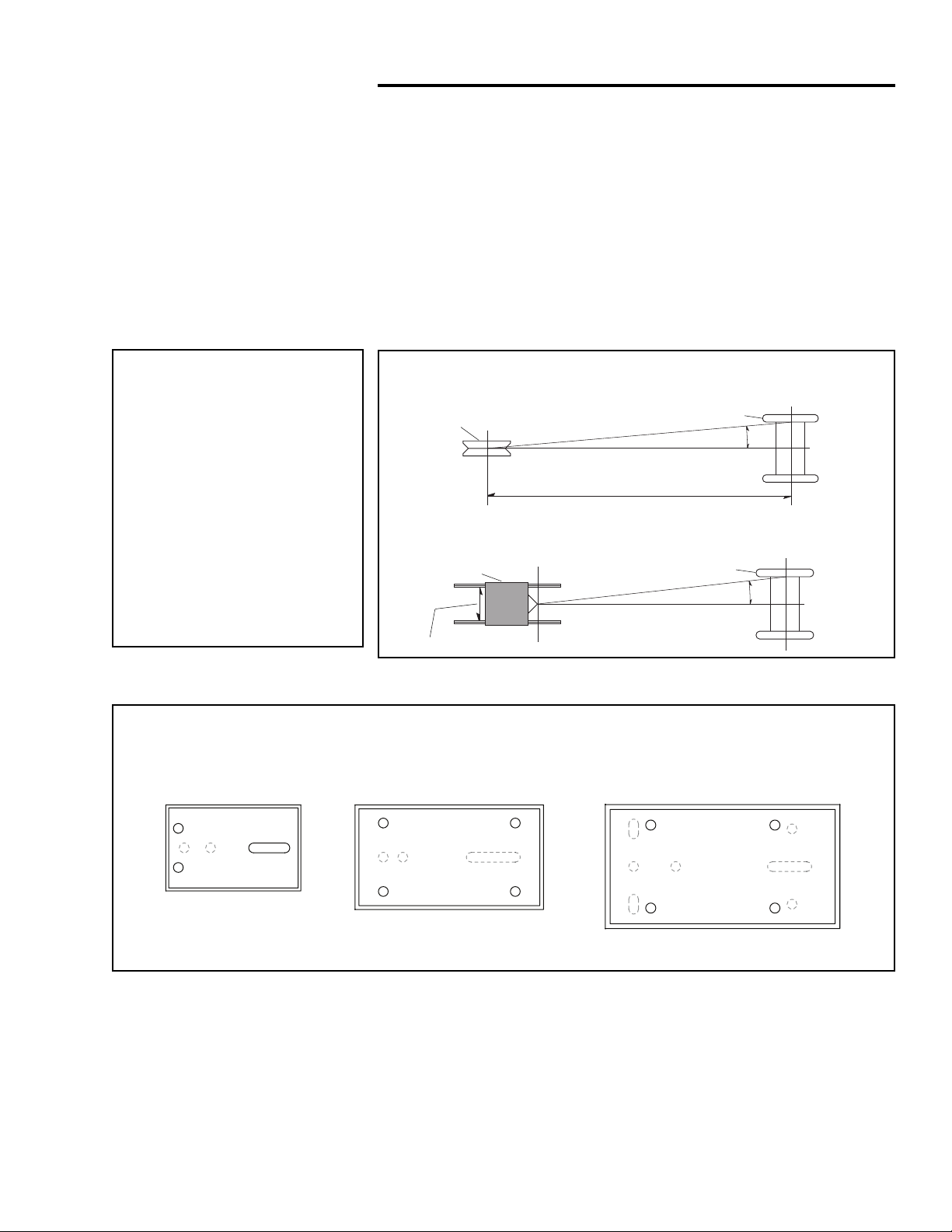

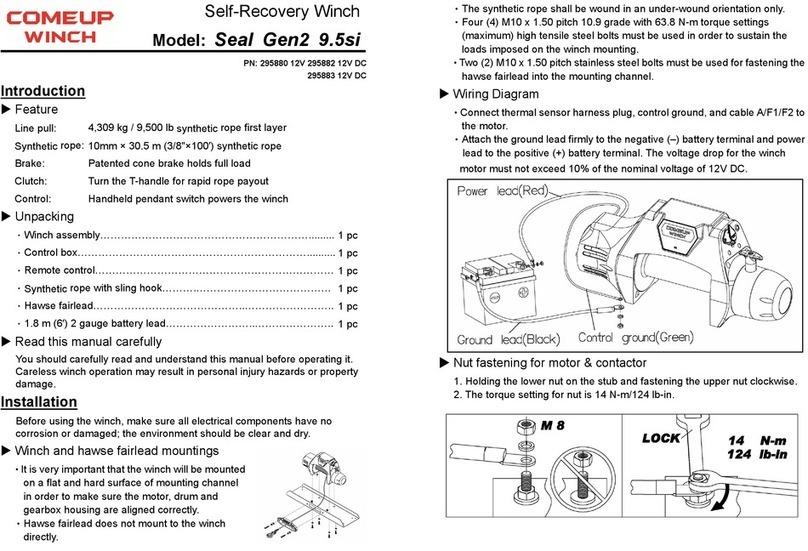

Figure 6 – Broken Wires

wire

strand

one

lay

Wire rope assembly must be re-

placed if more than 6 wires are

broken in one lay, or if more than

3 wires are broken in one strand

in one lay.

Figure 7 – Load Hook

Inspection

throat

opening

twist

thickness

The wire rope assembly must be

replaced if the throat opening is

15% wider than nominal, if the

thickness is 10% less than nomi-

nal, or if the hook is twisted 10° or

more.