Thevco TC6-2V1SA User manual

7&96

$

7(03(5$785(&21752//(5

USER'S MANUAL

67$786

+80,',7<

2876,'(7(03(5$785(

67$7,&35(6685(

'(,&,1*67$*(

7(03(5$785(&859(

0,1,08063(('&859(

'()(&7,9(352%(

'()(&7,9(327(17,20(7(5

7(03(5$785($/$50

:$7(563,//

23(1

&/26(

0$18$/02'(

&$/,%5$7,21

0,67

+($7(5

/27(03(5$785(29(55,'(

&203(16$7,21

$/$506

92873876

,1/(7

)$167$*(6

&855(17&21',7,216

6(77,1*6

021,725,1*

6(783

52207(03(5$785(

352%(7(03(5$785(

2876,'(7(03(5$785(

5(/$7,9(+80,',7<

67$7,&35(6685(

7,0('$7(

67$*(

67$*(

67$*(

0,67

+($7(5

,1/(7

9287387

9287387

$/$506

:$7(5

+($7(55817,0(

86(5

7(67

6(732,17&859(

0,1,08063(( '&859(

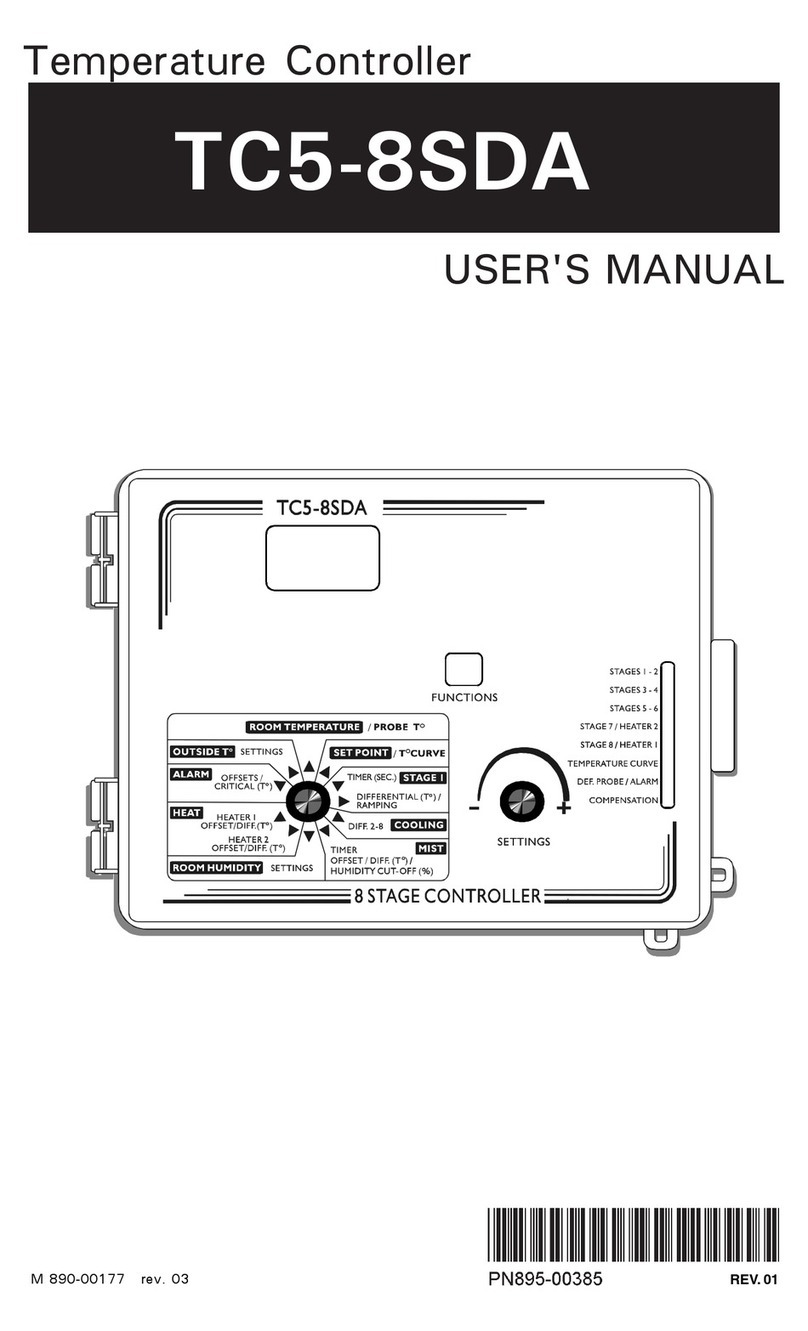

7&96$

7(03(5$785(&21752//(5

M 890-00181 rev. 05 REV. 01

2TC6-2V1SA.rev.05

TABLE OF CONTENTS

PRECAUTIONS ............................................................ 4

FEATURES .................................................................. 5

LOCATION OF THE CONTROLS..................................... 8

INSTALLATION .......................................................... 10

Mounting Instructions ................................................................ 10

Connections ............................................................................. 10

Motor Types ............................................................................ 12

TIME AND DATE FUNCTIONS ..................................... 13

MONITORING FUNCTIONS ......................................... 14

USER SETUP ............................................................. 15

TEMPERATURE SETTINGS ......................................... 23

Displaying Temperatures ............................................................ 23

Temperature Set Points .............................................................. 25

Temperature Curve .................................................................... 26

MINIMUM VENTILATION ............................................ 29

Principle of Operation ................................................................. 29

Stage 1 Minimum Ventilation Settings .......................................... 29

Minimum Ventilation's Speed Curve ............................................. 31

Using Stage 2 Fans for Minimum Ventilation ................................. 34

Low Temperature Override: ......................................................... 34

COOLING .................................................................. 36

Fan Stages Operation ................................................................. 36

Outside Temperature Compensation ............................................. 40

Merging Fan Stages 1 and 2 ....................................................... 43

Merging Stages 2 and 3 ............................................................. 43

De-icing Stage 2 Fans ................................................................ 45

Mist Cooling ............................................................................. 47

Relative Humidity (RH) Compensation .......................................... 50

HEATER SETTINGS .................................................... 54

Heating Stage ........................................................................... 54

Heater Stage's Timers ................................................................ 54

3

TC6-2V1SA.rev.05

TC6-2V1SA

AIR INLET CONTROL.................................................. 57

Principle of Operation ................................................................. 57

Low Temperature Override: ......................................................... 57

Maximum Opening Stage ........................................................... 59

Calibrating the Air Inlet ............................................................... 60

Manual Mode ........................................................................... 61

Static Pressure Compensation ..................................................... 64

0-10V OUTPUTS........................................................ 67

0-10V Outputs: Ventilation Settings ............................................ 68

0-10V Outputs: Heating Settings ................................................ 72

0-10V Outputs: Chimney Damper Settings ................................... 75

ALARM SETTINGS ..................................................... 78

Temperature Alarms: .................................................................. 78

Defective Probe Alarm ................................................................ 80

Defective Potentiometer Alarm ..................................................... 80

Water Spill Alarm ...................................................................... 81

TEST MODE .............................................................. 82

TECHNICAL SPECIFICATIONS .................................... 83

USING THE CONFIGURATION MODULE ....................... 84

INSTALLATION REPORT ............................................. 86

INDEX ...................................................................... 89

4TC6-2V1SA.rev.05

We strongly recommend installing supplementary ventilation as

well as a backup thermostat on at least one fan stage (refer to the

wiring diagram enclosed with this user's manual to connect the

thermostat).

Although overload and overvoltage protection is provided for the

controller circuits, we recommend installing additional protection

devices in the electrical panel.

The room temperature where the controller is located MUST

ALWAYS REMAIN BETWEEN 32°F AND 104°F (0°C TO 40°C).

To avoid exposing the controller to harmful gases or excessive

humidity, it is preferable to install it in a corridor.

DO NOT SPRAY WATER ON THE CONTROLLER

PRECAUTIONS

FOR CUSTOMER USE

Enter the serial number located on

the side of the controller below for

future reference.

Model number:

Serial number:

TC6-2V1SA

5

TC6-2V1SA.rev.05

The TC6-2V1SA is an electronic device used for environmental control in

livestock buildings. It allows the user to maintain a specified target

temperature by controlling the operation of ventilation and heating

equipment. Two stages of variable fans and one stage of either heaters,

mist or ON/OFF fans can be controlled. The main features of the

TC6-2V1SA are as follows:

LCD DISPLAY

An LCD display provides an efficient interface for displaying, monitoring

and adjusting parameter values.

PILOT LIGHTS

Pilot lights indicating the state of outputs allow the user to monitor the

operation of the system without having to enter the building.

REMOVABLE CONNECTORS

The inputs' connection is now made easier by removing the connectors

from the main board.

MINIMUM VENTILATION CYCLE

When ventilation is not required for reducing room temperature, the first

and second fan stages can be operated either continuously or intermit-

tently to reduce the level of humidity and supply oxygen to the room.

TEMPERATURE AND MINIMUM VENTILATION CURVES

The controller can be set to automatically change the temperature set

point and the minimum ventilation cycle over a given period of time, in

accordance with the user's requirements, by specifying a temperature curve

and a minimum ventilation cycle curve with up to ten different points each.

CHOICE OF TEN MOTOR TYPES

The variation in motor speed resulting from a change in voltage will depend

on the make and capacity of the motor. In order to achieve a high degree

of compatibility between controller and motor, the user can choose from

among ten different motor types, thus ensuring that the correct voltage is

supplied.

FEATURES

6TC6-2V1SA.rev.05

TC6-2V1SA

PROBE READINGS RECORDED FOR PAST DAYS

Minimum and maximum readings from temperature probes, static pressure

sensors and humidity sensor are recorded for the current day and the

previous six days.

WATER MONITORING

A pulse input is provided for monitoring water consumption for the current

days and the previous six days.

HEATER RUN TIME MONITORING

Heater run times are kept in memory for the current day and for the previous

6 days.

ALARM MANAGEMENT

Alarms are provided for high-low temperatures, defective probes and other

system functions.

FOUR INDEPENDENT TEMPERATURE PROBE INPUTS

Up to four temperature probes can be connected to the controller in order

to obtain a more accurate reading of the average room temperature and a

faster reaction time.

OUTSIDE TEMPERATURE COMPENSATION

Fan stages are automatically adjusted according to the outside tempera-

ture. It ensures a better stability in the room temperature.

0-10V OUTPUTS

Two 0-10V outputs can be activated to control supplementary ventilation

or heating stages. The 0-10V output can also control chimney dampers.

HUMIDITY COMPENSATION

The minimum speed of stage 1 fans can automatically be adjusted accord-

ing to the humidity level in the barn. Cooling units can also be shut off

when humidity levels are too high.

STATIC PRESSURE CONTROL

A static pressure input is provided to control the static pressure level by

opening and closing the air inlets. When the pressure level is too high, the

inlet opens to compensate. When the pressure level is too low, the air inlet

closes.

7

TC6-2V1SA.rev.05

TC6-2V1SA

CONTROL OF AIR INLET MOVEMENT

The movement of air inlets can be coordinated with the operation of the

fans using a potentiometer located on the panel drive. This allows the air

inlets to be adjusted correctly, without the influence of uncontrollable

factors such as wind or air from adjoining rooms.

PASSWORD PROTECTION

A password allows restricting access to the controller's setup functions.

BACKUP BATTERY

A backup battery allows the unit to keep time in case of a power failure.

OVERLOAD AND OVERVOLTAGE PROTECTION

Resettable fuses are provided at low-voltage inputs and outputs of the

controller to protect its circuitry in the case of an overload or overvoltage.

COMPUTER CONTROL

The controller can be connected to a computer, thus making it possible to

centralize the management of information and diversify control strategies.

TEST MODE

A test mode allows you to simulate temperature changes and verify

controller's performance.

8TC6-2V1SA.rev.05

LOCATION OF THE CONTROLS

LCD DISPLAY

OUTPUT STATUS

MENU SELECT

BUTTONS

FUNCTIONS

ARROW KEYS

67$786

+80,',7<

2876,'(7(03(5$785(

67$7,&35(6685(

'(,&,1*67$*(

7(03(5$785(&859(

0,1,08063(('&859(

'()(&7,9(352%(

'()(&7,9(327(17,20(7(5

7(03(5$785($/$50

:$7(563,//

23(1

&/26(

0$18$/02'(

&$/,%5$7,21

0,67

+($7(5

/27(03(5$785(29(55,'(

&203(16$7,21

$/$506

92873876

,1/(7

)$167$*(6

&855(17&21',7,216

6(77,1*6

021,725,1*

6(783

52207(03(5$785(

352%(7(03(5$785(

2876,'(7(03(5$785(

5(/$7,9(+80,',7<

67$7,&35(6685(

7,0('$7(

67$*(

67$*(

67$*(

0,67

+($7(5

,1/(7

9287387

9287387

$/$506

:$7(5

+($7(55817,0(

86(5

7(67

6(732,17&859(

0,1,08063(('&859(

7&96$

7(03(5$785(&21752//(5

9

TC6-2V1SA.rev.05

TC6-2V1SA

Led Display: The display on the top right corner of the faceplate shows the

current room temperature averaged over all selected room temperature

probes. It can also display the static pressure level or the air inlet position.

LCD Display: The LCD display at the left

shows the current readings and parameters

to be adjusted when you select a function.

The three keys beside the display are used to edit parameters and step

through the display. When the parameters for a given function cannot all

be presented at once on the display, arrows are displayed on the right hand

side to indicate that additional parameters can be displayed using the

arrow keys . After 15 minutes of inactivity, the display returns to the

current temperature display.

Adjustment and navigation arrow keys: The arrow keys that are located

next to the LCD display are used to scroll menus when all parameters

cannot be presented all at once. These keys are also used to modify a

parameter's value once the MODIFY have been pressed.

Status Leds: The status leds that indicates which function is actually

selected.

Adjusting a Parameter: Press on the "MODIFY" button to edit a param-

eter, the parameter will then flash on the display. This means that it can

now be modified. Use the up and down-arrow keys that are located beside

the display to modify the parameter's value.

Output Status LEDs: LEDs at the right side of the control panel give the

status of each output. When the LED is turned on, the output is activated;

when the LED is turned off, the output is deactivated.

Room T° 76.9°F

Pr.Act:1234

10 TC6-2V1SA.rev.05

INSTALLATION

MOUNTING INSTRUCTIONS

Open the latch and lift the cover. Remove the black caps located on each

of the four mounting holes. Mount the enclosure on the wall using four

screws. Be sure the electrical knockouts are at the bottom of the enclo-

sure in order to prevent water from entering the controller. Insert the screws

in the mounting holes and tighten. Fasten the four black caps provided

with the controller onto the four mounting holes. The enclosure must be

mounted in a location that will allow the cover to be completely opened

right up against the wall.

CONNECTIONS

To connect the controller, refer to the wiring diagram enclosed with this

user's manual. Use the electrical knockouts provided at the bottom of the

enclosure. Do not make additional holes in the enclosure, particularly on

the side of the enclosure when using a computer communications module.

Note that the input connectors are now removable. This makes

it easier to connect the different elements to the terminals.

1. PROBES

Probes operate at low voltage and are isolated from the supply.

Be sure that probe cables remain isolated from all high voltage

sources. In particular, do not route the probe cables through the

same electrical knockout as other cables. Do not connect the

shield from the probe cable to a terminal or a ground.

Extending a probe: Each probe can be extended up to 500 feet (150 meters).

To extend a probe:

Use a shielded cable of outside diameter between 0.245 and 0.260 in

(6.22 and 6.60 mm) (the cable dimensions should not be under 18

AWG) to ensure the cable entry is liquid tight. Do not ground the

shielding.

ALL WIRING MUST BE DONE BY AN AUTHORIZED ELECTRI-

CIAN AND MUST COMPLY WITH APPLICABLE CODES,

LAWS AND REGULATIONS. BE SURE POWER IS OFF BEFORE

DOING ANY WIRING TO AVOID ELECTRICAL SHOCKS AND

EQUIPMENT DAMAGE.

!

WARNING

11

TC6-2V1SA.rev.05

TC6-2V1SA

2. ALARM

There are two types of alarms on the

market. One type activates when current

is cut off at its input, whereas the other

activates when current is supplied at its

input. For an alarm of the first type, use

the NC terminal as shown on the wiring

diagram. For an alarm of the second type,

use the NO terminal.

1: 74.2 2:-----

3: 72.3 4:73.0

It is preferable to solder the cable joint to ensure a proper contact

between the two cables.

CAUTION: Do not run probe cables next to other power cables. When

crossing over other cables, cross at 90°.

Defective probes:

An alarm is generated when a defective probe

is detected. To identify the defective probe,

select the PROBE TEMPERATURE or OUT-

SIDE TEMPERATURE function. Dashes are displayed instead of a reading

when the probe is defective. In the case of room temperature probes, the

controller will operate according to the temperature of the remaining probes.

MNO

ALARM

NC

C

NO

12 TC6-2V1SA.rev.05

TC6-2V1SA

MOTOR TYPES

The relationship between the voltage supplied to a motor and its operating

speed is described by a motor curve. This curve varies with the make and

capacity of the motor. The various motors available in the industry have

been divided into ten categories and the controller has been programmed

with a different motor curve for each of these categories. To ensure that

the controller supplies the correct voltages, an appropriate curve must be

selected separately for stages 1 and 2 variable fans, according to the type

of fan motors in use.

Stages 1-2 : Motor Curve Selection:

Select the STAGE 1 or the STAGE 2 function using the menu select

buttons depending on which stage's motor you want to adjust.

Press on the down-arrow key, in order

to select the "Motor curve" screen

display.

Press on the MODIFY button, the motor curve flashes on the display.

Use the arrow keys to adjust the motor curve of the selected stage

then press on the MODIFY button once again to validate.

Motor curve

4

13

TC6-2V1SA.rev.05

TIME AND DATE FUNCTIONS

Set the function to TIME & DATE using the menu select buttons. The

current time and date are displayed.

Press on the MODIFY button. The hours

flash on the display. Use the arrow keys

to set the hours. Press on the MODIFY

button. The minutes flash on the display.

Use the arrow keys to set the minutes. Press on the MODIFY button

once again. The seconds flash on the display. Use the arrow keys to

adjust the seconds to the desired value.

Press on the MODIFY button. The month flashes. Use the arrow keys

to set the month. Press the Modify button. The day flashes. Use the

arrow keys to set the day. Press the Modify button once again, the

year flashes. Use the arrow keys to set the year.

12:00:00 PM

01/01/2003

14 TC6-2V1SA.rev.05

MONITORING FUNCTIONS

1

Viewing Heater Run Times

The controller has an history in which the heater run times , for the past 6

days, are logged in.

Set the function to HEATER RUN TIME

using the menu select buttons.

Note that this function is only available if the

heating stage has been enabled in the USER

SETUP.

The heater's current running time is displayed along with the time and

date.

Keep pressing the down-arrow key to scroll the display. The heater's

run times that have been recorded for the past 6 days are displayed.

2

Viewing Water Consumption

The controller provides a pulse input to monitor the water consumption.

The water consumption is logged into an history for the current day and for

the past 6 days.

Set the function to WATER using the

menu select buttons. Today's water

consumption is displayed.

Note that this function is only available if the

water counter has been enabled in the USER

SETUP.

Press on the down-arrow key to scroll the display. The water

consumption for the past 6 days is displayed.

02/01/02 1:24

01/01/02 2:30

01/31/03 1241l

01/30/03 6189l

15

TC6-2V1SA.rev.05

USER SETUP

The following section describes how to customize the controller for your

particular application. Normally, this setup needs to be done only once. A

template is available at the end of this manual to write down all these

parameters.

It is recommended to clearly define every stage that is going to

be used by your controller. Select the proper stage configuration

on the table below.

1. Set the function to USER using the menu select buttons.

The following parameters are presented below in the order they appear on the

display. The installer's password must first be entered to access these menus. To

modify a parameter, press on the MODIFY button then use the arrow keys to

change it. When you are finished adjusting a parameter, press on the MODIFY

button to validate the new value and to return to the display mode. Press on the

down-arrow key to move to the next parameter.

2. Time of Day Format:

Select the time format:

AM-PM or 24 hours mode.

3. Temperature Units:

Select the temperature units:

Fahrenheit (F°) of Celsius (°C) degrees.

Time ormat

AM-PM

Temp. units

°F

STAGES' DEFINITION TABLE

CHECK THE PROPER STAGE DEFINITION THAT IS GOING TO BE USED BY

YOUR CONTROLLER

1EGATS2EGATS3EGATS

1NOITPO

ELBAIRAV

1NAF

ELBAIRAV

2NAF

RETAEH

2NOITPO

ELBAIRAV

1NAF

ELBAIRAV

2NAF

TSIM

3NOITPO

ELBAIRAV

1NAF

ELBAIRAV

2NAF NAFFFO/NO

16 TC6-2V1SA.rev.05

TC6-2V1SA

4. # of Temperature Sensors in the Room: Set

the total number of temperature sensors

that are wired to the controller. Up to 4

temperature sensors can be selected.

5. Room Probes:

Select which of the room sensors are used

to be part of the average room

temperature. Blinking digits represent

probes that are selected to be part of the

average room temperature. At least one

temperature probe must be selected.

Press on the MODIFY button then set each

probe status by using the arrow keys.

6. Use Water Meter:

Select "Yes" if a water meter is

connected to the controller.

7. Water Meter Units:

Select the water units: Gallons or liters.

This menu is only available if the water meter

has been enabled above.

8. Water Meter Calibration:

Set the # of gallons or liters per pulse.

This menu is only available if the water meter

has been enabled above.

9. Use Humidity Sensor:

Select "Yes" if a relative humidity

sensor is connected to the controller.

10. Humidity Compensation on Min. Speed:

Select "Yes" to enable the compensa-

tion of stage 1 fans' speed, according to

the humidity level (refer to the Relative

Humidity Compensation chapter).

This menu is only available if the humidity

sensor has been enabled above.

Use water meter?

No

Water meter units

lit

Water unit/pulse

1

Use humidity

sensor? No

Rh in luence on

Min. Speed? No

#T° sensors in

the room: 4

Room probes

1234

Room probes

1 On

17

TC6-2V1SA.rev.05

TC6-2V1SA

11. Use Outside Temperature Sensor:

Select "Yes" if an outside temperature

sensor is connected to the unit.

12. Outside T° Compensation on Min. Speed:

Select "Yes" to activate the outside

temperature compensation on the

minimum speed of stage 1 fans (refer to

the Outside T° Compensation chapter).

This menu is only available if the outside

temperature sensor has been enabled above.

13. Use Outside T° Compensation on Stg 1:

Select "Yes" to activate the outside

temperature compensation on stage 1's

# of degrees to 100% (refer to the

Outside T° Compensation chapter).

This menu is only available if the outside

temperature sensor has been enabled above.

14. Use Outside T° Compensation on Stg 2:

Select "Yes" to activate the outside

temperature compensation on stage 2's

# of degrees to 100% (refer to the

Outside T° Compensation chapter).

This menu is only available if the outside

temperature sensor has been enabled above.

15. Winter's Reference Temperature:

Set the temperature that indicates the

beginning of the winter season.

This menu is only available if the

compensation has been enabled on #12, 13

or 14 above) feature has temperature sensor

has been enabled above.

16. Summer's Reference Temperature:

Set the temperature that indicates the

beginning of the summer season.

This menu is only available if the

compensation has been enabled on #12, 13

or 14 above) feature has temperature sensor has been enabled above.

Out T° compens.

stage2 ? No

Outside T° in

winter: 41.0°F

Outside T° in

summer: 59.0°F

Out T° compens.

stage1? No

Use Out T°

sensor? Yes

Out T° compens.

Min Speed? No

18 TC6-2V1SA.rev.05

TC6-2V1SA

17. Use the Static Pressure Sensor:

Select "Yes" if a static pressure sensor

is connected to the controller.

18. Use the Static Pressure Compensation:

Select "Yes" if to activate the static

pressure compensation (refer to the

Static Pressure Compensation chapter).

This menu is only available if the static

pressure sensor has been enabled above.

19. Heating Stage and 0-10V Outputs:

Select "Yes" to enable the heater stage.

Activating the heater stage will automatically

disable the mist stage.

Set the number of 0-10V outputs. Up to

two 0-10V outputs can be used.

20. Use Mist:

Select "Yes" to activate the mist stage.

This menu is only available if the heater stage

has been disabled above.

21. Use Inlet:

Select "Yes" to activate the air inlet

22. Use a timer on the heating stage:

Select "Yes" to activate the heater stage

in a timer mode, according to the room

temperature.

This menu is only available if the heater stage

has been enabled above.

23. Merge between stages 1 and 2:

Select "Yes" if to enable the merge

between fan stages 1&2 (refer to the

"Merge" section of the "Cooling" chapter).

Use Inlet?

Yes

Use Stat. P

sensor? Yes

Use Stat. P

compens.? No

Use Heat? Y e s

#0-10V 2

Use Mist?

Yes

Use heater on

timer ? No

Use merge or

stages 1-2 No

19

TC6-2V1SA.rev.05

TC6-2V1SA

24. Merge between stages 2 and 3:

Select "Yes" if to enable the merge

between fan stages 2 and 3 (refer to

the "Merge" section of the "Cooling"

chapter).

This menu is only shown if stage 3 is used as a fan stage. Refer to the beginning

of this chapter to see if stage 3 is used as a fan stage.

25. De-icing Stage 2:

Select "Yes" if to enable the de-icing

feature on fan stage 2.

26. 0-10V Output # 1 Used for:

Select the proper operation for the first

0-10V output: Ventilation / Heating /

Chimney damper.

This menu is only available if a 0-10V output

has been enabled above.

27. 0-10V #1 follows the Set Point ? :

Select "Yes" if the start temperature of

the first 0-10V output is related to the

set point. This means that when the set

point changes, the start temperature is

adjusted by the same amount. Select "No" to use an absolute start

temperature on this output.

This menu is only available if a 0-10V output has been enabled above.

28. 0-10V or 10-0V Signal:

Select the proper signal of the first

0-10V output (0-10V or 10-0V).

This menu is only available if a 0-10V output

has been enabled above.

29. 0-10V Output # 2 Used for:

Select the proper operation of the

second 0-10V output: Ventilation /

Heating / Chimney damper.

This menu is only available if two 0-10V

outputs have been enabled above.

Use de-icing on

stage 2? No

Use merge or

stages 2-3 No

0-10V 1 used or

Ventilation

0-10V 1 ollows

setpoint? No

0-10V 1 Mode

0-10V

0-10V 2 used or

Heating

20 TC6-2V1SA.rev.05

TC6-2V1SA

30. 0-10V #2 follows the Set Point ? :

Select "Yes" if the start temperature of

the second 0-10V output is related to

the set point. This means that when the

set point changes, the start temperature

is adjusted by the same amount. Select

"No" to use an absolute start tempera-

ture on this output.

This menu is only available if two 0-10V

outputs have been enabled above.

31. 0-10V or 10-0V Signal:

Select the proper signal of the second

0-10V output (0-10V or 10-0V).

This menu is only available if two 0-10V

outputs have been enabled above.

32. Use Night Set Point:

Select "Yes" to enable the night set point.

33. Night Set Point Starts at:

Select the time at which the night set

point starts being used by the controller.

This menu is only available if the night set

point has been enabled above.

34. Day Set Point Starts at:

Select the time at which the day set point

starts being used by the controller.

This menu is only available if the night set

point has been enabled above.

35. Transition Time:

Set the transition time between day and

night set points to the desired value. It

can be adjusted from 15 to 120 minutes.

This menu is only available if the night set point

has been enabled above.

Use night setp?

Yes

Night setp at

8:00P

Day setp at:

7:30A

Transition time

60 min

0-10V 2 ollows

setpoint? No

0-10V 2 Mode

0-10V

Table of contents

Other Thevco Temperature Controllers manuals

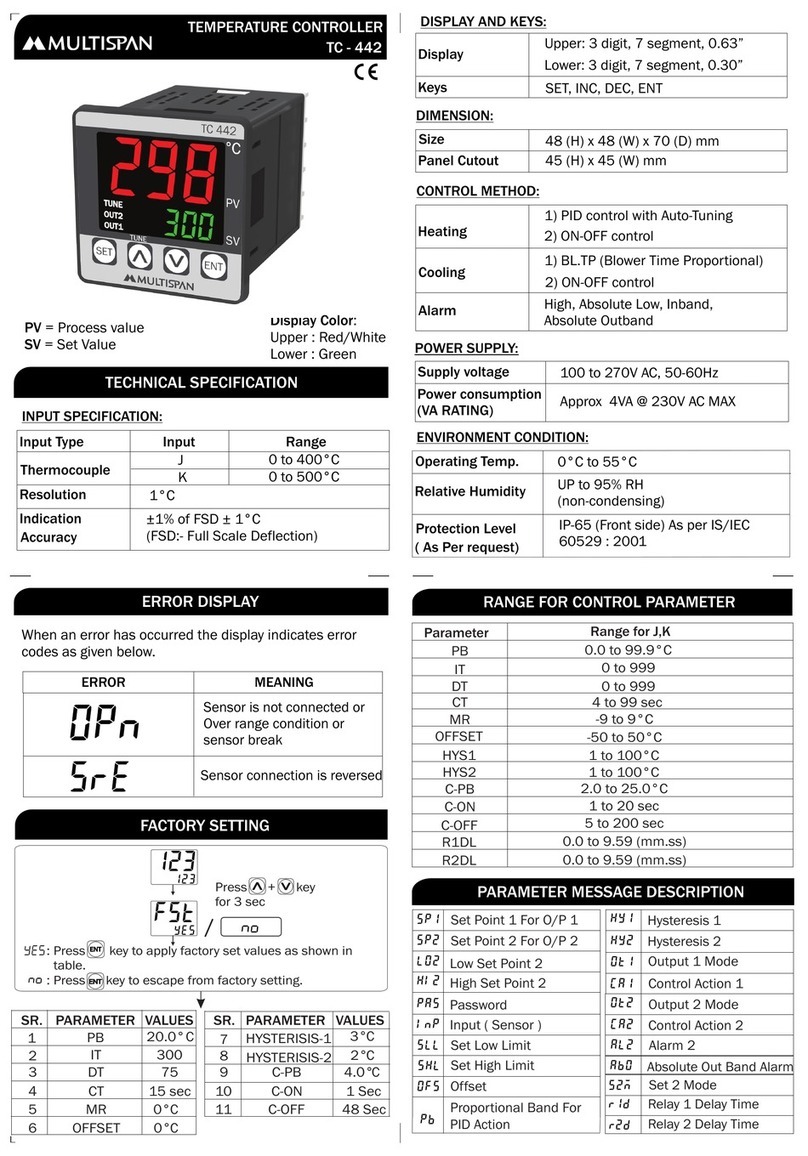

Popular Temperature Controllers manuals by other brands

Nibe

Nibe PCM 40 Installer manual

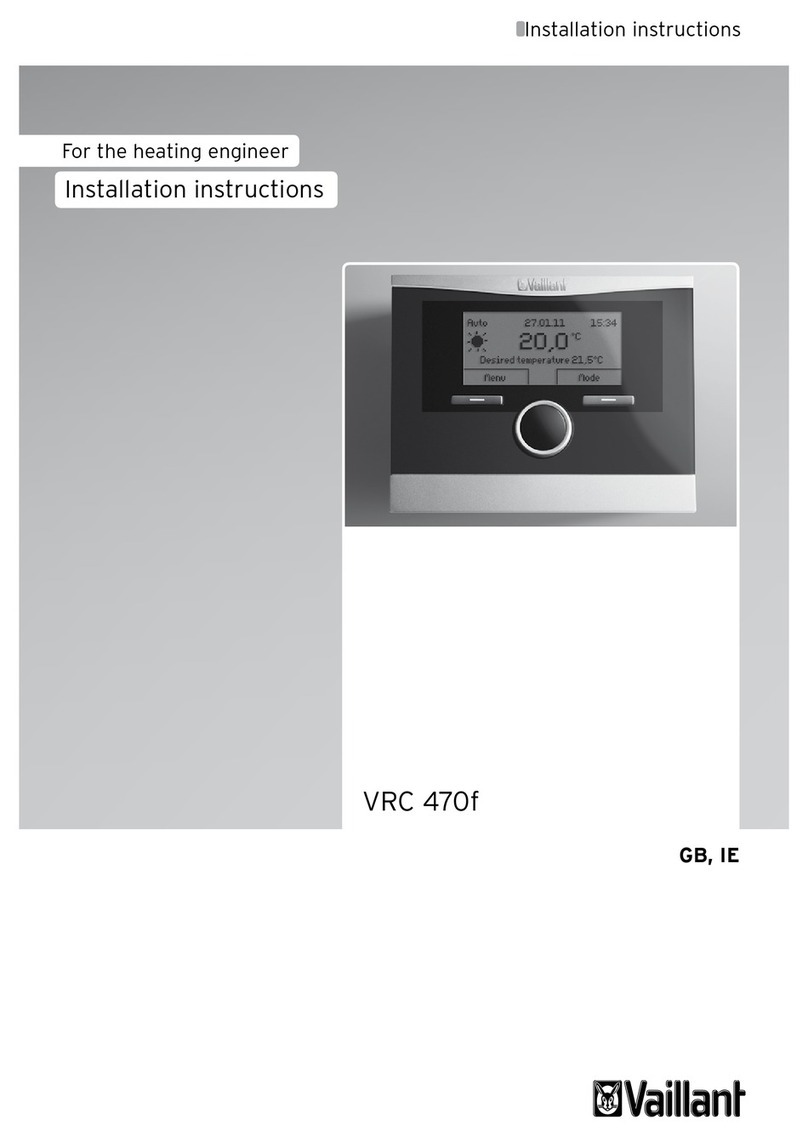

Vaillant

Vaillant VRC 470 installation instructions

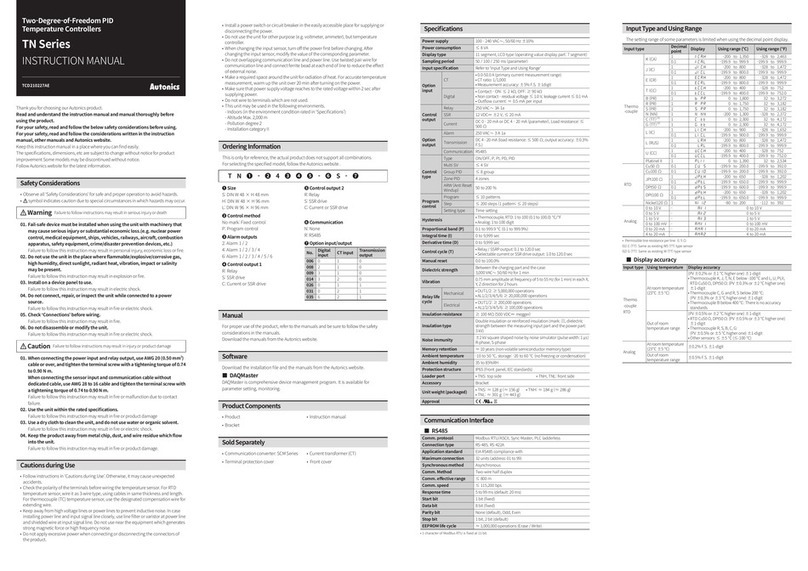

Autonics

Autonics TN Series instruction manual

Sentera

Sentera RXTP Series Mounting and operating instructions

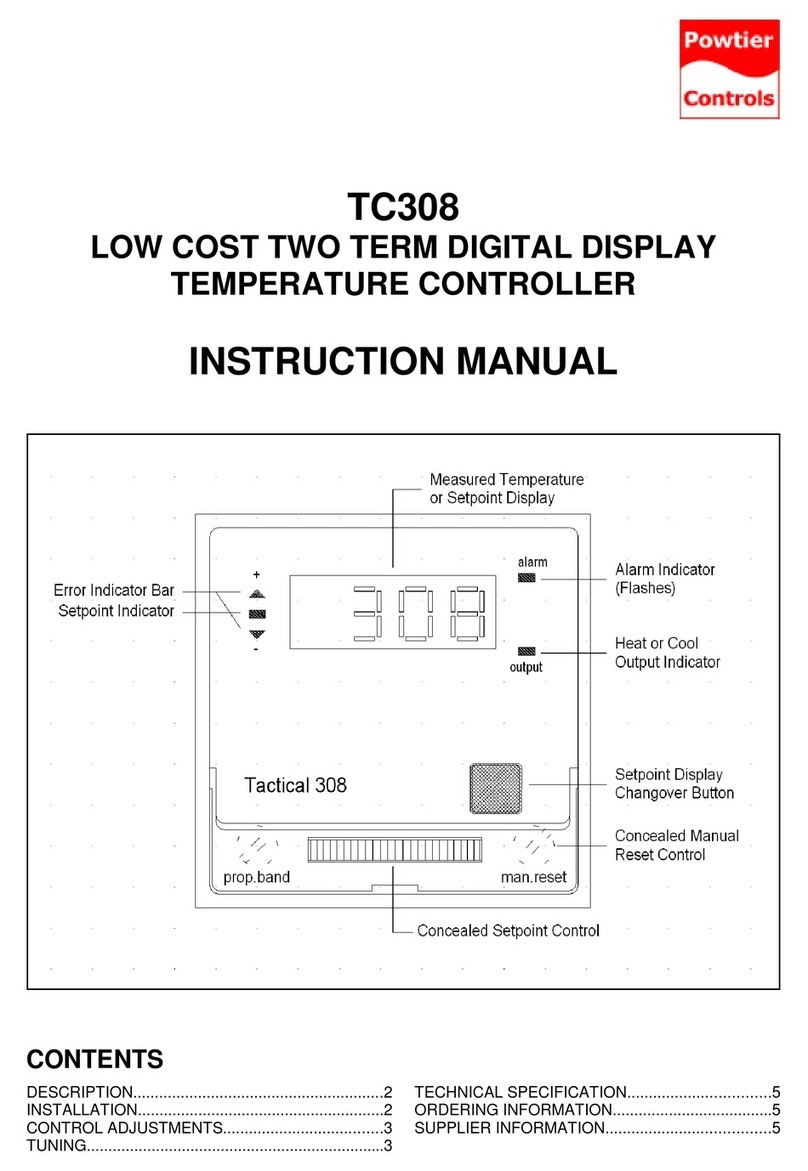

Powtier Controls

Powtier Controls TC308 instruction manual

Sterling

Sterling Sterltronic S-Series Service and instruction manual