xiv

Safety Precautions 3

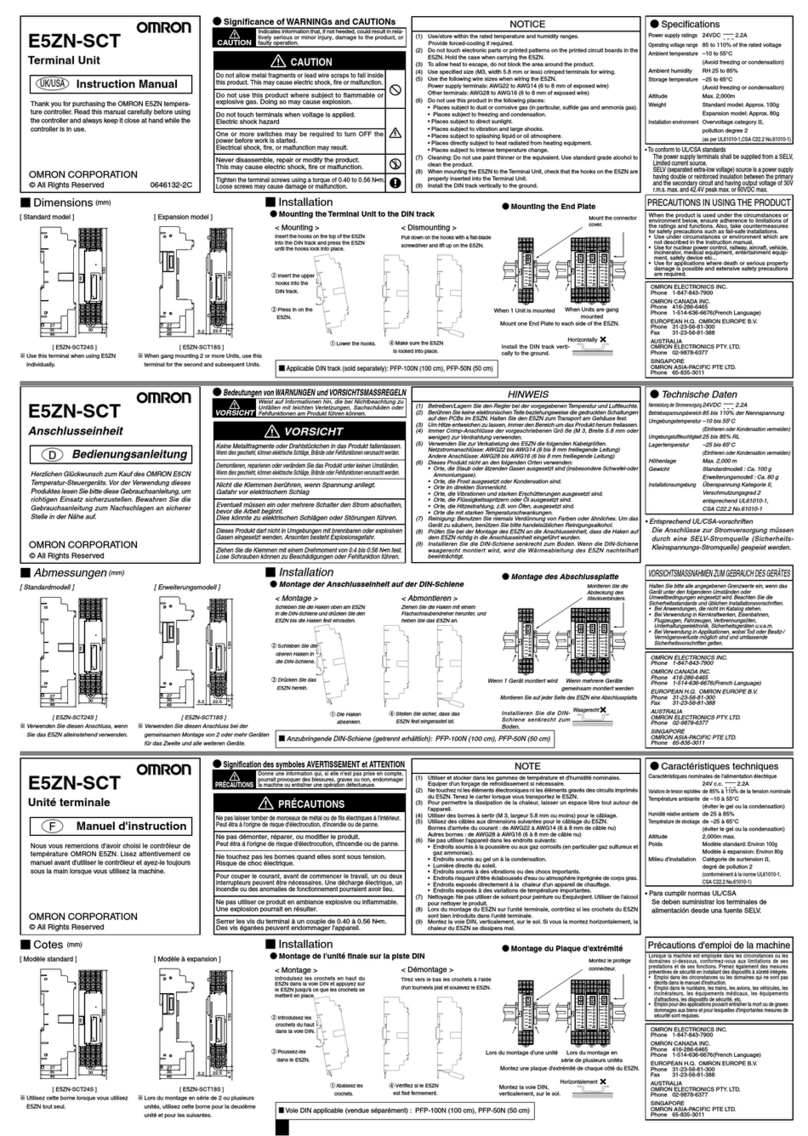

3. To reduce induction noise, separate the high-voltage or large-current pow-

er lines from other lines, and avoid parallel or common wiring with the pow-

er lines when you are wiring to the terminals. We recommend using

separating pipes, ducts, or shielded lines.

4. Do not use this product in the following places:

• Places subject to dust or corrosive gases (in particular, sulfide gas and

ammonia gas)

• Places subject to high humidity, condensation or freezing

• Places subject to direct sunlight

• Places subject to vibration and large shocks

• Places subject to splashing liquid or oily atmosphere

• Places directly subject to heat radiated from heating equipment

• Places subject to intense temperature changes

5. To allow heat to escape, do not block the area around the product. (Ensure

that enough space is left for the heat to escape.)

• Do not block the ventilation holes on the casing.

6. When you draw out the internal mechanism from the housing, never touch

electric components inside or subject the internal mechanism to shock.

7. Cleaning: Do not use paint thinner or the equivalent. Use standard grade

alcohol to clean the product.

8. Use specified size (M3.5, width 7.2 mm or less) crimped terminals for wir-

ing.

9. Allow as much space as possible between the E5CN and devices that gen-

erate powerful high-frequency noise (e.g. high-frequency welders, high-

frequency sewing machines) or surges.

10. When executing self-tuning, turn the load (e.g. heater) ON simultaneously

or before you turn the E5CN ON. If you turn the E5CN ON before turning

the load ON, correct self-tuning results and optimum control may no longer

be obtained.

11. Use a 100 to 240 VAC (50/60 Hz), 24 VAC (50/60 Hz) or 24 VDC power

supply matched to the power specifications of the E5CN. Also, make sure

that rated voltage is attained within two seconds of turning the power ON.

12. Attach a surge suppresser or noise filter to peripheral devices that gener-

ate noise (in particular, motors, transformers, solenoids, magnetic coils or

other equipment that have an inductance component).

13. When mounting a noise filter on the power supply, be sure to first check the

filter’s voltage and current capacity, and then mount the filter as close as

possible to the E5CN.

14. Use within the following temperature and humidity ranges:

• Temperature: -10 to 55°C, Humidity: 25 to 85% (with no icing or conden-

sation)

If the E5CN is installed inside a control board, the ambient temperature

must be kept to under 55°C, including the temperature around the E5CN.

If the E5CN is subjected to heat radiation, use a fan to cool the surface of

the E5CN to under 55°C.

15. Store within the following temperature and humidity ranges:

• Temperature: -25 to 65°C, Humidity: 25 to 85% (with no icing or conden-

sation)

16. Never place heavy objects on, or apply pressure to the E5CN as it may

cause it to deform and deteriorate during use or storage.

17. Avoid using the E5CN in places near a radio, television set, or wireless in-

stallation. These devices can cause radio disturbances which adversely af-

fect the performance of the E5CN.