Thiel Coherent Source CS3.6 Manual

THIEL • 1026 Nandino Boulevard • Lexington, Kentucky 40511 • USA

Telephone: 859-254-9427 Fax: 606-254-0075 7/92

Technical Information

THIEL CS3.6

Coherent Source

®

Loudspeaker

This paper describes some of the technical performance aspects, design

considerations and features of the THIEL model CS3.6 loudspeaker system.

It is intended to supply information for those who are interested in such

matters. It is not intended to imply that good measured technical

performance is sufficient to guarantee good sonic performance.

DESIGN PHILOSOPHY

The CS3.6 is a precision instrument designed to very accurately translate electronic information into musical sound. All our efforts have

been directed toward achieving extremely faithful translation of all tonal, spatial and dynamic information supplied by the amplifier.

The CS3.6 is not intended to mask or mitigate shortcomings of the recording or other components in the music playback system.

We believe this approach is the only way to provide the potential of experiencing all the subtle aspects that help make reproduced music

a most enjoyable human experience.

PERFORMANCE GOALS

Since quality of musical performance is a very complex issue it is helpful to objectively identify the aspects involved. We believe

musical performance can be described, with not much oversimplification, as performance in four areas.

Tonal fidelity includes overall octave-to-octave balance, the fidelity of timbres, absence of vowel-like colorations, and bass extension.

Spatial fidelity includes how wide and deep the performing space seems, how convincingly instruments are placed from the center to

laterally beyond the speakers, how realistic the depth perspective is, how little the speakers’ positions seem to be the source of the sound,

and how large the listening area is.

Transient fidelity includes how convincingly realistic is the reproduction of the initial or ‘attack’ portions of sounds and how clearly

reproduced is musically subtle low–level information.

Dynamic fidelity includes how well the speaker maintains the contrasts between loud and soft and how unstrained and effortless is the

reproduction of loud passages.

FUNDAMENTAL DESIGN CONSIDERATIONS

In our opinion, natural spatial reproduction requires creating a realistic sound field within the listening room by mimicking the properties

of natural sound sources. These properties include wide area radiation and the absence of out-of-phase energy. To meet these requirements

the CS3.6 employs dynamic drivers. Dynamic drivers have the advantages of providing a point source radiation pattern with good dispersion

of sound over a wide area, great dynamic capability, good bass capability and a lack of rearward out-of-phase energy. Another advantage of

dynamic drivers is their small size which allows the multiple drivers to be arranged in one vertical line. This alignment avoids the problem

of line source designs which must place their different drivers side-by-side, causing the distances from each driver to the listener to change

with different listener positions.

The major potential disadvantages of dynamic speakers are diaphragm resonances (“cone break-up”), time errors, phase errors, cabinet

resonance, and cabinet diffraction. None of these problems is a fundamental limit and all can be minimized or eliminated by thorough and

innovative engineering, resulting in a speaker system without significant fundamental limitations.

TECHNICAL REQUIREMENTS

The task of engineering a speaker system requires the translation of the musical performance goals into technical goals. Although there

are also many minor design considerations, the following are what we believe to be the major technical requirements that contribute to each

of the musical goals.

1

CS3.6 DESIGN HIGHLIGHTS

• Extremely accurate frequency response:

29 Hz - 20 KHz ±11/2dB

• Coherent Source design: complete phase and time coherence

• Point source radiation pattern

• Very low energy storage

• Very high quality, innovative driver design

Crossover

The CS3.6 crossover incorporates 25 elements implemented

with 38 components. Most of the components are used to provide a

high degree of response shaping, correcting even small

imperfections that are usually ignored. Very high quality

components are used to ensure very low distortion levels. For

example, polypropylene capacitors are used extensively and all

capacitors are bypassed with custom–made polystyrene and foil

units. Also, all inductors are air-cored types wound with low

oxygen wire.

Specifications:

Bandwidth (-3dB) 27 - 22 KHz

Frequency response 29 - 20 KHz ±11/2dB

Phase response minimum ±5°

Time response 150 µs -20 dB

Sensitivity 86 dB @ 2.8v-1m

Impedance 4Ω(2.5Ωminimum)

Recommended power 100 - 500 watts

Size 481/2h x 121/2w x 17 d inches

Weight 107 pounds

Driver Complement:

• 10" very long excursion woofer with advanced magnet system

and aluminum diaphragm operates up to 500 Hz.

• 4" mid-range with two–layer, air-core diaphragm and long-

gap/short coil motor system operates from 500 to 3000 Hz.

• 1" high output metal dome tweeter operates above 3 KHz.

• 10" passive bass radiator

Tonal fidelity:

• Accurate frequency response so as to not over or under

emphasize any portion of the sound spectrum

• Absence of resonances in the drivers or cabinet so as not to

introduce tonal colorations

Spatial fidelity:

• Point-source, uni-polar radiation

• Time response accuracy to preserve natural spatial cues

• Lack of cabinet diffraction

Transient fidelity:

• Phase coherence to provide realistic reproduction of attack

transients

• Very low energy storage to provide clarity of musical detail

Dynamic fidelity:

• High output capability

• Low distortion

DESIGN GOALS

The technical requirements result in the following major technical design goals:

1. Very uniform frequency response

2. Time response accuracy

3. Phase response accuracy

4. Low energy storage

5. Low distortion

FREQUENCY RESPONSE

In our opinion the human ear is sensitive enough to the balance between component harmonics of musical sounds to detect frequency

balance errors of as little as 0.2 dB if they are over a range of an octave or more. Therefore we believe that extremely accurate frequency

response is an absolute requirement for a truly good speaker. Our design goal was to achieve accuracy in the design prototype of ±.75 dB

with a production tolerance of ±.75 dB. The result is a tolerance in every production speaker of only ±1.5 dB and a tolerance from speaker

to speaker of only ±1.5 dB at all frequencies.

Even more important than the maximum amount of response error at any frequency is the octave averaged, octave-to-octave balance

which has a very high correlation with the perceived tonal balance. Our design goal was to achieve octave-averaged response within ±0.5

dB from 200 Hz to 10 KHz. Any deviation more than 0.5 dB is confined to only a narrow frequency range and therefore will have less

effect on the perceived balance.

Achieving these goals requires the use of drivers with exceptionally uniform responses, drivers with very high consistency (so that few

units need be rejected), drastic reduction of usual cabinet diffraction which causes response errors, and an unusual degree of compensation

in the electrical network of even minor driver response anomalies.

Driver Response

The major cause of non-uniform driver response is diaphragm resonance. These resonances are also the major energy storage

mechanism.

In the case of the CS3.6 tweeter, a metal diaphragm is used that is stiff and light enough so the lowest diaphragm resonance occurs

above the range of hearing at 26 KHz. Therefore, there are no resonances in the audible range to cause energy storage or response

irregularities.

The CS3.6 mid driver uses a very effective new method of greatly reducing diaphragm resonance (patent applied). The diaphragm is

constructed of two cones, each with a different shape, which are joined at the rim and at the neck with only air between them. The resulting

three-dimensional structure is drastically stronger than a conventional diaphragm of equal weight. This increased strength causes the

frequency of lowest diaphragm resonance to be

substantially higher and low level vibrations to be

substantially less.

Figure 1 illustrates a conventional diaphragm

and the vibrations that normally cause irregular

frequency response. Figure 2 shows the response

of a CS3.6 mid driver built with a conventional

diaphragm. Apparent in the response is a

depression in the 1 to 2 KHz region followed by

a hump from 2 to 3 KHz, a dip at 4 KHz and a

final peak at 4.7 KHz. These irregularities are

due to diaphragm resonances. Figure 3 is the

frequency response of this driver through time

and illustrates how the resonances cause the

driver’s output to ring. It can be seen that the

driver’s output up to 5 KHz requires 1 milli-

second (ms) before reducing to the -20 dB floor.

Figure 4 illustrates the new diaphragm.

Figure 5 shows that the response is much more

uniform than the conventional driver and shows

far fewer irregularities. Figure 6 shows that

diaphragm resonances are virtually eliminated

below 7 KHz. Even the one resonance at 7 KHz

is mild. Below 6 KHz the driver’s output is

exceptionally clean, reaching the -20 dB floor in

less than 0.5 ms.

The CS3.6’s woofer is the first in a THIEL

product to employ a metal diaphragm. The

anodized aluminum material provides much

higher stiffness and compressive strength than

conventional diaphragm materials. The primary

2

Figure 6 Frequency-time response of new diaphragm

Figure 2 Frequency response of conventional

diaphragm Figure 5 Frequency response of new diaphragm

Frequency response magnitude - dB

10

log Frequency - KHz

1

45

40

35

30

25

20

15

10

Frequency response magnitude - dB

10

log Frequency - KHz

1

45

40

35

30

25

20

15

10

Figure 1 Conventional diaphragm with vibration Figure 4 New double diaphragm

Figure 3 Frequency-time response of conventional

diaphragm

benefit provided is that the lowest resonance is at 2 KHz, two octaves above the crossover

frequency. Below 2 KHz there are no resonances to store energy and cause ringing. An

additional benefit is that the aluminum’s much higher compressive strength results in almost

all the energy of a transient attack being transferred to sonic output rather than being absorbed

in compression of the diaphragm material.

Even though the diaphragm resonance at 2 KHz is two octaves above the crossover, it’s

ringing would cause a slight sonic effect if not corrected. We have therefore incorporated into

the electrical network a notch filter which complements and cancels the resonance. To our

knowledge, this is the first application of a metal woofer with resonance compensation.

Figure 7 shows the time response of the woofer with its crossover network but without

resonance compensation. The peak with its consequent ringing at 2 KHz can be clearly

identified. Figure 8 shows the time response with resonance compensation. Although some

trace of the resonance is still discernible, it has been drastically reduced to a minor level.

Diffraction

Diffraction causes frequency response and time response errors and therefore a reduction

in tonal, spatial, and transient fidelity. Diffraction occurs when some of the energy radiated by

the drivers is re-radiated from the cabinet edges at a later time. For musical signals that

remain constant for a few milli-seconds, diffraction causes, by constructive and destructive

interference, an excess of energy to the listener at some frequencies and a deficient amount of

energy to the listener at other frequencies. Diffraction also causes all transient signals to be

radiated to the listener a second (and possibly a third) time, smearing transient impact and

distorting spatial cues.

To greatly reduce diffraction the CS3.6

employs a front baffle that is curved at the edges so energy radiated along the baffle can

continue into the room without encountering abrupt cabinet edges. Figures 9 and 10 illustrate

the beneficial effects of the CS3.6’s curved baffle on the response of the tweeter.

Results

The end result of greatly reducing

diffraction and diaphragm resonances is

a speaker with very accurate tonal

characteristics. Figure 11 shows the

on-axis frequency response of the

CS3.6. It is uniform within ±1.5 dB

from 28 Hz to 20 KHz. Typically, it is

within ±1 dB from 30 Hz to 10 KHz.

Subjectively even more important is the

octave-averaged frequency response.

Figure 12 shows this response to be

within ±0.5 dB from 36 Hz to 20 KHz

showing extremely accurate overall

tonal balance. Furthermore, as a result

of gradual crossover slopes and

relatively low crossover points made

practical by the use of high output

driver design, the off-axis frequency

response of the speaker system is

almost as smooth as its on-axis

response. This unusual performance is

important for producing a uniform

amount of ambient energy at all

frequencies, necessary for natural

spatial reproduction. Figure 13 shows

this octave-averaged, 30°off-axis

response to be almost within ±1 dB

from 33 Hz to 17 KHz, showing

extremely uniform dispersion of energy

at all frequencies.

200 300 400500 1k 2k 3k 4k 5k 10k 20k

80 dB

90 dB

200 300 400500 1k 2k 3k 4k 5k 10k 20k

80 dB

90 dB

3

Cabinet-edge diffraction

tweeter

Figure 10 Response of tweeter in CS3.6 cabinet

Figure 9 Response of tweeter in square-edged cabinet

Figure 11 On-axis frequency response

10K

Frequency

1K

90

80

70

100

20 20K

Amplitude — dB

Figure 12 Octave-averaged on-axis frequency response

10K

Frequency

1K

90

80

70

100

20 20K

Amplitude — dB

Figure 13 Octave-averaged 30°off-axis frequency response

10K

Frequency

1K

90

80

70

100

20 20K

Amplitude — dB

Figure 7 Time response of woofer without compensation

Figure 8 Time response of woofer with compensation

TIME RESPONSE

In most loudspeakers the sound from each driver reaches the listener at different times causing the loss of much spatial information.

Therefore, with most speakers the only dependable locational clue is the relative loudness of each speaker which causes the sound stage to

exist only between the speakers. In contrast to this loudness type of imaging information, the ear–brain interprets real life sounds by using

timing information to locate the position of a sound. The ear perceives a natural sound as

coming from the left mainly because the left ear hears it first. That it may also sound louder to

the left ear is of secondary importance.

For realistic reproduction, it is important that the attack, or start, of every sound be clearly

focused in time. Because more than one driver is involved in the reproduction of the several

harmonics of any single sound, the drivers must be heard in unison to preserve the structure of

the sound. Since, in most speakers, the tweeter is closer to the listener’s ear, the initial attack of

the upper harmonics arrives as much as two milliseconds before the body of the sound. This

delay results in a noticeable reduction in

the realism of the reproduced sound.

To eliminate this problem the CS3.6

mounts the drivers on a sloped baffle to

position them so the sound from each

reaches the listener at the same time.

This arrangement can work perfectly for

only one listening position. However,

because the drivers are positioned in a

vertical line the error introduced by a

listener to the side of the speaker is very

small. Also, because the driver spacing is small compared to the wavelength at the crossover

frequency, the error introduced by changes in listener height are small within the range of

normal seated listening heights provided the listener is 8 feet or more from the speakers.

Figure 14 shows the group delay, the measure of time error, of the CS3.6 from 200 Hz to

20 KHz. For all frequencies above 300 Hz the delay is less than 0.5 ms. The general trend is

toward zero delay at higher frequencies.

PHASE RESPONSE

We use the trade mark Coherent Source to describe the unusual technical performance of

our products. This phrase is descriptive of the time and phase coherence which gives THIEL

products the unusual ability to accurately reproduce musical waveforms.

Usually, phase shifts are introduced by the crossover slopes, which changes the musical

waveform and results in the loss of spatial and transient information. During the past decade

the fourth order Linkwitz-Riley crossover has risen in popularity and it is sometimes

promoted as being phase coherent. What is actually meant is that the two drivers are in phase

with each other through the crossover region. However, neither driver is in phase with the

input signal nor with the drivers’ output at other frequencies; there is a complete 360°phase

rotation at each crossover point.

There is a type of crossover system that does not introduce any phase shift or time smear,

although it is difficult and expensive to execute. This crossover is the first order (6dB/octave)

system that THIEL has employed since 1978 in all our Coherent Source systems. A first order

system is the only type that can achieve perfect phase coherence, no time smear, uniform

frequency response, and uniform power response.

A first order system achieves its perfect results by keeping the phase shift of each roll-off

to less than 90°so that it can be canceled by the roll-off of the other driver that has an

identical phase shift in the opposite direction. The phase shift is kept low by using very

gradual (6dB/octave) roll-off slopes which produce a phase lag of 45°for the low frequency

driver and a phase lead of 45°for the high frequency driver at the crossover point. Because

the phase shift of each driver is much less than 90°and is equal and opposite, their outputs

combine to produce a system output with no phase shift and perfect transient response.

Figure 15 graphically demonstrates how the outputs of each driver in a two-way speaker

system combine to produce the system’s output. The first graph shows the ideal output. The

second shows the operation of a time-corrected, fourth order crossover system. The two

drivers produce their output in the same polarity and both drivers start responding at the same

time. However, since the high-slope network produces a large amount of phase shift, the

tweeter’s output falls quickly and the woofer’s output increases only gradually. Therefore, the

two outputs do not combine to produce the input step signal well but instead greatly alter the waveform.

The third graph shows how, in a first order crossover system, the outputs of the two drivers combine

to reproduce the input waveform without alteration.

4

Time correction

Figure 14 Time response

10

Frequency - KHz

1

2.5

2.0

1.5

1.0

0.5

0.0

-0.5

-1.0

-1.5

-2.0

-2.5

Transfer Function Group Delay - msecs

Figure 15

Time

Output

-

+

Ideal step response

Time corrected fourth order crossover system

First order crossover system

tweeter output

woofer output

combined output

Time – msec

0.5 1.0

Output

1.5 2.0 2.5

Frequency - KHz

100

80

60

40

20

0

-20

-40

-60

-80

-100

Transfer Function Excess Phase - deg

101

0.1

5

Figure 16 CS3.6 phase response

10

Frequency - KHz

1

100

80

60

40

20

0

-20

-40

-60

-80

-100

Transfer Function Phase - deg

Figure 17 CS3.6 excess phase

Figure 18 CS3.6 step response

In practice the proper execution of a first order system requires very high quality, wide

bandwidth drivers and that the impedance and response variations of the drivers and the

cabinet be compensated across a wide range of frequencies. This task is complex since the

acoustic outputs of the drivers must roll off at 6 dB/octave and not simply for the networks

themselves to roll off at 6 dB/octave. For example, if a typical tweeter with a low frequency

roll-off of 12 dB/octave is combined with a 6 dB/octave network, the resulting acoustical

output will roll off at 18 dB/octave.

Figure 16 is a plot of the absolute phase response of the CS3.6. It shows that the phase

response is within ±20°above 200 Hz and within ±10°from 400 Hz to 15 KHz. However, in

our opinion, what is most important is the phase deviation from the mathematical “minimum”

phase response of an ideal transducer with the same frequency response. This deviation is

called the excess phase and is plotted for the CS3.6 in Figure 17. This graph shows the excess

phase to be less than ±5°to beyond 10 KHz.

The result of phase coherence (in conjunction with time coherence) is that all waveforms

will be reproduced without major alterations. The speaker’s reproduction of a step waveform

best demonstrates this fact. Like musical waveforms, a step is made up of many frequencies

which have precise amplitude and phase relationships. For a step signal to be accurately

reproduced, phase, time and amplitude response must all be accurate. Because this waveform

is so valuable, it is commonly used to evaluate the performance of electronic components. It is

not typically used for speaker evaluation because most speakers are not able to reproduce it

recognizably. Figure 18 shows the CS3.6’s response to a step. That the step is reproduced so

recognizably is the result of accurate phase, time and amplitude response.

ENERGY STORAGE

Any part of the speaker that absorbs energy will re-radiate it later in time in a highly distorted manner. Although not loud enough to be

consciously heard, stored energy causes significant detrimental effects. The music’s subtle detail is obscured, causing both a reduction in

clarity and loss of spatiality as well as noticeable colorations of voice and other midrange sounds. The main storage mechanisms are the

driver diaphragms and cabinet walls, especially the baffle.

The lack of cabinet wall vibrations is one advantage of membrane speakers and why they have an “unboxy” sound. However the

problem of cabinet vibrations in dynamic loudspeakers is not inherent but rather can be reduced as much as is affordable.

One method of attempting to reduce the problem of stored energy is to apply damping to the offending component. The idea is to damp

motion with a viscous material so that the stored energy can be dissipated as heat instead of mechanical vibration which produces unwanted

sound. This method has limited benefit for two reasons. First, energy can only be dissipated as heat after there is unwanted mechanical

vibration to convert. Secondly, even though some of the absorbed energy is transformed into heat, it is still absorbed from the desired sonic

output and therefore the distortion mechanism still exists. A much better approach, in our opinion, is to reduce the energy absorbed.

The primary cabinet problem is baffle vibration because movement of the drivers can directly excite the baffle and the resulting

extraneous energy it is radiated directly toward the listener. The CS3.6 employs a 3" thick baffle in order to reduce unwanted vibration.

The walls of the CS3.6 enclosure are constructed of 1" thick fiberboard, and extensive internal

bracing further increases wall stiffness.

To increase the mechanical rigidity and therefore reduce unwanted vibration, all CS3.6

drivers incorporate chassis of cast magnesium rather than stamped steel or plastic.

As previously discussed, much attention has been given to the reduction of diaphragm

vibrations to reduce the amount of energy absorbed through resonances.

Figure 19 is the Energy-Time curve of the CS3.6. It shows how the output energy of the

speaker is distributed in time. First, it shows that all of the primary energy is focused in the

first 150 microseconds, a result of very good time coherence. It also shows that the speaker’s output has already decayed to -20 dB after

only 200 microseconds and has fallen to -40 dB after only 900 microseconds. This rapid decay provides very clean reproduction with very

good inter-transient silence.

DISTORTION

The primary sources of distortion are the drivers’ magnetic motor systems and the electrical components of the crossover network. We

have taken unusual steps in the design of the CS3.6 to greatly reduce these sources.

Crossover Components

The usual type of capacitor for speakers is electrolytic. This type has the advantage of very low cost but also causes audible distortion

due to dielectric absorption and other mechanisms. There are only three electrolytics used in the CS3.6 and none of these is in the signal

path. All are used in zobel networks to correct the drivers’ impedance and are bypassed with high quality polystyrene types to provide

performance closer to the polystyrene type than the electrolytic. The polystyrene capacitors are custom–made to our specifications and

employ tin foil rather than aluminum. The use of tin allows the copper lead wires to be soldered, rather than welded, to the conductor

resulting in purer sound. The tweeter feed capacitors are pure polystyrene and all other capacitors, including a very large 200 µfd mid-range

feed, are polypropylene bypassed with polystyrene.

All the CS3.6 inductors are air-core, which completely eliminates distortions caused by magnetic saturation, and hysteresis and are

wound of high purity, low oxygen copper. Also, the speaker’s internal wiring uses custom–made solid conductor, high purity copper with

polypropylene insulation.

Figure 19

Time – msec

0.5

5

0

-5

-10

-15

-20

-25

-30

-35

1.0

Output — dB

1.5 2.0 2.5

Driver Motor Systems

Unlike the other sources of distortion, motor system distortion is very dependent

on volume level, being low during quiet playback levels but increasing rapidly as

volume levels increase. At moderate to loud playback levels it is the major source of

distortion and can therefore be considered a dynamic range limit. The CS3.6

incorporates several unusual features in its drivers to decrease distortion and increase

dynamic range.

Excursion: The most basic limit to dynamic range of a dynamic driver is the

limit on diaphragm movement caused by the driving voice coil leaving the magnetic

gap beyond a certain excursion. The solution of using a longer coil requires that the

magnet be much larger and is therefore usually avoided. The CS3.6 woofer has a very

long coil, 13 mm longer than the magnetic gap, which provides output twice as high

as typical “long excursion” woofers.

The midrange driver uses a short coil/long gap design that provides very low

levels of distortion. As shown in Figure 20, the distortion produced by the short coil

motor system at normal excursion levels

(±1 mm or less) is only one-tenth that

produced by the typical long coil

system.

The tweeter has been specially

designed to achieve a dynamic range 15

dB greater than standard tweeters. This

performance is achieved by utilizing an

unusual wide roll surround and a short

coil/long gap magnetic system which

allows much greater linear excursion

(±1.5 mm).

Woofer magnet system: The purpose of the driver’s motor system is to apply a

force to the diaphragm that is directly proportional to the voltage supplied by the amplifier as modified by the electrical network. In order

for the force to be directly proportional to the voltage applied, as desired, the magnetic field must be constant, the length of voice coil wire

acted on by the magnetic field must be constant, and the current must be directly proportional to the applied voltage. In fact, none of these

conditions actually exist but the CS3.6 woofer incorporates refinements of design that improve the accuracy of each of these factors.

The strength of the magnet’s field is not actually constant in operation but is changed by the current from the amplifier through the coil.

This change occurs because the amplifier current through the coil creates its own magnetic field that “pushes” against the magnet’s field,

generating the force to move the diaphragm. Magnets are somewhat demagnetized by the coil’s magnetic field when current flows in one

direction and are remagnetized when current flows in the opposite direction. Therefore, since the magnet’s field strength is not constant, the

force generated is not in the desired direct proportion to the current in the coil. To drastically reduce this effect the CS3.6 woofer

incorporates heavy copper rings around the center pole. With these rings any changes in the magnet’s strength induces an electrical current

in the rings which generates a magnetic field that is opposed to and practically cancels the original change.

A second problem is that the field strength is not symmetrical in front of and behind the gap but is stronger behind the gap than in front

of the gap. Therefore, when the diaphragm moves outward, the coil experiences less magnetic field than when it moves inward. This

mechanism is the major cause of even harmonic distortion . The woofer in the CS3.6 utilizes a specially shaped pole piece to reduce this

problem. Figure 21 and figure 22 show the standard and improved field strength symmetry and distortion. At most output levels distortion

is reduced by 75%.

The third problem stems from the fact that the coil current is dependent not only on the driving voltage and the coil resistance but also

on the coil inductance. The problem is that the coil inductance varies with the amount of iron inside the coil and, with conventional pole

piece geometry, changes during the excursions necessary to reproduce low frequencies. As the diaphragm and coil move back, more of the

coil is around the pole, increasing the inductance and decreasing the

output of the driver by about 1 dB. As the coil moves forward, less of

the coil is around the pole, the inductance decreases and the response

increases approximately 1 dB. By this mechanism the frequency

response of the speaker is modulated by driver excursion. This

problem has been drastically reduced in the CS3.6 woofer. The same

pole geometry which makes the field symmetrical also results in a

constant amount of iron inside the coil regardless of coil position. In

addition, the problem is further reduced by the copper rings around

the pole which reduce the inductance of the coil to a small fraction of

its normal value by acting as a shorted turn of a transformer

secondary winding.

All of these design details contribute to the CS3.6’s exceptional

technical performance, its accurate reproduction of all musical

information, and its ability to faithfully reproduce the musical

experience.

6

CS3.6 midrange

Cast magnesium frame

for rigidity and clearer

reproduction Double cone diaphragm

for extremely transparent

reproduction

Short coil / long gap motor

for very low levels of distortion

Heavy copper sleeve

for exceptional attack

Phase plug for more

uniform response

Figure 20 Distortion comparison

10

8

6

4

2

0

THD — %

2.01.51.00.50.0 peak excursion — ±mm

2 mm coil

10 mm coil

1.0

0.8

0.6

0.4

0.2

0.0

flux density – tesla

100-10 position from

g

ap center – mm

Figure 21 Field strength and

distortion of standard pole geometry

10

8

6

4

2

0

THD — %

6543210 peak excursion — ±mm

1.0

0.8

0.6

0.4

0.2

0.0

flux density – tesla

-10 010

position from

g

ap center – mm

Figure 22 Field strength and distortion

of CS3.6 woofer

10

8

6

4

2

0

THD — %

6543210 peak excursion — ±mm

Table of contents

Other Thiel Speakers manuals

Thiel

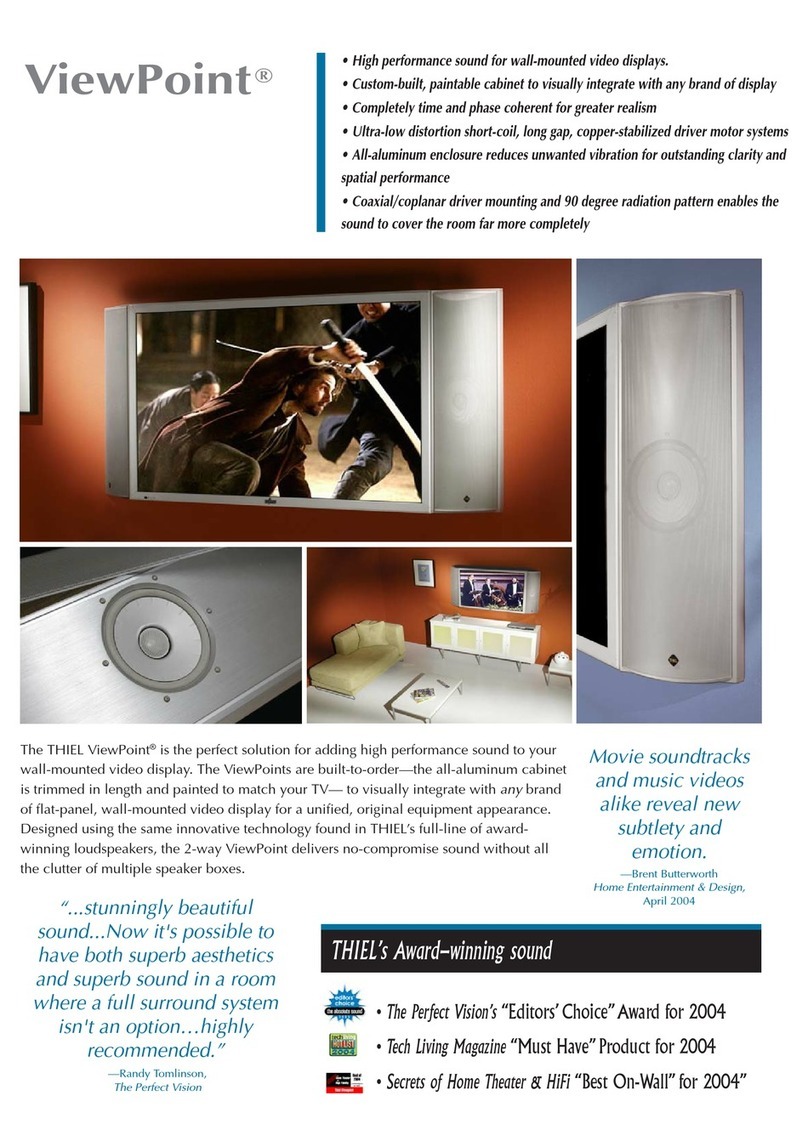

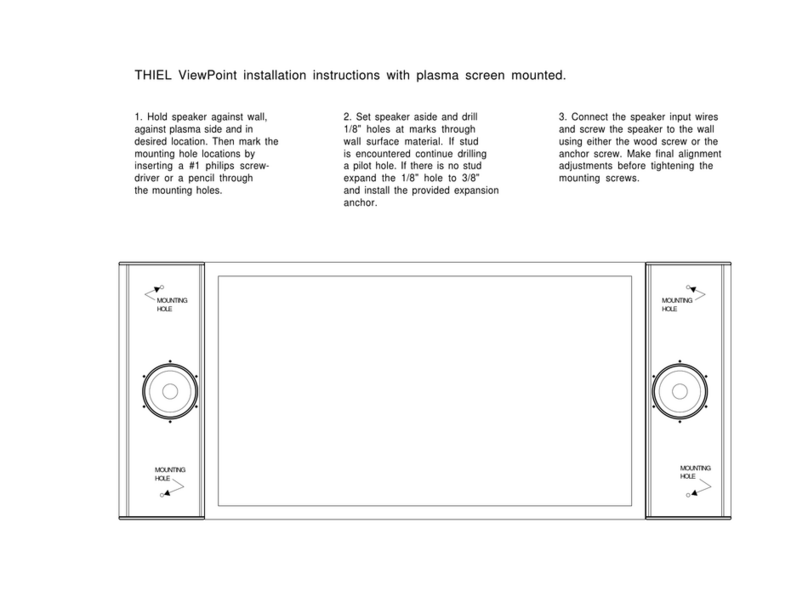

Thiel ViewPoint User manual

Thiel

Thiel Coherent Source SCS3 Manual

Thiel

Thiel CS3.6 User manual

Thiel

Thiel PowerPoint 1.2 User manual

Thiel

Thiel CS2.4 User manual

Thiel

Thiel CS6 User manual

Thiel

Thiel CS6 Manual

Thiel

Thiel Coherent Source CS3.7 User manual

Thiel

Thiel SCS4T Technical manual

Thiel

Thiel CS3.6 User manual