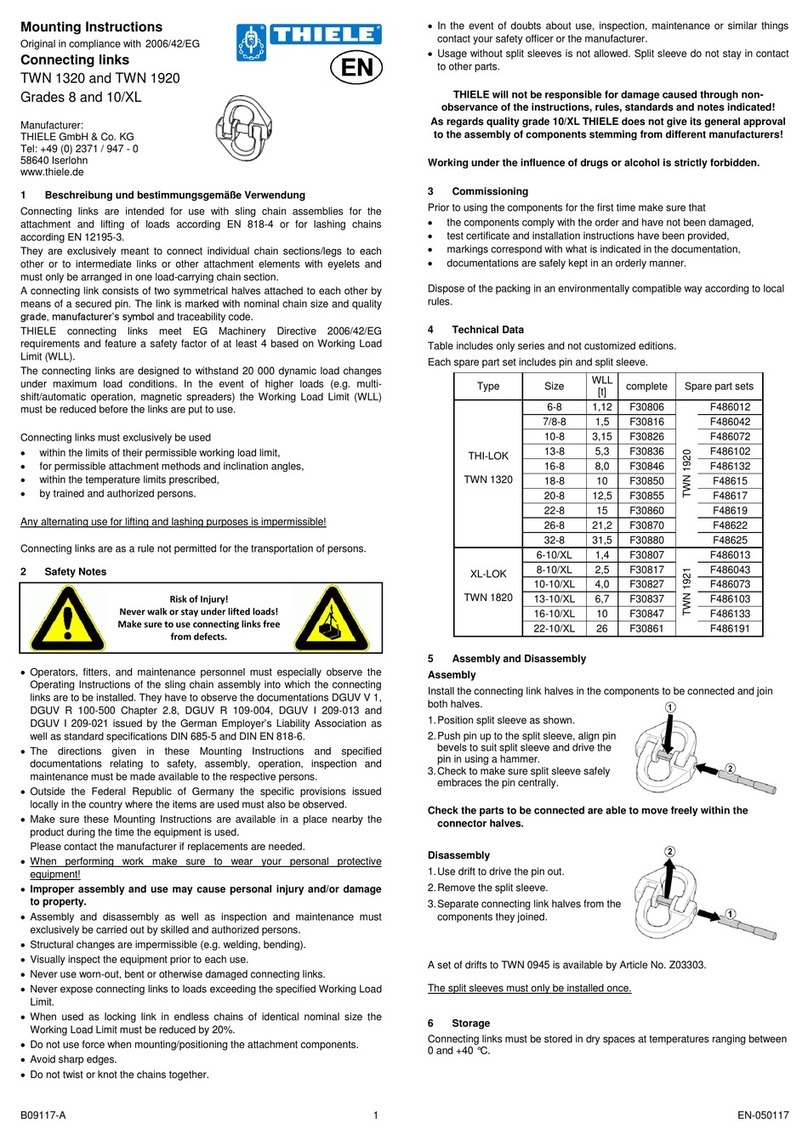

Thiele TWN 0063 User manual

OPERATING INSTRUCTIONS

HOIST CHAINS

THIELE GmbH & Co. KG # Change indicator

www.thiele.de | info@thiele.de 08285-D replaces 08285-C

© All rights reserved EN 04.2022 1 | 3

Original in compliance with 2006/42/EC

1DESCRIPTION AND INTENDED USE

1.1 General

THIELE hoist chains in accordance with EN 818-7 are intended for use in manually

or motor-driven chain hoists for lifting loads.

THIELE hoist chains are manufactured in accordance with EN 818-7 or more

specifically other requirements for types T (tempered) and DAT or DT (case-

hardened).

Hoist chains must exclusively employed

•for chain hoists of suitable design,

•within the limits of their permissible working load limit,

•within the limits of the maximum stresses shown in EN 818-7 and ISO 3077

table .1,

•within the temperature limits prescribed,

•by trained and authorized persons.

THIELE hoist chains meet EG Machinery Directive 2006/42/EC requirements and

feature a safety factor of at least 4 based on WLL (Working Load Limit).

On delivery, the container is marked with the CE mark.

#

THIELE hoist chains are marked with specifications according type and quality

grade data, manufacturer’s symbol and traceability code.

1.2 Use of type T

•for manually operated chain hoists

•intended for motorized chain hoists operating at lower speed rates, very light

duty cycles and under conditions causing low wear only

1. Use of type DAT

•intended for motor-operated chain hoists

•for higher loads and speed rates

•for longer duty cycles

•NOT intended for portable, manually operated chain hoists

1.4 Use of type DT

•for motor-operated chain hoists in wear-causing environments, e.g. where high

dust loads arise

•NOT intended for portable, manually operated chain hoists

2SAFETY NOTES

Risk of injury!

Never walk or stay under lifted loads!

Make sure to use hoisting/attachment means

free from defects!

•Operators, fitters, and maintenance personnel must in particular observe the

operating instructions of the used chain hoists, documentations DGUV V 1,

DGUV R 109-017

#

, DGUV V 52, DGUV V 54, if applicable DGUV V 17 and

DGUV I 209-013 issued by the German Employers’ Liability Insurance

Association, as well as standard specifications DIN 685-5 and EN 818-7.

•In the Federal Republic of Germany, the Operational Safety Ordinance

( etrSichV) has to be implemented and the Technical Rule for Industrial Safety

TR S 1201, in particular Annex 1, Chapter 2 "Special regulations for the use of

working equipment for lifting loads" must be observed.

•Outside the Federal Republic of Germany the specific provisions issued locally

in the country where the items are used must be observed.

•The directions given in these Operating Instructions and specified

documentations relating to safety, assembly, operation, inspection, and

maintenance must be made available to the respective persons.

•Make sure these Operating Instructions are available in a place near the product

during the time the equipment is used. Please contact the manufacturer if

replacements are needed. See also chapter 9.

•When performing work make sure to wear your personal protective equipment!

•Improper assembly and use may cause personal injury and/or damage to

property!

•Structural changes are impermissible (e.g. welding, bending, galvanizing).

•Assembly and removal as well as inspection and maintenance must exclusively

be carried out by skilled and authorized persons.

•Operators must carry out a visual inspection and if necessary a functional

test of the safety equipment before each use!

•Only lift loads the mass of which is less than or equal to the Working Load Limit

of the chain hoist.

•Never expose chains to loads exceeding the specified Working Load Limits.

•Never use hoist chains as sling chains or for „choke hitch“ or „basket hitch“

attachment methods.

#

•Position the load hook above the load’s center of gravity.

•Make sure the load can take the forces to be applied without suffering

deformation.

•Do not twist or knot the chains together.

•Only lift loads that are freely movable and not attached or fastened.

•Do not start lifting before you have made sure the load has been correctly

attached.

•Make sure no one including you (operator) is in the way of the moving load

(hazard area)!

•During lifting/hoisting make sure your hands or other body parts do not come

into contact with hoisting means.

•Avoid impacts, e.g. due to abruptly lifting loads with chain in slack condition.

•Never move a suspended load over persons.

•Never cause suspended loads to swing.

•Always monitor a suspended load.

•Put the load only down in flat places/sites where it can be safely deposited.

•Safety elements must not be excessively stressed or strained operationally.

•Avoid diagonal pull.

•Take care for sufficient place for the personnel to move when choosing the

route of transportation and storage location. Danger to life and risk of injury by

crushing hazards.

•In the event of doubts about the use, inspection, maintenance or similar things

contact your safety officer or the manufacturer.

THIELE will not be responsible for damage caused through non-observance of

the instructions rules standards and notes indicated!

As a rule hoist chains are not permitted for the transportation of persons!

Working under the influence of drugs medications impairing the sense and/or

alcohol (including residual alcohol) is strictly forbidden!

#

3COMMISSIONING

Prior to using the components for the first time make sure that

•the components comply with the order and have not been damaged,

•test certificate, statement of compliance, and Operating Instructions are at

hand,

•markings correspond with what is specified in the documentation,

•inspection deadlines and the qualified persons for examinations are

determined,

•visibility and functional testing are carried out and documented,

•the documentation is safely kept in an orderly manner.

Dispose of the packing in an environmentally compatible way according to local

rules.

OPERATING INSTRUCTIONS

HOIST CHAINS

THIELE GmbH & Co. KG # Change indicator

www.thiele.de | info@thiele.de 08285-D replaces 08285-C

© All rights reserved EN 04.2022 2 | 3

4TECHNICAL DATA

Data concerning working load limit and article numbers for spare parts ordering

are shown in the pertinent test/inspection certificate.

5ASSEM LY AND DISASSEM LY

5.1 Preparations

Ensure that all components to be installed are in perfect condition and that the

Working Load Limits of all components are designed for the load.

5.2 Assembly and disassembly

When mounting or removing hoist chains the relevant instructions issued for the

components are to be observed, especially those issued for chain hoists and crane

equipment.

Take care of an assembly of chain with connected parts that there is enough

clearance and no deformation occurs to the chain.

The operating instructions of the chain hoists may give hints for the mounting

orientation of the chain (orientation of the welded areas).

Ensure sufficient lubrication EFORE applying a load for the first time.

#

6CONDITIONS OF USE

6.1 Lubrication

To achieve a long service life, hoist chains must be carefully lubricated and

lubrication must be ensured in all joining areas of all links. The lack of lubrication

of a chain link can lead to premature wear and tear and the necessary replacement

of the entire hoist chain.

In particular, the chain links which are particularly stressed by recurring starting

positions require permanent lubrication and regular relubrication.

The choice of lubricant depends on the operating and environmental conditions.

Appropriate lubricant specifications can usually be found in the chain hoist

operating instructions.

Recommendations can be requested from THIELE.

6.2 Influence of temperature

The temperature ranges for use are shown in the following table.

Once the hoist chains have been heated above the maximum operating

temperature, they must no longer be used.

6. Environmental influence

Hoist chains must not be used in environments where acids, aggressive or

corrosive chemicals or their fumes are present.

#

Hoist chains must not be exposed to pollution that obstructs the free movement

of the individual links.

6.4 Miscellaneous

Hoist chains may never be turned and have to run straight line on the wheels and

supported by guiding devices. A twisted hook block causes a non allowed chain

twisting.

7INSPECTIONS, MAINTENANCE, DISPOSAL

7.1 Inspections

Inspections and maintenance must be arranged for by the owner!

Inspection deadlines shall be determined by the owner!

Check the hoist chains visually at regular intervals. Visual inspections must focus

on the entire length of the chains and also include the concealed inside of the link

crowns.

The inspections shall be documented in the respective inspection logs in

conjunction with the chain hoists.

An inspection must be performed at minimum once a year or more often if the

chains are in heavy-duty service (e.g. multi-shift or automatic operation, recurring

hoisting positions, corrosive environment etc.).

When designing a hoist chain according to EN 818-7 and operating it as intended,

fatigue cracks are not to be expected. Under these conditions, a crack test that is

not explicitly excluded in DIN 685-5:2020 does not need to be carried out.

Nevertheless, an additional check for cracks offers increased security, especially if

cross-border conditions cannot be completely excluded during use. As no fatigue

strength certification is required for hoist chains of type T according to EN 818 7,

THIELE recommends crack testing of these chains if they are installed in motor-

driven hoists with higher speeds (e.g. repair hoists in wind turbines).

#

Immediately stop using chain hoists if their hoist chains show the following

defects:

•deformation/elongation (even if only individual chain links are concerned),

•cuts, notches, cracks, incipient cracks, pinching,

•chains heated beyond permissible limits,

•severe corrosion,

•Reduction by more than 10% of the average chain link thickness (Calculate the

average of two perpendicular diameter measurements of the most stressed

areas. These areas are usually located where individual chain links come to a

standstill at the intake to the drive and return sprockets due to recurring drive

positions.)

#

,

•pitch enlargement of single chain links by more than 5 %,

•pitch enlargement over 11 links by more than 2 % for motor- or more than 3 %

for hand-operated chain hoists,

•identification marks are unreadable.

If there is no significant damage or wear on the sprockets, used sprockets with

new hoist chains can also be used.

7.2 Inspection service

THIELE offers inspection, maintenance and repair services by trained and

competent personnel.

7. Maintenance

Maintenance and repair work must only be performed by competent persons!

Only use THIELE spare parts. Replace without delay any hoist chains that show

signs of damage.

Do not repair hoist chains, instead replace complete chain legs only.

Document all maintenance measures.

#

7.4 Disposal

All components and accessories of steel taken out of service are to be scrapped in

line with local regulations and provisions.

8STORAGE

Make sure hoist chains are stored in dry locations at temperatures ranging

between 0 °C and +40 °C.

Type Operating temperature range

T -40 °C ≤ t ≤ +200 °C

DAT -20 °C ≤ t ≤ +200 °C

DT -10 °C ≤ t ≤ +200 °C

OPERATING INSTRUCTIONS

HOIST CHAINS

THIELE GmbH & Co. KG # Change indicator

www.thiele.de | info@thiele.de 08285-D replaces 08285-C

© All rights reserved EN 04.2022 3 | 3

9THIELE OPERATING AND MOUNTING

INSTRUCTIONS

Current operating and installation instructions are available as a PDF download on

the homepage.

10 IMPRINT

THIELE GmbH & Co. KG

Werkstrasse 3

58640 Iserlohn, Germany

Tel.: +49(0)2371/947-0

11 DECLARATION OF CONFORMITY

EC DECLARATION OF CONFORMITY

acc. to Machinery Directive 2006/42/EC, Annex II A for a machine

THIELE GmbH & Co. KG herewith declares as manufacturer that

HOIST CHAINS acc. EN 818-7 Grade T (Types T DAT or DT)

are in compliance with the applicable provisions of the EU Machinery Directive

2006/42/EC.

The following harmonized standards have been observed:

•EN 12100 Safety of machinery - General principles for design

Risk assessment and risk reduction

•EN 818-7 Short link round steel link chains for lifting purposes - Safety

Part 7: Fine toleranced hoist chains, Grade T

This declaration/statement is not meant to warrant any product properties.

Safety notes and instructions pertinent to the products must be observed.

Responsible for documentation

Rene Völz (Head of QA and EP), Tel.: +49(0)2371/947-541

Iserlohn, 28

th

April 2022

Dr. Michael Hartmann (Managing director)

This manual suits for next models

1

Other Thiele Chain Hoist manuals

Popular Chain Hoist manuals by other brands

KITO

KITO TCR Series owner's manual

Steinberg

Steinberg SBS-FZ 500/1,5M user manual

Steinberg Systems

Steinberg Systems SBS-FZ 1500/2M user manual

OZ Lifting Products

OZ Lifting Products OZ500EC Operator's manual

Jet

Jet S90 Series Operating instructions and parts manual

Daktronics

Daktronics DBH-150 Operation & maintenance manual

Yale

Yale lift LHP operating instructions

Grizzly

Grizzly T23102 owner's manual

RED ROOSTER

RED ROOSTER TCR-6000/2 user manual

OZ Lifting Products

OZ Lifting Products STAINLESS Series Operator's manual

HADEF

HADEF 70/06AP Installation, operating and maintenance instructions

Sonardyne

Sonardyne Lodestar 500 user manual