10 Safety check .................................................................................... 18

11 Functional test................................................................................. 19

11.1 Checks before the initial start-up .................................................................................19

11.2 Functional test...............................................................................................................19

12 Maintenance ....................................................................................19

12.1 General...........................................................................................................................19

12.2 Monitoring......................................................................................................................19

12.3 Replacing the load chain...............................................................................................19

12.4 Pneumatic motor ...........................................................................................................21

12.5 Overload protection.......................................................................................................21

13 Inspection........................................................................................ 22

13.1 General Overhaul for motor-driven units.....................................................................22

13.2 Periodic checks .............................................................................................................22

13.3 Checking the load chain................................................................................................22

13.4 Checking the load hook ................................................................................................23

13.5 Inspection –Gear –Oil level.........................................................................................24

14 Service .............................................................................................24

14.1 Load chain......................................................................................................................24

14.2 Pulleys............................................................................................................................24

14.3 Load hook ......................................................................................................................25

14.4 Hoist gear.......................................................................................................................25

14.5 Trolley.............................................................................................................................26

14.6 Pneumatic motor ...........................................................................................................26

14.7 Lubricant selection........................................................................................................27

14.8 Lubricant for food industry –selection (as option*) ...................................................27

15 Trouble............................................................................................. 27

16 Remedy............................................................................................28

17 Decommissioning ...........................................................................29

17.1 Temporary decommissioning.......................................................................................29

17.2 Final decommissioning/disposal..................................................................................29

18 Additional documents.....................................................................29

18.1 Pneumatic connections diagram..................................................................................29

Pos: 5.1/ 1_HADEF/1--INFORM ATION/*Ü1*/#.Ka pitel- Inf ormation @ 0\mod_11744 70941082_52.doc x@ 811 @ @ 1

1 Information

Pos: 5.2.1 /1_HADEF/ 1--INFORMATION/Allgem ein/*Information*/01.I nformation @ 0\mod_117 6734820982_52. docx@ 4653 @ @ 1

The products meet European Union requirements, in particular the valided EU Machine Directive.

The entire company works acc. to a certified quality assurance system as per ISO 9001.

The production of components at our work is subject to strict, intermediate checks.

After assembly, each product is subject to a final test with overload.

For the operation of hoists, the national accident prevention regulations apply in Germany, amongst others.

The stated performance of the devices and meeting any warranty claims require adherence to all instructions

in this manual.

Before delivery, all products are packed properly. Check the goods after receipt for any damage caused

during transport. Report any damage immediately to the forwarding agent.

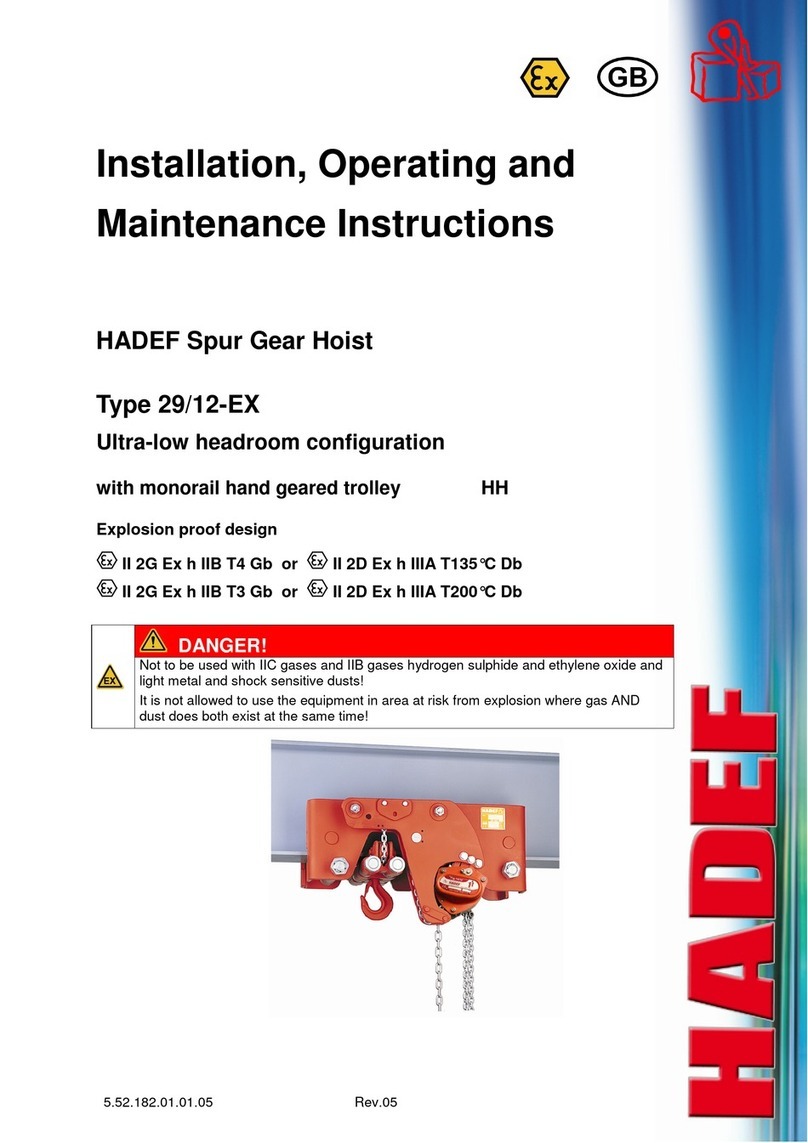

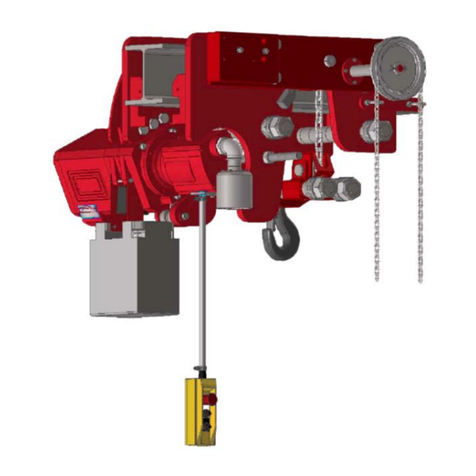

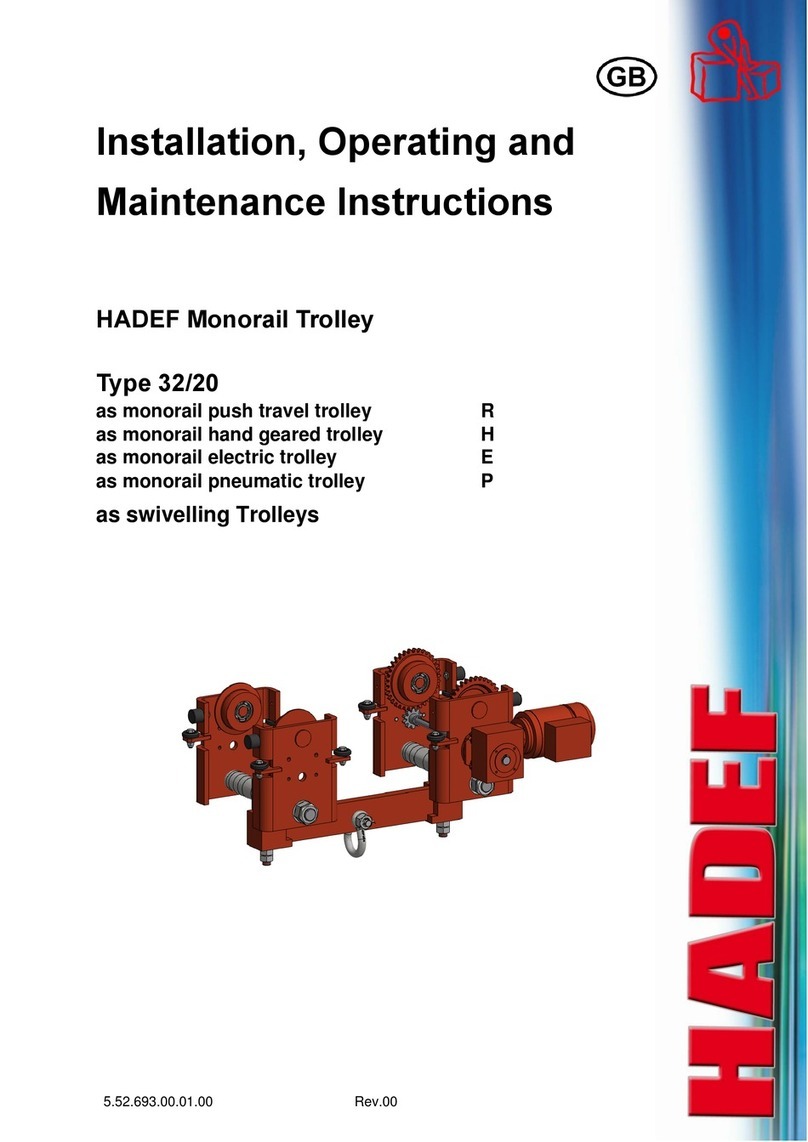

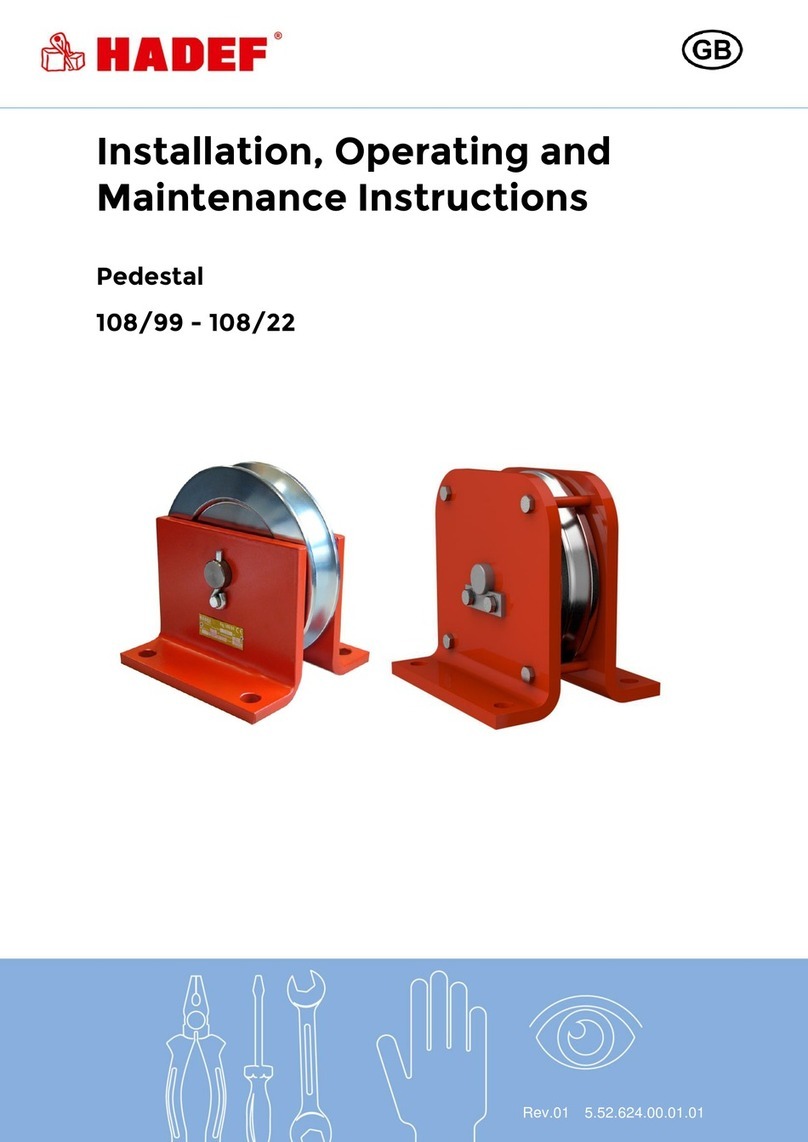

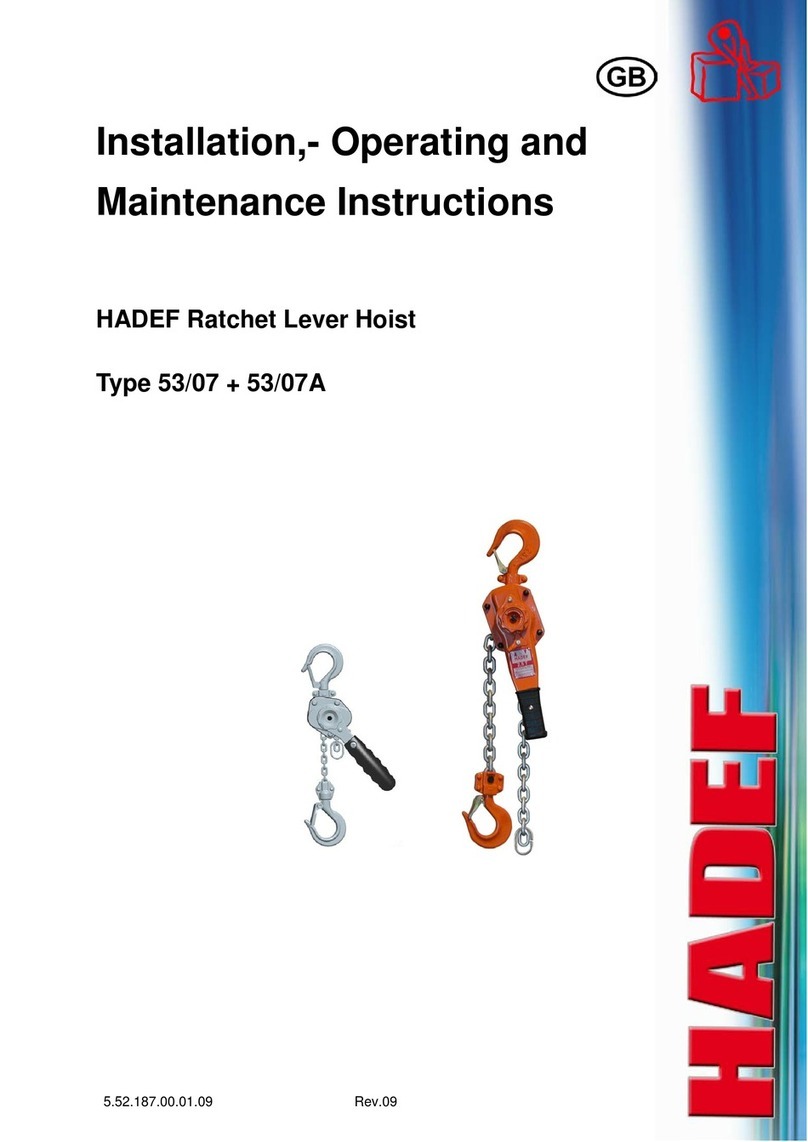

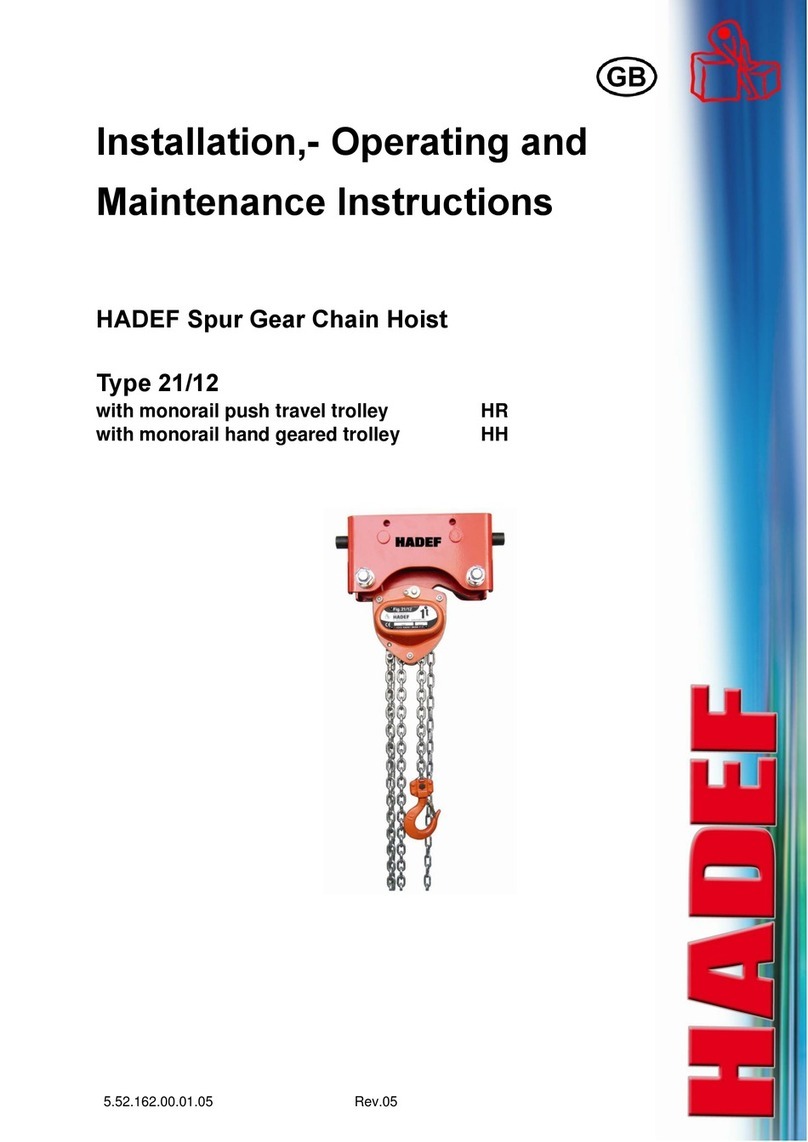

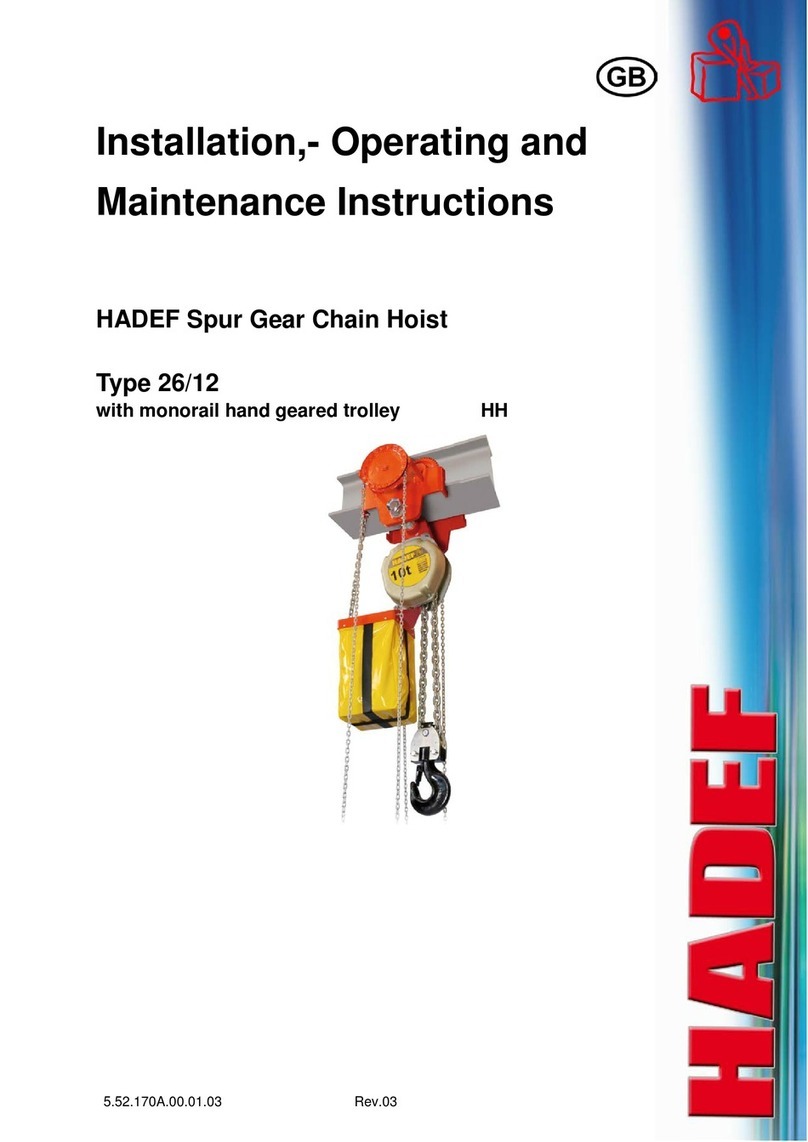

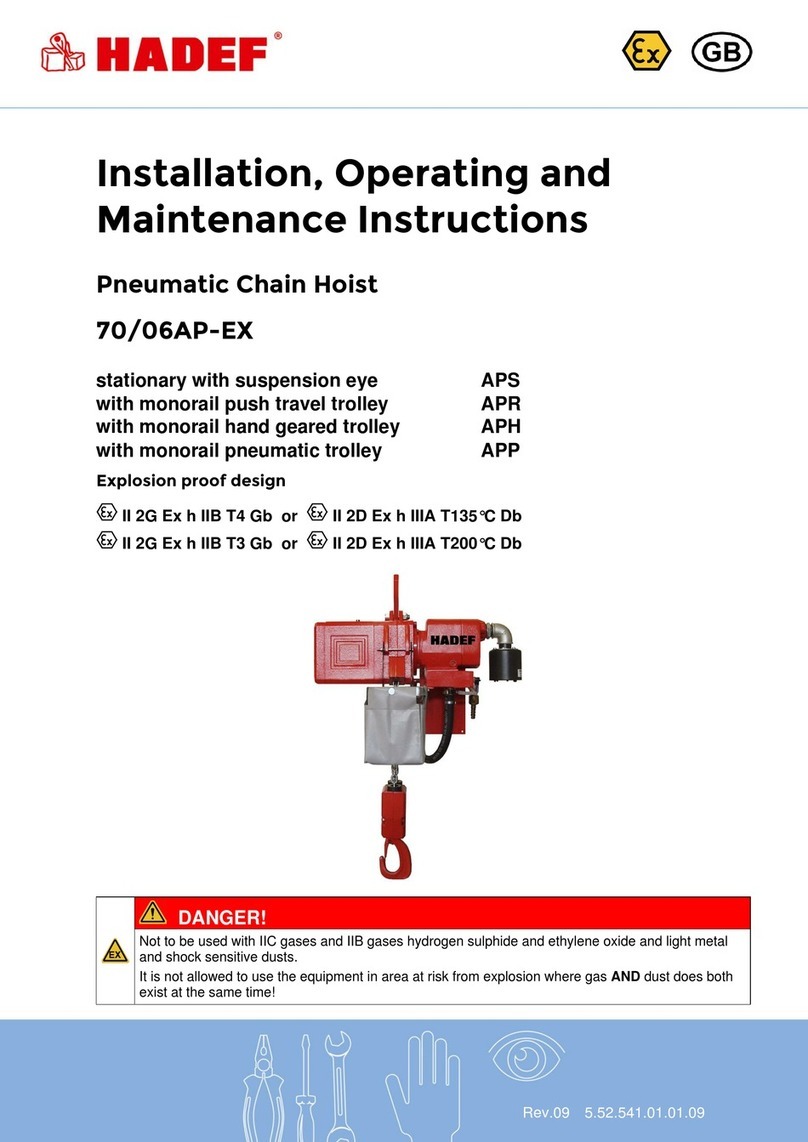

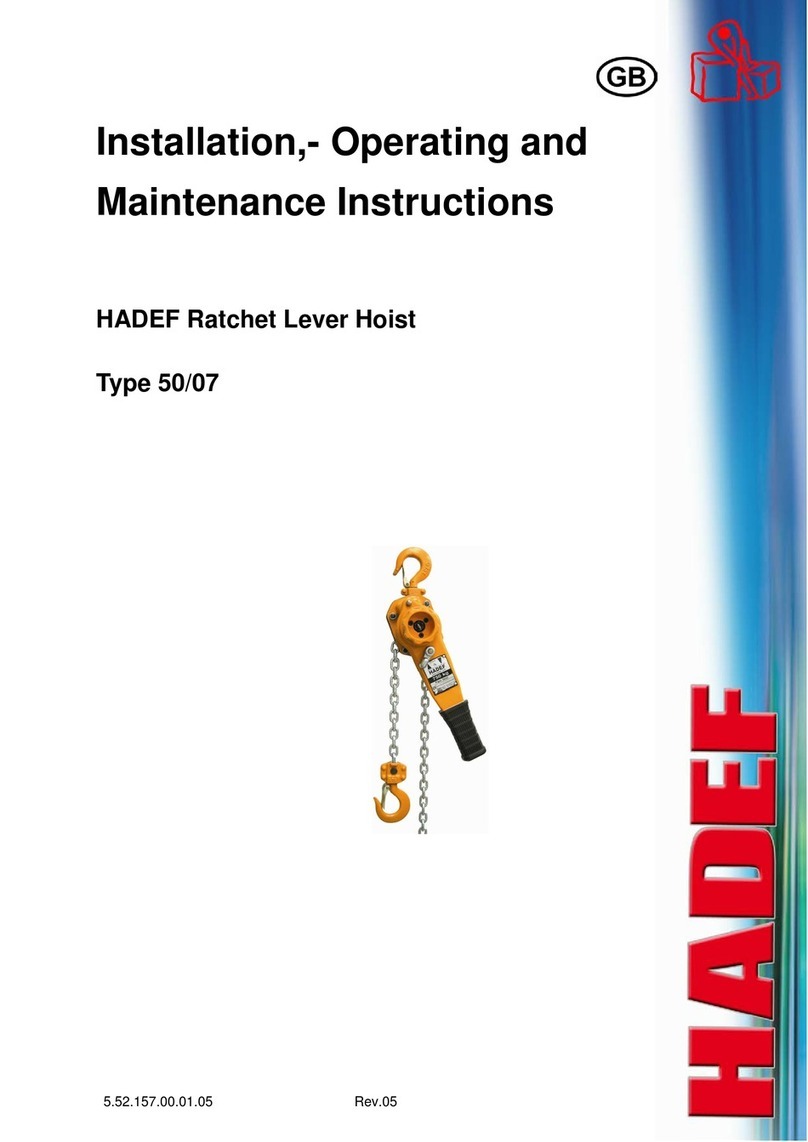

This manual allows a safe and efficiently use of equipment. Images of this manual are for a principle

understanding and can be different from the real design.