THOMAS DÖRR TD 3000L M14 User manual

Operating instructions

Cutlery polishing machine

TD 3000L M14

Kitchen and Cutlery Systems

Hettenbergring 47

D-74889 Sinsheim

Tel.: +49 (0)7261 / 9754-93

Fax: +49 (0)7261 / 9754-94

08/2017

English translation of the original operating instructions manual

Page 2 of 18

Table of Contents

1. GENERAL INFORMATION 3

1.1 INTRODUCTION 3

1.2 EXPLANATIONS 3

1.3 DELIVERY CONTENTS 3

2. SAFETY 4

2.1 PROPER USE 4

2.2 IMPROPER USE 4

2.3 GENERAL SAFETY INSTRUCTIONS 4

3. SHIPPING, STORAGE AND SET UP 5

3.1 SHIPPING 5

3.2 STORAGE 5

3.3 UNPACKING 5

3.4 SET UP 5

3.5 REMOVING THE TRANSPORTATION SAFETY DEVICE 6

4. HANDLING 7

4.1 BEFORE INITIAL OPERATION 7

4.2 EXPLANATION TO MACHINE OPERATION 7

4.3 START UP AND OPERATION OF THE CUTLERY POLISHING MACHINE 8

4.4 FURTHER SAFETY REFERANCES 8

5. CLEANING AND MAINTENENCE 9

5.1 DAILY CLEANING 9

5.2 REPLACING THE GRANULATE AND CLEANING THE MACHINE 9

5.3 REPLACING THE UVC LAMP 10

6. TROUBLESHOOTING 11

7. ACCESSORIES FOR THE CUTLERY POLISHING MACHINE 14

8. COMPANY ADDRESS 15

9. TECHNICAL DATA 15

10. DISPOSAL OF THE MACHINE 15

11. CE - DECLARATION OF CONFORMITY 16

12. NOTES 17

Page 3 of 18

1. General Information

1.1 Introduction

This instruction manual contains useful information on the use and service of the cutlery polisher and must be read

thoroughly before the machine is put into operation.

Requirements for operating and maintenance personnel

Anyone working on or with the machine, whether its initial start-up, installation, operation, or maintenance is required to

read and understand this operating instructions manual. Especially the chapter on “safety” which is listed ahead.

Only sufficiently trained personnel are elligeable to operate the machine.

► Always keep this manual within reach

► Observe all safety precautions and indications

► When passing on the machine to any other persons be sure to hand over this instruction manual with it

1.2 Explanations

1.2.1 Meaning of safety indications

Symbol

Signal term

Meaning

Result if ignored

WARNING!

Possible dangerous situation

Death or serious injury

CAUTION!

Injury

CAUTION!

Possible property damage

Slight or heavy damage to the

machine

No signal term

Useful tips and indications

none

1.3 Delivery Contents

1 x cutlery polishing machine

1 x operation instructions manual

1 x instruction sheet for easy machine operation (place near polishing machine)

1 x granulate replacement chart

Page 4 of 18

2. Safety

2.1 Proper use

The intended use of the machine is only drying and polishing chrome, steel, or silver cutlery. The following cutlery

pieces can be used:

► spoon ► fork

► knife ► small fork

► tea spoon

2.2 Improper use

The machine is not designed to polish any other sorts of cutlery or foreign utensils. Any other use is not according to

regulations and therefore prohibited. We take no responsibilities for damage caused by improper use.

2.3 General safety instructions

Warning!

Death or serious injury may accur by means of electrical shock

>Never install or operate the machine with a damaged power cord.

>By suspicion of damage, for example an electrical fault smell, disconnect the machine from the power circuit

immediately and contact the Dörr-service personnel.

>A damaged power cable can only be repaired by a Dörr-service member or a from Dörr authorized service

technician.

>Make sure the power cable is never placed near a hot surface.

>Make sure the power cable is never pinched or brushed along a sharp edge or surface.

>Never open and repair the machine yourself. Make no changes to the machine that are not listed in this manual.

This device contains electrical current-carrying parts. After opening, the risk of death or serious injury could

occur. Repairs can only be made by Dörr authorised service technicians with original Dörr spare parts and

accessories.

>Never expose the machine to gushes or jets of water.

Caution!

Risk of injury

>Any installed safety components are not to be changed or demounted.

>Never put your hands in the machine.

>To prevent cuts always insert cutlery by holding the handle of the cutlery.

>Never touch hot parts.

>Never let the power cord hang loose. It could be tripped over or damaged.

>Before performing any cleaning or maintenence work be sure that the power switch is turned off to “O” and the

power cord is disconnected.

>Turn the machine off when not using it for a longer period of time.

>This device must be installed to an appropriate connected power circuit.(See page 15)

>Exclusively use the original Dörr Polishing Granulate SG 3000L as well as original Dörr cleaning products.

>Install the device far from the reach of children.

>Persons, including children, who by reason of physical,sensual or mental complications or unexperience or

ignorance may not operate the machine without guidance from a responsible person.

>Persons who are not capable of reading or cannot read this manual`s language must be educated and trained

about the contents of this manual and operation of the machine.

Page 5 of 18

3. Shipping, storage and set up

3.1 Shipping

The following steps must be followed when the machine is being, or has been transported:

► Never tilt or turn over the machine

► Check the machine in advance for any damage caused by the shipment

► Use the transportation safety device when shipping the machine

► When reshipping, make sure the machine has a straight and sturdy stance

► Do not place any transport goods on top of the machine

There will be no replacements or warranty claims eligible by improper transportation methods.

3.2 Storage

Take note to the following information when storing the machine:

► Do not store the machine in a moist area

► Cover up, wrap up or keep the machine in its original packaging

►Assure a stable storing method

► Always keep in mind that the weight of the machine can be a factor when storing on shelves

► Do not place any items on top of the machine

3.3 Unpacking

► Never tilt or turn over the machine

► Save the packaging for future shipments or dispose it properly

3.4 Set up

It is recommended to set up the cutlery polisher in the dish washing area.

► Place the machine on a safe and sturdy leveled surface

► Leave approximately 20 mm of space between the wall since the machine causes light vibrations when running

► Operating and cleaning must be enabled from a safe stand point

Page 6 of 18

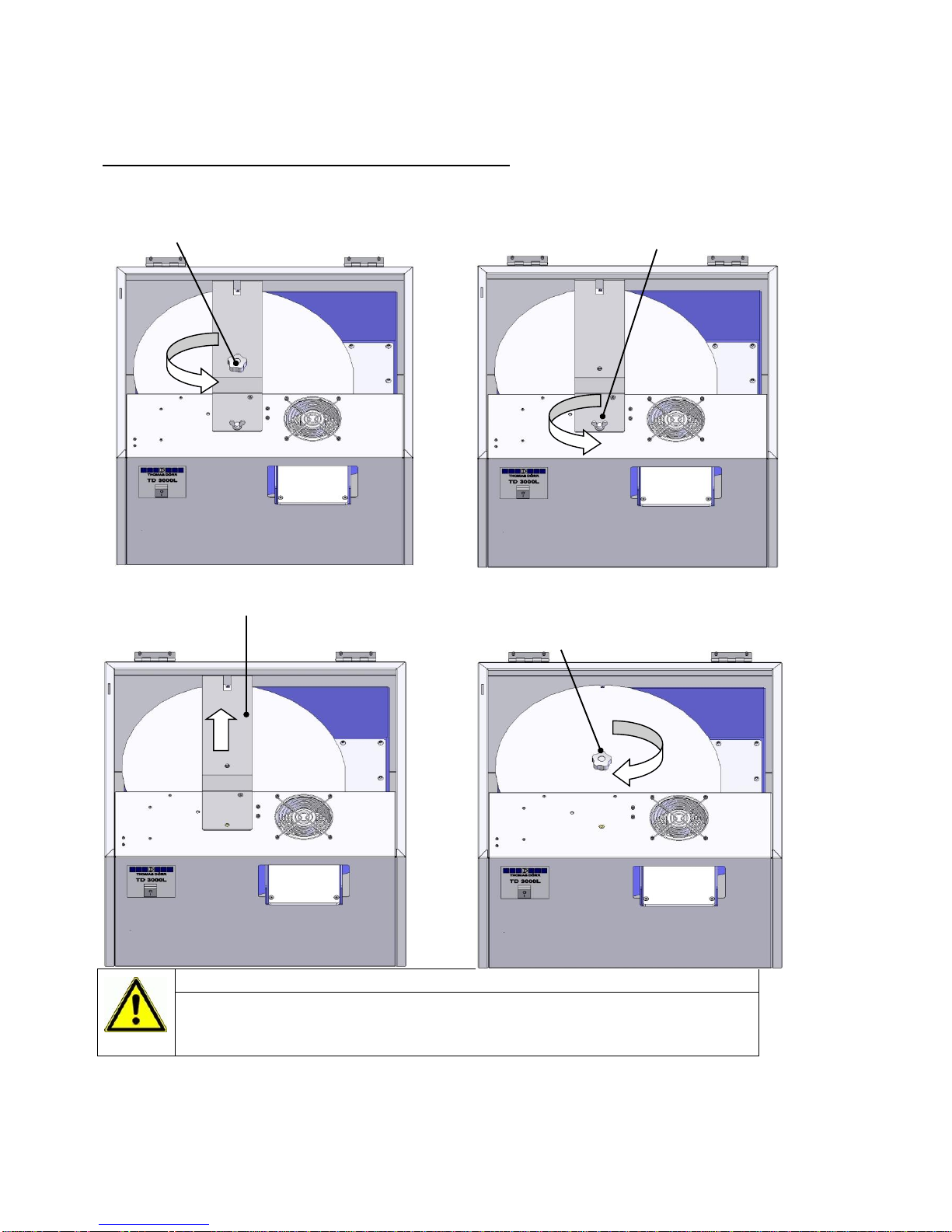

3.5 Removing the transportation safety device

Instructions for removing the transportation safety device:

CAUTION!

Never operate the machine before removing the transportation safety device. It could result in damaging

the machine!

The transportation safety device must be removed before the first initial operation.

1. Open the top cover and remove the

Star grip by loosening it

2. Loosen and remove the wing nut by

turning it counter clockwise

3. Remove transportation safety device

4. Fasten the star grip and close the top

cover

Page 7 of 18

4. Handling

4.1 Before initial operation

Initial operation is only allowed when

► the machine has been checked for complete sufficiency

► the set up conditions have been followed

► the transportation safety device has been removed

► the instruction manual has been read completely

► all safety regulations have been adhered to

4.2 Explanation to machine operation

feed chute

top cover

rockerswitch

On/Off

ejection opening

frame

cover sheet

name plate

transportation

safety device

front cover

LED indicating

the readiness

for operation

polishing bin

Page 8 of 18

4.3 Start up and operation of the cutlery polishing machine

CAUTION!

Never install or operate the machine with a damaged power cord.

By suspicion of damage, for example an electrical fault smell, disconnect the machine from the power circuit

immediately and contact the Dörr-service personal.

Make sure the power cable is never placed near a hot surface.

Make sure the power cable is never pinched or brushed along a sharp edge or surface.

Never expose the machine to gushes or jets of water.

1. Remove the transportation safety device.(see chapter 3.5).

2. Plug the power plug into a regulated power outlet (220/230V).

3. Fill the complete contents of the original Dörr polishing granulate Type SG 3000L into the polishing bin of the

machine.

4. Place the cutlery basket directly underneath the ejection opening of the machine

5. Turn on the machine by switching to “I” on the rockerswitch..

The heating process will start automatically.

6. The readiness for operation is indicated after 30 min by the green LED. The wet cutlery can now be inserted

into the feed chute.

7. After use, let the machine run for about 20 minutes so the wet granulate can dry.

Depending on the amount of operating hours, replace granulate within 4-8 weeks (approx. 200 Hours). (See

chapter 5.2 Replacing the granulate)

The best polishing results can be achieved by inserting wet cutlery either straight from the dishwasher or a

water bath.

Already dried water spots (lime residue) cannot be removed by the cutlery polisher.

Insert one hand full of cutlery (approx. 10 pieces) into the feed chute every 10 seconds to get the most

capacity out of the cutlery polisher.

4.4 Further safety references

CAUTION!

Crushing can occur if the top cover falls down

Always open the top cover till the limit stop till the mounted gasprop is fully extended

Wrong way

Right way

CAUTION!

Fingers can be pinched between the ejection opening and the frame

Never stick fingers in between the ejection opening or feed chute and the frame because the

machine vibrates during operation which causes the bin to sway back and forth

Danger zone

Page 9 of 18

5. Cleaning and maintenance

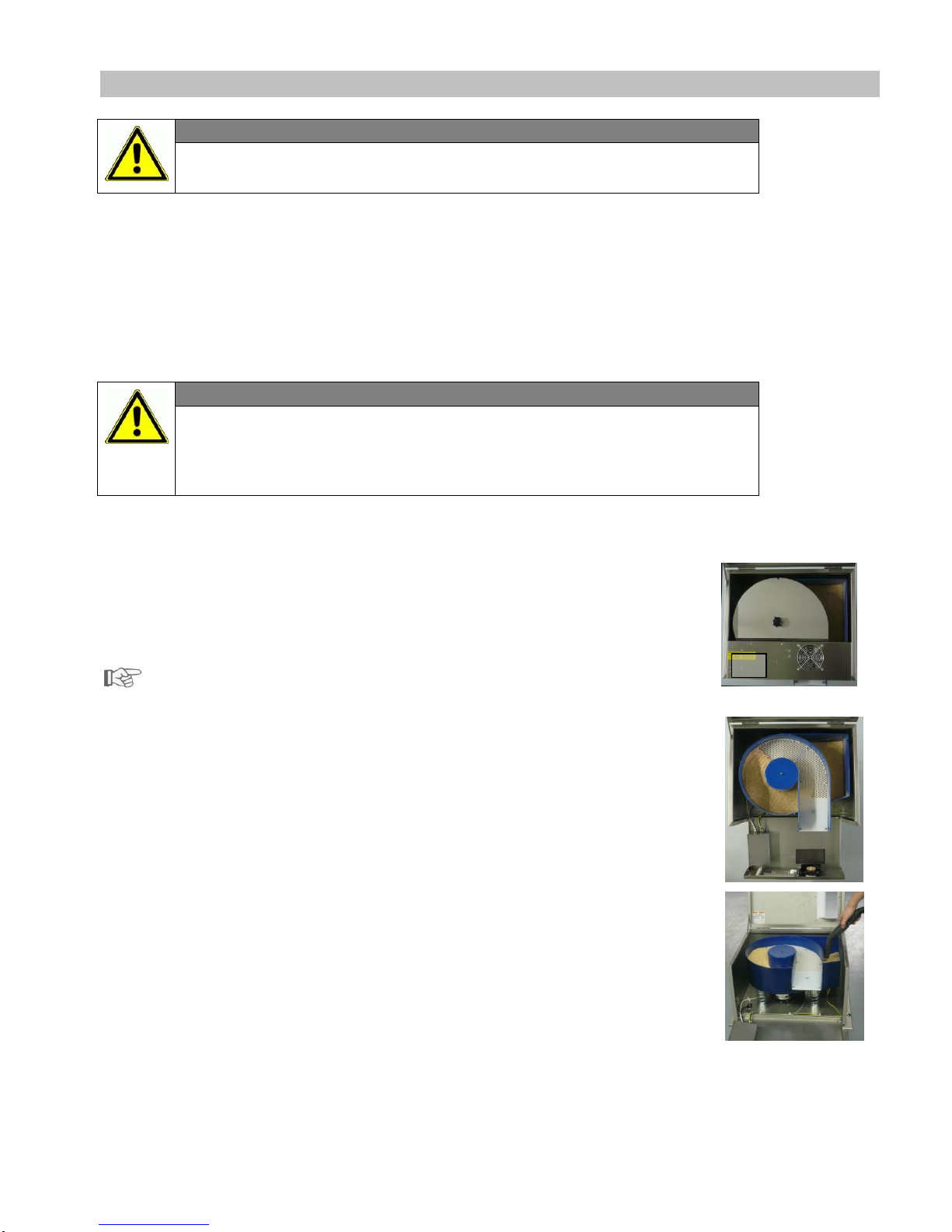

CAUTION!

Risk of serious injury or death by means of electrical shock

Before any maintenance or cleaning jobs are performed always assure the rocker switch is

switched to “O” and the power plug is removed from the power circuit

5.1 Daily cleaning

Clean the cutlery polishing machine daily by following these Steps:

1. Assure the rocker switch is switched to “O” and the power plug is removed from the power circuit.

2. Open the top cover to the machine and remove the granulate dust from the polishing bin, cover sheet,

frame and top cover with a damp cloth.

3. Remove the granulate dust from the UVC lamp with a dry cloth. The UVC lamp is found underneath the

front cover. (See picture 1 or picture 2 on page 10)

WARNING!

Damage may occur to the frame and / or the electronics

The in and outside of the machine should never be exposed to water.

Never hose down the machine or use a high pressure cleaner on it.

Never use cleaning powder, acid, leaching, steel wool or wire brushes to clean

the machine.

5.2 Replacing the granulate and cleaning the machine

The granulate must be replaced after approx. 200 operating hours or 8 weeks for hygienical

reasons.

Replace the granulate prior to if :

it is heavily filled with food leftovers.

it soaked up too much water and is wet.

It is heavily greasy (Granulate is dark).

1. Before changing the granulate, turn off the machine by switching the rocker switch

to „O“ and disconnect the power plug.

2. Open the top cover. Remove the cover sheet on the polishing bin by loosening

and removing the star grip. (See picture 1) Open the front cover by removing the

the 2 top screws (See picture 2 or page 10, Position 1-2).

3. Vacuum out the granulate with a vacuum cleaner (See picture 3). Clean the

Interior area if needed.

4. Spray cleaning alcohol on the polishing bin, cover sheet and top cover and wipe

Off with a dry cloth.

5. Remount cover sheet and front cover after cleaning.

6. Insert a complete filling of original Dörr polishing granulate Type SG 3000L into

The polishing bin.

7. Close the top cover. The Machine is now ready for use.

Picture 1

Picture 2

Picture 3

UVC-

Lampe

Page 10 of 18

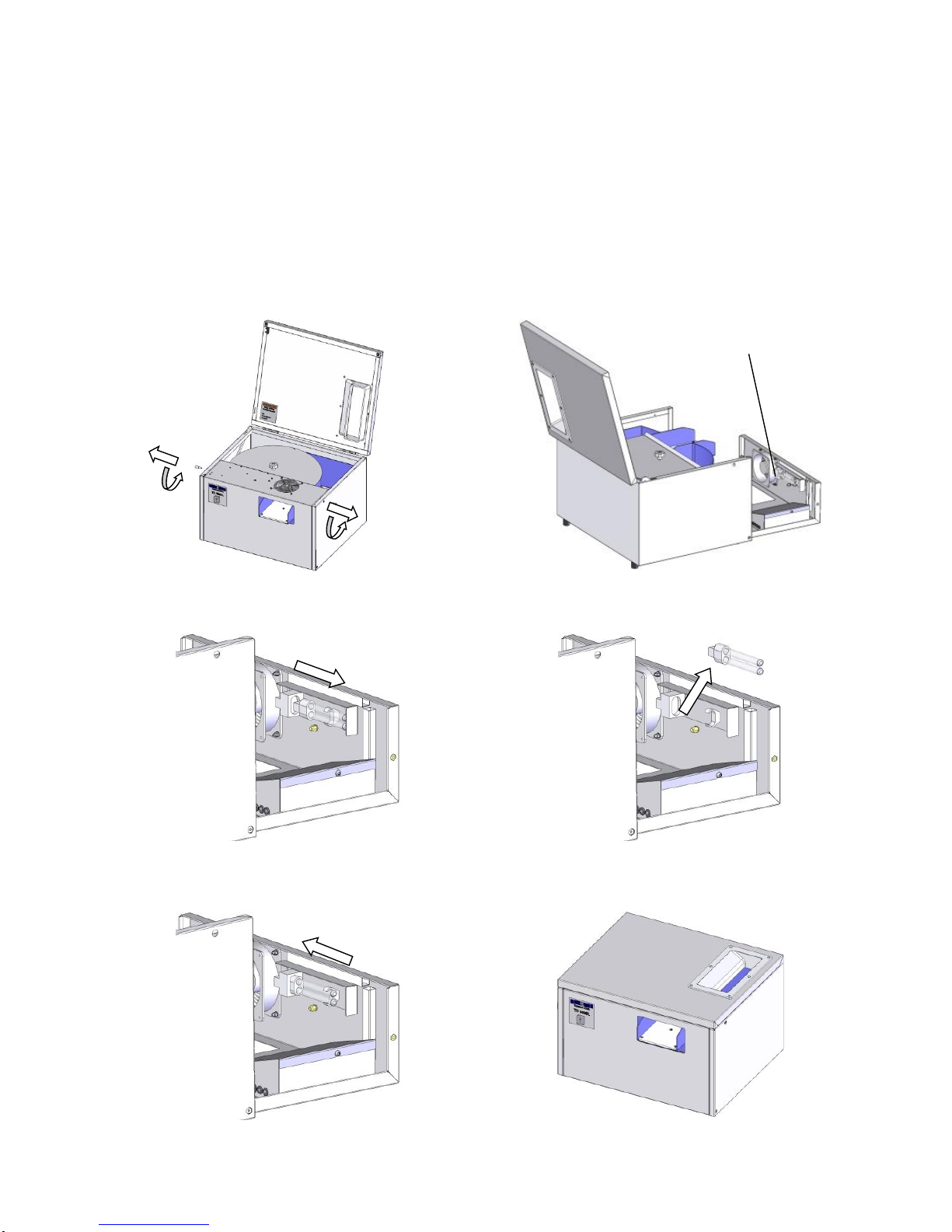

5.3 Replacing the UVC Lamp

To assure sterilisation of the granulate, replace the UVC lamp after 8000 operating hours. Replacement of the lamp is

shown on the pictures below.

Before replacing the UVC lamp turn the machine off by switching the rocker switch to “O” and disconnect the power

plug from the electrical socket.

1. Open the top lid and remove the upper screws

from the front cover using a 4mm allen wrench.

Loosen the bottom 2 screws by turning them counter

clockwise. (1-2 rotations)

2. Open the front cover

3. Slide the lamp carefully away from the socket

4. Remove the lamp

5. Insert the new lamp into the socket by sliding it

frontwards until it stops

6. Close the front cover and top lid. Insert the

screws and fasten them.

UVC-Lamp

Page 11 of 18

6. Troubleshooting

Malfunction /

Problem

Possible causes

Solution

Granulate sticks to

cutlery

1.

2.

Cutlery is still

dirty.

Dishwasher is

not operating

correctly. Or too

much detergent

is being used.

1.

2.

Wash the cutlery again thouroughly and insert into

the machine again.

If granulate pieces no longer stick to the

cutlery then the problem was the dishwashing

results.

There may have been too much cutlery in the

basket.

Wash the cutlery by hand, rinse thouroughly, then

insert it into the cutlery polisher again. If the

polishing results are good then there was too much

dishwashing detergent in the dishwasher.

Contact your dishwasher service technician to

reduce the dishwashing detergent or rinsing agent

dose.

Granulate falls out of

machine

1.

2.

3.

Granulate is or

was too wet.

There is too

much granulate

in the machine.

It is possible that

spoons transport

some granulate

out of the

machine.

1a

.

1b

.

1c

.

2.

3.

If the granulate is or was too wet, the volume of

each granulate grain increases; it comes out

through the holes in the screen and falls out of the

machine. The granulate can become too wet when

it is not hot enough and the water therefore does

not evaporate. Observe the specified heat-up

period. Let the cutlery drip dry to prevent too much

water getting into the machine.

The inserted cutlery was too wet. Let the water drip

off the cutlery to prevent it from dripping into the

machine.

The machine may have been turned off directly

after a polishing procedure. After use, allow the

machine to run for 30 minutes so the granulate can

dry.

› Replace the granulate and consider the heating

process and the drying procedure.

Remove some granulate

The axial fan may not be working properly. Contact

an authorized service technician. The form of the

spoon makes it impossible to eliminate that

granulate falls out of the machine.

Granulate does not

heat up

1.

2.

Heating element

malfunction.

Thermo element

malfunction.

1.

2.

Contact an authorized service technician

Contact an authorized service technician

UVC lamp does not

switch on

1.

UVC-lamp

malfunction.

1.

Replace the UVC lamp as described in chapter 5.3.

UVC lamps can be ordered from us.

Page 12 of 18

Continued on the following page

Malfunction /

Problem

Possible causes

Solution

Granulate dust

particles on cutlery

1.

2.

New granulate.

Dishwash

detergent or

rinsing agent in

the dishwasher.

1.

2.

Fresh granulate can cause more dust deposits at

first. When the granulate has been heated up as

required, dump 4-5 shot glasses of water into the

feed chute of the machine.

The cutlery is smeary, causing granulate dust to

stick on it. Wash the cutlery by hand, rinse

thouroughly, then insert it into the cutlery polisher

again. If the polishing results are good then there

was too much dishwashing detergent in the

dishwasher.

Contact your dishwasher service technician to

reduce the dishwashing detergent or rinsing agent

dose.

Cutlery is not

transported out of the

machine

1.

2.

Insufficient

quantity of

granulate in

machine.

Cutlery jam may

have occurred.

1.

2.

If there is not enough granulate in the machine the

cutlery cannot be transported correctly.

Replace the granulate with our original Dörr

polishing granulate.The amount needed is exactly

one filling.

Switch off the machine, open the top cover and if

necessary, also the cover sheet and remove the

cutlery. If this happens often, the granulate may be

swelled up. (See troubleshooting section

„Granulate falls out of the machine“)

Poor polishing results

1.

2.

3.

Dry cutlery might

have been

inserted.

Heating element

malfunction.

The granulate is

too old.

1.

2.

3.

Always insert the cutlery dripping wet.

Turn off the machine and check the granulate

temperature by hand. It must be noticeably warm.

If not the heating element does not work properly.

Contact an authorized service technician.

The granulate should be replaced every 4 to 8

weeks depending on the daily operation hours.

The machine is too

loud

1.

2.

3.

4.

Cutlery has fallen

into the machine.

Transportation

safety device was

not properly

removed.

Stainless steel

frame is vibrating

The machine is

defect.

1.

2.

3.

4.

Remove all cutlery pieces laying by the motor,

springs and cover sheet.

Remove the transporting safety device (see

chapter3.5).

Make sure all screws are fastened, if not tighten

them.

If the steps mentioned above do not solve the

problem, contact an authorized service technician.

Page 13 of 18

Continued on the following page

Malfunction /

Problem

Possible causes

Solution

Machine does not

start

1.

2.

3.

4.

Top cover is not

closed.

Damaged Fuse.

Power plug may

not be plugged in.

Machine has a

malfunction.

1.

2.

3.

4.

Close the top cover.

Check the fuses and have them replaced by an

authorized service technician.

Check if the power plug is inserted correctly.

Contact an authorized service technician.

A cutlery jam has

occurred inside the

machine.

1.

2.

Too much cutlery

has been placed

into the machine.

The granules

have swollen,

caused from

absorbing too

much moisture.

1.

2.

Begin feeding the machine with 30-40 cutlery

pieces. Afterwards only place a hand full of

cutlery inside the machine after the previous fed

cutlery has vanished underneath the granules.

In case the granules have absorbed too much

moisture, it will swell causing each corn to

expand. The filling volume will expand by

approximately 20-30%. This means the openings

for the cutlery pieces become smaller. To avoid

this happening we strongly recommend

performing the heating up and final drying

process. Please change the granules immediately

if this is the case. (See page 9, chapter 5.2)

The cutlery is

abnormally

intensively scratched.

1.

The cutlery

pieces fall too

deep from the

ejection chute.

1.

Please immediately make sure the cutlery basket,

in which the cutlery pieces fall into, is placed

directly underneath the ejection chute.

Page 14 of 18

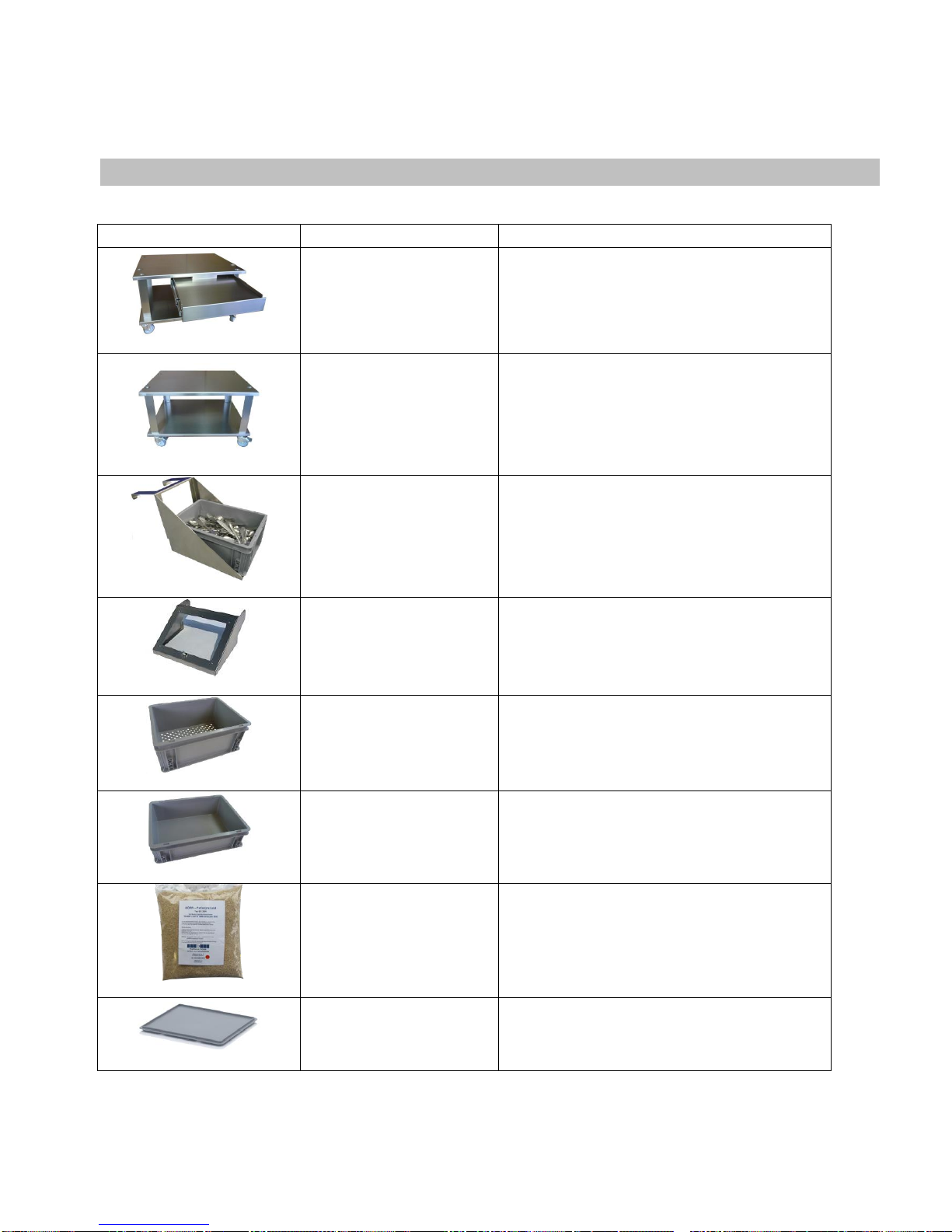

7. Accessories for the cutlery polishing machine

The following accessories can be ordered with your cutlery polishing machine TD 3000L M13:

Picture

Name

Description

Art.No.: 0014768

Mobile underframe TD

3000L with extendable

drawer

Mobile underframe with fixation for a secure

stand of the cutlery polisher.

With an extendable drawer for a cutlery basket.

For an optimized working height of the machine.

Mobile thanks to steering adjustable wheels.

ART. No.: 0016462

Mobile underframe TD

3000L without drawer

Mobile underframe with fixation for a secure

stand of the cutlery polisher.

For an optimized working height of the machine.

Mobile thanks to steering adjustable wheels.

We recommend in addition the basket holder or

the sound absorbing cutlery catcher.

Art. No.: 0017212

Basket holder TD 3000L

It’s installed over the ejection opening. The

cutlery basket can be placed on it.

Art. No.: 1000239

Sound absorbing cover

TD 3000 L

Reduces the volume of ejected cutlery. Optimized

for use with the mobile underframe

TD 3000 L.

Art.No.: 0016339

Perforated cutlery basket

400 x 300 x 170 (L x W x H)

Perforated cutlery basket

Art.No.: 0016365

Cutlery basket

400 x 300 x 75 (L x W x H)

Cutlery basket

Art.No.: 0015199

Original Dörr-polishing

granulate

Type SG 3050

Original Dörr-polishing granulate. One bucket

equals one filling.The granulate should be

replaced every 4 to 8 weeks depending on the

daily operation hours.

Art.No.: 1007415

Plastic underlay

Is only required if the TD 3000 L is used directly

on the table, without a mobile underframe

Page 15 of 18

Art.No.: 0015204

Cleaning alcohol (1000 ml)

Recommended cleaning alcohol for daily

cleaning.

The actual status of available accessories and prices can be read on our website. Go to www.t-td.de .

8. Company address

If there are any questions about our products, ordering spare parts or demand for our mobile customer service please

contact us.

When ordering spare parts always indicate serial number and manufacturing year. You will find it on the inside of the

frame to your upper left (See illustration on page 7).

Kitchen and Cutlery Systems

Hettenbergring 47

D-74889 Sinsheim

Tel.: +49 (0)7261 / 9754-93

Fax: +49 (0)7261 / 9754-94

9. Technical data

TD 3000L M14

Capacity

3000 cutlery pieces per hour

Consumption

550 W

Weight

50 kg

Dimensions (L x W x H)

60 x 54 x 40,5 cm

Noise level, not in operation

64 dB (A) –67 dB (A)

Noise level, in operation

67 dB (A) –72 dB (A)

Noise level, discharging

72 dB (A) –76 dB (A)

Input

1 Ph / N / PE (1 x 230 V AC 50 Hz)

Supply voltage

230 V AC 50 Hz

Control voltage

220 - 240 V AC

Nominal current

2,5 Ampere

10. Disposal of the machine

Most parts of the machine are steel, stainless steel or plastic. These parts can be disposed in a normal matter.

Electronic parts such as the control board, axial fan, motor and so on belong to electronic scrap.

The polishing bin is made of sheet metal and has a special certified FDA plastic coating.

By seperating and disposing wastes according to specifications we bear and maintain our natural resources and

guarantee re-use. The healthiness of man and nature will be protected by doing so.

Page 16 of 18

We will gladly dispose your machine for you. Just send the machine to the following adress:

Robert-Bosch-Straße 2

75050 Gemmingen

11. EG/EU - DECLARATION OF CONFORMITY

By means of the EU Machine Guidelines 2006/42 EG

Robert-Bosch-Straße 2

75050 Gemmingen

Tel: +49 (0)7267 / 9122-0

Fax: +49 (0)7267 / 9122-22

We hereby certify that the machine described below fulfills the applicable basic safety and health requirements of the

associated EU Guidelines in terms of its design and construction as well as the version put into circulation by us. Any

modification to the machine not coordinated with us invalidates this Declaration of Conformity.

Description of the machine:

Cutlery polishing machine

Type:

TD 3000L M14

Applicable

EU Guidelines:

EU Machine Guidelines (2006/42 EG)

EMC Guidelines (2014/30 EU)

The declaration was issued by:

Page 17 of 18

MAX DÖRR GmbH

-Förderanlagen-

Gemmingen, 13.04.2016 ___________________________________

(Thomas Dörr, CEO)

12. Notes

Page 18 of 18

Table of contents

Other THOMAS DÖRR Sander manuals

Popular Sander manuals by other brands

Stanley

Stanley SS28 instruction manual

Alpha tools

Alpha tools AWP 1200 E Original operating instructions

SKIL MASTERS

SKIL MASTERS 7520 Original instructions

Makita

Makita BO4555 instruction manual

Dynabrade

Dynabrade Dynangle 14200 Disassembly and Assembly Instructions

GRS

GRS GraverHone VS Operation and maintenance manual