THOR MS-PD1002 User manual

THOR

POST

DRIVERS

MS-PD1002

MS-PD1004

Made in China

THOR– Post Driver

Instructions

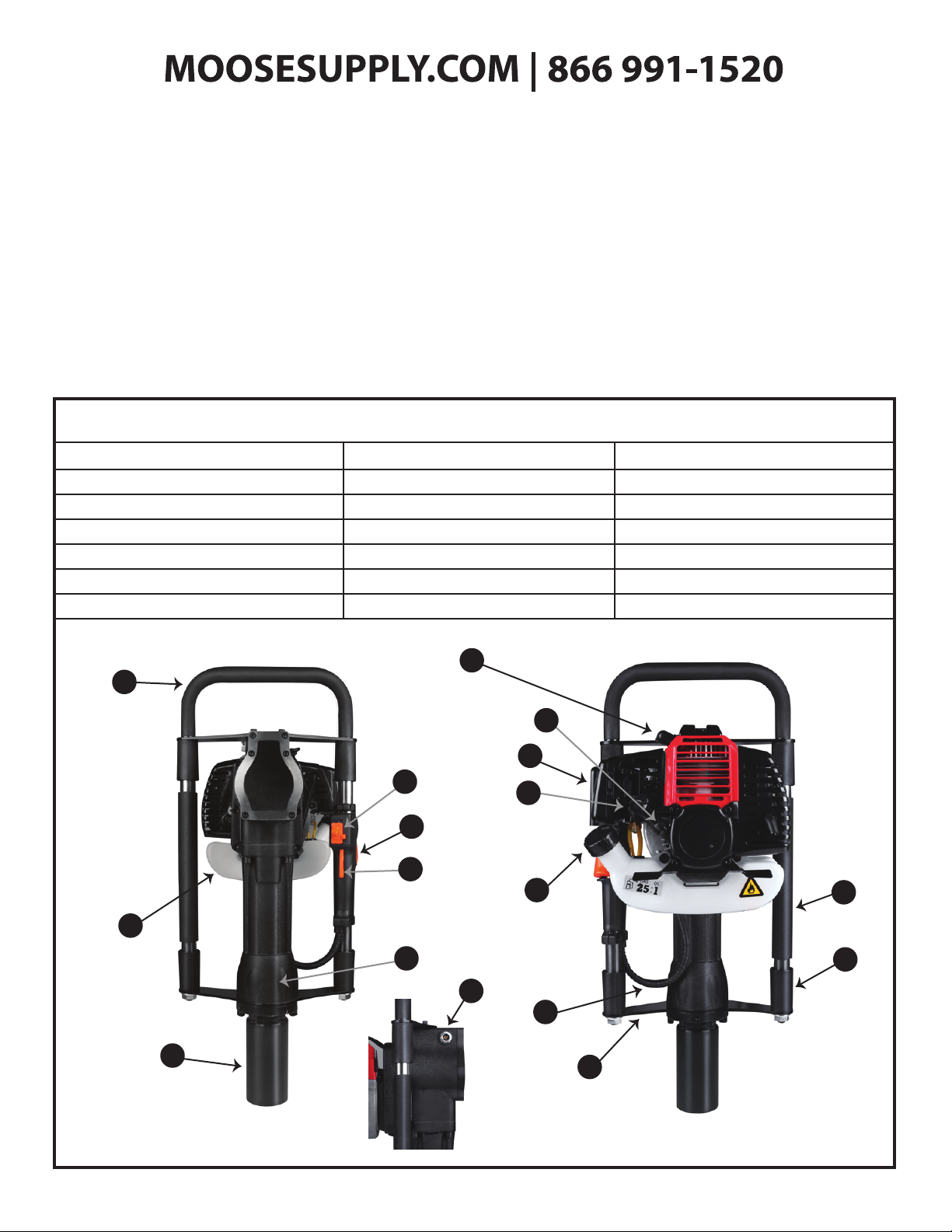

BASIC PARTS:

1

No.

1

2

3

4

5

6

Name:

Combination Switch

Throttle Switch

Handle

Spark Plug

Intake Switch

Fuel Bubble

No.

7

8

9

10

11

12

Name:

Fuel Tank

Stop Switch

Hammer Case

Piling Socket

Support Plate

Throttle Cable

No.

13

14

15

16

17

18

Name:

Lube Oil Filling Port

Fuel Tank Lid

Starter

Air Filter

Positioning Sleeve

Grip

THOR–POST DRIVERS OVERVIEW

THOR post drivers are light weight, hand-held gasoline pile drivers—that reduces working strength of

the operator and produces simple and comfortable operation. Post drivers can easily be one of the most

efficient tools you may ever use—to get large or small jobs completed quicker and with much less effort.

The design of these gas-powered post drivers have made them very portable. THOR post drivers work

with a variety of fence posts, including steel posts, t-posts, sign posts, u-channel posts, guide posts,

and grounding rods. Many of our customers employ these drivers to make quick work out of securing

tent stakes, for party tent projects.

Advantage notes: Reduces the effort of using heavy machines such as generators and air compressors.

The operating handle is rubber/plastic sponge handle which can greatly reduce the recoil force of the

driver— also installed, a two-way damping spring which adds to use comfortable.

3

4

5

6

7

9

10

1

2

8

16

15

12

11

17

18

14

OPERATION DESCRIPTION:

2

• The operator must wear slip-resistant safety shoes and protective clothing—including

goggles and helmet. For long-time operation, operator must wear earplugs.

• While operating the post driver, maintain balance of body—the user should stand in front

of air filter to operate the machine.

• After starting the machine, do not carry out one-handed operation.

• While lifting the machine, be careful not pull throttle switch— carry, only, in idle-speed.

• Keep non-staff away from operating area to avoid injury.

• Select the medium speed to operate pile driver.

• Keep the handle dry and clean free from greasy oil or fuel mixture.

• If operation is stopped midway, for any reason, be sure to turn off the engine.

• Before use, be sure to check fastening screws of the connector are properly tightened.

(If it’s loose, it’s necessary to tighten the screws before use).

• Pure gasoline (without two-stroke engine oil) is prohibited. Compound it according to the

recommended ration of fuel on (page 3), for use.

• Gasoline is highly flammable—important, replenish fuel in a well-ventilated environment.

During fuel filling, gasoline engine MUST be turned off.

• Do not add too much oil—the oil should not exceed the neck of oil filer of fuel tank. If fuel

spills over, wait until the fuel volatilizes completely and then start the machine.

• During work, check whether fuel tank is damaged and frequently leaking—and check the

oil lid, tighten properly.

(If damage is found, close down the operation immediately for replacement).

• Remove hazardous materials such as, oil containers, gas cans or open flame from

work area.

• While post driver is used in closed areas such as tunnels, trenches and deep groove,

take precaution to ensure air circulation is adequate, to avoid gas fume poisoning.

• Avoid quick acceleration or braking, so as not to damage the machine.

• Before transport, empty fuel tank to avoid leakage and accidental fires.

• Non-professional maintenance is prohibited—avoid disassembling post driver to avoid

structural damage of parts, shortened service life of post driver.

PREPARATION FOR USE:

3

Fuel

• Use qualified 86 Octane – unleaded gasoline or higher gasoline

(For model MS-PD1002, use a 25 to 1 Fuel Mixture)

• Add fuel in a well-ventilated place.

• Do not add too much oil. The oil should not exceed the neck of fuel tank filling port.

If fuel spills, wait until the fuel is removed or volatilizes completely and then restart

the machine.

• After refueling, tighten the lid of fuel tank.

Figure 1.

STARTING:

OPERATION:

4

Choke

(cold engine)

Starter

• Before starting the new post driver, press the

transparent and semi-circle fuel bubble

repeatedly until carburetor is filled with fuel

see (figure 2).

(If the engine is cool, close the air door

—open air door after starting)

• Set the machine upright according to (figure 3). Hold the upper part of the handle tightly

with one hand, while the other pulls the starter grip quickly (remember to extend cord

sufficiently). Do not let the starter grip go back freely in repeated pulling—but hold it

tightly to avoid injury.

• Start the gasoline engine and then open-air door completely. After idle operation of

5 minutes, start normal work operations.

• After the gasoline engine is started, idle engine for 5 minutes to warm up the driver.

• After warmed up, press throttle handle to the appropriate regulatory position, according

to the required impact energy.

(Note: The new gasoline post driver use should mainly be set to low or medium-speed for the

first 20 hours of operation—refrain from using maximum throttle— this will extend the

service life).

• Operating speed of gasoline engine is best at medium speed.

• High-speed operation of post driver during non-piling is prohibited.

Figure 2.

TECHNICAL MAINTENANCE:

TURNING OFF POST DRIVER:

5

Stop

Switch

‘Stop’

• Release throttle handle and maintain idle

running of the engine for 3-5 minutes.

• Pull stop switch to the position of off/

flame-out. See the position of stop switch in

(figure 3).

Air Filter

• Check air filter regularly. Soot deposit blocking filter element of air filter will reduce power

of gasoline engine and service life. If the filter has too much soot deposit, clean it with warm

water and detergent, and then wipe dry it with dry cloth, and then install the air filter. Filter

should be replaced if damaged. In dirty environs, maintenance cycle should be shortened.

Fuel filter

• If the fuel filter is blocked, pile driver will have reduced speed and weaker impact energy.

Cleaning:Open the tank lid—remove the fuel filter from fuel tank with metal hook and clean

it. When cleaning the fuel filter, clean the fuel tank at same time— (see figure 4, 5 and 6).

Figure 3.

Figure 4. Figure 5. Figure 6.

TECHNICAL MAINTENANCE:

6

Carburetor

• Fuel tank and carburetor generally have

residual oil.

After some time, the residual oil will become

greasy oil which block up the oil line, prevent-

ing the engine from starting. Therefore, when

the post driver is not used for more than one

week— completely take the fuel out.

• Method: Pull out the oil inlet pipe, press

rubber bubble of fuel bubble of carburetor

repeatedly for oil discharge, and press the oil

inlet pipe back to its position when fuel in fuel

bubble and oil return pipe is emptied.

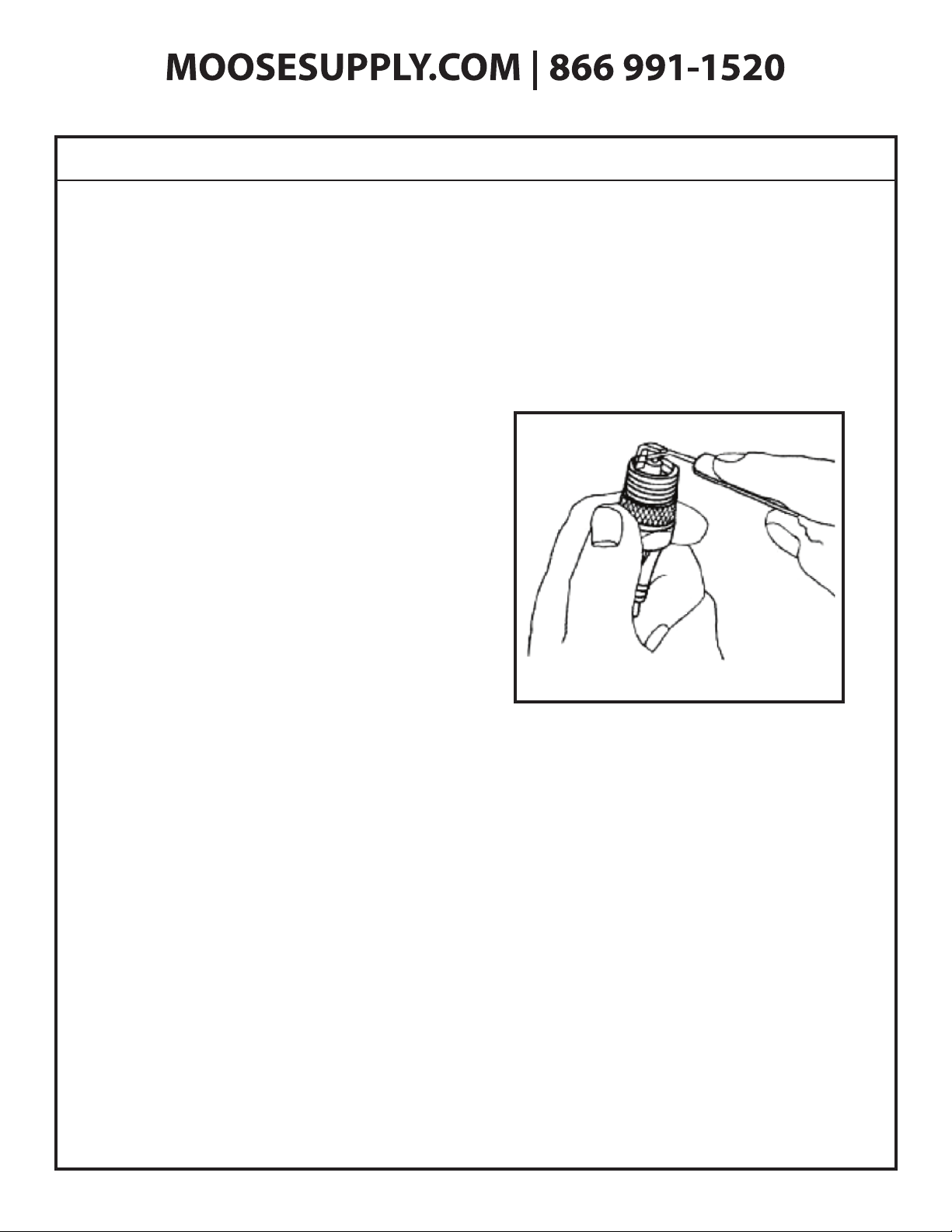

Spark Plug

To ensure normal operation of the engine,

spark plug gap must be proper. Remove

sediment with a wire brush.

See (figure 7).

Muffler

• Regularly remove dirt on inlet and outlet of muffler, or clean dirt in it with detergent.

Gearbox Lubrication

• Open the cover of the gear boxes, and lubricate the driving gear regularly with

lubricating oil to guarantee full lubrication of the gear.

Figure 7.

TECHNICAL MAINTENANCE:

7

The Cylinder Heat Sink

• Regularly remove dust to ensure the cylinder cooling. The gasoline post driver is

air-cooling type. If dust accumulates on the cylinder heat sink, the cooling effect will be

influenced directly, which will lead to failure of the cylinder.

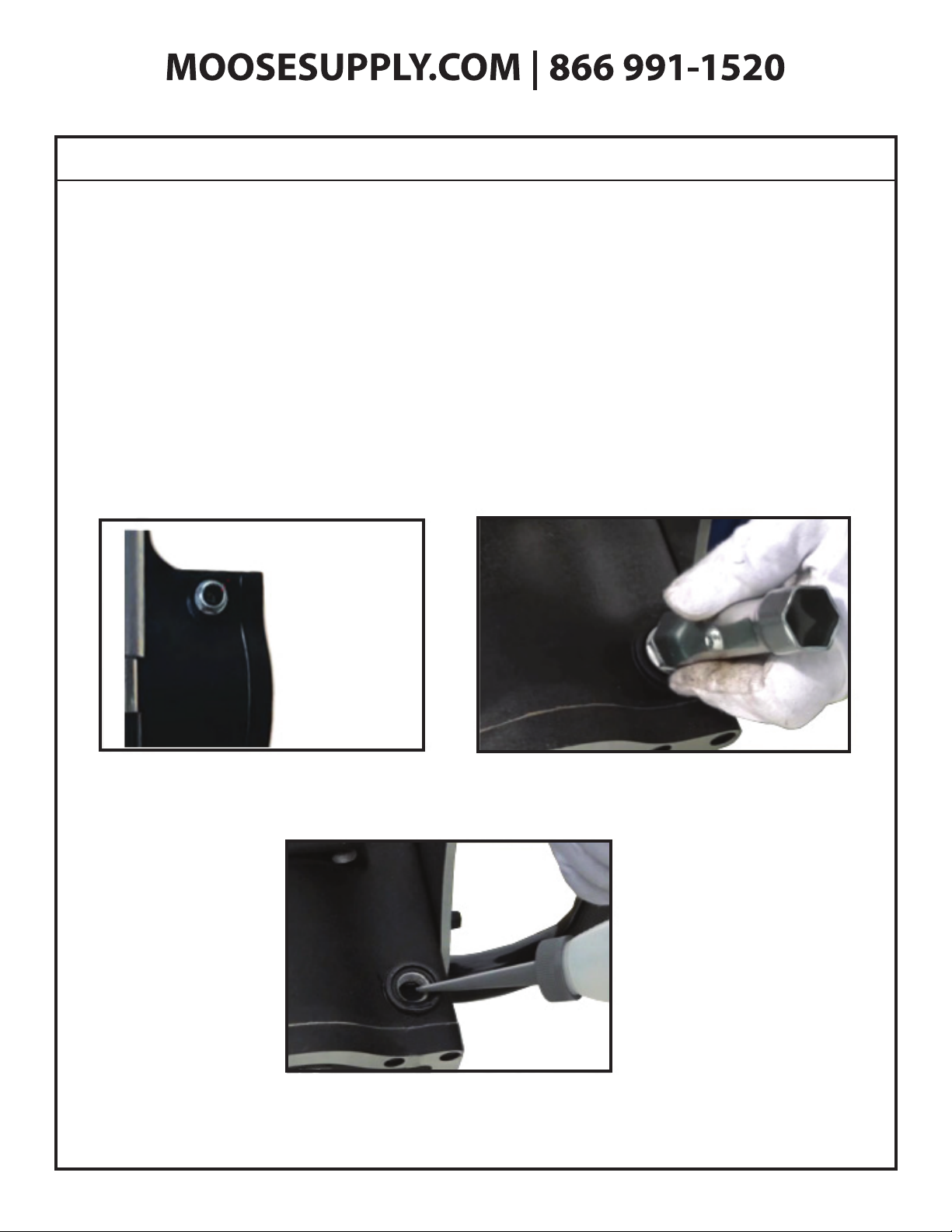

Filling of Impact Cylinder Lubrication

• After working for an accumulated 50 hours, fill special lubrication (50g) for the impact

cylinder. See (figure 8, 9, and 10).

Figure 8. Figure 9.

Figure 10.

TROUBLESHOOTING:

8

Difficulties in starting engine

in cooling state.

Difficulties in restarting after

a sudden stop

Slow speed and weak power

Abnormal sound

The machine is working

normally but the work

efficiency is very low

Whether Spark Plug is damp

↓

Whether the spark plug

produces electric spark

↓

Too much fuel absorbed

Whether fuel is used up or

carburetor is blocked

↓

Whether fuel filter is blocked

↓

Too much carbon deposit of

Spark Plug

Carbon deposit of the cylinder

or silencer

↓

Either the oil tube and the

air vent of the fuel Tank is

blocked

↓

Air filter is blocked

Carbon deposit found in

combustion chamber

↓

Serious abrasion in active

components

Rubber ring of impact piston is

aged and worn

• Wipe dry Spark Plug

• Replace Spark Plug

• Reduce the fuel supply

• Refill Fuel tank or clean

carburetor

• Clean fuel filter

• Remove carbon deposit of

Spark Plug and clean filter

element

• Remove carbon deposit

• Clean

• Clean filter

• Remove carbon deposit

• Replace

• Replace or renew

Problem Analysis Action

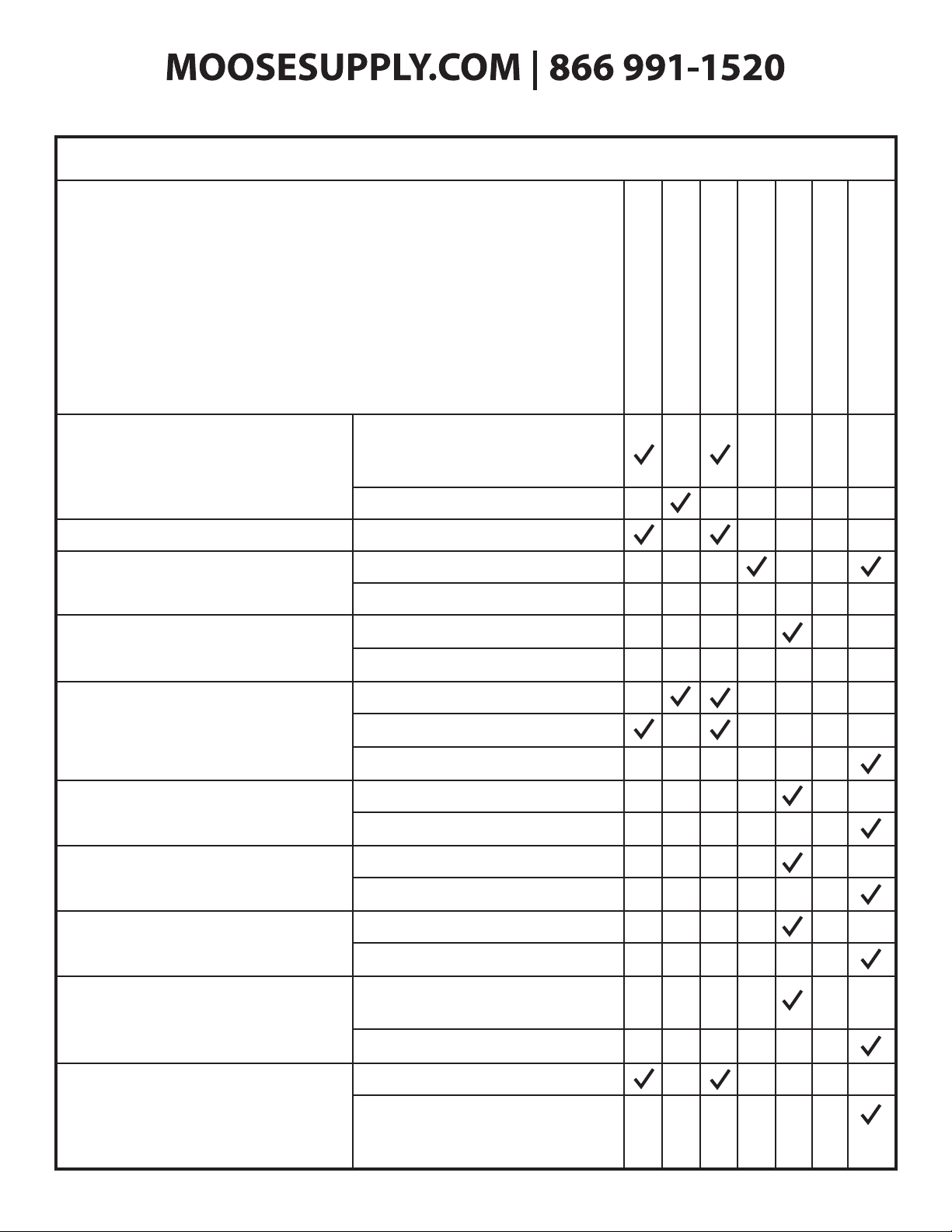

MAINTENANCE SCHEDULE:

9

The whole machine

Control handle/stop button

Air Filter

Fuel Filter

GasTank/Gas Tank cover

Gear Box/Cylinder

Silencer

Cylinder Cooling Fin

Spark Plug

Screw and Nut

If Necessary

Temporary Failure

Every Month

Every Week

After Filling Oil

After Work (every day)

Before Work

The following data are general data for the

product. Under the worse working conditions such

as thick dust or long work hours of the post driver,

the maintenance cycle should be shortened

accordingly.

Outlook check (state,

tightness of screws)

Clean

Function check

Clean

Replace

Check

Replace

Clean

Check

Tighten

Clean

Add oil

Check

Remove carbon deposit

Check

Clean

Check/Adjust the distance

between electrodes

Replace

Check

Tighten

EXPLODED VIEW / PARTS LIST:

10

EXPLODED VIEW / PARTS LIST:

11

MS-PD099 Tent Stake Metal Head 1

MS-PDTSK Tent Stake Metal Head Kit

Includes: MS-PD099, MS-PD100, MS-PD101, 1

MS-PD102, MS-PD103

MS-PDFPK Fence Post Metal Head Kit 1

Includes: MS-PD101, MS-PD102, MS-PD103, MS106

MS-PD100 Hammer Block Small 1

101 MS-PD101 Hammer block Large 1

102 MS-PD102 100mm piling socket 1

103 MS-PD103 M6X16 Inner hexagon socket screw, 3

washers, plain cushion combination

104 MS-PD104 M8X45 hexagon socket cap screws 10

105 MS-PD105 Φ8 spring washer 16

106 MS-PD106 Metal head 1

107 MS-PD107 Buffer spring 1

108 MS-PD108 Impact hammer 1

109 MS-PD109 Large rubber band 1

110 MS-PD110 O ring (Shank adapter 23.6*5) 1

111 MS-PD111 Shank adapter 1

112 MS-PD112 broken ring gum cover 1

113 MS-PD113 broken ring 1

114 MS-PD114 Small rubber band 1

115 MS-PD115 Air cylinder gasket (59*69-2) 1

116 MS-PD116 Air cylinder 1

117 MS-PD117 Front placket 1

Part SKU Description Quantity

EXPLODED VIEW / PARTS LIST:

12

118 MS-PD118 O ring 70x67x1.5 1

119 MS-PD119 M6X30 hexagon socket cap screws, 6

washer combination

120 MS-PD120 Connecting rod 1

121 MS-PD121 Impact Piston 1

122 MS-PD122 Lip ring 1

123 MS-PD123 Impact Piston Pin 12x44 1

124 MS-PD124 M5X16 hexagon socket cap screw 6

and spring combination

125 MS-PD125 Cover for gear box 1

126 MS-PD126 Paper pad for gear box 1

127 MS-PD127 Flange hexagon screw M8X16LH 1

128 MS-PD128 Pressing plate 1

129 MS-PD129 Quill bearing NK18/20 1

130 MS-PD130 Eccentric shaft 1

131 MS-PD131 Wick 1

132 MS-PD132 Oil leveler 1

133 MS-PD133 Oil leveler leather collar 1

134 MS-PD134 Handle 1

135 MS-PD135 M6X20 hexagon socket cap screws, 4

washer combination

136 MS-PD136 Upper support plate 1

137 MS-PD137 Bearing 6205 1

138 MS-PD138 Gland 6205 1

139 MS-PD139 Shaft Retainer 1

Part SKU Description Quantity

EXPLODED VIEW / PARTS LIST:

13

140 MS-PD140 Big gear 1

141 MS-PD141 Bearing 6202 3

142 MS-PD142 Center cover 1

143 MS-PD143 Clutch drum 1

144 MS-PD144 Circlip 35 1

145 MS-PD145 Framework oil seal 25X19-3 1

146 MS-PD146 M8X12 Sunk screw 4

147 MS-PD147 Gland cover 1

148 MS-PD148 Gear shaft 1

149 MS-PD149 M5X12 Sunk screw 4

150 MS-PD150 Gear box 1

151 MS-PD151 Handle 1

152 MS-PD152 Tube as handle 1

153 MS-PD153 Φ8 plain washers 4

154 MS-PD154 Switch block 1

155 MS-PD155 Reduction spring 4

156 MS-PD156 Spring pocket 4

157 MS-PD157 Under support plate 1

158 MS-PD158 M14 flanged tooth nut 2

Part SKU Description Quantity

This manual suits for next models

1

Table of contents

Popular Construction Equipment manuals by other brands

TESTING

TESTING 2 0231 operating manual

Fayat

Fayat Dynapac DFP7AX Operating Instruction, Maintenance Instruction

Manitowoc

Manitowoc Grove RT9150E Operator's manual

Grove Crane

Grove Crane GMK 5175 operating manual

Turbosol

Turbosol MINI AVANT Use and maintenance manual

MetalTech

MetalTech MAXI SQUARE CISC instructions