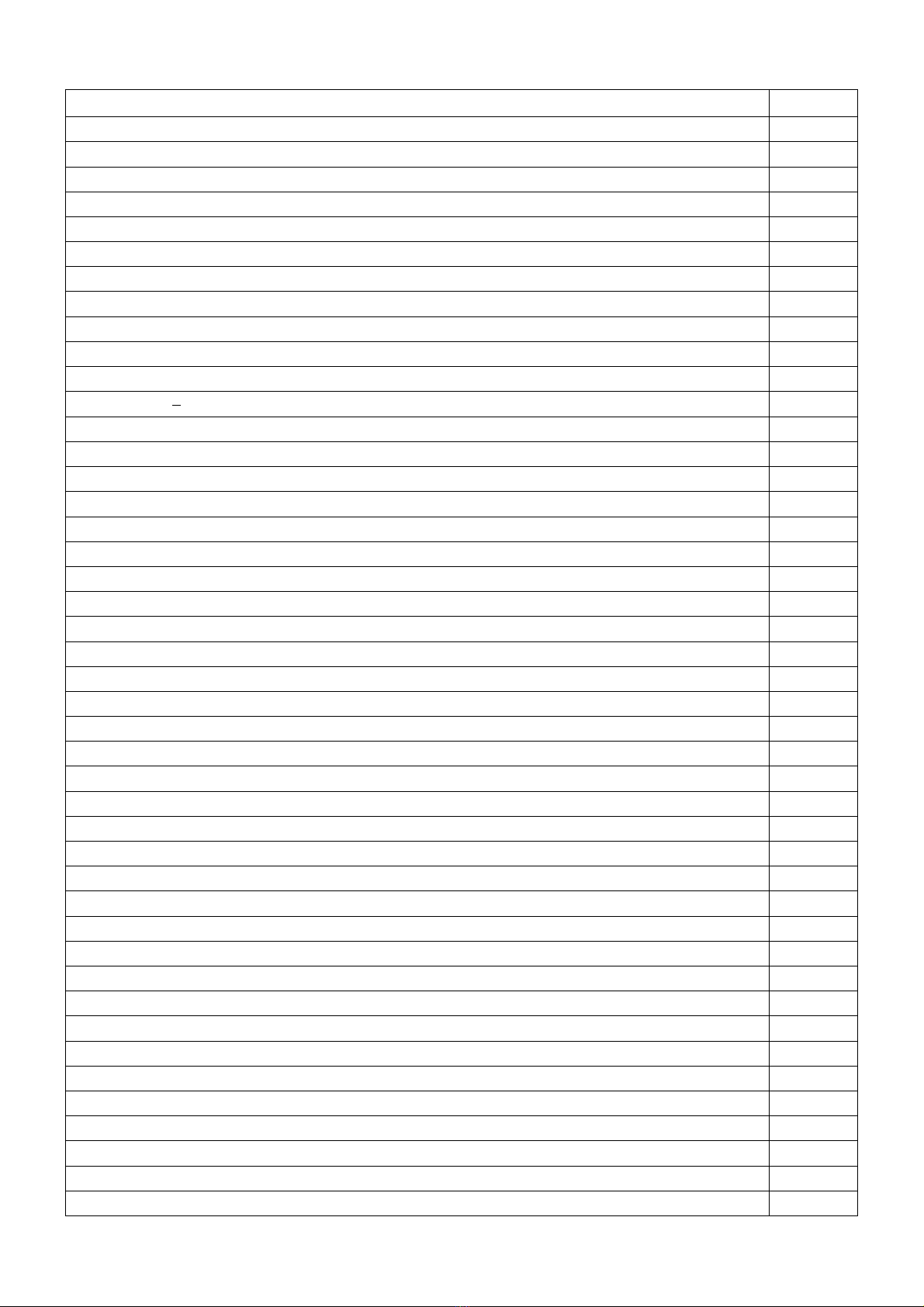

0-5

ITEM

Page

8 TESTING ENGINE OIL PRESSURE 4-13

9 HANDLING FUEL SYSTEM PARTS 4-14

10 RELEASING RESIDUAL PRESSURE FROM FUEL SYSTEM 4-14

12 TESTING FUEL PRESSURE 4-15

13 TESTING FUEL RETURN RATE AND FUEL LEAKAGE 4-16

14 BLEEDING AIR FROM FUEL CIRCUIT 4-18

15 CHECKING FUEL CIRCUIT FOR LEAKAGE 4-20

16 TESTING AND ADJUSTING ALTERNATOR BELT TENSION 4-21

17 TESTING AND ADJUSTING AIR CONDITIONER COMPRESSOR BELT TENSION 4-22

18 CHECKING AND ADJUSTING TRACK SHOE TENSION 4-23

19 TESTING AND ADJUSTING OIL PRESSURE IN WORK EQUIPMENT, SWING AND TRAVEL CIRCUIT 4-25

20 TESTING CONTROL CIRCUIT BASIC PRESSURE 4-28

21 TESTING AND ADJUSTING OIL PRESSURE IN PUMP PC CONTROL CIRCUIT 4-29

22 TESTING AND ADJUSTING OIL PRESSURE IN PUMP LS CONTROL CIRCUIT 4-32

23 TESTING SOLENOID VALVE OUTPUT PRESSURE 4-36

24 TESTING PPC VALVE OUTPUT PRESSURE 4-37

25 ADJUSTING PLAY OF WORK EQUIPMENT AND SWING PPC VALVES 4-39

26 RELEASING RESIDUAL PRESSURE FROM HYDRAULIC CIRCUIT 4-40

27 TESTING OIL LEAKAGE 4-41

28 BLEEDING AIR FROM EACH PART 4-43

29 CHECKING CAB TIPPING STOPPER 4-45

30 ADJUSTING MIRRORS 4-45

31 ADJUSTING CLEARANCE OF BOOM 4-46

32 ADJUSTING BOOM TELESCOPING WIREROPE 4-47

33 CRITERIA FOR WINCH WIRE ROPE REPLACEMENT 4-49

34 CHECKING HOOK BLOCK 4-50

35 SPECIAL FUNCTION OF MACHINE MONITOR 4-52

36 HANDLING VOLTAGE CIRCUIT OF ENGINE CONTROLLER 4-102

37 PRECAUTION WORK FOR TROUBLESHOOTING OF ELECTRICAL SYSTEM 4-103

38 PROCEDURE FOR TESTING DIODES 4-108

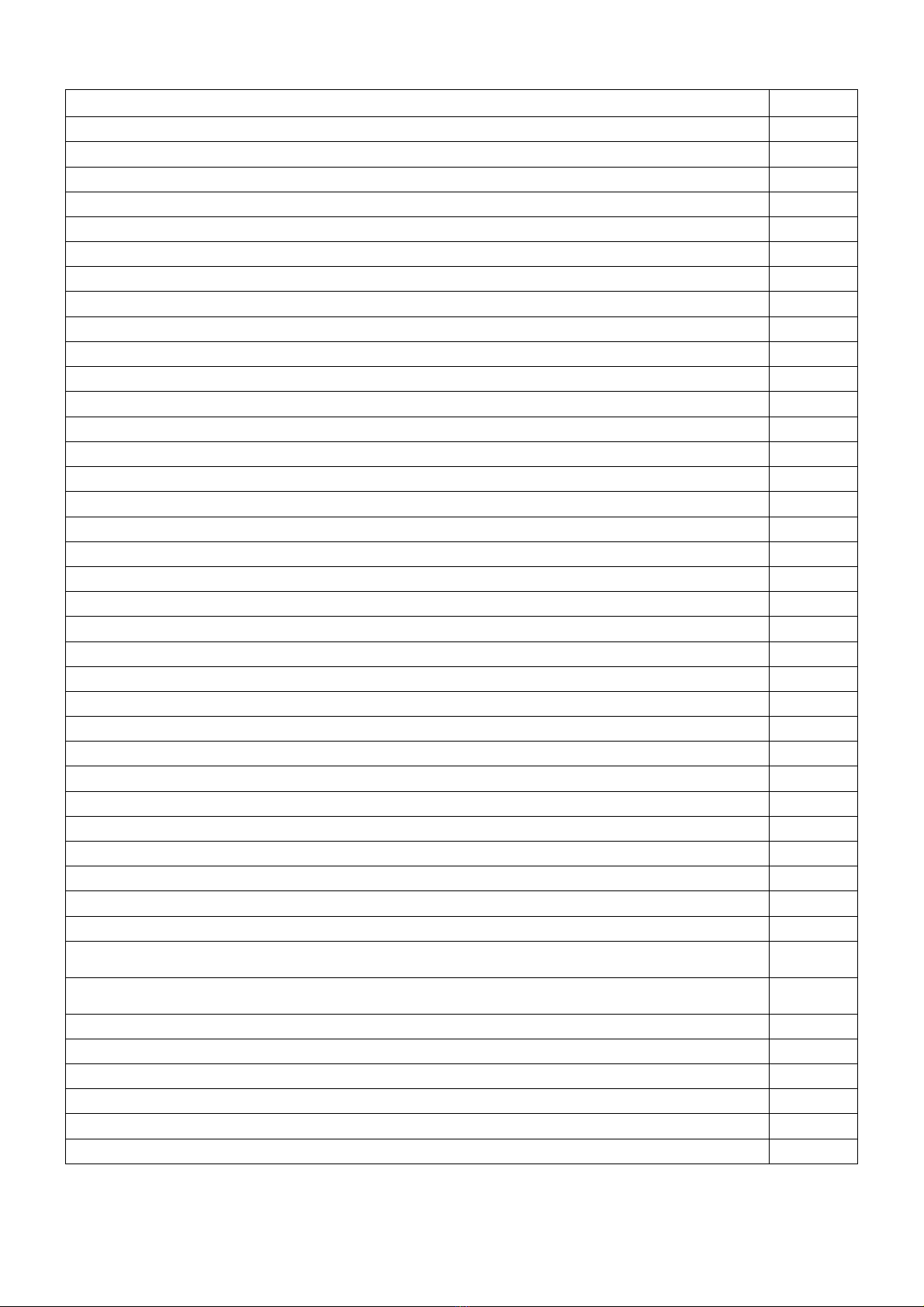

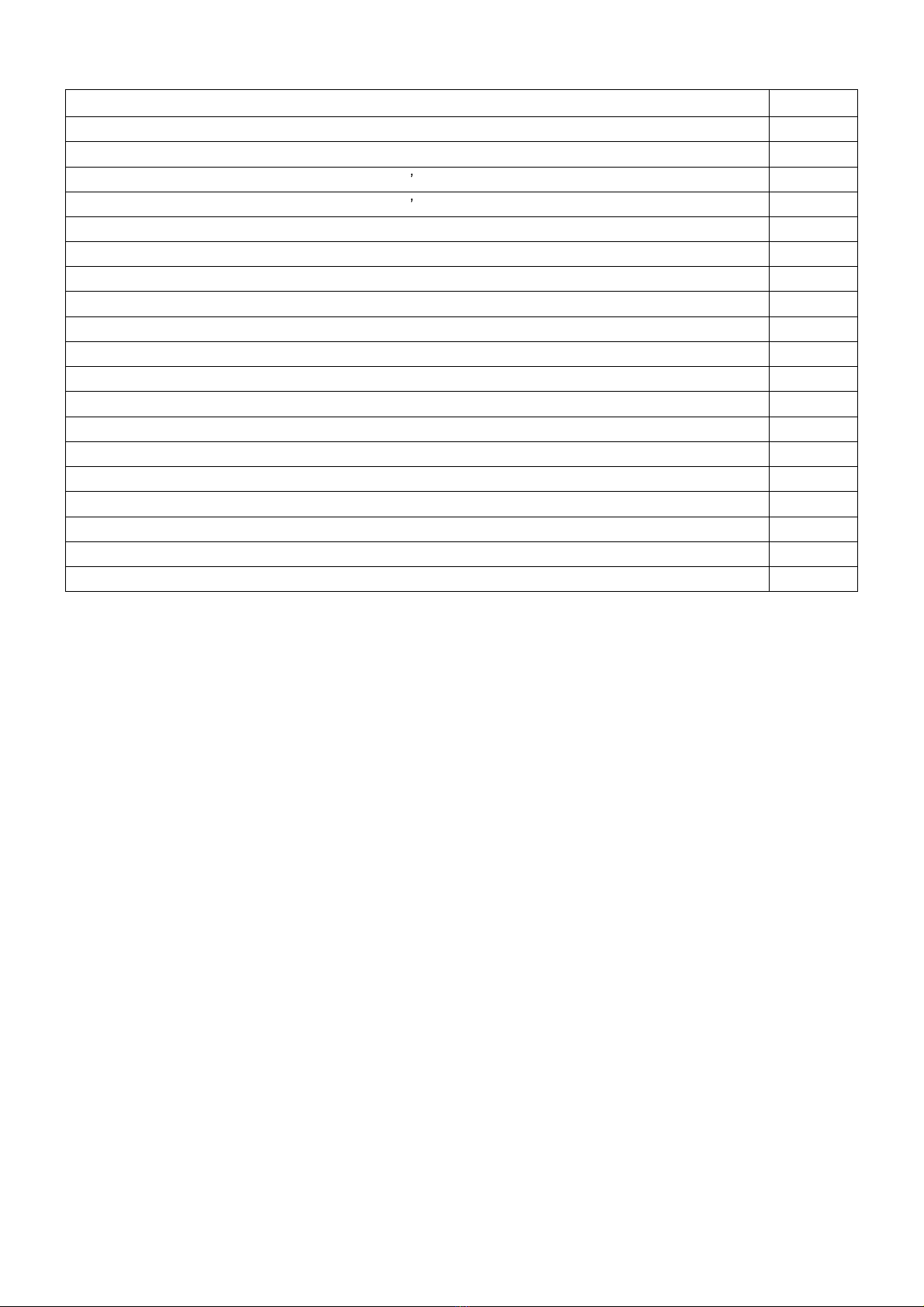

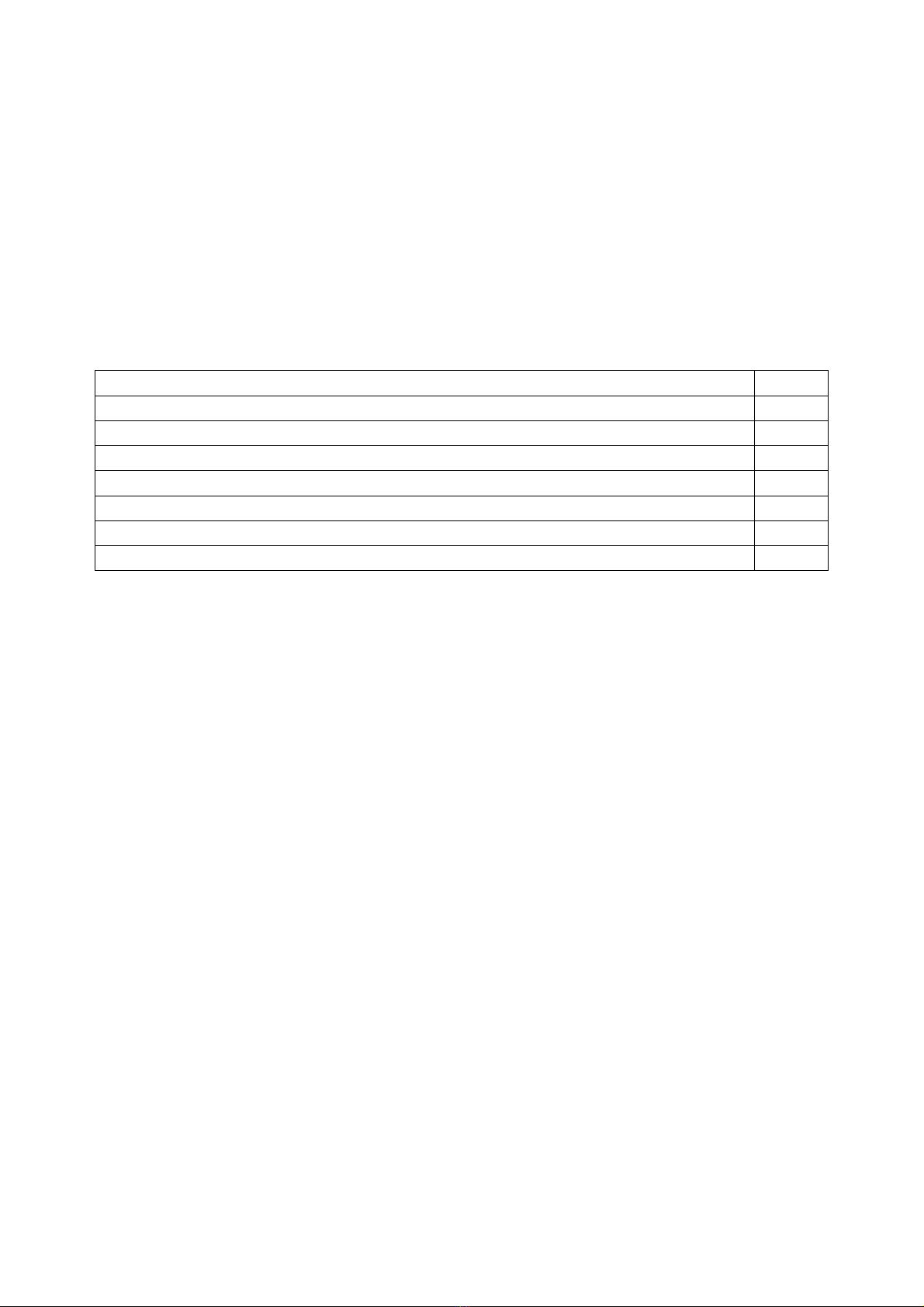

TROUBLESHOOTIN

5-1

1 GENERAL INFORMATION ON TROUBLESHOOTING 5-2

1 1 POINTS TO REMENBER WHEN TROUBLESHOOTING 5-2

1 2 SEQUENCE OF EVENTS IN TROUBLESHOOTING 5-3

1 3 CHECKS BEFORE TROUBLESHOOTING 5-4

1 4 CLASSIFICATION AND PROCEDURES FOR TROUBLESHOOTING 5-5

1 5 INFORMATION IN TROUBLESHOOTING TABLE 5-6

1 6 PHENOMENA LOOKING LIKE TROUBLES AND TROUBLESHOOTING NOS 5-8

1 7 WIRING TABLE FOR CONNECTOR PIN NUMBERS 5-11

1 8 T-ADAPTER BOX AND T-ADAPTER TABLE 5-44

1 9 FUSE LOCATIONS 5-48

2 TROUBLESHOOTING BY FAILURE CODE 5-101

2 1 FAILURE CODE TABLE 5-101