Table of Contents

Chapter 1 Introduction................................................................................................................. 1

1.1. Safety....................................................................................................................... 2

1.2. Care and Maintenance ........................................................................................... 3

Optical Cleaning..........................................................................................................4

Fiber Cleaning Using the FBC250..............................................................................4

Service ........................................................................................................................4

Accessories and Customization..................................................................................4

Chapter 2 Setup ............................................................................................................................ 5

2.1. Unpacking............................................................................................................... 5

2.2. System Connections.............................................................................................. 5

Base Unit Connections................................................................................................5

Internal Electrical Connections ...................................................................................6

Electrical Interfaces to Imaging Scanner ....................................................................6

2.3. Optical Interface to Imaging Scanner................................................................... 6

2.4. System Installation................................................................................................. 7

Chapter 3 Description.................................................................................................................13

3.1. Tutorial.................................................................................................................. 13

Theory.......................................................................................................................14

Thorlabs Swept-Source OCT System Technology...................................................15

Nomenclature in OCT imaging..................................................................................17

3.2. SS-OCT Base Unit Components ......................................................................... 19

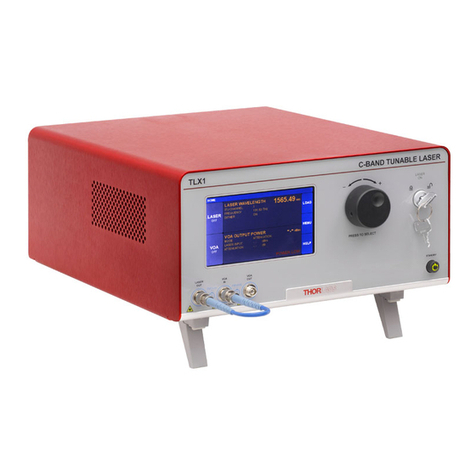

Base Unit...................................................................................................................19

PC with Graphical User Interface..............................................................................19

SDK...........................................................................................................................19

Imaging Scanner (Accessory)...................................................................................21

OCT-Stand (Accessory)............................................................................................23

Chapter 4 System Operation......................................................................................................25

4.1. Starting the System.............................................................................................. 25

Turning on the Base Unit ..........................................................................................25

Starting the Software.................................................................................................25

4.2. Basic Adjustments............................................................................................... 26

Adjusting the Focus...................................................................................................26

Adjusting the Reference Length................................................................................27

Adjusting Polarization................................................................................................28

Adjusting the Reference Light Intensity and Amplification........................................29

4.3. Advanced Adjustments ....................................................................................... 31

Focus and Choice of Objective Lens........................................................................31

Imaging through Refractive Media............................................................................33

Reflecting Surfaces and Interfaces...........................................................................34

Rough Surfaces ........................................................................................................34

4.4. Shutting Down the System.................................................................................. 34

4.5. Example Images................................................................................................... 35

Chapter 5 Imaging Artifacts.......................................................................................................37

5.1. Saturation and Non-Linearity.............................................................................. 37

5.2. Multiple Scattering ............................................................................................... 38