Airfield Lighting Safegate Group

Manual Date: March 2014

Ref: PRT3 Version: 1.0

Page 3 of 18

1. INTRODUCTION

In this section you can find a general description and safety instructions related to the

installation and usage of the fitting.

PRT3 is a flood light that allows lighting of Heliport Touchdown and Lift Off area

(T.L.O.F).

The fitting has many advantages and special features:

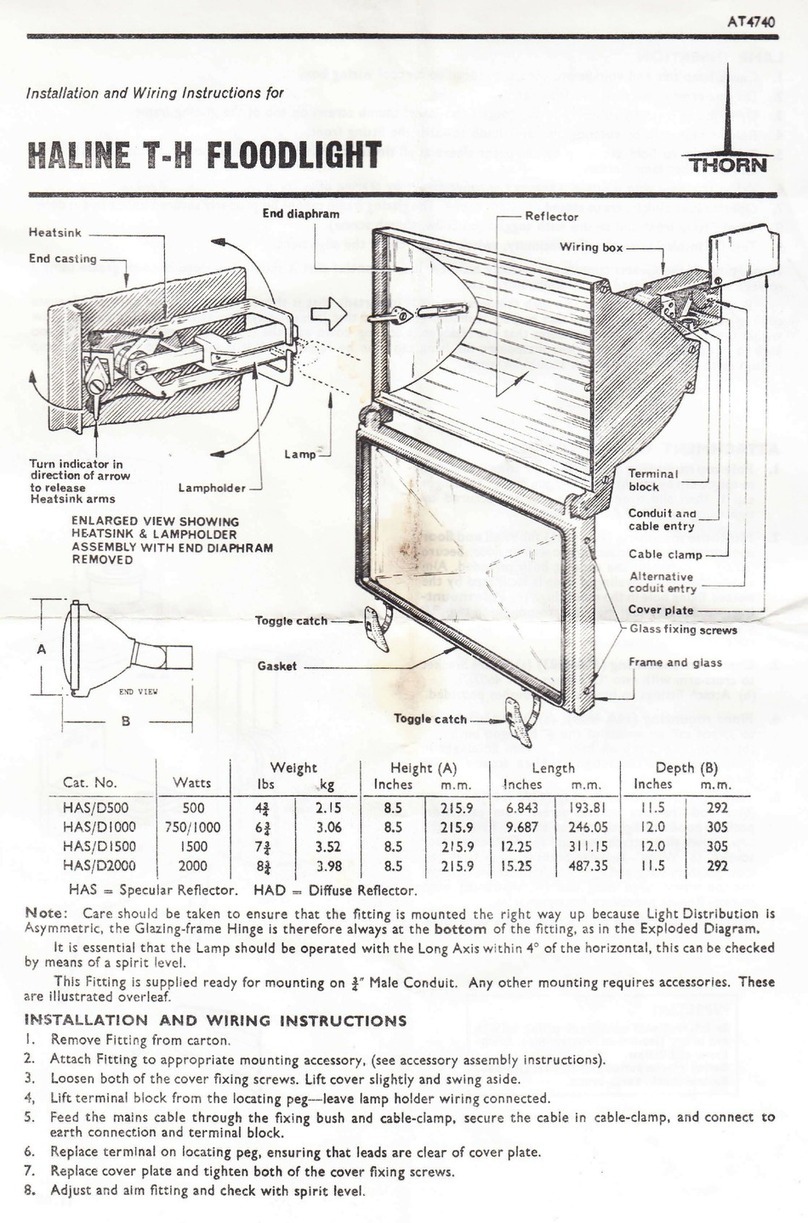

Uses the standard R7s 500w linear halogen lamp.

Small size and weight.

Sturdy design.

High efficiency.

Easy access to all components.

Easy installation: mechanical installation and electrical connections are easy to

carry out.

The adjustable light beam is based on a fixation system (Fixation Stirrup and

fixation Holes).

Easy maintenance; replacement of a defective lamp is easy.

Can be equipped of an optional PRT G3 Louver.

SAFETY INSTRUCTIONS1.1 Make sure you read this section and are familiar with safety precautions before any

work is started.

1.1.1. Product Safety

Airfield lighting fixtures in a constant current circuits are connected in a circuit via

isolating transformers with currents between 2.0 –6.6A in the primary circuits.. The

primary voltages, depending on the circuitry, are usually several kilovolts and

therefore lethal. Although the open circuit voltages of the isolating transformers are

much lower, the peak voltage while opening the secondary circuit under current is

also hazardous. So it is vitally important to follow all the safety regulations with

adequate circumspection.

In the design of this equipment all the practical safety aspects have been taken into

account. It is also important to strictly follow existing international or national

regulations, the instructions established by civil aviation authority or airport operator

and the following instructions.

1.1.2. Electrical Maintenance

Valid safety regulations must always be followed. Never carry out any maintenance or

maintenance measures before the current is confirmed as safely disconnected. Use

extreme caution when disconnecting or connecting high voltage primary connectors.

WARNING! PRIOR TO THE COMMENCEMENT OF WORK ALL ELECTRICAL

SERVICES MUST BE ISOLATED FROM THE SUPPLY AND CONNECTED TO

EARTH. FULL DETAILS OF THE WORK INVOLVED MUST BE GIVEN TO THE

AUTHORISED PERSON RESPONSIBLE FOR THE ELECTRICAL ENGINEERING

SERVICES AT THE AIRPORT WITH REGARD TO THE DURATION OF THE WORK

AND SO ON. IT IS RECOMMENDED THAT PRIOR TO STARTING ANY CUTTING

WORK, THE NATURE AND LOCATION OF SERVICES SUCH AS CABLE DUCTS