Thunder Laser NOVA-51 User manual

THUNDER LASER NOVA-51

www.thunderlaser.com DONGGUAN THUNDER LASER EQUIPMENT CO.,LTD

Tel :(86)769 826653 Dongguan, Guangdong, China

2

Introduction

This manual has been designated as the thunder laser systems, laser cutting

machine installation and user guide;The manual is divided into five chapters,

Including general information instructions, safety instructions, the key

components of every laser cutting systems and the installation steps, operation

instructions and maintenance instructions from THUNDERLASER Company.

Frist, it should be emphasized that the installation of each system must meet

the requirements, and make it consistent with the installation requirements of

THUNDERLASER. If not, the machine will not working properly,poor performance,

life shortened,maintenance costs increased and even machine damage .

The note is for getting a specific requirement of system installation,and we

hope every customer try to understand these notes before installation and usage,

thus you can correctly install and use. If you meet any installation problems,

you can contact our technical staff and customer service staff.(At the same time,

you can also refer to the machine installation video that we posted on youtube.

The specific URL is

http://www.thunderlaser.com/how-to-use-your-laser-machine/how-to-setup-your-nova-las

er-cutter.html Or

https://www.youtube.com/watch?v=NpLo1L0NQx8&list=PLjSZrgjcrhs7QucNN-3jx7rZapDGfj

G-5 .)

THUNDER LASER NOVA-51

www.thunderlaser.com DONGGUAN THUNDER LASER EQUIPMENT CO.,LTD

Tel :(86)769 826653 Dongguan, Guangdong, China

3

Contents

Chapter1 General..................................................................................................................................5

1.1 General Information ......................................................................................................................5

1.2 Designated ....................................................................................................................................6

1.3 Disposal remarks ..........................................................................................................................6

1.4 Technical Data/Device Specification ............................................................................................7

1.5 Manufacturer’s Label ....................................................................................................................9

Chapter 2 Safety..................................................................................................................................10

2.1 General Safety Information ......................................................................................................10

2.2 Laser Safety Information ..........................................................................................................12

2.3 Safety Precautions When Operating the Device .......................................................................13

2.4 Warning and Information Labels ................................................................................................14

Chapter 3 Process of Installing ........................................................................................................16

3.1 Unpacking ...................................................................................................................................16

3.2 Location........................................................................................................................................17

3.3 Before Installaion ........................................................................................................................18

3.4 Exhaust System - Requirements...................................................................................................20

3.5 Air System - Requirements...........................................................................................................20

3.6 Computer - Requirements.............................................................................................................21

3.7 Connections..................................................................................................................................22

3.7.1 Connecting the Mains..........................................................................................................22

3.7.2 Connecting the Computer....................................................................................................23

3.7.3 Connecting the Exhaust System ..........................................................................................24

3.7.4 Connecting theAir System..................................................................................................26

3.7.5 Connecting the Cooling System ..........................................................................................27

Chapter 4 Operation .........................................................................................................................28

4.1 Machine View .............................................................................................................................28

4.2 ON/OFF Switch ..........................................................................................................................32

4.3 How to use the TL-Timer ...........................................................................................................33

4.4 How to replace the 4 inch laser head and HR laser head ............................................................35

4.5 How to adjust focus distance using manual/auto ........................................................................37

4.6 How to Use the Display ..............................................................................................................40

4.6.1 Function of the Buttons .......................................................................................................40

4.6.2 The Main Interface...............................................................................................................42

4.6.3 Speed Key............................................................................................................................43

4.6.4 Max/Min Power Keys..........................................................................................................43

4.6.5 Set the Layer Parameters .....................................................................................................44

4.6.6 Z/U Key...............................................................................................................................44

4.6.7 Z Move ................................................................................................................................45

4.6.8 U Move................................................................................................................................45

4.6.9Axis Reset+..........................................................................................................................45

4.6.10 Manual Set+.......................................................................................................................46

4.6.11 Laser Set+..........................................................................................................................46

4.6.12 Origin Set...........................................................................................................................47

4.6.13 Set Fact Parameters............................................................................................................48

THUNDER LASER NOVA-51

www.thunderlaser.com DONGGUAN THUNDER LASER EQUIPMENT CO.,LTD

Tel :(86)769 826653 Dongguan, Guangdong, China

4

4.6.14 Def. Fact Parameters..........................................................................................................48

4.6.15Auto Focus.........................................................................................................................48

4.6.16 Language ...........................................................................................................................48

4.6.17 IP Setup..............................................................................................................................49

4.6.18 Diagnoses...........................................................................................................................49

4.6.19 Screen Origin.....................................................................................................................50

4.6.20 File Key .............................................................................................................................51

4.6.21Alarm Information of Display............................................................................................53

4.7 The First Time Running the Laser ..............................................................................................54

4.8 WorkstationArea Indication.........................................................................................................56

4.9 Rotary EngravingAttachment ....................................................................................................57

4.10 For Laser Engraving .................................................................................................................60

Chapter 5 Maintenance ....................................................................................................................61

5.1 Cleaning the Laser Machine .......................................................................................................61

5.2 Cleaning the Optical Parts ..........................................................................................................62

5.2.1 Cleaning the Focus Lens......................................................................................................62

5.2.2 Cleaning the Mirrors ..........................................................................................................64

5.2.3 Cleaning Beam Combiner....................................................................................................66

5.3 Maintain the X/Y/Z Rails ...........................................................................................................67

5.4 Check the Beam Path ..................................................................................................................68

5.5 Change Cooling Water for The Water Chiller...............................................................................69

5.6 Maintenance Plan ........................................................................................................................70

THUNDER LASER NOVA-51

www.thunderlaser.com DONGGUAN THUNDER LASER EQUIPMENT CO.,LTD

Tel :(86)769 826653 Dongguan, Guangdong, China

5

Chapter1 General

1.1 General Information

Caution:

Please read and follow this Operation Manual carefully, before installation

and operation. Damage to persons and/or material can result from not following

individual points of the Operation Manual!

Operation of the system is only permitted with equipment and spare parts

supplied or listed in the spare parts and consumables lists.

Auxiliary equipment must be adjusted to the base machine (any queries to

dealer or manufacturer).

The following symbols are used for easier understanding of the Operation Manual:

Caution: This component is under voltage. In these areas strictly

observe the safety instructions regarding electricity. Care is to be taken

in particular during maintenance and repair work.

Caution: In this area pay attention to the possible dangers of the laser

beam.

Caution: Warning of hand injury

Caution: Indicates the potential for fire danger when operation the

laser. Do operate the laser machine when unattended

Tips: Note or information on individual components of the device that

simplify the use or make it more understandable.

THUNDER LASER NOVA-51

www.thunderlaser.com DONGGUAN THUNDER LASER EQUIPMENT CO.,LTD

Tel :(86)769 826653 Dongguan, Guangdong, China

6

1.2 Designated

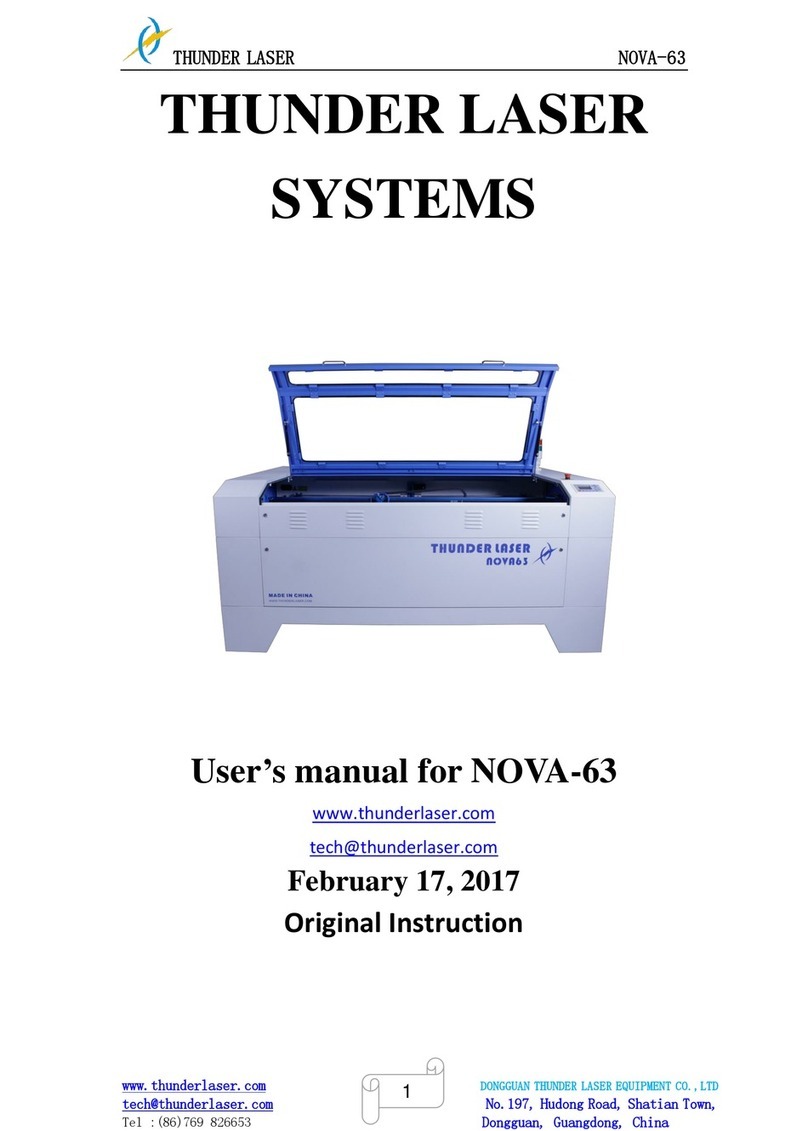

The THUNDER LASER NOVA-51 is used for engraving and cutting of signs, stamps

and suchlike.

A wide variety of materials such as rubber, acrylic, coated metal, tin, special steel,

anodized aluminum, cork, cardboard, glass, leather, marble, several plastics and wood

can be processed on the laser.

1. The engraving process must only be performed with a perfectly adjusted machine.

2. For cutting applications with 100 W the use of the cutting table is absolutely necessary.

3. Use of the system in other areas is against the designated use. The manufacturer does

not admit liability for damage to personal and/or equipment resulting from such use.

4, The system must only be operated, maintained and repaired, by personnel that are

familiar with the designated field of use and the dangers of the machine!

5. Non-observance of the instructions for operation, maintenance and repair described in

this Operation Manual excludes any liability of the manufacturer if a defect occurs.

6. Caution when processing conductive materials (carbon fibers), Conductive dust or

particles in the ambient air might damage electrical components and lead to short circuits.

Bear in mind that those defects are not warranted.

1.3 Disposal remarks

Do not dispose the machine with domestic waste!

Electronic devices have to be disposed according to the regional directives on electronic

and electric waste disposal. In case of further questions, please ask your supplier. He

might take care of proper disposal.

THUNDER LASER NOVA-51

www.thunderlaser.com DONGGUAN THUNDER LASER EQUIPMENT CO.,LTD

Tel :(86)769 826653 Dongguan, Guangdong, China

7

1.1 Technical Data / Device Specification

Mechanics

Working area 51.2“x 35.4“/ 1300 x 900 mm

Table Size 55.1“x 40.6“/ 1400 x 1030 mm

Z Axis Height 9.1 inch / 230 mm

Max. Height of work piece (Motorized Table, Standard laser head) 9.1 inch / 230 mm

Max. Height of work piece (No Motorize Table, Standard Laser head) 1-2.1 inch /27- 55mm

Max. Engraving speed 39 inch/sec. / 1000 mm/sec. Standard

Cutting speed depending on material, thickness, laser power

Motor Easy Servo Motor

Drive Hybrid Servo Drive

Work piece table Solid metal (Honey comb table)

Max. load of work piece table 30 kg

Net Weight 230kgs (507Ibs)

Lenses available (focal distance) 2, 0”

Focus lens diameter 20mm

Reflector diameter 25mm

Beam combiner diameter 25mm

Dimensions

W x D x H 74.8“x 55.3“x 40.9“/ 1900 x 1405 mm x 1040 mm

Max Part Size (W x L x H)

Front Door Closed 55.1“x 40.6“x 10.6“/ 1400 x 1030 mm x 230 mm

Pass-Through Door 55.1“ x∞“x 1.2“/ 1400 x∞mm x 20 mm

Features

Standard:

Red Dot Pointer, Auto Focus, Motorized Table, Pass-Through Door, Air Assist, Water

Pump, Exhaust Fan, Honey Comb Table, 2,0”(50.8mm)Focus Lens, Easily Adjustable

Home Position, LCD Display, 3D Engraving, “No Water “protection, Emergency Stop,

Maintenance mode, Open cover protection, TL-Timer, The warning light.

Optional:

RotaryAttachment,Water Chiller Attachment, High Resolution head (up to 1000DPI, while

standard laser head Max is 500DPI), High air compressor set (Includes water filter).

Control System

Laser power Adjustable from 2 - 70% (typically 12-70%)

Interface Hardware USB: connect to PC and U-disk

Ethernet: connect to PC

Interface Software RDWorksV8

Operating Modes Optimized raster, vector, and combined mode

Buffer Memory 128 MB Standards

THUNDER LASER NOVA-51

www.thunderlaser.com DONGGUAN THUNDER LASER EQUIPMENT CO.,LTD

Tel :(86)769 826653 Dongguan, Guangdong, China

8

Laser Equipment

Laser Type Sealed CO2 Glass Laser Tube

Laser Power: 80W, 100W, 130W, 150W

Wavelength 10, 6µm

Red dot pointer Laser Power< 5mW

Wavelength 630nm –680nm

Cooling System

Air Cooling System Air-Cooled

Water Cooling System Water Cooled

Electricity, Power, Fuse

Electricity Requirement 110 to 240 volts, 50 or 60 Hz, Single phase

Power consumption 1400W (Assembly 80Watt Laser Tube)

1500W (Assembly 100Watt Laser Tube)

1700W (Assembly 130Watt Laser Tube)

1700W (Assembly 150Watt Laser Tube)

Recommended fuse 15A, 230V (80W/100W Laser Tube)

20A, 115V (80W/100W Laser Tube) and 20A, 230V (130W Laser Tube)

25A, 115V (130W Laser Tube)

Ambient Conditions

Ambient temperature +15°C to +25°C / 59°F to 77°F

Humidity 40% to max. 70%, not condensing

Laser Safety

Laser class CDRH Laser Safety

Laser Class 2(H)

CE compliant FDAapproved

THUNDER LASER NOVA-51

www.thunderlaser.com DONGGUAN THUNDER LASER EQUIPMENT CO.,LTD

Tel :(86)769 826653 Dongguan, Guangdong, China

9

1.2 Manufacturer's Label

The manufacturer's label is located on the back of the device (see Figure below).

It is recommended to enter data such as serial number and year of manufacture into the

Manufacturer label below so that you always have this data handy if you have problems

with your device or require spare parts.

THUNDER LASER NOVA-51

www.thunderlaser.com DONGGUAN THUNDER LASER EQUIPMENT CO.,LTD

Tel :(86)769 826653 Dongguan, Guangdong, China

10

Chapter 2 Safety

2.1 General Safety Information

All personnel involved in installation, set-up, operation maintenance and repair of the

machine, must have read and understood the Operation Manual and in particular the

"Safety" section. The user is recommended to generate company-internal instructions

considering the professional qualifications of the personnel employed in each case, and

the receipt of the instruction/Operation Manual or the participation at introduction/training

should be acknowledged in writing in each case.

Safety-conscious of Working

The machine must only be operated by trained and authorized personnel.

The scopes of competence for the different activities in the scope of operating the

machine must be clearly defined and observed, so that under the aspect of safety no

unclear questions of competence occur. This applies in particular to activities on the

electric equipment, which must only be performed by special experts.

For all activities concerning installation, set-up, start-up, operation, modifications of

conditions and methods of operation, maintenance, inspection and repair, the switch-off

procedures that may be provided in the Operation Manual must be observed.

Safety Information for the User and/or Operating Personnel

1. No working methods are permitted that affect the safety of the machine.

2. The operator must also ensure that no unauthorized persons work with the machine

(e.g. by activating equipment without authorization).

3. It is the duty of the operator, to check the machine before start of work for externally

visible damage and defects, and to immediately report changes that appear (including

behavior during operation) that affect the safety.

4. The user must provide that the machine is only operated in perfect condition.

5. The user must guarantee the cleanness and accessibility at and around the machine

by corresponding instructions and controls.

6. Principally, no safety components may be removed or disabled (already here we

emphasize the imminent dangers, for example severe burns, loss of eye-sight). If the

removal of safety components is required during repair and service, the replacement

of the safety components must be performed immediately after completion of the

service and repair activities.

7. Preparation, retooling, change of work piece, maintenance and repair activities must

only performed with equipment switched off, by trained personnel.

THUNDER LASER NOVA-51

www.thunderlaser.com DONGGUAN THUNDER LASER EQUIPMENT CO.,LTD

Tel :(86)769 826653 Dongguan, Guangdong, China

11

8. It is forbidden to perform unauthorized modifications and changes to the machine. It is

emphasized, that any unauthorized modifications to the machine are not permitted for

safety reasons.

THUNDER LASER NOVA-51

www.thunderlaser.com DONGGUAN THUNDER LASER EQUIPMENT CO.,LTD

Tel :(86)769 826653 Dongguan, Guangdong, China

12

2.2 Laser Safety Information

1. To assess the potential dangers laser systems pose, they are classified into

2 safety classes, thunder laser NOVA-51 is a device of class 2. This is guaranteed by the

protective housing and the safety installations.

Please note that improper and warranty operation of the device can override the status of

Safety class 2 and can cause the emission of harmful radiation.

2. This laser engraving system contains a carbon dioxide (CO2) laser of class 2

that emits intensive and invisible laser radiation. Without safety precautions

the direct radiation or even diffuse reflected radiation is dangerous!

3.Without safety precautions, the following risks exist with exposure to laser radiation:

Eyes: Burns to the cornea

Skin: Burns

Clothing: Danger of fire

4. Never try to modify or disassemble the laser and do not try to start up a system that had

been modified or disassembled!

5. Dangerous radiation exposure can result from the use of operation or adjustment

equipment other than that described here, and if different operational methods are

performed.

THUNDER LASER NOVA-51

www.thunderlaser.com DONGGUAN THUNDER LASER EQUIPMENT CO.,LTD

Tel :(86)769 826653 Dongguan, Guangdong, China

13

2.3 Safety Precautions when Operating the Device

In your thunder laser NOVA-51, a closed safety system is integrated which immediately

stop a job when the protection cover is opened. Consequently an incomplete engraving

can occur if the cover is opened during operation. Therefore, first press the "PAUSE"

button, if you want to interrupt an engraving process.

Please remember the following safety precautions when working with this device:

CO2 Fire extinguishers should be placed near laser

Do not store any flammable materials in the inside of the device. Particularly leftovers of

produced materials have to be removed to prevent fire hazard.

Please maintain Free air-flow surrounding this system. At all times, do not cover during

operation.

These lasers emit invisible radiation; safety glasses should be worn when maintenance

these machines for your protection.

Do not disable limit switches or safety features as this can invalidate warranties and cause

damage to you and the machine.

Do not leave the laser unattended when it is working, small scraps can ignite and without

supervision can destroy the machine if not checked.

Adjustment of the beam path must be performed only by especially trained personnel.An

improper setting can lead to uncontrolled emission of the laser radiation.

Before processing materials the user must verify, whether harmful materials can be

generated and whether the filter equipment of the exhaust system is suitable for the

harmful materials. We emphasize that it is the responsibility of the user, to consider the

national and regional threshold values for dust, fogs and gases when selecting the filters

and the exhaust system. (The values for the maximum workplace concentration must not

be exceeded.)

PVC (polyvinyl chloride) must under no circumstances be processed with the laser.

Should you have further questions before starting work, please feel free to write us

an email at: tech@thunderlaser.com

THUNDER LASER NOVA-51

www.thunderlaser.com DONGGUAN THUNDER LASER EQUIPMENT CO.,LTD

Tel :(86)769 826653 Dongguan, Guangdong, China

14

2.4 Warning and Information Labels

The warning and information labels are attached in such positions of the device that could

represent a source of danger during set-up and operation. Therefore, follow the

information on the labels. If labels are lost or damaged, they must be replaced

immediately.

THUNDER LASER NOVA-51

www.thunderlaser.com DONGGUAN THUNDER LASER EQUIPMENT CO.,LTD

Tel :(86)769 826653 Dongguan, Guangdong, China

15

THUNDER LASER NOVA-51

www.thunderlaser.com DONGGUAN THUNDER LASER EQUIPMENT CO.,LTD

Tel :(86)769 826653 Dongguan, Guangdong, China

16

Chapter 3 Process of Installing

3.1 Unpacking

You receive your THUNDER LASER NOVA-51 packed in a wooden box, which contains

the laser machine and additional accessories. The following steps give you an overview of

the unpacking and assembly of the laser. Please follow these steps carefully.

Tips: Keep the packing box. You will require it in case of a return.

Dispose all waste according to the applicable waste disposal law.

1. Put the wooden box on a flat and spacious room for unpacking.

2. Remove the machine box; carefully remove the foam material, which protects the

viewing window of the cover and around the machine.

3. Take out the key,open the door of the laser,Remove the accessories box which

contains all accessory parts required for the installation of the laser machine.

And check if there’s anything damaged or missed during shipping.

4. You will see an attachment table on the machine; please check whether the

accessories are all on the table.

5. Please keep the keys and the warranty certificate well (and please show us your

warranty certificate if you need tech support for the machine failure, then we will provide

you the best technical service).

6. Remove the sponge and nylon cable ties from inside the machine, and then start to

install the machine (below chapters are installation details)

THUNDER LASER NOVA-51

www.thunderlaser.com DONGGUAN THUNDER LASER EQUIPMENT CO.,LTD

Tel :(86)769 826653 Dongguan, Guangdong, China

17

3.2 Location

Before you install the laser system, you should select an appropriate location. Follow the

guidelines shown below:

1. Avoid locations where the system is exposed to high temperatures, dust and high

humidity. (The humidity must not exceed 70% and the temperature must not be close

to the dew point.)

2. Avoid locations, where the system is exposed to mechanical shocks.

1. Fuse protection:

Do not connect other devices via the laser fuse, as the laser system requires the full

amperage.

Tips:

1. Avoid locations with poor air circulation; select a location close to ventilation (if

available).

2. Select a location, whose room temperature is between 15 °C and 25 °C (59°–77°F).

This is fundamental to maintain consistent and reliable operation of a CO2 laser, Metal

RF or Glass tube and the machine itself.

Avoid higher ambient temperatures and strong exposure of the engraver to the sun.

Use blinds, if required.

3. Mechanical shock and vibration of the laser will have detrimental effects on the

performance and life expectancy of the machine. It will manifest (over a period of time)

with a noticeable decrease in performance and increased maintenance required,

possibly even damage. Setting your Thunder Laser up in s suitable temperature

controlled, dust free, moisture free, level, stable surface (a level concrete floor) with

the recommended extraction is critical to the ongoing performance of the machine. It

is also a warranty condition.

THUNDER LASER NOVA-51

www.thunderlaser.com DONGGUAN THUNDER LASER EQUIPMENT CO.,LTD

Tel :(86)769 826653 Dongguan, Guangdong, China

18

3.3 Before Installation

1. Take out the sponge around the laser tube. Like below:

2. Take out the nylon cable ties around the honey comb plate and X axis.

Remove the transparent bag out of the first mirror mounts, the second mirror

mounts, the third mirror mounts and the standard laser head. Like below:

PS: The lid with a set of key and a manual focusing tool for users

THUNDER LASER NOVA-51

www.thunderlaser.com DONGGUAN THUNDER LASER EQUIPMENT CO.,LTD

Tel :(86)769 826653 Dongguan, Guangdong, China

19

3. Open the emergency switch (must do it for the first time to use the machine).

Like below

4. After carried the machine into room, please re-fix the foot of the four corners.

Please refer to below shown:

THUNDER LASER NOVA-51

www.thunderlaser.com DONGGUAN THUNDER LASER EQUIPMENT CO.,LTD

Tel :(86)769 826653 Dongguan, Guangdong, China

20

3.4 Exhaust System –Requirements

To guarantee the right ventilation during the engraving and the cutting. The device must

be equipped with a fine exhaust fan(generation of rubber dust), if you use an carbon filter

(neutralization of smells) will be better for exhaust effect. A good exhaust fan of the

outgoing air is also required when cutting plastics or engraving wood.

Connection - see section 3.7.3 connecting the Exhaust System.

Do not start the machine without an adequate exhaust system.

3.5 Air System –Requirements

To guarantee do not catch file and too much smoke during the engraving and the cutting.

The device must be connecting with the laser to make sure the laser is safe during the

work.

Table of contents

Other Thunder Laser Cutter manuals