Shannon HRT 65 User manual

User’s Guide

English

Plastic bending machine

HRT 65 - 125

User’s Guide

HRT 65-125

-1-

hs

User’s Guide

Plastic bending machine

HRT 65-125

2013 SHANNON BV. All rights reserved.

No part of this User's Guide may be photocopied, altered or

translated without prior written consent.

Information contained in this User's Guide is subject to

change without notice

User’s Guide

HRT 65-125

-2-

hs

Contents

Contents 2

Introduction 3

1 Description of the machine 4

2 Technical data 5

3 Safety 6

4 Legend 7

4.1View 7

4.2Control units 7

5 Installation 8

5.1Assembly 8

5.2Connecting main voltage 8

6 Operation 9

6.1Preparation 9

6.2Switching on heating elements 9

6.3Setting temperature 9

7 Adjustment 10

7.1Safety precautions 10

7.2Heating element 10

7.3Filament height 11

7.4Stop 12

8 Maintenance 13

8.1Safety precautions 13

8.2Profiles 13

9 Tensioning and changing filament 14

9.1Safety precautions 14

9.2Tensioning 14

9.3Changing the filament 15

10 Fuses 17

10.1 Safety precautions 17

10.2 Control unit fuse 17

Annexes 18

A Options 18

Accessories 19

Equipment 19

B Service and warranty 21

User’s Guide

HRT 65-125

-3-

hs

Introduction

Congratulations on purchasing Shannon’s plastic bending

machine HRT 65-125. Read this guide completely before

installing and using the machine.

We want to keep in contact and to know how you find the

HRT 65-125. We are always willing to advise on the use of

the machine and its accessories.

SHANNON BV

Turfschipper 11-13

2292 JC Wateringen

P.O. box 84

2290 AB WATERINGEN

the Netherlands (EC)

Tel: +31 (0)174-225240

Fax: +31 (0)174-225249

Website: www.shannon.nl

User’s Guide

HRT 65-125

-4-

hs

Description of the machine

The Shannon HRT bending machine is a rapidly convertible

machine for the production of large series of items with

multiple bends for the plastic sheet processing industry.

The machine has two adjustable heating elements as

standard. The temperature of which can be adjusted

independently by electronic controls.

The filaments of the heating elements on the working

surface are adjustable in height.

The workpiece can be heated from one side and it is

possible to bend sheet up to 5 mm thick.

The working surface is made of scratch-resistant solid

core material with which the space between the zones to

be heated can be filled to support the plastic sheet.

When heated, thermoplastics become so flexible that they

can be shaped. When a plastic sheet is heated to its

softening point in a narrow zone, if can be bent to any angle

desired.

The bending radius is determined by the width of the heated

zone. The zone is determined by the thickness of the

material, the type of heating element and the distance

between the plastic and the filament.

Every plastic has its specific softening point. By coordinating

the temperature, heated zone and the heating time all kinds

of thermoplastic can be processed.

1

User’s Guide

HRT 65-125

-5-

hs

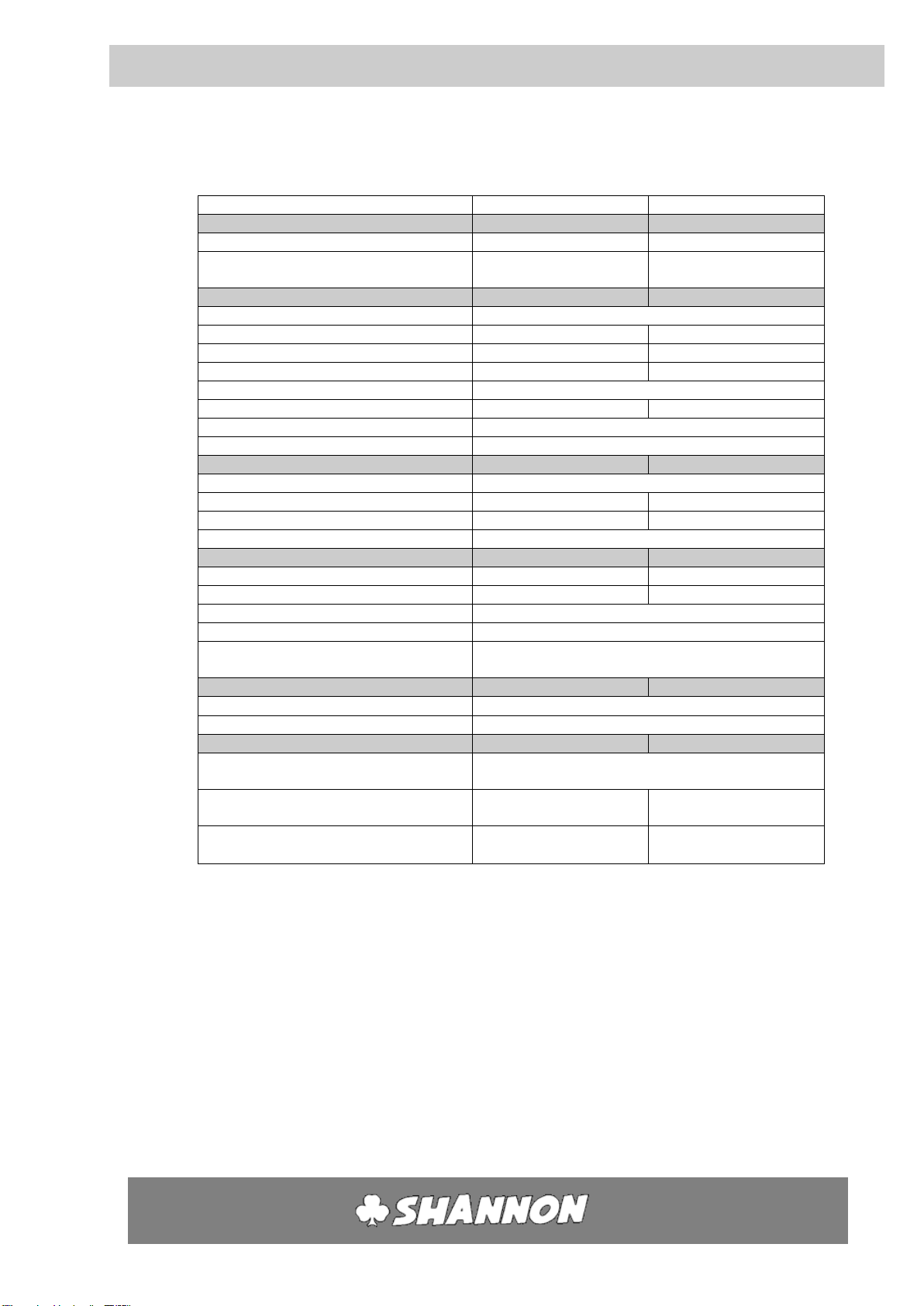

Technische Daten

type

HRT 65

HRT 125

Assembly

Control unit

Max.

2

4

Heating element

Max

2, fitted with single

filament

4, fitted with single

filament

Electrical

Control unit

Voltage

220 –240 V AC

Power

300 VA

500 VA

Fuse

2,5 AT x2

5 AT x2

max. power:

600VA

2000 VA

connection

CEE 7/4 16A 2P+A

Filament

0-17 V, 0-13 A ~

0-30 V, 0-13 A ~

Network connection

CEE 7/4 16A 2P+A

Network circuit breaker

16 A

Mechanical

Gradation of stop

0-640 mm

dimensions

[LxWxH]

835 x 680 x 160 mm

1470 x 850 x 160 mm

weight

40 Kg

60 kg**

Lifetime filament

±500 hours

Functional

Bending width

600 mm

1250 mm

Mutually extendible*

20-465 mm

20 - 610 mm

Sheet thickness*

1 - 5 mm

Temperature filament

Max

20-550 ◦C

Filament height

adjustment

1 - 6 mm

Ambient

Temperature

18-30 C

Humidity of the air

50-80 % (no condensed)

Miscellaneous

set of socket screws

keys

1 set [1½, 3, 5 mm]

Spare fuse

4 x [6.3x32 2,5 AT]

each controller

4 x [6.3x32 5 AT] each

controller

Spare filament

1 x [0.9 x 750 mm]

per element

1 x [0.9 x 1350 mm]

per element

* Depends on the heating element

** Depends on the amount of controllers

2

User’s Guide

HRT 65-125

-6-

hs

Safety

To ensure sfety when using the machine you should erad

this User’s guide carefully and follow the safety instructions

closely.

Attention!

The machine contains parts which are hot. Touching

them will cause burns.

Allow hot parts to cool sufficiently (at least 10 minutes)

before touching them.

Never touch the filaments or the reflectors when the

machine is in operation.

Always wear close fitting clothing.

Be particularly careful of sleeves and always tie back long

hair.

The machine may only be used for heating narrow

zones in flat plastic sheets. Any other use could lead to

very hazardous situations or cause damage to the machine!

The plastic sheets that have to be bent may never be

thicker than 5 mm.

Before commissioning and servicing, always check the

connection cable and plug for defects.

When servicing, switch off the machine and remove the

plug from the socket.

Only switch on those heating elements which are

needed.

Never leave the machine unattended without switching

it off.

3

User’s Guide

HRT 65-125

-7-

hs

Legend

4.1 VIEW

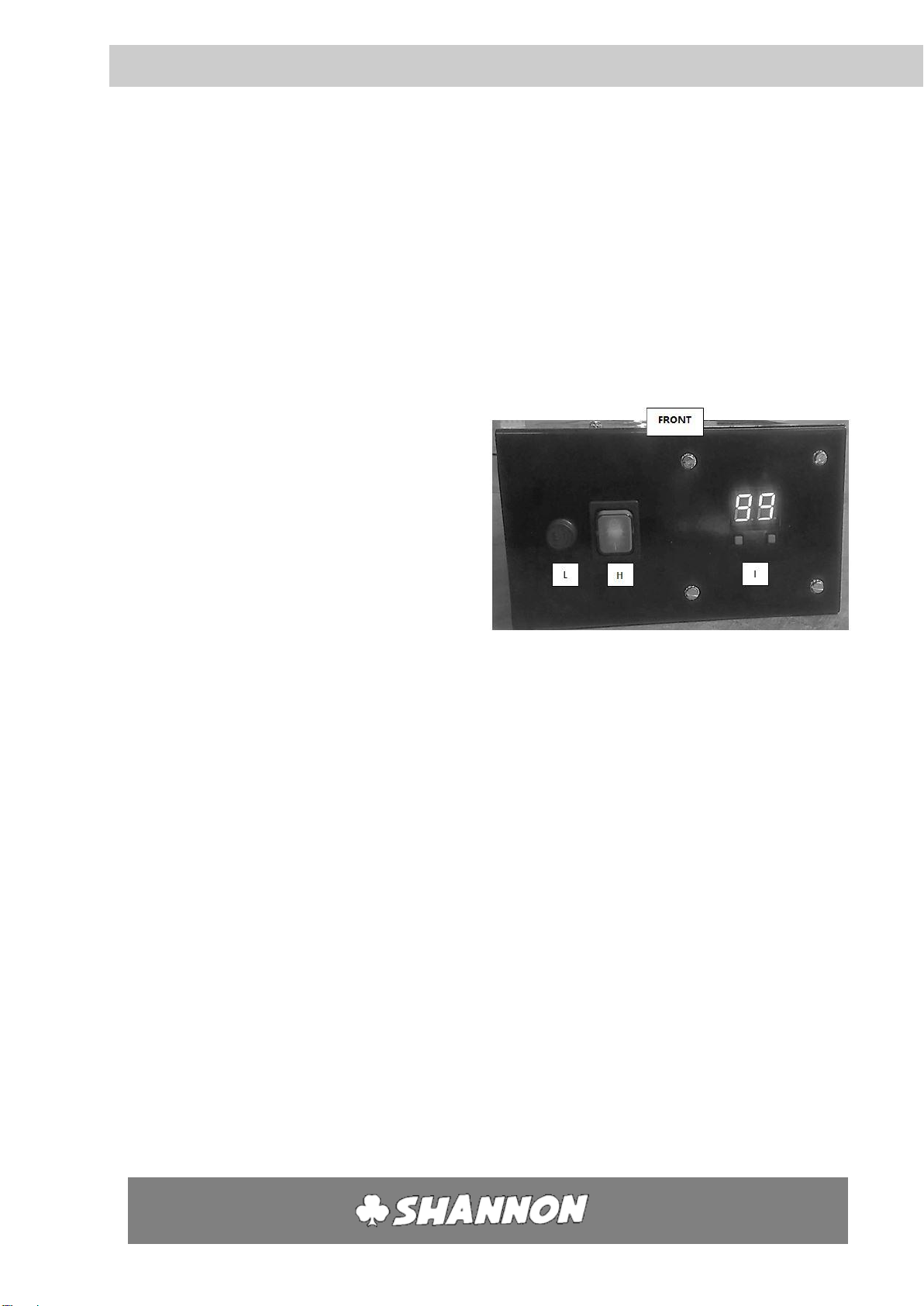

4.2 CONTROL UNITS

The control units contain an electronic

control with which the temperature of a

filament is set.

HSwitch on/off

ITemperature setting

J Connection to filaments

K Connection to 220 V AC

LFuseholder

4

User’s Guide

HRT 65-125

-8-

hs

Installation

5.1 ASSEMBLY

1. Place the machine on a level floor with sufficient space around and

above the machine.

2. Ensure that there is adequate ventilation and lighting at the workplace.

3. Avoid draughts, in order to prevent uneven heating.

5.2 CONNECTING MAIN VOLTAGE

1. Check that all switched of the control units are in the 0-position

(Switch H).

2. Put the plug into the socket

5

User’s Guide

HRT 65-125

-9-

hs

Operation

6.1 PREPARATION

1. Clear the working surface.

2. Check that all the heating elements are connected to the control units.

3. Check that no scraps of material remain in the reflectors.

6.2 SWITCHING ON HEATING ELEMENTS

Each heating element can be switched on and controlled individually.

Switch on the control unit with switch H.

6.3 SETTING TEMPERATURE

The temperature of the filament can be set using the temperature control.

1. When turning on the on/off switch, the display will show the value that

was last saved (keeping the machine on a certain value for >20

seconds will make it remember this value).

2. Press the right button (arrow up) to increase the value, up to 99

(keeping this pressed in will make the value cycle much faster)

3. Press the left button (arrow down) to decrease the value, down to 00

(keeping this pressed in will make the value cycle much faster)

4. Press both buttons at the same time to go directly to 00. Doing this also

resets the machine.

6

User’s Guide

HRT 65-125

-10-

hs

Operation 6

6.4 TROUBLE SHOOTING

Error message

Meaning

Solution

E1

The wire is loose (not connected)

Turn off the machine, check the filament, and reset the

machine

(see §9.1 for changing filament)

Note: Between the values 00 and 04, this fault

cannot be detected

E2

The wire connection is loose

(spark detection)

Check the connection of the filament

Check the filament, and reset the machine

This fault can also be reset by the arrow down button

(see §9.1 for changing filament)

E9

Broken circuit board

Contact the supplier for a new circuit board

Empty display

No power

Alert a maintenance engineer

Check the fuse (see §10.1)

Check the power supply cable

Contact the supplier if necessary

User’s Guide

HRT 65-125

-11-

hs

Adjustment

7.1 SAFETY PRECAUTIONS

Always take the following safety precautions before adjusting the heating

elements:

1. Switch off the heating elements one by one (Switch L).

2. Clear the working surface.

3. Allow the heating elements to cool for at least 10 minutes.

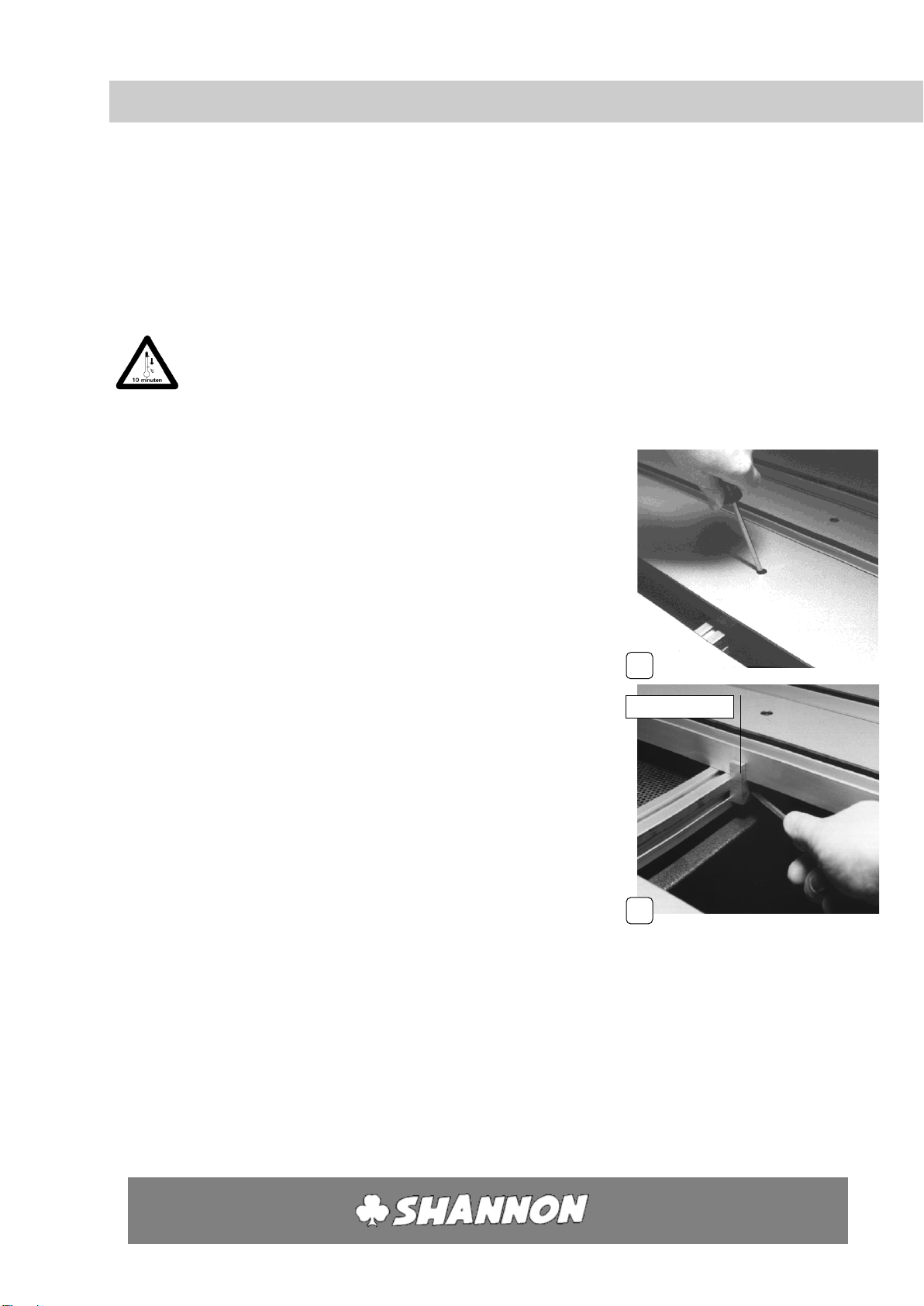

7.2 HEATING ELEMENT

1. Remove the strips of solid core material next to the

heating element to be adjusted by loosening the two

socket head screws (Use socket screw key no. 5).

2. Loosen the socket head screws in the supporting prongs

on the left and right of the heating element one half turn.

7

2

Supporting prong

1

User’s Guide

HRT 65-125

-12-

hs

Adjustment 7

3. Loosen the socket head screw in the centre of the

heating element one half turn (use socket screw key no.

3).

4. Take the heating element with both hands close to the

supporting prongs on the left and right, and slide it into the

desired position.

5. Hold the heating element parallel to the front of the

machine and the supporting prongs. This prevents the

notched nuts in the X-profiles from binding.

6. Hand tighten the socket head screws, starting in the

supporting prongs and then in the centre.

7. Position the other profiles in the same way if necessary.

8. Fill up the space between the heating elements as far as possible with

solid core strips and hand tighten them. First slide the notched nuts into

the aluminium X-profiles, roughly level with the holes and then lay the

solid core strip on top.

9. Switch on the machine again as in section 6.

7.3 FILAMENT HEIGHT

1. Adjust the height of the filament using the knurled nut.

These can be reached from the sides. Make sure that

the filament height is the same on both sides.

2. Start up the machine again as in Section 11.

Knurled nut

1

3

4

User’s Guide

HRT 65-125

-13-

hs

Adjustment 7

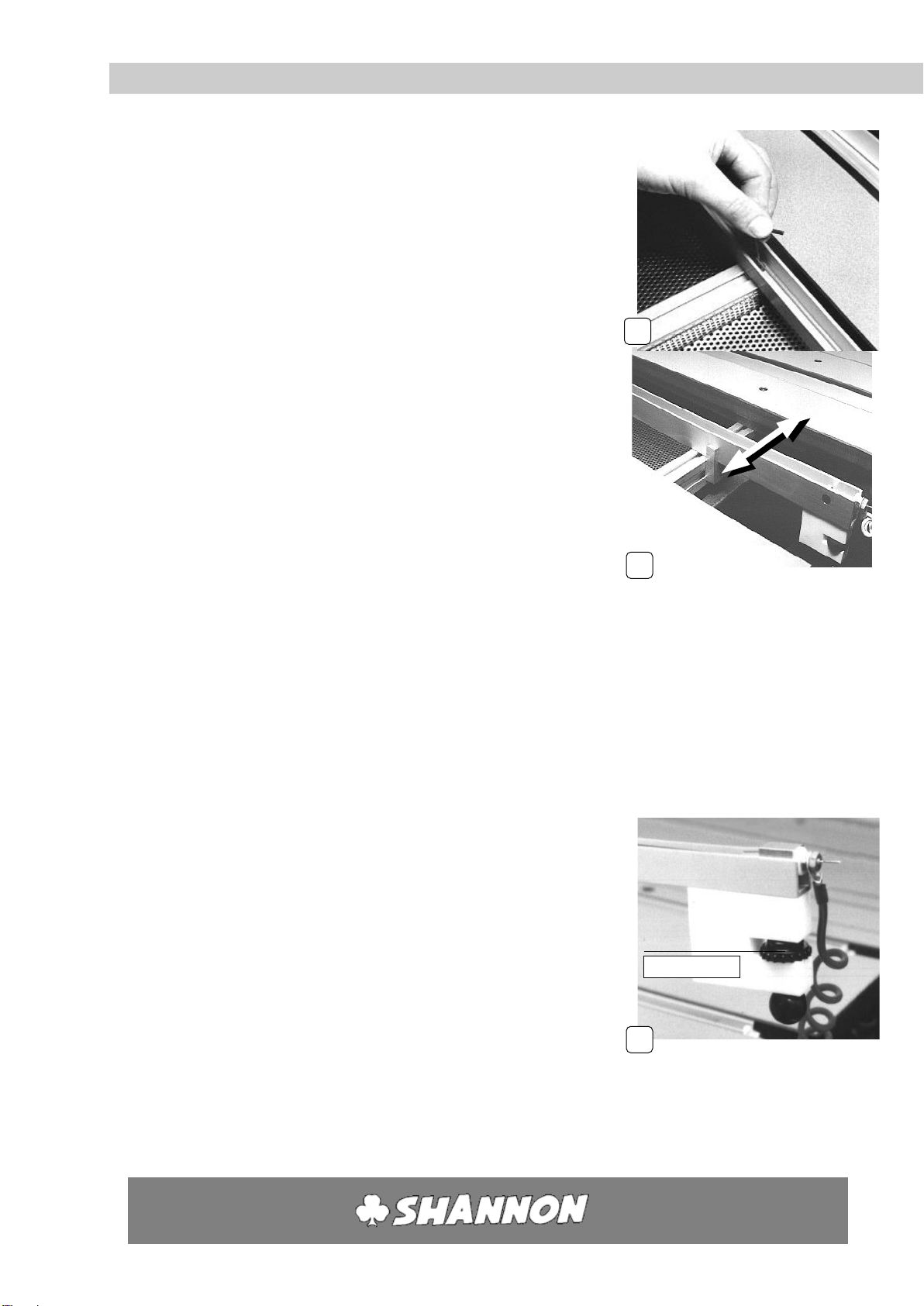

7.4 STOP

1. Loosen both the handles on the stop one half turn.

2. Slide the stop into the desired position.

3. Hold the guide parallel to the front of the machine. This

stops the clamping blocks from binding.

4. Tighten the handles.

5. Pull the handle upwards against the spring pressure, and

turn it outwards.

1

4

Handle

User’s Guide

HRT 65-125

-14-

hs

Maintenance

This machine needs little maintenance. Remove loose dirt once in a while.

8.1 SAFETY PRECAUTIONS

1. Switch of all regulating units (Switch H).

2. Clear the working surface.

3. Remove the plug from the socket.

8.2 PROFILES

The heating elements work more effectively when they are clean. Remove

dirt and deposits from the heating elements regularly. Blow away loose dirt

and brush them clean.

8

User’s Guide

HRT 65-125

-15-

hs

Tensioning and changing filament

9.1 SAFETY PRECAUTIONS

Before tensioning and changing filament always take the following safety

precautions.

1. Clear the working surface.

2. Switch off the control units one at a

time (Switch H).

3. Allow the heating elements to cool for

at least 10 minutes.

9.2 TENSIONING

1. Turn the filament to the lowest

position

2. Hold the end of the wire on the right with pliers, and undo

the screw in the wire pin.

(Use socket screw key No. 1½).

3. Pull the wire taut with pliers and tension the spring.

4. Tighten the socket head screw firmly again.

5. Cut off the end of the filament. Always leave 8-10 mm projecting in

order to be able to tension the filament again.

Attention! The end of the filament is sharp.

9

2

Wire pin

Socket head screw

3

4

User’s Guide

HRT 65-125

-16-

hs

Tensioning and changing filament 9

9.3 CHANGING THE FILAMENT

1. Turn the filament to the lowest position.

2. Unscrew the socket head screw in the wire pon on the

right. (Use socket screw key No. 1½).

3. On the left side, slide the expanding pin with the spring

out of the pin block.

4. Slide the spring off the expanding pin.

5. Unscrew the expanding pin from the connection screw

(incl. connection wire).

6. Remove the filament from the expanding pin and the wire pin.

7. Slide a new filament into the expanding pin, and make

sure that the eye is pulled well into the pin.

8. Screw the expanding pin onto the connection wire (incl.

connection wire), and attach firmly.

Take care not to damage the expanding pin. Tightening firmly by hand is

sufficient.

9. Slide the spring over the filament, and slide the filament through to the

expanding pin.

10. Slide the filament, with expanding pin, through the white insulation

sleeve of the pin block, and pull it through as far as possible.

2

5

Connection wire

Expanding pin

7

Eye

Pin block

User’s Guide

HRT 65-125

-17-

hs

Tensioning and changing filament 9

11. Then insert the socket head screw (use socket screw

key No. 1½).

12. Tighten the socket head screw (use screw key No. 1½).

13. Switch on the machine and the control unit, corresponding to the

replaced filament (switch H). then turn the temperature control (I) to the

highest position (position 99).

14. The filament will then glow red.

Never touch the filaments or the

reflectors when the machine is in

operation.

15. Hold the end of the filament with pliers, and loosen the socket head screw

one turn (use socket screw key No. 1½).

16. Pull the filament taut, and tighten the socket head screw. Check that the

filament is straight. If not, repeat this operation.

11

User’s Guide

HRT 65-125

-18-

hs

Fuses

A maintenance engineer should always be alerted when a fuse blows. Do

not replace the fuse until the short circuit has been corrected.

10.1 SAFETY PRECAUTIONS

Before replacing a fuse, always take the following safety precautions.

1. Clear the working surface.

2. Switch the control units off one by one (switch H).

3. Remove the plug from the socket.

4. Allow the heating elements to cool for at least 10 minutes.

10.2 FUSES CONTROL UNIT

1. Open the fuse holder (L). Push it in slightly, and turn one-quarter to the

left. The fuse will come out.

2. Verify and replace the fuse if necessary, in the reversed order.

N.B. Fuse 6,3x32mm; 2,5 AT 1 pieces per control unit for HRT 65.

N.B. Fuse 6,3x32mm; 5 AT 1 pieces per control unit for HRT 125.

10

User’s Guide

HRT 65-125

-19-

hs

Annex

OPTIONS

Additional heating elements can easily be fitted to the machine, both at the

top and the bottom. All extensions and accessories are easy for the

customer to mount and connect. Non-standard sizes and quantities on

request.

Control units

Maximum two controllers for an HRT 65

Maximum four controllers for an HRT 125

Heating elements

Heating elements are available in a variety of widths and with 1 or 2

filaments.

Heating elements with 2 filaments are suitable for heating wide zones, and

for obtaining a large radius.

Maximum two heating elements for the HRT 65.

Maximum four heating elements for the HRT 125.

Number of filaments per heating

element

Profile width

1 filament

15 mm

30 mm

2 filaments

30 mm

All heating elements are provided with fastening material and connecting

cables.

Service contract

Shannon offers you an opportunity to take out a service contract. Let us tell

you about it.

Spare parts

Part

HRT 65

HRT 125

Filament

0,9 x 750mm

0,9 x 1350mm

Fuse

2,5 AT

5 AT

Wise tensioning set

0.9 mm

A

This manual suits for next models

1

Table of contents

Other Shannon Cutter manuals

Shannon

Shannon ABM-D 135 User manual

Shannon

Shannon HRP/D User manual

Shannon

Shannon HRT/D 300 User manual

Shannon

Shannon HRK 65 User manual

Shannon

Shannon HRT 220 User manual

Shannon

Shannon HRP/S User manual

Shannon

Shannon HR 220-300 User manual

Shannon

Shannon HRP 220 User manual

Shannon

Shannon AFF/D 135 User manual