Ti-Research Cast User manual

March 2004

T

i

-

Research

Cast Product Information

2

T

i

-

Research

TABLE OF CONTENTS

LIST OF PARTS ........................................................................ 4

Specifications ........................................................................................... 5

Used symbols and their meaning................................................................ 5

PRINCIPLE OF OPERATION ..................................................... 6

SAFETY INSTRUCTIONS........................................................... 7

Intended Use............................................................................................ 7

Electrical Safety......................................................................................... 7

Safe Operation......................................................................................... 7

INSTALLATION AND FIRST OPERATION.................................... 8

Unpacking ............................................................................................... 8

Installation ............................................................................................... 8

First Operation ....................................................................................... 10

Conversion of the Device for large Moulds................................................ 11

PRODUCTION OF CASTINGS ............................................... 12

Sprueing ................................................................................................ 12

Invest..................................................................................................... 13

Preheating.............................................................................................. 14

Casting.................................................................................................. 14

Devesting............................................................................................... 16

MAINTENANCE AND SERVICING........................................... 17

Maintenance .......................................................................................... 17

Servicing and Cleaning ........................................................................... 17

PROBLEMS AND SOLUTIONS ................................................ 18

CONSUMABLES, SPARE PARTS AND ACCESSORIES................. 19

3

T

i

-

Research

ANNEX I: CORRECT SPRUEING...............................................20

The Waxdisk ...........................................................................................20

Fixing of Sprues to the Waxdisk.................................................................20

Positioning of Models in the Mould ...........................................................21

ANNEX II: HINTS FOR PROPER MELTING.................................23

4

T

i

-

Research List of Parts

1cabinet 9mould pliers

2top lid 10 wax disks

3lever 11 crucible

4power switch 12 crucible holder

5power cord 13 crucible holder handle

6metal ring, large 14 mounting screw M4 x 6mm

7metal ring, small 15 wrench 3mm, 5mm

8mould socket 16 3 screws M6 x 10mm

5

T

i

-

Research

Specifications

Dimensions

diameter: 170 mm

height: 270 / 320 mm

weight: 8,5 kg

Power

EU US

voltage: 230 V 115 V

frequency: 50 Hz 60 Hz

power consumption: 30 W 40 W

rotation speed: 930 min-1 850 min-1

Environment

temperature range 5 °C - 40 °C

rel. humidity 90 % @ 20 °C

Used symbols and their meaning

Attention!

hot surface

Caution!

dangerous electrical voltage

open lid

close lid

The type plate with serial number and CE-sign is on the rear side of the device.

6

T

i

-

Research Principle of Operation

Cast made by Ti-Research is a centrifugal casting device for the production

of precision castings. The device is suitable for all kinds of castable materials.

The scope of usage reaches from technical products for further processing,

jewelry and dental appliances.

For the production of castings made of metal, precious and non-precious

alloys may be used. The device is designed for melting of metals by flame with

a suitable torch which provides the best means for controlling the melting

process.

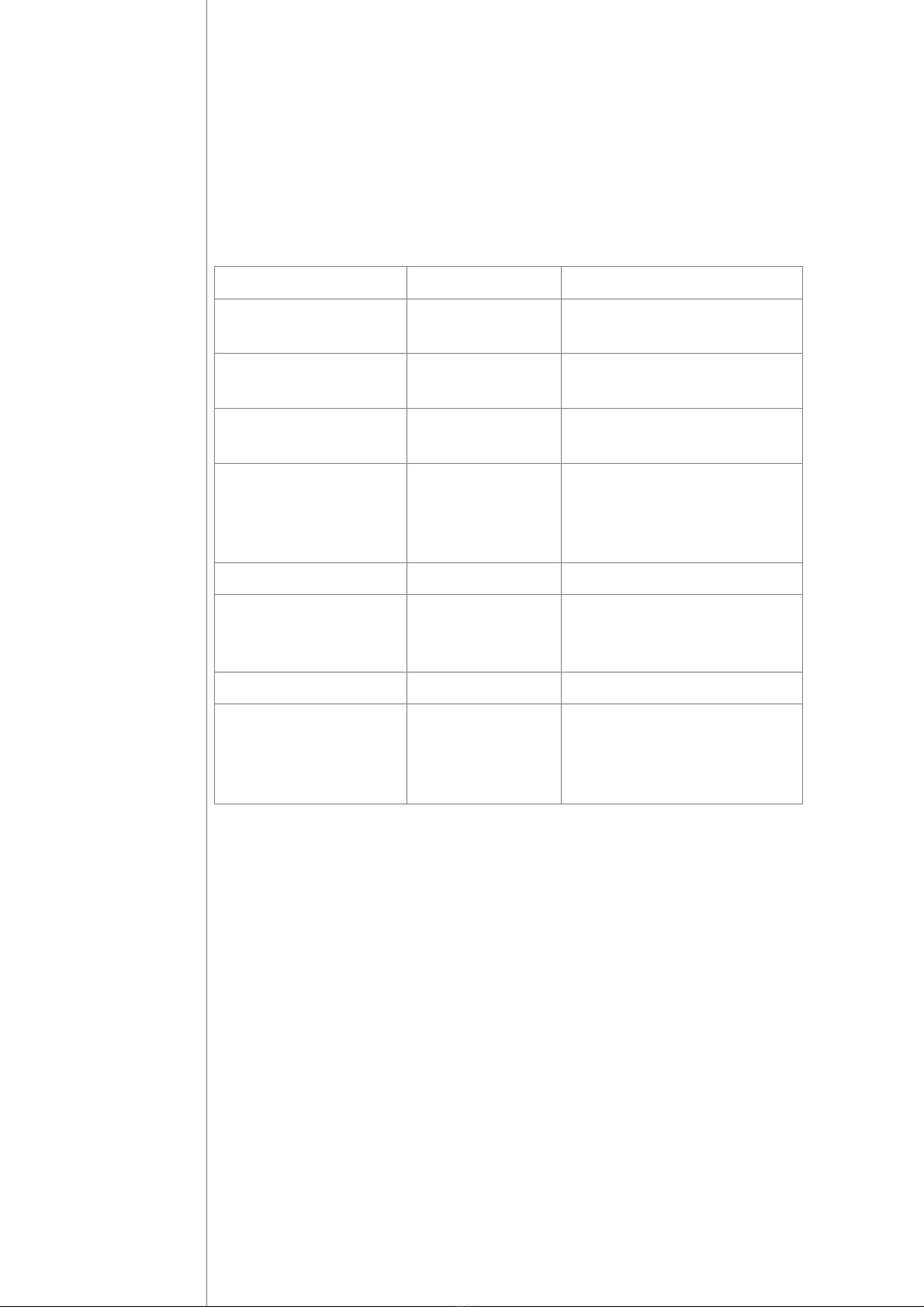

With a small and a large metal ring for different sizes of moulds various sizes of

parts or different numbers of castings may be produced. For the casting of

dental parts, for example 40 and more crowns and/or bridge elements may be

produced with a mould in the small ring and three or more partials may be

casted with a mould in the large ring in one cast.

The operation of Cast is based on a patented process where balancing of the

rotating part is not necessary. Despite of the extraordinary small dimensions the

device allows the production of more parts in one process than any other

competitors‘ dental casting device today available on the market.

Cast is distinguished by ease of use and the extraordinary small size and is the

first choice for locations with limited workspace.

The device comprises of a special safety mechanism to protect the user by

activating a mechanical brake while opening the top lid and switching off the

power to protect from accidental restart.

The device meets all applicable safety standards. Nevertheless care has to be

taken to prevent dangerous situations during operation.

For safe operation of the device, this instruction manual is to be read

prior to the first usage and the instructions given here are to be obeyed.

7

T

i

-

Research

Safety Instructions

For safe operation the following instructions are mandatory:

Intended Use

The usage of Cast by Ti-Research is intended for the production of castings

with the centrifugal casting principle by qualified users only. Any other

application is not intended use and not permitted.

Ti-Research is not liable for damages resulting of not intended use. Not

intended use is any use not mentioned in this instruction manual.

All local regulations for safety at work and accident prevention are to be

obeyed for operation.

Electrical Safety

Prior to the connection it is to be verified that the local power supply, i. e.

voltage and frequency meets the technical specifications of the device.

The device may be connected to a power outlet with protection earth contact

and a leakage current safety switch with FI< 30mA only. Care has to be taken

for the power cord is not subject to mechanical tension.

For maintenance or repair purposes the device is to be disconnected from

power supply by pulling the power plug out of the socket.

Repair of the device is to be carried out by the manufacturer or persons

appointed by the manufacturer only.

Ti-Research is not liable for damages resulting of improper work.

After repair-work on electrical parts of the device an insulation test and

protection earth inspection is to be carried out by a certified electrician.

Safe Operation

During operation heat sensitive parts have to be kept in a sufficient distance

from the device.

Combustible, inflamable and explosive substances are to be kept away from

the device during operation.

Do not touch hot parts, i. e. the crucible, crucible holder, top lid, mould, etc..

Handling of preheated moulds while inserting into or removing from the mould

holder may cause danger of burning. For the safe handling of moulds the

specially shaped mould pliers has to be used.

8

T

i

-

Research For the usage of torches the local safety regulations and precautions are to be

obeyed. In case of defects or damages resulting in dangerous conditions for

use the device is to be disconnected from the power supply and to protect

against accidental use.

Installation and first Operation

Unpacking

After unpacking check the content for damages of transportation and

completeness according to the packing list.

Not complete deliveries are to be claimed with the invoice and the serial

number of the device within three days after delivery at the retailer.

Damages of transportation are to be complained immediately at the

transportation company.

Installation

The table-top device 1is to be placed on top of a horizontal, flat and non-

slippery surface with sufficient distance from heat sensitive objects. Care is to

be taken to provide enough working space for the handling of hot parts.

The crucible holder 12 is to be mounted on the top lid 2and to be fixed with

the mounting screw M4 x 6mm 14. The crucible holder 12 must be easily

tipped over by moving the crucible holder handle 13.

9

T

i

-

Research

Lift the top lid 2by turning the lever 13 upward and turn it to the side. The

mould holder inside the device must not be able to rotate free by hand

operation. In case the mould holder rotates free proceed as indicated in the

troubleshooting section.

Check the mould rings for easy insertion and correct fit using the special

shaped pliers. In any other case claim to your retailer.

Close the top lid 2by turning it back over the device 1and turning the lever

13 downward. The top lid 2must close tight with the cabinet 1.

10

T

i

-

Research First Operation

Before connecting to the power outlet check the specifications of your power

supply with the specification of the device on the type plate.

In case the specifications of the device do not match to your local power

supply, the device must not be connected.

Make shure the device is switched off by pushing the main switch button 4:

button snapped out – device off,

button snapped in – device on.

Connect the power cord 5of the device to a correctly installed and fuse

protected power socket protected by a leakage current switch (FI< 30mA).

In case the top lid 2is open, turn it back over the cabinet 1and close it firmly

by turning the lever 13 downward. The top lid 2must close tight with the

cabinet 1.

Snap in the power switch 4by pushing it – device is running: the mould holder

in the device starts rotating counterclockwise. Turning is visible through the

central hole in the top lid.

NEVER put fingers or other parts through the central hole in the

top lid. Danger of injuries may occur!

In case the device does not start rotation proceed as indicated in the

troubleshooting section.

Snap out the power switch 4by pushing it again – device is turned off: the

rotation of the mould holder slows down. Turning is visible through the central

hole in the top lid. For a quick stop of the mould holder turn the lever upward

to activate the break mechanism.

11

T

i

-

Research

Conversion of the Device for large Moulds

Unscrew the three mounting screws of the mould holder with the small key (part

of delivery). Take the mould holder and the 3 cm high adapter-ring underneath

out of the device.

Place the mould holder without the adapter-ring in the device and fix it by hand

with the three short screws at equal torque.

Place the large metal ring 6onto the mould holder and check for correct fit.

The top lid 2must close tight with the cabinet 1.

For re-conversion to the small ring just follow the instructions in reverse order.

Incorrect mounting may cause damages to the device and/or to the

user.

12

T

i

-

Research Production of castings

Depending on type and volume of objects to be casted three different types of

mould rings may be used:

-small 30 mm high mould ring for crowns, bridges and small partial

dentures,

-small 30 mm high mould ring with reduced volume for a few or even single

parts (to be purchased separately),

-large 60 mm high mould ring for large and/or more than one partial

dentures.

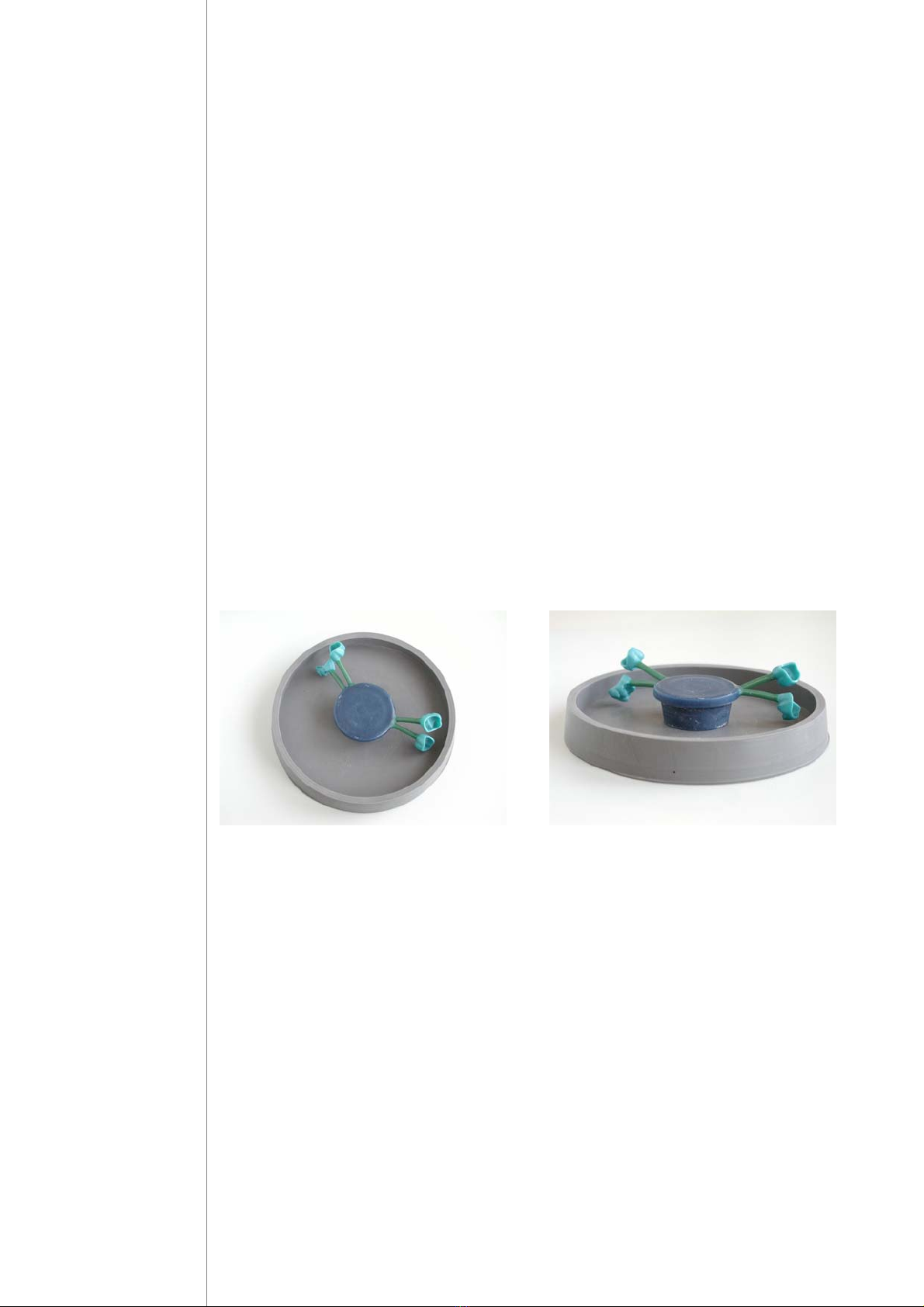

Sprueing

In contrast to conventional sprueing the wax modellations are mounted radially

around the wax disks 10.

To prevent air bubbles it is important that the parts are fixed with the open side

on top or at least parallel to the mould socket base.

Hint:

For most alloys the remaining metal ring is suitable to replace the bar in

conventional castings, thus there is no bar or other reservoir constructions

necessary. This circumstance is time saving and advantageous for preparation

of large castings like full metal bridge elements or wide bridges.

13

T

i

-

Research

Depending on the density of the alloys used different distances from the metal

ring are recommended:

non precious alloys approx. 1 cm to the inner side of metal ring

precious alloys (reduced) approx. 1,5 cm to the inner side of metal ring

precious alloys approx. 2 cm to the inner side of metal ring

These recommendations may vary depending on the alloy, investment material

and mould temperature.

Best values are to be determined individually at work with the materials used.

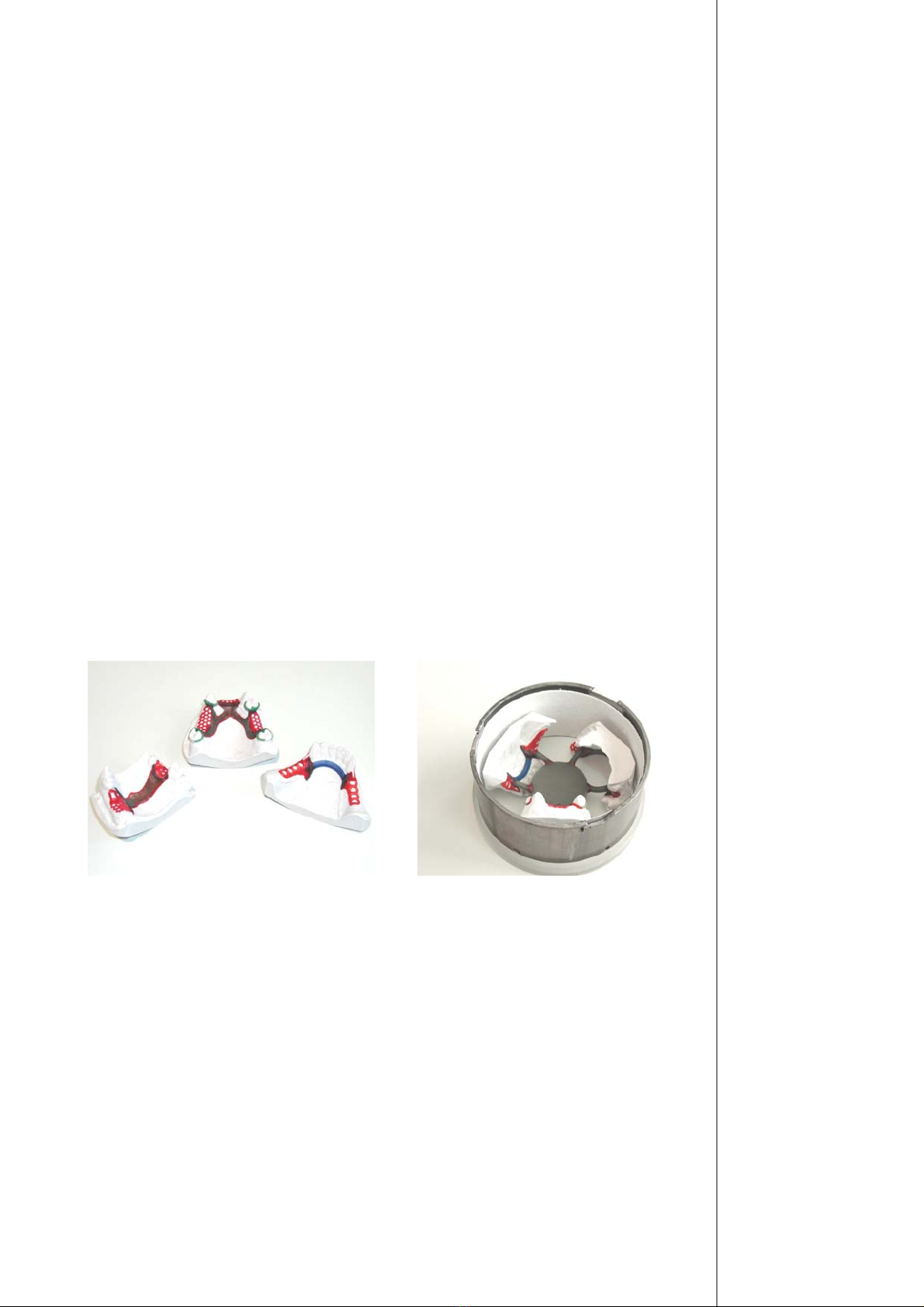

Invest

Prior to the investment an approx. 1 mm thick liner of 25 mm width for the

small metal ring 7or 55 mm width for the large metal ring 6respectively are to

be placed to the inner side of rings (Fleece 25 or Fleece 55 of Ti-Research is

recommended). A small contact zone of approx. 2 mm on top and bottom side

remains to prevent the mould from sliding out of the hot metal ring.

Important!

While pourring the invest material into the ring the shaped edge of the

ring must be on top.

Invest the modellation with a suitable investment (e. g. Invest C/P or Invest NP

by Ti-Research)

Important!

By filling the prepared metal ring placed on the mould socket 8 with

invest-material care has to be taken that the invest material does not

exceed the edge of the metal ring. Otherwise mounting of the mould

into the mould holder is more difficult or not possible.

14

T

i

-

Research

Warning!

The shaped edge of the metal rings must be free of investment.

Preheating

The mould and the crucible are to be preheated as usual according to the

instructions of the invest material used.

Casting

After preheating the mould is to be taken out of the furnace and placed into

the mould holder by turning the ring clockwise to the stop. A correctly placed

ring may not be lifted off the holder. The lid is to be closed and the crucible is

to be mounted into the crucible holder and filled with alloy. After these

preparations melting of the metal may start.

The type and power of the torch used is crucial for the quality of the casting

result – see annex II: hints for proper melting.

15

T

i

-

Research

Prior to the melting process or at least 5 seconds before pourring the device is

to be switched on to reach nominal speed for casting.

After reaching the liquidus point of the metal it may be pourred into the mould

by turning the crucible holder handle 13 in a smooth move to tip over the

crucible 11.

Depending on the alloy used and the preheating temperature of the mould the

device must kept running for a sufficient time to allow cooling down the metal

before switching off.

After solidification the top lid 2may be opened by turning the lever 3to access

the mould with the mould pliers 9for cooling down.

ATTENTION: Danger of burning at hot parts

16

T

i

-

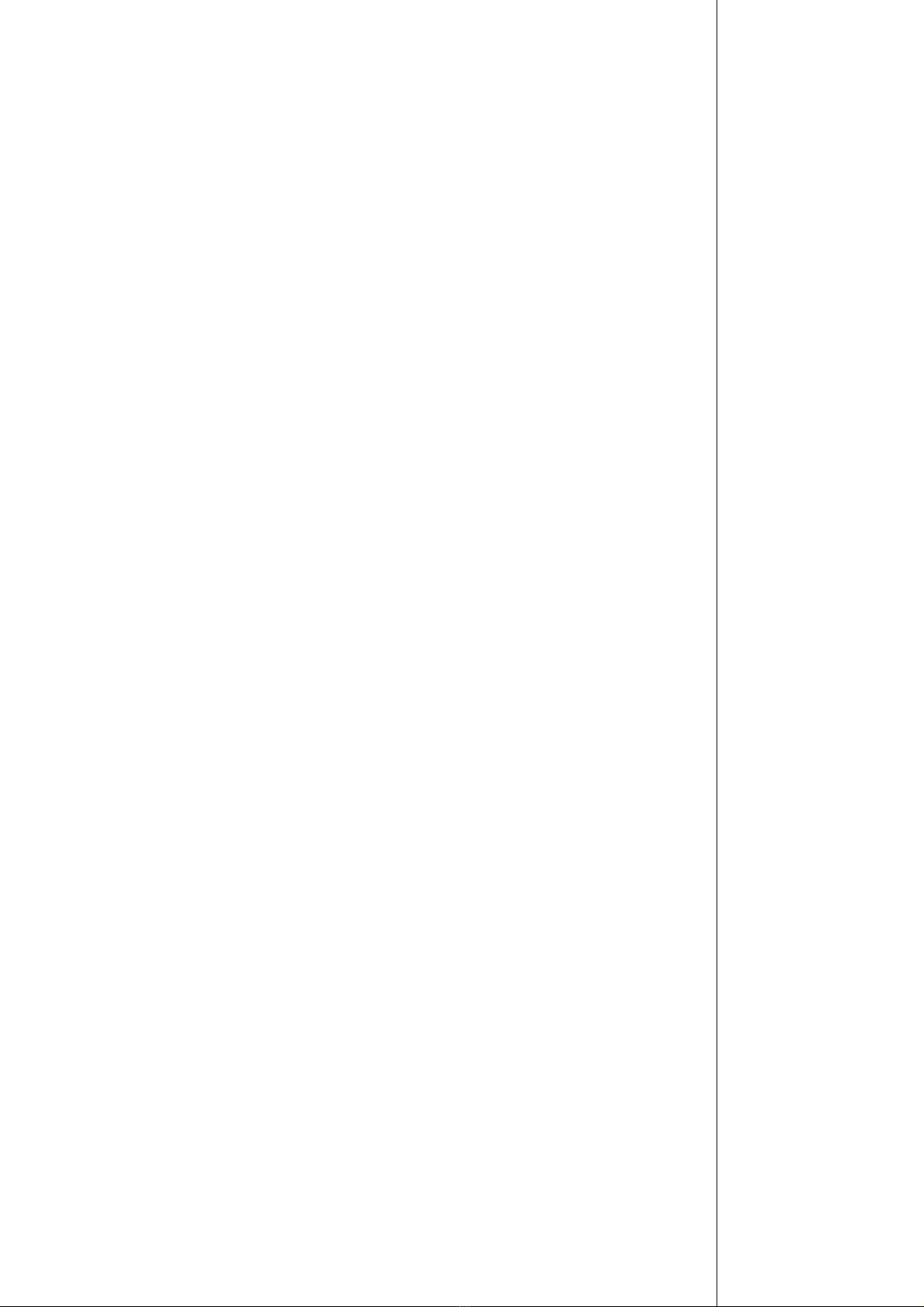

Research Devesting

After sufficient time of cooling down the casting may be taken out of the mould

as usual for further processing.

17

T

i

-

Research

Maintenance and Servicing

Maintenance

The casting device requires no special maintenance. With respect to safe

operation a visual check of the cabinet or other parts of the device and the

power cord should be done before each use. The top lid 2must close tight with

the cabinet 1.

Prior to any placement of moulds the three pins of the mould holder must be

checked visually for damages. The pins must be firmly fixed, equally long (3

mm) and straight pointing towards the center.

Prior to any use the crucible 11 has to be checked for damages. Cracked,

broken or damaged crucibles must not be used.

Usage of defective crucibles may cause danger of burning by splashed

metal.

Defective parts are to be replaced by the manufacturer or a person appointed

by the manufacturer. Unusable crucibles must be replaced by crucibles from

Ti-Research only. Ti-Research is not liable for any damages caused by

defective or third party replacements.

Servicing and Cleaning

Prior to each cleaning the device is to be disconnected from mains

power by pulling the power plug out of the socket.

The drive assembly is dust protected. To prevent accumulation of invest

material or others during usage cleaning of the device by compressed air on a

weekly basis or more frequent if necessary is strongly recommended.

Keep off liquids from inside the device!

The cabinet may be cleaned by a moistened piece of cloth. For special care the

usage of stainless steel detergents (e. g. Clean by Ti-Research) is

recommended.

Maintenance, servicing and cleaning is to be performed by qualified

personnel only.

18

T

i

-

Research Problems and Solutions

problem possible cause solution

no spin up device not

connected

connect device to an

appropriate mains socket.

top lid not closed close top lid by turning the

lever.

mould is stuck open top lid and check

mould for correct fit.

defective electrical

components

disconnect the device by

pulling the power plug and

protect from accidental use –

inform customer service.

device does not stop

within 5 seconds with

opened top lid

brakes used up or

misadjusted

inform customer service.

mould holder turns free

by moving by hand,

device runs free with

top lid open

misadjusted

brakes or defect

in breaking

appliance

disconnect the device by

pulling the power plug and

protect from accidental use –

inform customer service.

Use original packing for transportation.

19

T

i

-

Research

Consumables, Spare parts and Accessories

The items listed below may be ordered at your local retailer or at Ti Research.

Accessories/consumables

Item No. Item

3010-00 Mouldpliers (Cast-System)

3020-00 Mould socket

3030-00 Metal ring 30 mm (C&B/small PD)

3030-10 Metal ring, sectioned 30 mm (C&B)

3040-00 Metal ring 60 mm (PD)

3100-00 Melting set for propane

3110-10 Pressure regulator for oxygen

3110-20 Pressure regulator for propane

3110-30 Gas saving device with torch holder

3120-00 Torch handpiece with screw connections

3120-10 Melting torch, 27000 kJ/h

3120-20 Melting torch, 38000 kJ/h

3120-30 Micro-welding inserts with 3 exchangeable nozzles

3130-10 Gas-station, portable

3130-20 Refill adapter for oxygen

3130-30 Refill adapter for propane

3180-10 Flame arresting device for oxygen

3180-20 Flame arresting device for propane

3190-00 Twin feeding hose, propane/oxygen Ø 6mm, 1m

3190-10 Single feeding hose, oxygen Ø 6mm, 1m

3190-20 Single feeding hose, propane Ø 6mm, 1m

3190-30 Goggles

4010-00 Fleece 55R (40 m roll, 55 mm)

4020-00 Fleece 25R (40 m roll, 25 mm)

4030-00 Waxdisk (25 pieces)

4100-00 Invest C/P 5 kg, speed investment for C&B

4100-10 Invest C/P 20 kg, speed investment for C&B

4110-00 Invest NP 5 kg, speed investment for PD

4110-10 Invest NP 20 kg, speed investment for PD

4200-00 Invest Liquid 1l

4200-10 Invest Liquid 5l (buy five get six)

4500-00 Clean (stainless steel detergent) 100 ml

4600-00 Carry firing tray, Ø77 mm, incl. 5 pins

5010-00 Partialloy, non-precious alloy for PD 1kg

5020-00 Bondalloy High, non-precious bonding alloy (CTE 14.3) 1kg

5030-00 Bondalloy Low, non-precious bonding alloy (CTE 16.1) 1kg

6000-00 Cast-crucibles M (150g gold) package of 5

6000-10 Cast-crucibles L (250g gold) package of 5

20

T

i

-

Research Annex I:

Correct Sprueing

As common to any casting system some device dependent and physical

properties have to be obeyed to obtain satisfactory results.

The Waxdisk

The waxdisk of the Cast – system replaces the sprue base known from other

casting systems.

In common casting systems objects are sprued to a central sprue base acting

as a bottleneck for the metal flow. Using the Cast – system objects are sprued

radially to the waxdisk resulting in a higher flow rate for each single sprue.

Fixing of Sprues to the Waxdisk

The sprues are to be fixed radially around the widest extent of the waxdisk with

wax as depicted in the illustration below. Care has to be taken that the sprues

are fixed with their full intersection along the waxdisk – otherwise the effective

diameter for metal flow will be reduced resulting in a delayed or insufficient

filling of the mould or miscasts.

Table of contents

Popular Laboratory Equipment manuals by other brands

Belden

Belden HIRSCHMANN RPI-P1-4PoE installation manual

Koehler

Koehler K1223 Series Operation and instruction manual

Globe Scientific

Globe Scientific GCM-12 quick start guide

Getinge

Getinge 86 SERIES Technical manual

CORNING

CORNING Everon 6000 user manual

Biocomp

Biocomp GRADIENT MASTER 108 operating manual