Tides Marine SmartSeal TPS-BH-TE User manual

User Manual

Temperature Sensor System

®

SmartSeal

Congratulations on your purchase of the Tides Marine

SmartSeal® Temperature Sensor System. This manual will

describe how the system works, the various system components

and how to operate the system. Detailed information on

Installation can be found in the Installation / Specifications

Manual.

System Overview

The SmartSeal Temperature Sensor System is designed to

compliment Tides Marine’s SureSeal Shaft Seal Systems on

vessels with single or twin engines. Its purpose is to detect and

warn of various vessel conditions which could potentially lead to

shaft seal damage or failure. It is compatible with vessels which

utilize the NMEA 2000 communication protocol for connecting

marine electronics, sensors and display units to a backbone

network for centralized monitoring of various types of vessel

information. It is also designed to operate on non-NMEA 2000

equipped vessels as well on vessels with certain other networks

via a converter (e.g. NMEA 01830).

Functional Overview

The SmartSeal System is comprised of a number of components

designed to work with a wide range of vessel types and

installation needs. At the heart of the system is a Main Control

Unit which is located in the engine compartment. Connected to

this unit are temperature sensors for each shaft seal in use.

Remote Monitoring Units can be connected and placed in other

areas of the vessel as can a remote external siren. In operation,

temperature status data is displayed on both the Main and

Remote unit’s control panels. When connected to a vessel’s

NMEA 2000 onboard network, temperature data is also sent to the

main or auxiliary computer display. In the event that the

temperature of the shaft seal(s) or the engine compartment

exceeds the normal operating range limit, visible and audible

alerts are initiated so that corrective action can be taken.

2

Table Of Contents

External Siren.........................................................................5

System Operation:

Remote Unit............................................................................3-4

Shaft Seal Sensor...................................................................5

Powering.................................................................................6

Operating................................................................................6

Operating States:

Normal State...........................................................................7

Error Indications.....................................................................9

Troubleshooting.....................................................................10

Causes of Alerts......................................................................9

Self-Test Function...................................................................9

System Overview....................................................................2

Functional Overview...............................................................2

System Components:

Main Control Unit....................................................................3-4

Warning State.........................................................................7-8

Critical Alert State...................................................................8

Congratulations on your purchase of the Tides Marine

SmartSeal® Temperature Sensor System. This manual will

describe how the system works, the various system components

and how to operate the system. Detailed information on

Installation can be found in the Installation / Specifications

Manual.

System Overview

The SmartSeal Temperature Sensor System is designed to

compliment Tides Marine’s SureSeal Shaft Seal Systems on

vessels with single or twin engines. Its purpose is to detect and

warn of various vessel conditions which could potentially lead to

shaft seal damage or failure. It is compatible with vessels which

utilize the NMEA 2000 communication protocol for connecting

marine electronics, sensors and display units to a backbone

network for centralized monitoring of various types of vessel

information. It is also designed to operate on non-NMEA 2000

equipped vessels as well on vessels with certain other networks

via a converter (e.g. NMEA 01830).

Functional Overview

The SmartSeal System is comprised of a number of components

designed to work with a wide range of vessel types and

installation needs. At the heart of the system is a Main Control

Unit which is located in the engine compartment. Connected to

this unit are temperature sensors for each shaft seal in use.

Remote Monitoring Units can be connected and placed in other

areas of the vessel as can a remote external siren. In operation,

temperature status data is displayed on both the Main and

Remote unit’s control panels. When connected to a vessel’s

NMEA 2000 onboard network, temperature data is also sent to the

main or auxiliary computer display. In the event that the

temperature of the shaft seal(s) or the engine compartment

exceeds the normal operating range limit, visible and audible

alerts are initiated so that corrective action can be taken.

2

Table Of Contents

External Siren.........................................................................5

System Operation:

Remote Unit............................................................................3-4

Shaft Seal Sensor...................................................................5

Powering.................................................................................6

Operating................................................................................6

Operating States:

Normal State...........................................................................7

Error Indications.....................................................................9

Troubleshooting.....................................................................10

Causes of Alerts......................................................................9

Self-Test Function...................................................................9

System Overview....................................................................2

Functional Overview...............................................................2

System Components:

Main Control Unit....................................................................3-4

Warning State.........................................................................7-8

Critical Alert State...................................................................8

Remote Monitoring Units (RMU)

The Remote Monitoring Units are display extensions of the Main Control Unit.

On larger vessels, one or more RMUs are typically installed in locations where

they can be easily monitored. To afford installation flexibility, two mounting

configurations are offered: Surface / Bulkhead mount (identical to the Main

Control Unit), and a panel mount design for installing into Consoles or Helm

Stations.

The RMU’s front panel display will have the same LED indicators and alarm

speaker as found on the Main Control Unit.

Main Control Unit

/ NMEA 2000

Connector

Temp. Status

Indicators

Onboard

Alarm

Speaker

Remote Unit,

Bulkhead Mount

Twin Engine

P/N TPS-RDBH

Remote Monitoring Unit,

Bulkhead Mount

Single Engine

P/N TPS-RSBH

Remote Unit Monitoring,

Panel Mount

Single Engine

P/N TPS-RSPN

Remote Monitoring Unit,

Panel Mount

Twin Engine

P/N TPS-RDPN

4

System Components

Main Control Unit (MCU)

Mounted in the engine compartment, the Main Control Unit contains a

microprocessor which is responsible for the systems operation.

The MCU front panel has an onboard audible alarm and silence

control, ambient temperature sensor and LED temperature status

indicators. There are single and twin engine models available. Both

models are identical in size and have flanges for surface mounting.

Units are ideally positioned on vertical surfaces/ bulkheads which are

both visually and physically accessible.

Each MCU has two types of connectors on the bottom of its enclosure.

The first is used to connect the shaft seal sensor, neutral safety switch

and optional remote siren. The second is used for connecting the

Remote Monitor Unit and 12VDC power source or to connect the

SmartSeal System to a NMEA 2000 network.

Main Control Units are IP66 rated (waterproof for heavy spray and brief

submersion)

Main Control Unit,

Bulkhead Mount

Twin Engine

P/N TPS-BH-TE

PORT Side

Harness

Connector

STBD. Side

Harness

Connector

Ambient Temp.

Sensor

Temp. Status

Indicators

Alarm/Siren

Control

Onboard

Alarm

Speaker

Remote Unit

/ NMEA 2000

Connector

Main Control Unit,

Bulkhead Mount

Single Engine

P/N TPS-BH-SE

3

Remote Monitoring Units (RMU)

The Remote Monitoring Units are display extensions of the Main Control Unit.

On larger vessels, one or more RMUs are typically installed in locations where

they can be easily monitored. To afford installation flexibility, two mounting

configurations are offered: Surface / Bulkhead mount (identical to the Main

Control Unit), and a panel mount design for installing into Consoles or Helm

Stations.

The RMU’s front panel display will have the same LED indicators and alarm

speaker as found on the Main Control Unit.

Main Control Unit

/ NMEA 2000

Connector

Temp. Status

Indicators

Onboard

Alarm

Speaker

Remote Unit,

Bulkhead Mount

Twin Engine

P/N TPS-RDBH

Remote Monitoring Unit,

Bulkhead Mount

Single Engine

P/N TPS-RSBH

Remote Unit Monitoring,

Panel Mount

Single Engine

P/N TPS-RSPN

Remote Monitoring Unit,

Panel Mount

Twin Engine

P/N TPS-RDPN

4

System Components

Main Control Unit (MCU)

Mounted in the engine compartment, the Main Control Unit contains a

microprocessor which is responsible for the systems operation.

The MCU front panel has an onboard audible alarm and silence

control, ambient temperature sensor and LED temperature status

indicators. There are single and twin engine models available. Both

models are identical in size and have flanges for surface mounting.

Units are ideally positioned on vertical surfaces/ bulkheads which are

both visually and physically accessible.

Each MCU has two types of connectors on the bottom of its enclosure.

The first is used to connect the shaft seal sensor, neutral safety switch

and optional remote siren. The second is used for connecting the

Remote Monitor Unit and 12VDC power source or to connect the

SmartSeal System to a NMEA 2000 network.

Main Control Units are IP66 rated (waterproof for heavy spray and brief

submersion)

Main Control Unit,

Bulkhead Mount

Twin Engine

P/N TPS-BH-TE

PORT Side

Harness

Connector

STBD. Side

Harness

Connector

Ambient Temp.

Sensor

Temp. Status

Indicators

Alarm/Siren

Control

Onboard

Alarm

Speaker

Remote Unit

/ NMEA 2000

Connector

Main Control Unit,

Bulkhead Mount

Single Engine

P/N TPS-BH-SE

3

Operation

System Power

The SmartSeal system operates on 12VDC (+/-3VDC).

The Main Control Unit and Remote Monitoring Units are connected to each

other using standard NMEA network hardware components. Use of this

hardware allows the SmartSeal system to be easily added to (and be

powered by) an existing NMEA 2000 network.

If no existing network is available, a suitable power source must be

connected (thus creating a private SmartSeal network). The system is

designed such that you can plug or unplug it from its network whether or not

it is powered.

Operating the System

The SmartSeal Temperature Sensor is an autonomous system. It

continuously monitors shaft seal temperature(s) and reports results as visual

and audible indications on the Main and Remote unit front panels. It also

broadcasts shaft seal and engine room temperature measurements on the

NMEA 2000 network for display on MFDs, etc.

Proper operation of the system is very simple:

If a WARNING or CRITICAL ALERT occurs, the condition must be

immediately resolved.

External Siren

The External Siren is an optional component which is typically installed on

larger vessels where engine rooms can be quite loud and are located some

distance from the main helm station. There are several options for the types of

sound the siren will emit which can be selected at the time of installation.

Siren

P/N SP-SS-SIREN

65

Cabling

The SmartSeal system uses two types of cabling to connect the various

components:

A custom harness is supplied for connecting the Shaft Seal sensor, Neutral

Safety Switch and External Siren to the Main control unit.

Standard NMEA network cables and hardware are used to connect the power

supply and Remote Monitoring Units to the Main control Unit.

Sensor Mounted On Shaft Seal

Injection Fitting

Sensor and Clamp-on Fitting

System Components

Shaft Seal Sensor

Connected to the Main Control Unit, The Shaft Seal Sensor is attached to the

water injection fitting on the SureSeal. It is held in place by a clamp-on

connector located just below the blue water pick up line running to the engine.

While it should not require any maintenance after installation, it should be

inspected periodically to be sure it is securely attached and in good contact

with the injection fitting.

SmartSeal Harness NMEA Network

cable

Operation

System Power

The SmartSeal system operates on 12VDC (+/-3VDC).

The Main Control Unit and Remote Monitoring Units are connected to each

other using standard NMEA network hardware components. Use of this

hardware allows the SmartSeal system to be easily added to (and be

powered by) an existing NMEA 2000 network.

If no existing network is available, a suitable power source must be

connected (thus creating a private SmartSeal network). The system is

designed such that you can plug or unplug it from its network whether or not

it is powered.

Operating the System

The SmartSeal Temperature Sensor is an autonomous system. It

continuously monitors shaft seal temperature(s) and reports results as visual

and audible indications on the Main and Remote unit front panels. It also

broadcasts shaft seal and engine room temperature measurements on the

NMEA 2000 network for display on MFDs, etc.

Proper operation of the system is very simple:

If a WARNING or CRITICAL ALERT occurs, the condition must be

immediately resolved.

External Siren

The External Siren is an optional component which is typically installed on

larger vessels where engine rooms can be quite loud and are located some

distance from the main helm station. There are several options for the types of

sound the siren will emit which can be selected at the time of installation.

Siren

P/N SP-SS-SIREN

65

Cabling

The SmartSeal system uses two types of cabling to connect the various

components:

A custom harness is supplied for connecting the Shaft Seal sensor, Neutral

Safety Switch and External Siren to the Main control unit.

Standard NMEA network cables and hardware are used to connect the power

supply and Remote Monitoring Units to the Main control Unit.

Sensor Mounted On Shaft Seal

Injection Fitting

Sensor and Clamp-on Fitting

System Components

Shaft Seal Sensor

Connected to the Main Control Unit, The Shaft Seal Sensor is attached to the

water injection fitting on the SureSeal. It is held in place by a clamp-on

connector located just below the blue water pick up line running to the engine.

While it should not require any maintenance after installation, it should be

inspected periodically to be sure it is securely attached and in good contact

with the injection fitting.

SmartSeal Harness NMEA Network

cable

PORT

STBD

NORMAL CRITICAL

WARNING

SILENCE

Temperature Sensor System

®

SmartSeal

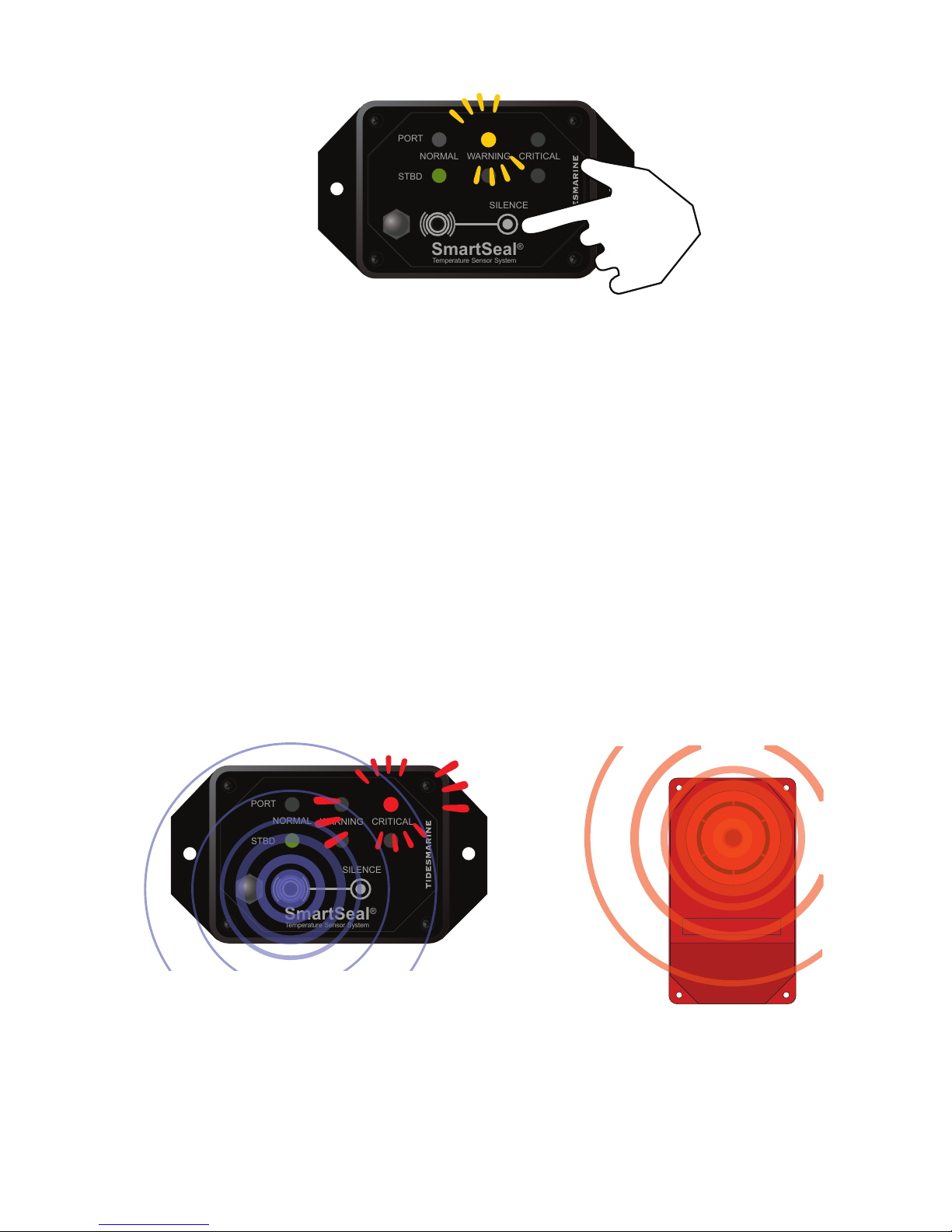

The audible onboard alarm may be silenced by pressing the “SILENCE”

control on the front panel of the Main Control Unit. THIS ACTION DOES

NOT INDICATE THAT THE ISSUE CAUSING THE ELEVATED

TEMPERATURE HAS BEEN FIXED.

If the shaft seal temperature remains above 50° C (122° F) the yellow

LED(s) will continue to flash and the alarm will activate again. After

resolving the issue causing the elevated temperature warning, the

“NORMAL”green status LED(s) will illuminate.

Silence Alarm / Siren

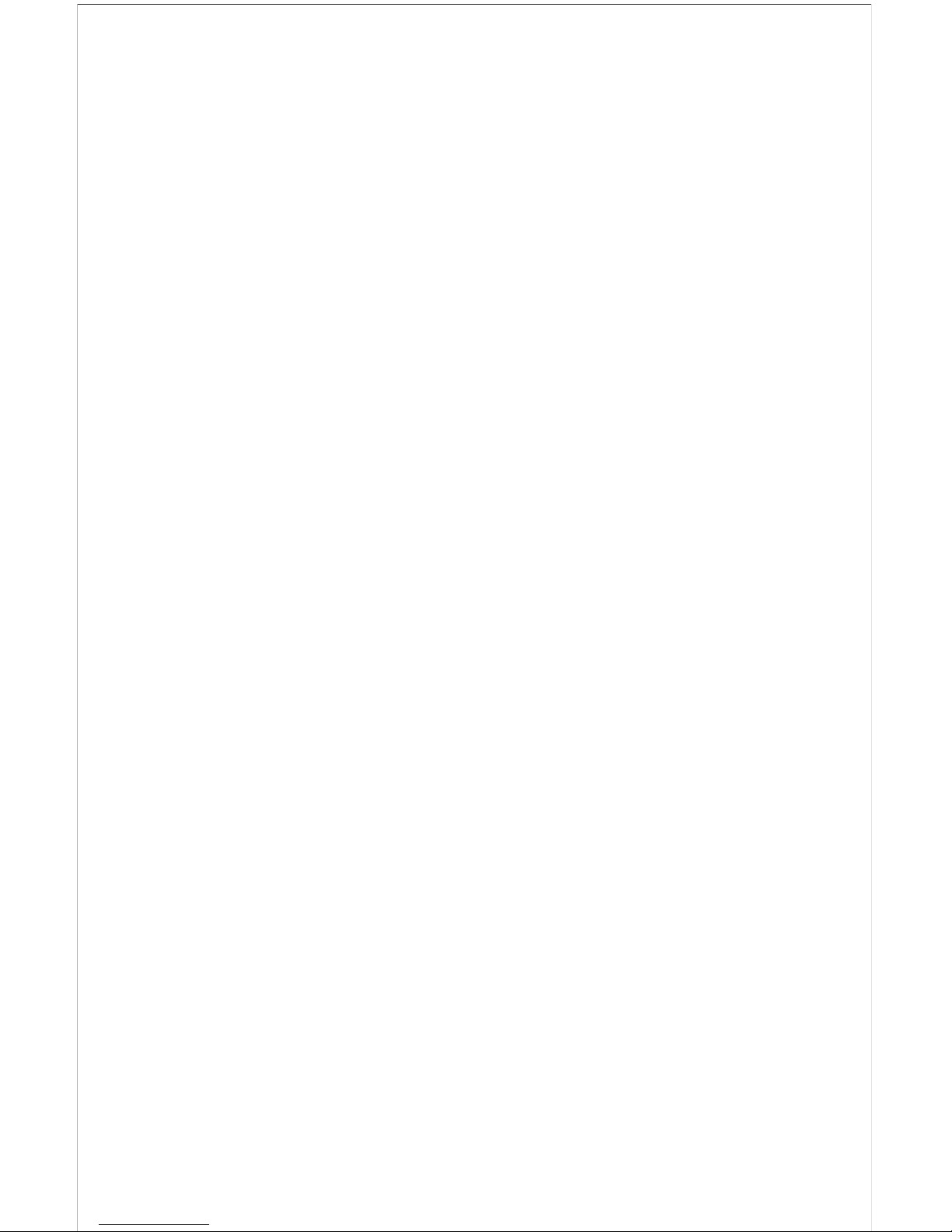

Rapidly Flashing Red LEDs with Alarm & Siren Sound

-indicate CRITICAL ALERT condition

+

PORT

STBD

NORMAL CRITICAL

WARNING

SILENCE

Temperature Sensor System

®

SmartSeal

Critical Alert State

A Critical Alert is indicated by the Red LED(s) flashing rapidly. The

audible alarm and external siren (if equipped) will sound with every flash.

This indicates that the shaft seal temperature is above 70° C (158° F),

and that ACTION MUST BE TAKEN IMMEDIATELY TO RESOLVE THE

PROBLEM.

The Critical alert audible alarm and external siren may be silenced via the

control on the Main Control Unit front panel. Once the problem has been

solved and the shaft seal begins to cool down, the Warning State may

temporarily occur. Once the shaft seal temperature goes below 50° C

(122° F), the green LED(s) will illuminate and audible alarms will stop.

PORT

STBD

NORMAL CRITICAL

WARNING

SILENCE

Temperature Sensor System

®

SmartSeal

System Operation

There are three states of operation: “NORMAL, WARNING and CRITICAL”

which are indicated by the LEDs on the front panels of each unit in

operation. For twin engine configurations the Port and Starboard states are

independent of each other such that one may be normal when the other

indicates an overheating condition.

Normal Operation

Normal state is indicated by the Green LED(s) being illuminated when the

engines are running. This indicates that the system is operating with the

shaft seal temperature below 50° C (122° F).

Warning State

Warning State is indicated by the Yellow LED(s) flashing slowly (every 4

to 5 seconds). The audible alarm will sound with every flash. This

indicates that the shaft seal temperature is above 50° C (122° F) but less

than 70° C (158° F).

Steady Green LEDs- indicate Normal Operation

Slowly Flashing Yellow LEDs with Alarm Sound- indicate WARNING condition

PORT

STBD

NORMAL CRITICAL

WARNING

SILENCE

Temperature Sensor System

®

SmartSeal

87

PORT

STBD

NORMAL CRITICAL

WARNING

SILENCE

Temperature Sensor System

®

SmartSeal

The audible onboard alarm may be silenced by pressing the “SILENCE”

control on the front panel of the Main Control Unit. THIS ACTION DOES

NOT INDICATE THAT THE ISSUE CAUSING THE ELEVATED

TEMPERATURE HAS BEEN FIXED.

If the shaft seal temperature remains above 50° C (122° F) the yellow

LED(s) will continue to flash and the alarm will activate again. After

resolving the issue causing the elevated temperature warning, the

“NORMAL”green status LED(s) will illuminate.

Silence Alarm / Siren

Rapidly Flashing Red LEDs with Alarm & Siren Sound

-indicate CRITICAL ALERT condition

+

PORT

STBD

NORMAL CRITICAL

WARNING

SILENCE

Temperature Sensor System

®

SmartSeal

Critical Alert State

A Critical Alert is indicated by the Red LED(s) flashing rapidly. The

audible alarm and external siren (if equipped) will sound with every flash.

This indicates that the shaft seal temperature is above 70° C (158° F),

and that ACTION MUST BE TAKEN IMMEDIATELY TO RESOLVE THE

PROBLEM.

The Critical alert audible alarm and external siren may be silenced via the

control on the Main Control Unit front panel. Once the problem has been

solved and the shaft seal begins to cool down, the Warning State may

temporarily occur. Once the shaft seal temperature goes below 50° C

(122° F), the green LED(s) will illuminate and audible alarms will stop.

PORT

STBD

NORMAL CRITICAL

WARNING

SILENCE

Temperature Sensor System

®

SmartSeal

System Operation

There are three states of operation: “NORMAL, WARNING and CRITICAL”

which are indicated by the LEDs on the front panels of each unit in

operation. For twin engine configurations the Port and Starboard states are

independent of each other such that one may be normal when the other

indicates an overheating condition.

Normal Operation

Normal state is indicated by the Green LED(s) being illuminated when the

engines are running. This indicates that the system is operating with the

shaft seal temperature below 50° C (122° F).

Warning State

Warning State is indicated by the Yellow LED(s) flashing slowly (every 4

to 5 seconds). The audible alarm will sound with every flash. This

indicates that the shaft seal temperature is above 50° C (122° F) but less

than 70° C (158° F).

Steady Green LEDs- indicate Normal Operation

Slowly Flashing Yellow LEDs with Alarm Sound- indicate WARNING condition

PORT

STBD

NORMAL CRITICAL

WARNING

SILENCE

Temperature Sensor System

®

SmartSeal

87

SmartSeal Troubleshooting

Main Control

Unit Has No

LEDs

Illuminated

Main Control

Unit Powers up

and the RED

LEDs are

Blinking and

the Audible

Alarm is

Sounding

All LED Colors

Are Flashing in

Unison

Remote LEDs

or audible

alarm are not

functioning

Ensure that the SmartSeal Temperature Sensor

is properly connected to the NMEA 2000 network

and is getting power.

If this is a vessel without a NMEA 2000 network,

ensure that the power connector is properly

connected to the “private” network and the 12V

power source is operating correctly.

Verify that the harness cable(s) are

properly connected to the Main control

unit.

Inspect the ring thermistor(s) at the

injection fitting(s) for poor connection to

the sensor cable. If any problem is

found, replace the sensor cable.

This condition is due to a failure

detected in the Main control unit self-test

which occurs on each power up. Other

internal issues could cause the self-test

to fail. In this case, please contact

Technical Support for assistance.

This is the same indication as the power up

flashing Red LEDs above but the error has been

detected while the Main control unit is operating

(vs powering up as above).

Verify that the sensor cable(s) are properly

connected to the Main control unit.

Inspect the ring thermistor(s) at the injection

fitting(s) for poor connection to the sensor cable.

If any is found, replace the sensor cable.

Remote units are designed to enter this state if

no communication is received from the Main

control unit. This condition can also occur if the

Remote unit is not receiving power.

Ensure the Remote is properly connected to the

NMEA 2000 network or the “private” network

created on installation and that it is receiving

power.

Ensure the Main unit is powered and operating.

System Operation

Possible Causes of Alerts

In general, the temperature of the shaft seal may become elevated if there is

a problem with the cooling water supply to the shaft seal which is necessary.

If an alert has occurred, check for the following:

-Twisted, kinked or leaking water pick-up line from engine to shaft seal.

-Water pick-up line has become blocked with debris (sand, rust particulate

etc.)

-Crossover water line (twin engine applications) is either kinked or blocked

when only one engine is running.

-Water pump malfunction

System Self Test

The SmartSeal Temperature Sensor system has a built in self-test function.

When the system is powered on, both the Main Control and Remote

Monitoring units will cycle through each LED color 2-3 times indicating all

internal self-tests have passed and the unit is operating correctly. In

addition, the Main Control Unit will beep one or two times indicating it is a

single or twin engine unit. The Remote will beep once in either a single or

twin engine installation.

Error Indications

If the self test determines that the Smart Seal System is not operating

correctly after power up, the following error indications will be displayed

Red LEDs flashing and audible alarm sounding rapidly.

-Occurs if the system is powered up and there is a problem in one or both of

the thermal sensor connections of the Sensor cable.

All three LED colors are flashing.

-Occurs, while the system is operating, if trouble is detected in one of the

thermal sensor connections.

The Remote Unit(s) have no illuminated LEDs

-This indicates that the Remote unit(s) are either or both not receiving data

from the Main Control Unit or power from the network to which it is

connected.

109

SmartSeal Troubleshooting

Main Control

Unit Has No

LEDs

Illuminated

Main Control

Unit Powers up

and the RED

LEDs are

Blinking and

the Audible

Alarm is

Sounding

All LED Colors

Are Flashing in

Unison

Remote LEDs

or audible

alarm are not

functioning

Ensure that the SmartSeal Temperature Sensor

is properly connected to the NMEA 2000 network

and is getting power.

If this is a vessel without a NMEA 2000 network,

ensure that the power connector is properly

connected to the “private” network and the 12V

power source is operating correctly.

Verify that the harness cable(s) are

properly connected to the Main control

unit.

Inspect the ring thermistor(s) at the

injection fitting(s) for poor connection to

the sensor cable. If any problem is

found, replace the sensor cable.

This condition is due to a failure

detected in the Main control unit self-test

which occurs on each power up. Other

internal issues could cause the self-test

to fail. In this case, please contact

Technical Support for assistance.

This is the same indication as the power up

flashing Red LEDs above but the error has been

detected while the Main control unit is operating

(vs powering up as above).

Verify that the sensor cable(s) are properly

connected to the Main control unit.

Inspect the ring thermistor(s) at the injection

fitting(s) for poor connection to the sensor cable.

If any is found, replace the sensor cable.

Remote units are designed to enter this state if

no communication is received from the Main

control unit. This condition can also occur if the

Remote unit is not receiving power.

Ensure the Remote is properly connected to the

NMEA 2000 network or the “private” network

created on installation and that it is receiving

power.

Ensure the Main unit is powered and operating.

System Operation

Possible Causes of Alerts

In general, the temperature of the shaft seal may become elevated if there is

a problem with the cooling water supply to the shaft seal which is necessary.

If an alert has occurred, check for the following:

-Twisted, kinked or leaking water pick-up line from engine to shaft seal.

-Water pick-up line has become blocked with debris (sand, rust particulate

etc.)

-Crossover water line (twin engine applications) is either kinked or blocked

when only one engine is running.

-Water pump malfunction

System Self Test

The SmartSeal Temperature Sensor system has a built in self-test function.

When the system is powered on, both the Main Control and Remote

Monitoring units will cycle through each LED color 2-3 times indicating all

internal self-tests have passed and the unit is operating correctly. In

addition, the Main Control Unit will beep one or two times indicating it is a

single or twin engine unit. The Remote will beep once in either a single or

twin engine installation.

Error Indications

If the self test determines that the Smart Seal System is not operating

correctly after power up, the following error indications will be displayed

Red LEDs flashing and audible alarm sounding rapidly.

-Occurs if the system is powered up and there is a problem in one or both of

the thermal sensor connections of the Sensor cable.

All three LED colors are flashing.

-Occurs, while the system is operating, if trouble is detected in one of the

thermal sensor connections.

The Remote Unit(s) have no illuminated LEDs

-This indicates that the Remote unit(s) are either or both not receiving data

from the Main Control Unit or power from the network to which it is

connected.

109

3251A S.W. 13th Drive

Deereld Beach, FL 33442

Toll Free Phone: (800 420-0949

General Phone: (954) 420-0949

General Fax: (954) 420-5234

Order Fax: (954) 420-0945

WWW.TIDESMARINE.COM

TIDESMARINE

innovative products for the marine industry

© 2018 Tides Marine All Rights Reserved

User Manual- Smart Seal Rev 1.0

This manual suits for next models

5

Table of contents

Popular Marine Equipment manuals by other brands

Garmin

Garmin FUSION APOLLO MS-WB675 manual

Garmin

Garmin Gladiator TR-1 owner's manual

DESSALATOR

DESSALATOR AC PRO AUTOMATIC COMPACT D90 Assembly and user's manual

Observator Instruments

Observator Instruments OMC-131 Installation and technical manual

Safran

Safran MorphoAccess SIGMA Series Administration guide

Exalto

Exalto 255BSS user manual