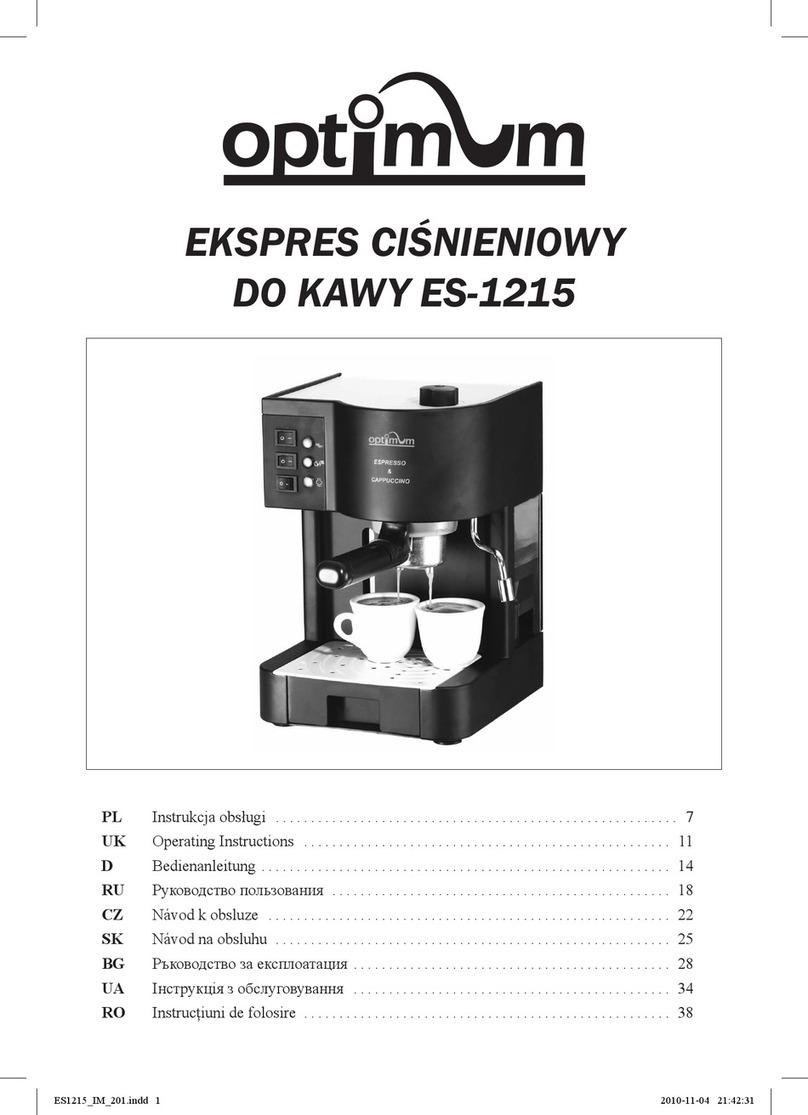

TIFATECH LA TIFALENO User manual

S21-037

ENGLISH

S

Coffee Machine

LA TIFALENO

Instruction Manual

2

S21-037

ENGLISH

S

PREFACE

Thank you for purchasing La Tifaleno, a coffee machine product from Tifatech.

This manual contains instructions for the mounting, functions, operations, and

notes when operating La Tifaleno coffee machine. To ensure safe and correct

use, thoroughly read and understand this manual before using this product.

To prevent accidents arising from the misuse of this product, please ensure the

operator receives this manual.

HAZARD INTENSITY LEVELS

The level of risk and importance of the notification is determined by the

following definitions. Always observe the warnings to ensure safety and prevent

potential injury and product damage.

Important:

Alerts against unsafe practices. Observe Important notifications to

prevent possible minor personal injury or damage to the board.

Warning:

Indicates a potentially hazardous situation that, if the Warning is

ignored, could result in injury or death.

Note:

Gives additional information which may be helpful for the proper

operation of the board.

S21-037

ENGLISH

S

WARNINGS:

Note: TIFATECH Co., Ltd declines all responsibility for damage to persons or

property resulting from failure to follow the instructions and warning listed

below when installing and using this machine.

▪The installation of the machine must be completed by Tifatech’s personnel.

▪This product needs to be wrapped appropriately before transport. A user

manual, accessories, and a La Tifaleno coffee maker should all be included in

the delivery. Please get in touch with us right away for assistance if any listed

items are missing.

▪Mount the machine 110cm above the ground on a solid, water-resistant

surface

▪Ensure that the power supply voltage does not fluctuate by more than 6%.

▪The main water supply must satisfy safety and stability requirements for a

perfect machine operation

▪Before mounting or removing the machine, disconnect it from the power

supply and wait a while for it to cool down.

▪Do not remove any original electrical part of the machine.

▪To protect the machine from electrical trouble, keep it away from sink, water

faucets or wet places to ensure water is not splashed into machine.

▪Repairing, or parts replacement should only be performed by TIFATECH or

other qualified service personnel.

▪Children should never be allowed to play with the machine.

▪This machine is intended to only use for coffee dispensing, steaming and

frothing milk. Do not use it for any other purpose.

PRECAUTIONS

➢Installation precautions

Read thoroughly the following conditions before installing the La Tifaleno

coffee machine.

4

S21-037

ENGLISH

S

The mounting location must be:

▪No flammable, explosive gases

▪No exposure to water.

▪An ambient temperature of 0 to 70°C that does not change rapidly, and

no icing.

▪An ambient non-condensing humidity of 35 to 85 %RH.

➢Operation and Maintenance Precautions

▪Do not touch live terminals. This may cause an electrical shock or

problems in operation.

▪Ensure the board surface is completely dry before powering.

▪Periodic cleaning will reduce the risk of damaging the board.

S21-037

ENGLISH

S

*** CONTENTS ***

I. GENERAL..............................................................................................................1

1. Introduction ..........................................................................................................1

II. TECHNICAL SPECIFICATIONS...................................................................1

III. INSTALLATION ...............................................................................................2

1. Position.................................................................................................................2

2. Electrical connection............................................................................................3

3. Water connection..................................................................................................3

IV. USE ......................................................................................................................3

1. Start the machine..................................................................................................3

2. Re-filling the boiler ..............................................................................................4

3. Heating the boiler.................................................................................................4

4. Coffee dispensing.................................................................................................4

5. Steaming and frothing milk..................................................................................6

V. PROGRAMMING..............................................................................................7

1. Programming standard dose.................................................................................7

2. Pre-infusion ..........................................................................................................7

3. Setting of operational parameters.........................................................................7

a. Temperature setting...........................................................................................8

b. Other parameters setting ...................................................................................9

4. Advanced setting (For technician only).............................................................11

VI. CLEANING AND MAINTENANCE.............................................................12

1. Cleaning the group head.....................................................................................12

2. Cleaning the filter basket....................................................................................13

6

S21-037

ENGLISH

S

3. Cleaning the group gasket..................................................................................13

4. Automatic group cleaning..................................................................................14

VII. TROUBLESHOOTING ...............................................................................15

1

S21-037

ENGLISH

S

I. GENERAL

1. Introduction

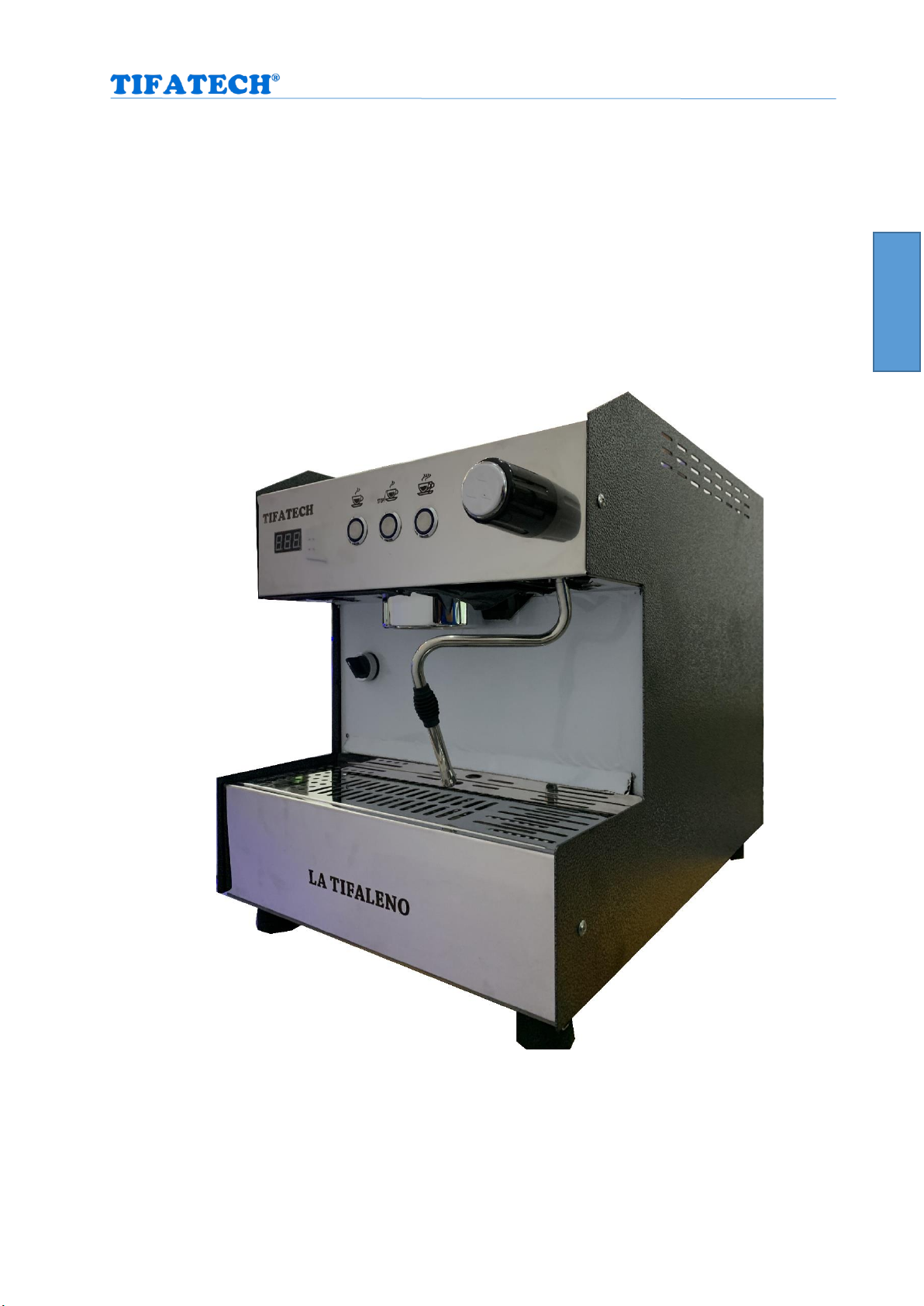

The La Tifaleno coffee machine by Tifatech is a one group coffee machine with

cutting edge features including pre-infusion, automatic group cleaning, and many

more innovative functions.

Note:

▪This manual contains important instructions regarding the safe intended use

of the machine.

▪If any damaged or loss to this manual, request a copy from the TIFATECH

manufacturer.

II. TECHNICAL SPECIFICATIONS

Specifications

La Tifaleno

1GW

1GB

1GW Plus

1GB Plus

Steam wand

1 unit

Heating element control

Temperature control

LED display

1 unit

Color

White

Black

White

Black

Width, Height, Depth (cm)

25, 35, 41

36, 41, 53

Boiler volume (lit)

2

2.5

Power supply

230V AC 50/60Hz

Heating element power

1200W

2000W

Daily coffee capacity

(cups/day)

150

200

Weight(kg)

25

30

2

S21-037

ENGLISH

S

Steam boiler operating

pressure(bar)

0.8 - 1.2

Ambient noise(dB)

< 70

Ambient temperature (°C)

0 - 70

Ambient humidity (%)

< 70

III. INSTALLATION

1. Position

•Put the machine in place on a level surface. Make sure the feet are adjusted so

that the coffee is distributed equally among the cups.

•The machine should be placed in a location that meets the minimum

requirements described below.

3

S21-037

ENGLISH

S

2. Electrical connection

•Ensure that the electrical specifications of the main supply match the

specifications of the power supply required of machine.

•The power supply should be equipped with circuit breaker to protect against

unexpected system failure.

3. Water connection

•Water supply pressure needs to be between 1.5 and 6 Bar.

•Use drinking water with a hardness of between 20 and 30 ppm for the greatest

coffee quality and avoid damaging the machine's components.

IV. USE

1. Start the machine

Set the rotary power switch to the position 2 to turn on the machine.

4

S21-037

ENGLISH

S

2. Re-filling the boiler

The filling operation will start automatically when the water level falls below

the minimum threshold and stop when the level probe is reached.

Note: The water source should always be available for filling operation.

3. Heating the boiler

•The heating element will kick on to heat the boiler when its temperature drop

below the preset value for heating (page xx).

•The heating element will be shut off if the actual boiler temperature exceeds the

set point.

Note: Open the steam tap briefly when the machine starts up for the first time

after being off for a day or more to let the old steam out of the boiler.

4. Coffee dispensing

Note:

•Keep the portafilter inserted to the brewing group to keep it warm. This

will ensure that the coffee is served at the optimal temperature.

•Place the portafilter face down and tap the metal side at the top of the filter

basket to remove any extra coffee.

5

S21-037

ENGLISH

S

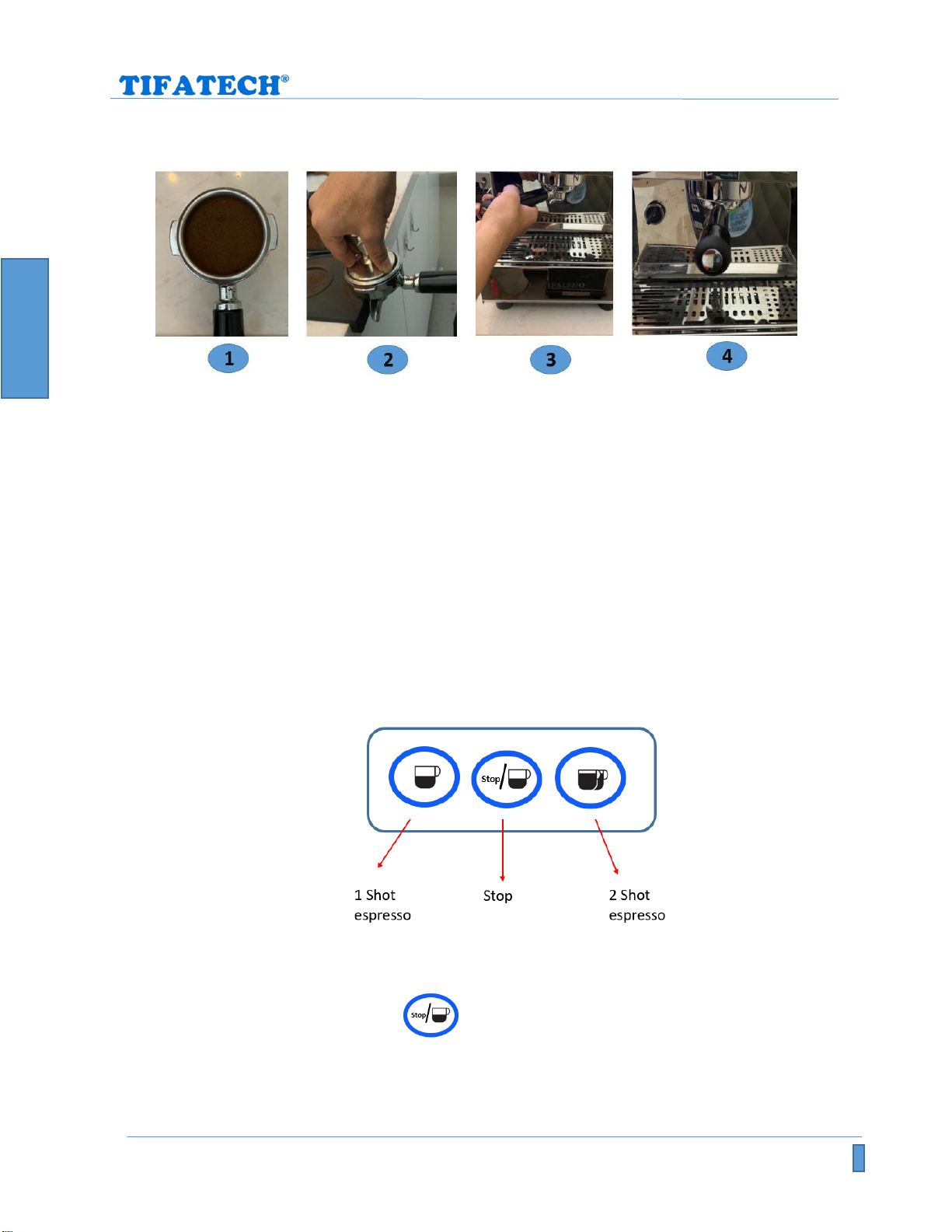

Follow these procedures to before starting to dispensing coffee:

Step 1: Unlock and remove the portafilter from the group head, fill the filter basket

with a proper amount of ground coffee.

Step 2: Press the coffee with a moderate force use coffee tamper.

Step 3: Insert the portafilter into the unit with the knob facing to the left, then turn

to the right until it lock to the correct position.

Step 4: Place the cup beneath portafilter outlet, then use the buttons to operate the

machine as directed below

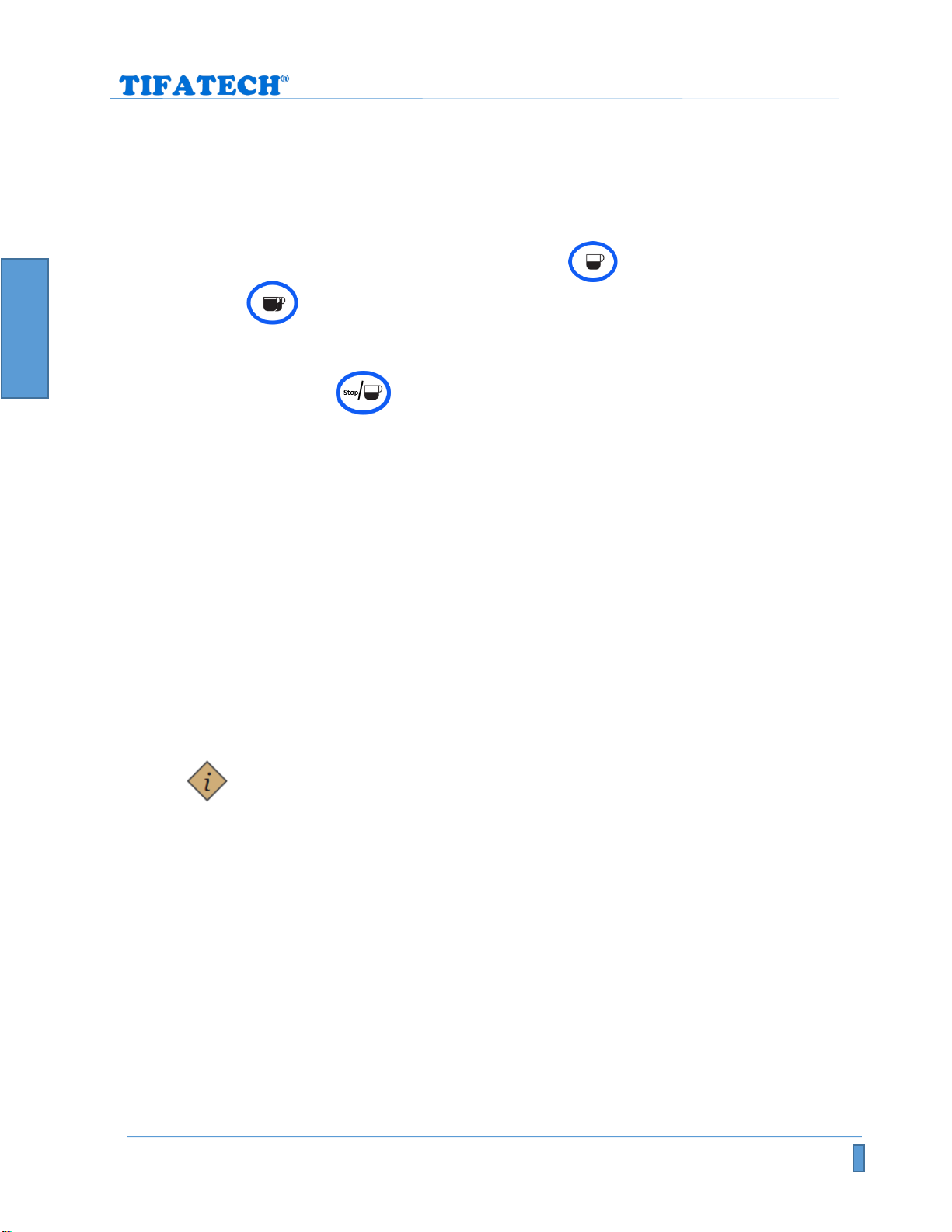

•Press the Stop button once to start the coffee brewing process, then

press it again to stop.

6

S21-037

ENGLISH

S

•Press the 1 shot espresso button or 2 shot espresso button

to dispense a preset coffee dose that is previously programmed (page 7).

Important:

•Ensure that the portafilter is correctly locked into the brewing group before

beginning any dispensing operation.

•Never take out the portafilter while dispensing.

➢Tips for a good cup of coffee:

Conditions

Coffee extract slowly

Coffee extract rapidly

Amount of ground coffee

Excessive

Insufficient

Coffee pressure

Excessive

Insufficient

Ambient humidity

Too damp

Too dry

Grinder temperature

Too fine

Too coarse

Filter state

Clogged or dirty

Hole enlarged due to wear

5. Steaming and frothing milk

•Place the steam wand into the beverage and rotate the steam tap in a

anticlockwise direction.

•Close the steam tap and take the pitcher away when the beverage archives the

expected temperature.

Note: Open the steam tap briefly both before and after steaming to let any

leftover condensed water out.

7

S21-037

ENGLISH

S

V. PROGRAMMING

1. Programming standard dose

Follow the instructions below for programming coffee dosage for drink buttons.

Step 1: Press and hold the 1 Shot espresso button or 2 Shot espresso

buttons for 3 seconds to start to program on that one. Siren sounds and

the selected button begin flashing.

Step 2: Press the Stop button to dispense coffee and press it again

when reaching the desired coffee dose. The Stop button light is on while dispensing.

Step 3: Press and hold the programmed button for 3 seconds to save its new dose

and finish the setting process.

Repeat the procedure above for programming on the remaining button.

2. Pre-infusion

•To enable the pre-infusion mode, press and hold the button for 3 seconds

until the siren sounds.

•Do similarly the step above to disable it

Note: The coffee dose on buttons needs to be reprogrammed for it to work

correctly.

3. Setting of operational parameters

In addition to the core functions, a machine’s operational parameters can be changed

to improve the user experience.

8

S21-037

ENGLISH

S

Button

Name

Replace function

1 shot espresso

Increase (+)

2 shot espresso

Decrease (-)

Stop

Change/Confirm

Temperature setting

Press and hold the 1 shot espresso and 2 shot espresso

simultaneously for 3 seconds until the siren sound.

The display starts to alternate between two states like the image below.

Use the increase/decrease button to adjust the threshold temperature of the boiler

heating process.

•Temperature range:0 -120°C

•Step: 1

•Default: 114°C

Press and hold the Confirm button for 3 seconds to exit the setting process.

9

S21-037

ENGLISH

S

Other parameters setting

Press and hold the 2 shot espresso and the Stop button

simultaneously for 3 seconds until the siren sound. The 2 shot espresso light begins

to flash.

•Use the Increase/Decrease button to adjust the parameter value.

•Use Confirm/Change button to save your changes and move on to set a new

parameter.

•Press and hold the Confirm button for 3 seconds to leave the setup

mode. All lights return to the off state.

10

S21-037

ENGLISH

S

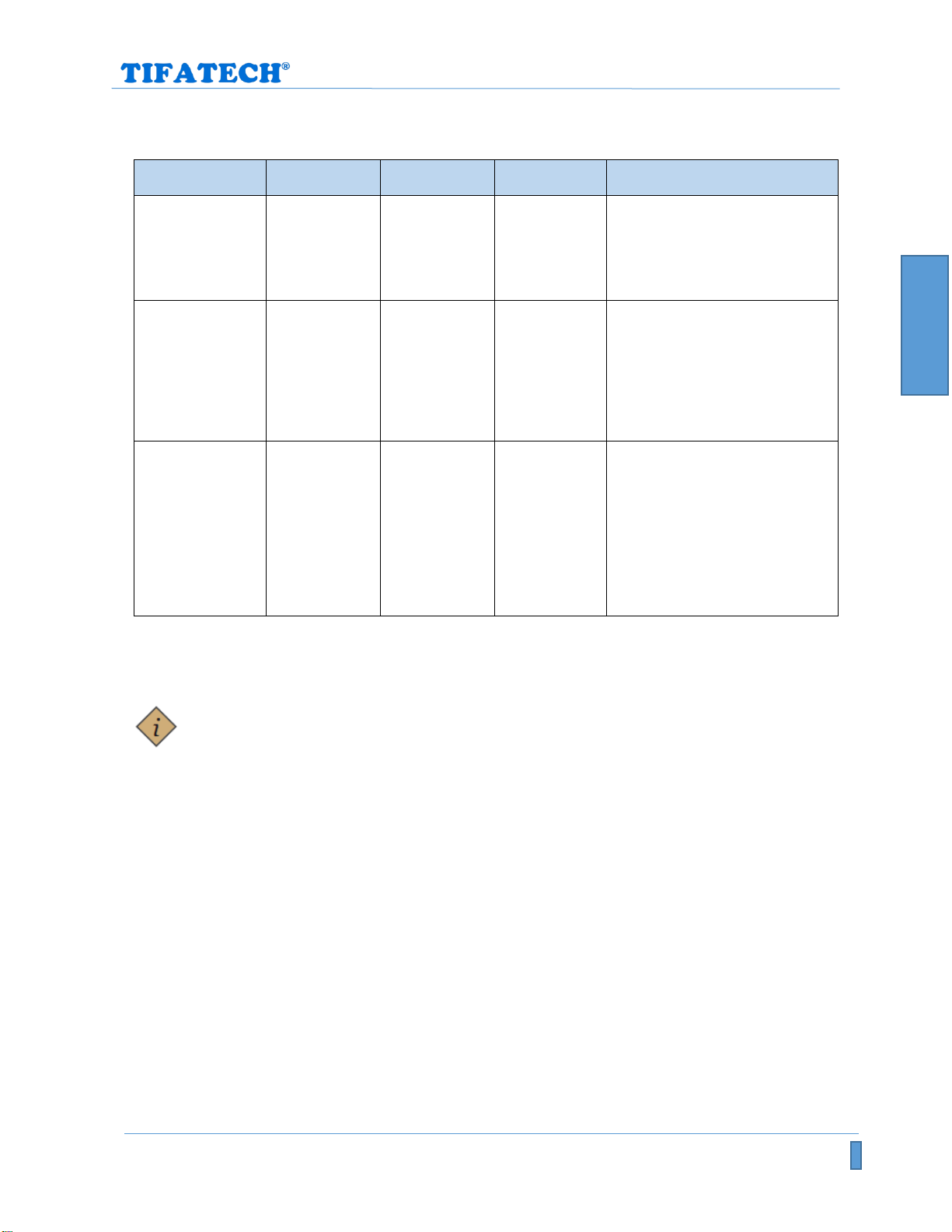

➢Table of parameters explanation :

Parameter

Range

Step

Default

Description

P

0 - 100

1

0

Propotional coefficient

(Recommend: P = 0)

HYS

1 - 10

1

2

The smallest temperature

difference required to

activate the heating element

ACT

1 - 10

1

7

Auto cleaning time

ACC

1 - 10

1

7

Period of the cleaning

process

SCF

1 - 5

1

3

Pre-infusion time

Unit: second

11

S21-037

ENGLISH

S

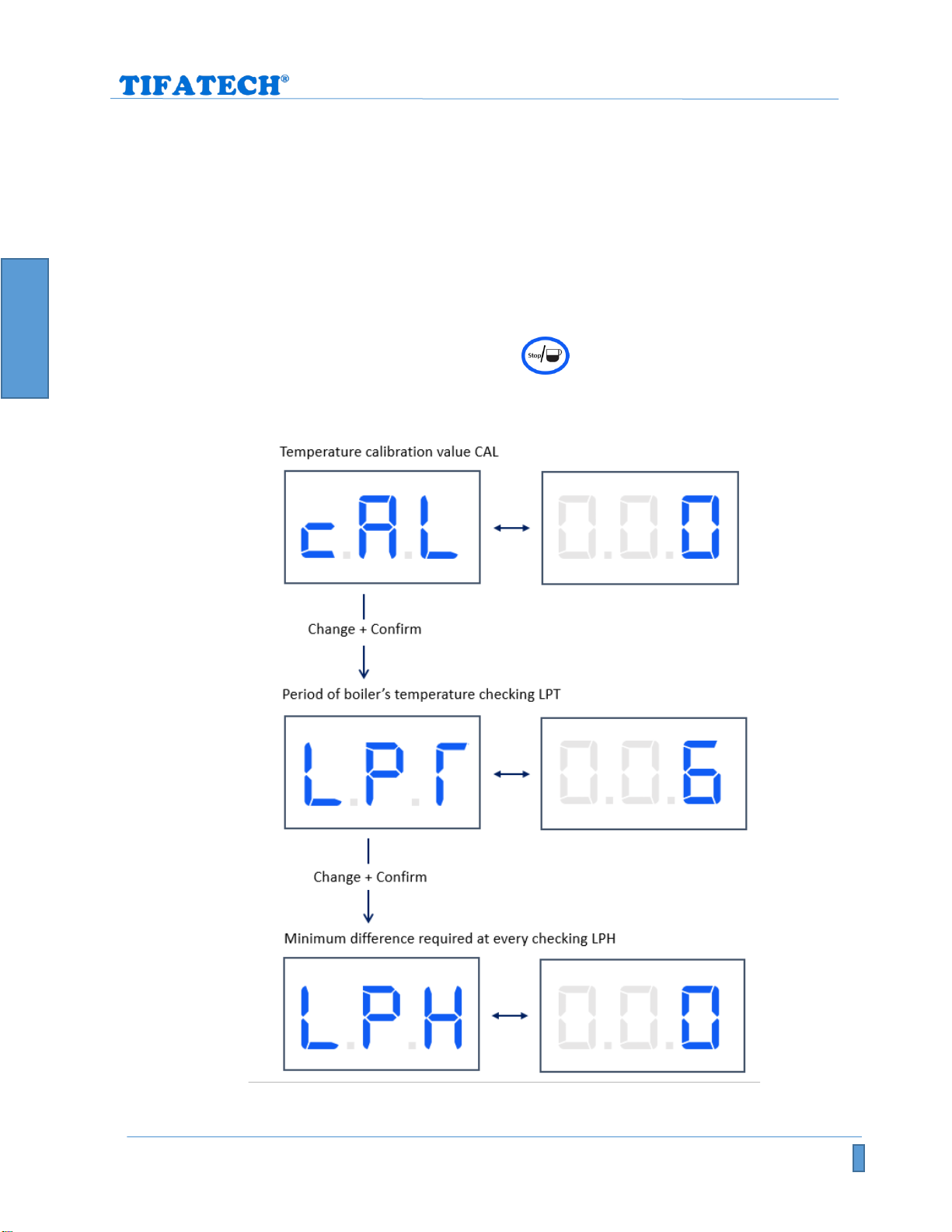

4. Advanced setting (For techinician only)

Press and hold all buttons simultaneously for 3 seconds until the siren sound. The 2

shot espresso light begins to flash.

•Use the Increase/Decrease button to adjust the parameter value.

•Use Confirm/Change button to save your changes and move on to set a new

parameter.

•Press and hold the Confirm button for 3 seconds to leave the setup

mode. All lights return to the off state.

12

S21-037

ENGLISH

S

➢Table of parameters explanation :

Parameter

Range

Step

Default

Description

CAL

-5 ÷ 5

0.1

0

Calibration value of

temperature sensor

Unit: °C

LPT

0 ÷ 200

1

6

Checking boiler’s

temperature with LPT

period

Unit: minute

LPH

0 ÷ 999

0.1

0

The minimum

temperature difference

required at every LPT

checking period.

Unit: °C

VI. CLEANING AND MAINTENANCE

Note: You should always follow to the cleaning instructions provided in this

manual to keep the machine running at its highest efficiency and prolong its life.

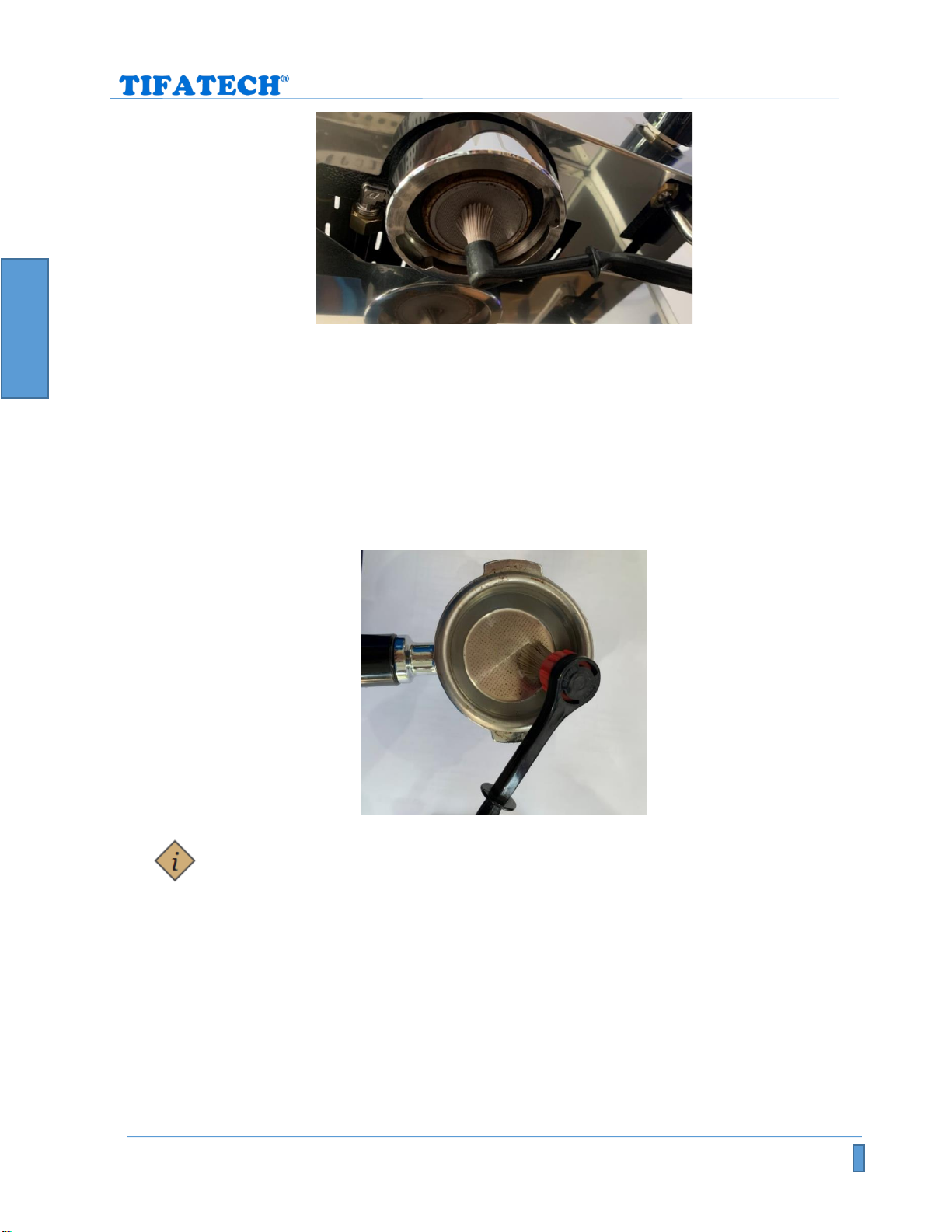

1. Cleaning the group head

Step1: Remove the portafilter from the filter holder and discharge water to wash

both group head and the portafilter.

Step2: Using the the provided brush supplied with the machine to eliminate the

coffee residues from the filters and the shower plate. Press Stop again to finish the

cleaning process.

13

S21-037

ENGLISH

S

2. Cleaning the filter basket

•Remove the basket filter from the portafilter, then also use provided brush to

get rid of the residual coffee.

•If the filter get clogged up and you're not able to clean it normally, burn any

coffee particles with a bare flame.

Note: Abusing this burning solution could harm the filter, thus avoid doing it

frequently.

3. Cleaning the group gasket

While dispensing coffee, the coffee may gather on the group's sealing surface. Over

time, it will make it difficult to open or close the portafilter to the group head and

eventually break the group gasket.

Follow the procedure below for cleaning the group gasket:

14

S21-037

ENGLISH

S

Step 1: Insert the blind basket into the portafilter

Step 2: Place the portafilter into group head and start to discharge water by pressing

Stop button.

Step 3: Briefly opening and closing the portafilter so that the water run out. Keep

your hands and other body parts out of the water to prevent burns.

Step 4: Stop discharging water and remove the portafilter from group head.

4. Automatic group cleaning

The group cleaning process can be automated to save user's time by following steps

below:

Step 1: Insert a suitable amount of provided cleaning powder into the blind basket,

then lock the portafilter into the group head.

Step 2: Press and hold the 2 shot espresso button for at least 5 seconds

until the siren stops sounding and the machine starts to discharge water.

Step 3: After completion of the cleaning process, remove the portafilter and

thoroughly clean the group head.

Note: The cleaning time and period can be modified by the user (page 9, 10).

This manual suits for next models

4

Table of contents