TRAINING

It is the responsibility of the users to assure that they are familiar with the instructions, and are

trained in the correct care and use of this equipment. Users must also be aware of the operating

characteristics, application limits, and the consequences of improper use of this equipment.

INSPECTION

Frequency:

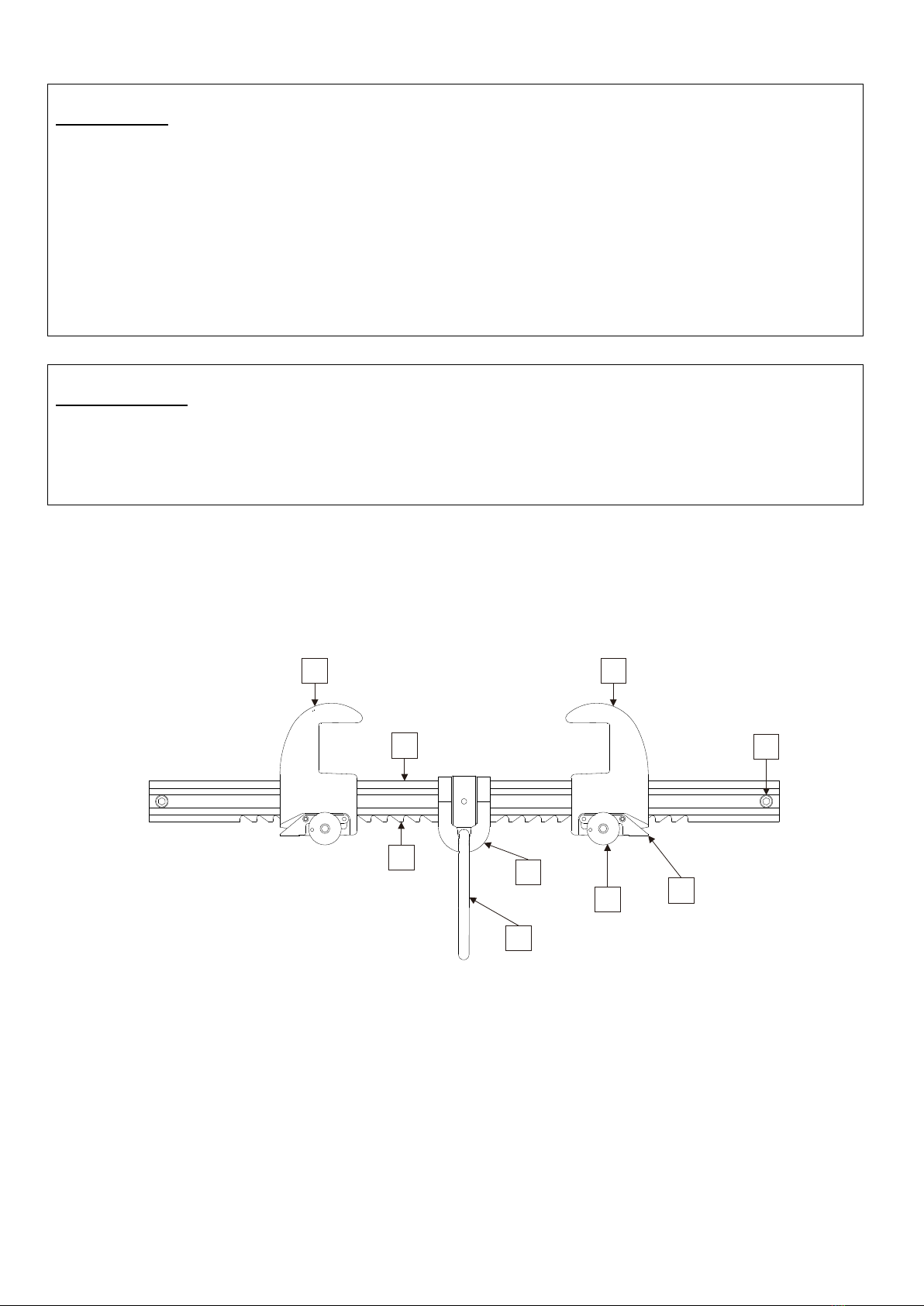

Before each use, inspect the Dual Sliding Beam Anchor according to following steps and see Dual

SLIDINGBEAM ANCHOR COMPONENTS for part identification. The Dual Sliding Beam Anchor must be

formally inspected by a competent person other than the user at least annually. Record the results in

INSPECTION AND MAINTENANCE LOG.

Inspection Steps:

Step 1.Inspect Dual Sliding Beam Anchor for damage: Look for cracks, dents, or deformities. Look for

bending or wear on the hexagonal rod, sliding clamps, safety lock, and quick release lock pin.

Ensure no parts are missing.

Step 2. Inspect entire unit for excessive corrosion.

Step 3. Ensure the quick release lock pin can be inserted through the hole on safety lock button, and

locks in place.

Step 4. Record the inspection date and results in the INSPECTION AND MAINTENANCE LOG.

If inspection reveals an unsafe or defective condition, remove the equipment from service and destroy, or

return to Tiger for repair.

NOTE: Only Tiger or parties authorised in writing are qualified to repair this equipment.

MAINTENANCE, SERVICE, STORAGE

Cleaning:

Periodically clean the Dual Sliding Beam Anchor by water and a mild soap solution. Do not use acids or

other caustic chemicals that could damage the system components. A lubricant may be applied to the

safety lock button and the quick release lock pin.

Storage:

Store the equipment in a cool, dry, dark place, chemically neutral, away from sharp corners, sources of

heat, humidity, corrosive substances or other damaging conditions.