TIGIEFFE AIRO A Series User manual

PIATTAFORME AEREE SEMOVENTI

SELF-PROPELLED WORK-PLATFORMS

PLATES-FORMES DE TRAVAIL AUTOMOTRICES

SELBSTFAHRENDE HUBARBEITSBÜHNEN

PLATAFORMAS ELEVADORAS AUTOPROPULSADAS

ZELFRIJDENDE HOOGWERKERS

SJÄLVGÅENDE ARBETSPLATTFORMAR

SAMOKRETNE RADNE PLATFORME

"A" SERIES

A12 A13 J

USE AND MAINTENANCE MANUAL

- ENGLISH - ORIGINAL INSTRUCTIONS

AIRO is a division of TIGIEFFE SRL

Via Villa superiore, 82 - 42045 Luzzara (RE) ITALY-

+39-0522-977365 - +39-0522-977015

WEB: www.airo.com

023.20.UEM-EN

2020 - 02

Use and Maintenance Manual –A12 A13 Series

Page 3

Revision date

Description of revision

2010-01

•Update due to new machine directive 2006/42/EC.

•Model names updated.

2010-11

•Biodegradable oil instructions introduced

•Temperatures and oil list updated.

2011-05

•Amended information on “Commissioning and first inspection, subsequent inspections

and title transfer report”.

•Added “Total quantity of battery electrolyte” in Technical Data.

•Corrected "Max. power" diesel engine and inserted "Adjusted Power"

2013-10

•Specified instructions for harness anchoring points

2014-09

•Inserted information on maximum limits of manual forces.

•Changed Name and Surname of CEO.

2015-01

•CE conformity declaration updated.

•Added position of hands instruction

2015-10

•Type of usable hydraulic oil updated.

•Added indication for spare parts. They must be original or approved by the

manufacturer of the machine in any way.

•Added "Leaving at height”.

•Updated system/battery charger ignition procedure.

2015-12

•Modified overload controller calibration procedure, removed insulation loss Sensor

2018-07

•Data sheets were added with units of measurement of the international system and US

unit of measurement.

•Changed Name and Surname of CEO.

•Unified First and Second Part.

2019-07

•Updated procedure description of commissioning declaration in Italy.

2020-01

•Updated normative references and certifying body

2020-02

•Removed A10 AND, A12 EB models

•Updated paragraph 5.6 “Manual emergency controls”: procedure for alternative

hydraulic block added

•Updated wiring diagram for control system unification with A16 J –A18 J.

•Updated images and instructions for use and calibration of components of the new

control system

•Updated information on engine oil, hydraulic oils and lubricating greases

•Corrected the technical data converted to the US measuring system

•Updated facsimiles of EC declarations of conformity: monolingual text.

Use and Maintenance Manual –A12 A13 Series

Page 4

Tigieffe thanks you for purchasing a product of its range and invites you to read this manual. Here you can find all the

necessary information for a correct use of the purchased machine; therefore, you are advised to follow the instructions

carefully and to read the manual thoroughly. The manual should be kept in a suitable place where no damage can occur to

it. The content of this manual may be modified without prior notice and further obligations in order to add changes and

improvements to the units already delivered. No reproduction or translation may take place without the written permission of

the owner.

Contents:

1. INTRODUCTION................................................................................................................................7

1.1. Legal aspects.................................................................................................................................................... 7

1.1.1. Delivery of the machine .................................................................................................................................... 7

1.1.2. Declaration of commissioning, first check, further periodical checks and transfers of ownership..................... 7

1.1.2.1. Declaration of commissioning and first check................................................................................................... 7

1.1.2.2. Further periodical checks.................................................................................................................................. 8

1.1.2.3. Transfers of ownership. .................................................................................................................................... 8

1.1.3. Operator training and information ..................................................................................................................... 8

1.2. Tests performed before delivery ....................................................................................................................... 8

1.3. Intended use ..................................................................................................................................................... 8

1.3.1. Leaving at height............................................................................................................................................... 9

1.4. Description of the machine ............................................................................................................................... 9

1.5. Control panels................................................................................................................................................. 10

1.6. Power supply .................................................................................................................................................. 10

1.7. Machine life, demolition and decommissioning............................................................................................... 10

1.8. Identification.................................................................................................................................................... 11

1.9. Location of main components......................................................................................................................... 12

2. TECHNICAL FEATURES OF STANDARD MACHINES..................................................................13

2.1. Model A12 E ................................................................................................................................................... 13

2.2. Model A12 ED................................................................................................................................................. 15

2.3. Model A13 JE.................................................................................................................................................. 18

2.4. Model A13 JED............................................................................................................................................... 20

2.5. Vibrations and noise ....................................................................................................................................... 23

3. SAFETY PRECAUTIONS. ...............................................................................................................24

3.1. Personal protective equipment (PPE)............................................................................................................. 24

3.2. General safety norms...................................................................................................................................... 24

3.3. Use instructions .............................................................................................................................................. 25

3.3.1. General ........................................................................................................................................................... 25

3.3.2. Handling.......................................................................................................................................................... 25

3.3.3. Operating procedures ..................................................................................................................................... 27

3.3.4. Wind speed according to Beaufort scale......................................................................................................... 28

3.3.5. Pressure of the machine on ground and load-bearing capacity of ground...................................................... 29

3.3.6. High-voltage power lines................................................................................................................................. 30

3.4. Hazardous situations and/or accidents ........................................................................................................... 30

4. INSTALLATION AND PRELIMINARY CHECKS.............................................................................31

4.1. Becoming acquainted with the machine.......................................................................................................... 31

4.2. Preliminary operation checks.......................................................................................................................... 31

5. USE INSTRUCTIONS ......................................................................................................................32

5.1. Platform control panel..................................................................................................................................... 32

5.1.1. Drive and steering........................................................................................................................................... 34

5.1.2. Platform positioning movements..................................................................................................................... 35

5.1.2.1. Pantograph (lower boom) lifting/lowering........................................................................................................ 35

5.1.2.2. Upper boom lifting/lowering ............................................................................................................................ 35

5.1.2.3. Jib lifting/lowering (A13 J only) ....................................................................................................................... 35

5.1.2.4. Telescopic boom extension/retraction ............................................................................................................ 35

5.1.2.5. Turret orientation (rotation) ............................................................................................................................. 35

5.1.2.6. Platform rotation.............................................................................................................................................. 36

5.1.2.6.1. Platform rotation A12 (OPTIONAL)................................................................................................................. 36

Use and Maintenance Manual –A12 A13 Series

Page 5

5.1.2.6.2. Platform rotation A13 J....................................................................................................................................36

5.1.2.7. Platform levelling.............................................................................................................................................36

5.1.3. Other functions of the platform control panel...................................................................................................37

5.1.3.1. Selection of electric/thermic drive power (“ED” models)..................................................................................37

5.1.3.2. Heat engine start key (“ED” models)...............................................................................................................37

5.1.3.3. Manual horn ....................................................................................................................................................37

5.1.3.4. Emergency stop ..............................................................................................................................................37

5.1.3.5. Fault warning light ...........................................................................................................................................37

5.1.3.6. Overload warning light.....................................................................................................................................38

5.1.3.7. Voltmeter.........................................................................................................................................................38

5.1.3.8. Fuel level indicator (OPTIONAL for “ED” models)...........................................................................................38

5.2. Ground control panel and electric control unit.................................................................................................39

5.2.1. Ground control panel.......................................................................................................................................39

5.2.1.1. On-off key and control panel selector (A)........................................................................................................40

5.2.1.2. Emergency stop button (B-N)..........................................................................................................................40

5.2.1.3. Powered-on machine warning light (C) ...........................................................................................................40

5.2.1.4. Platform control levers (D-E-F-G-H-L).............................................................................................................41

5.2.1.5. Battery charger light (I)....................................................................................................................................41

5.2.1.6. User interface display (M) ...............................................................................................................................41

5.2.2. Electric control unit on the ground...................................................................................................................42

5.3. Platform access...............................................................................................................................................43

5.4. Machine start-up..............................................................................................................................................44

5.4.1. Diesel engine start-up (“ED” models)..............................................................................................................44

5.5. Machine stop...................................................................................................................................................45

5.5.1. Normal stop.....................................................................................................................................................45

5.5.2. Emergency stop ..............................................................................................................................................45

5.5.3. Diesel engine stop (“ED” models) ...................................................................................................................45

5.6. Emergency manual controls............................................................................................................................46

5.6.1. Hydraulic block of type A.................................................................................................................................46

5.6.2. Hydraulic block of type B.................................................................................................................................47

5.7. Socket for electric tool connection (Optional)..................................................................................................48

5.8. Fuel level and re-fuelling (“ED” models)..........................................................................................................49

5.9. End of work .....................................................................................................................................................49

6. HANDLING AND CARRYING..........................................................................................................50

6.1. Handling..........................................................................................................................................................50

6.2. Transportation .................................................................................................................................................51

6.3. Emergency towing of the machine ..................................................................................................................52

7. MAINTENANCE...............................................................................................................................53

7.1. Machine cleaning ............................................................................................................................................53

7.2. General maintenance......................................................................................................................................54

7.2.1. Various adjustments........................................................................................................................................55

7.2.2. Greasing..........................................................................................................................................................56

7.2.3. Hydraulic circuit oil level check and change....................................................................................................57

7.2.3.1 Biodegradable hydraulic oil (Optional) ............................................................................................................58

7.2.3.2 Emptying .........................................................................................................................................................58

7.2.3.3 Filters ..............................................................................................................................................................58

7.2.3.4 Washing ..........................................................................................................................................................58

7.2.3.5 Filling...............................................................................................................................................................58

7.2.3.6 Commissioning / check ...................................................................................................................................58

7.2.3.7 Mix...................................................................................................................................................................59

7.2.3.8 Micro-filtration..................................................................................................................................................59

7.2.3.9 Disposal ..........................................................................................................................................................59

7.2.3.10 Topping up ......................................................................................................................................................59

7.2.4. Suction filter replacement................................................................................................................................60

7.2.5. Drive reduction gear oil level check and change.............................................................................................61

7.2.5.1 Checks in the use of synthetic biodegradable oil in drive reduction gears (Optional) .....................................61

7.2.6. Telescopic boom sliding blocks clearance adjustment....................................................................................62

7.2.7. Pressure relief valve adjustment and operation check....................................................................................63

Use and Maintenance Manual –A12 A13 Series

Page 6

7.2.8. Operation check and adjustment of the braking valves .................................................................................. 64

7.2.9. Inclinometer operation check.......................................................................................................................... 65

7.2.10. Operation check and adjustment of platform overload controller (load cells).................................................. 67

7.2.11. Overload controller by-pass –ONLY FOR EMERGENCY OPERATIONS ..................................................... 69

7.2.12. Operation check of M1 microswitches ............................................................................................................ 70

7.2.13. Operation check of dead-man pedal safety system........................................................................................ 70

7.3. Starter battery for “ED” models ....................................................................................................................... 71

7.3.1. Starter battery maintenance............................................................................................................................ 71

7.3.2. Starter battery recharge.................................................................................................................................. 71

7.4. “DRIVE” battery for “E” and “ED” models........................................................................................................ 72

7.4.1. General instructions for DRIVE battery........................................................................................................... 72

7.4.2. DRIVE battery maintenance ........................................................................................................................... 72

7.4.3. Battery charger: DRIVE battery recharge ....................................................................................................... 73

7.4.4. Battery charger: fault report ............................................................................................................................ 74

7.4.5. Battery replacement........................................................................................................................................ 75

8. MARKS AND CERTIFICATIONS.....................................................................................................76

9. PLATES AND STICKERS................................................................................................................77

10. CHECK REGISTER .........................................................................................................................79

11. WIRING DIAGRAM STANDARD MACHINES A12 E –A13 JE ......................................................95

12. HYDRAULIC DIAGRAM STANDARD MACHINES A12 E –A13 JE.............................................104

13. DECLARATION OF CONFORMITY EC FACSIMILE ....................................................................107

Use and Maintenance Manual –A12 A13 Series

Page 7

1. INTRODUCTION

This Use and Maintenance Manual provides general instructions concerning the complete range of machines indicated on

the cover. Therefore the description of their components, as well as control and safety systems, may include parts not

present on Your machine since supplied on request or not available. In order to keep pace with the technical development

AIRO-Tigieffe s.r.l. reserves the right to modify the product and/or the use and maintenance manual at any time without

updating the units already delivered.

1.1. Legal aspects

1.1.1. Delivery of the machine

Within EU (European Union) member countries the machine is delivered complete with:

▪Use and Maintenance manual in your language

▪CE mark applied on the machine

▪CE conformity declaration

▪Guarantee certificate

▪Declaration of internal testing

Only for Italy:

▪Instructions on commissioning declaration with INAIL and on the application for the first periodic check on the INAIL

portal.

It is to be noted that the Use and Maintenance Manual is an integral part of the machine and a copy of this, together with

copies of the documents certifying that the periodical checks have been carried out, must be kept on board in its suitable

container. In the event of a transfer of ownership the machine must always be provided with its use and maintenance

manual.

1.1.2. Declaration of commissioning, first check, further periodical checks and transfers of

ownership

The legal obligations of the owner of the machine vary according to the country of commissioning. It is therefore

recommended to inquiry about the procedures in force in your country from the boards responsible for industrial safety. This

manual contains a final section called "Check register" for a better filing of documents and recording of any modifications.

1.1.2.1. Declaration of commissioning and first check

In ITALY the owner of the Aerial Platform must notify the use of the machine to the local competent INAIL and submit it to

periodical compulsory checks. The first of such checks is performed by the INAIL within sixty days from a request being

made. In the event of such time passing without the inspection being made, the employer can call in the ASL (Local Health

Unit) or qualified public or private services. Subsequent checks are made by the already-mentioned parties within thirty days

from a request being made. In the event of such time passing without these checks being made, the employer can call in

qualified public or private services. The checks are on a payment basis and the employer (machine owner) will be charged

for them. For these checks, the territorial inspection boards (ASL/USL or ARPA) and INAIL can be supported by qualified

public or private services. The qualified private institutes acquire the qualification of responsible for the public service and

refer directly to the public structure that controls this function.

For the commissioning declaration in Italy, it is necessary to login to the INAIL portal. Follow the instructions delivered

together with other documents during the machine delivery, as well as the information about the portal.

The INAIL will assign a serial number and when the First Check is performed the “technical identification sheet” will be

completed indicating only the details obtained from the already-operating machine or from the instruction manual. Such

document shall form an integral part of the machine documentation.

Use and Maintenance Manual –A12 A13 Series

Page 8

1.1.2.2. Further periodical checks

Yearly checks are compulsory. In Italy the Aerial Platform owner must apply for a periodical check - by registered letter - to

the local competent inspection board (ASL/USL or other qualified public or private services) at least twenty days before the

expiry of the year from the last check.

NB: If a machine without a valid control document should be moved in an area outside the competence of the usual

inspection board, the owner of the machine must ask the inspection board, competent for the new territory where the

machine is to be used, for the annual check.

1.1.2.3. Transfers of ownership.

In case of transfer of ownership (in Italy) the new owner of the Aerial Platform must notify the ownership of the machine to

the local competent inspection board (ASL/USL or ARPA or other qualified public or private services) by enclosing a copy of:

▪Declaration of conformity issued by the manufacturer.

▪Declaration of commissioning carried out by the first owner.

1.1.3. Operator training and information

The employer must ensure that the workers appointed to use the equipment are adequately and specifically trained so they

are able to use the Mobile Elevating Work Platform in a proper and safe way and also avoid the risks caused by other

people.

1.2. Tests performed before delivery

Before being placed on the market, each MEWP undergoes the following tests:

▪Braking test

▪Overload test

▪Operating test

1.3. Intended use

The machine described in this use and maintenance manual is a mobile elevating work platform intended for lifting persons

and materials (equipment and work materials) in order to carry out maintenance, installation, cleaning, painting, de-painting,

sand-blasting, welding operations, etc.

The max. capacity allowed (which varies according to the model –see paragraph “Technical features”) is divided as follows:

▪80 Kg for each person on board.

▪40 Kg for equipment.

▪The remaining load is represented by the material being worked.

In any case NEVER exceed the maximum capacity allowed as indicated in paragraph "Technical features”. Persons, tools

and work materials can be loaded on the platform only from the access position (platform lowered). It is absolutely forbidden

to load persons, tools and work materials on the platform when it is not in access position.

All loads must be positioned inside the cage; do not lift loads (even if complying with the maximum capacity allowed)

hanging from the platform or from the lifting structure.

Do not carry large-sized panels since they increase the resistance to wind force thus causing the machine to overturn.

While the machine is being displaced with lifted platform, no horizontal loads can be loaded onto the platform (operators on

board are not allowed to pull wires or ropes, etc.).

An overload controller stops the operation of the machine if the load on the platform exceeds by 20% approx. the nominal

load (see chapter "General use rules”) and platform is lifted.

The machine cannot be used in areas where road vehicles operate. Always surround the working area by means of suitable

signs when the machine is used in public areas.

Do not use the machine to tow trucks or other vehicles.

All types of machine use other than those for which it was designed must be approved in writing by the machine

manufacturer following a specific request on the part of the user.

Use and Maintenance Manual –A12 A13 Series

Page 9

Do not use the machine for purposes other than those for which it was designed, except after making

a request and having obtained written permission in this sense from the manufacturer

1.3.1. Leaving at height

The mobile elevating work platforms are not designed by taking into account the risks of the “leaving at height” because the

only access position considered is when the platform is completely lowered. For this reason, this activity is formally

forbidden.

However, there are exceptional conditions in which the operator needs to access or leave the work platform not in the

access position. This activity is normally defined as “leaving at height”.

The risks connected to the “leaving at height” do not depend exclusively on the MEWP (mobile elevating work platform)

characteristics; a specific risk analysis carried out by the employer can authorize this specific use by taking into account:

▪The working environment characteristics;

▪The absolute prohibition to consider the work platform as a anchoring point for people working outdoors;

▪The use of the machine at xx% of its performances to avoid that additional forces created by a specific operation or

bending of the structure move away the access zone from the unloading zone. Provide for some tests in order to

define these limitations;

▪Provide for a specific evacuation procedure in case of emergency (for example: an operator always on the work

platform, one at the ground control panel while a third operator leaves the lifted platform);

▪Provide for a specific training of the staff both as operator and transported staff;

▪Equip the unloading zone with all the devices that are necessary to avoid the risk of fall of the staff that

accesses/leaves the platform.

What said above is not a formal authorization of the manufacturer for the “leaving at height”, but it wants to supply

information to the employer - who is fully responsible for that - which can be useful for the planning of this exceptional

activity.

1.4. Description of the machine

The machine described in this use and maintenance manual is a mobile elevating work platform equipped with:

▪motorized chassis equipped with wheels;

▪hydraulically driven rotating turret;

▪Articulated boom operated by hydraulic cylinders (the number of articulations and cylinders varies according to

machine model).

▪operator platform (the max. capacity varies according to the model - see chapter "Technical features”).

The chassis is motorised to allow the machine to move even with lifted platform (see “Use instructions”); the two rear

wheels are drive and two front wheels are steering. The drive wheels are equipped with hydraulic parking brakes, positive

logic type (when drive controls are released brakes are automatically activated).

The turret rests on a turntable fixed to the chassis and can be oriented (rotated) by 360° non-continuous around the central

axle of the machine by means of irreversible endless screw.

The lifting system, with articulated boom, can be divided into three main structures:

▪the first, consisting of a “simple parallelogram” for lifting (boom and tie rod);

▪the second, consisting of a telescopic extension of the primary boom

▪the third, consisting of the terminal boom named “Jib” (for A13 J only).

Such lifting structures are driven by double-acting hydraulic cylinders:

▪one cylinder for the “parallelogram” extension.

▪one cylinder for the boom extension;

▪one cylinder for the extension/retraction of the telescopic boom.

▪one cylinder for the “jib” extension (A13 J only).

The hydraulic cylinders which move the articulated structure (except for the boom tilt sensor cylinder) are provided with

over-centre valves directly flanged on the same. These devices allow the booms to remain in position even if one of the

supply tubes accidentally breaks.

Use and Maintenance Manual –A12 A13 Series

Page 10

The platform, hinged to the end of the primary boom or of the “jib”, is equipped with guard-rails and toe-boards of a

prescribed height (the height of the guard-rails is 1100 mm; the height of the toe-boards is 150 mm). As an option, the

platform can be rotated by a total of 140° (70° to the right and 70° to the left) by means of a rotary actuator, also provided

with an over-center valve.

The platform levelling is automatic and is ensured by two cylinders in closed circuit. The manual level compensation is

possible by acting on the relevant control only with completely lowered booms (and with “Jib” inclination ranging between

+10° and –70° with respect to the horizontal axis).

1.5. Control panels

The machine is equipped with two control panels:

▪On the platform for normal use of the machine.

▪On the turret (or on the ground) you can find the emergency controls to lower or stop the machine in emergency

situations, a key-selector to select the control panel and to start the machine.

1.6. Power supply

The machines can be powered by:

▪An electric-hydraulic system composed of rechargeable accumulators and electric pump.

▪electric/thermic dual-powered system (electro/diesel dual-powered models are identified by the abbreviation “ED”).

In any case both the hydraulic and the electric systems are equipped with all necessary protections (see wiring and

hydraulic circuit diagrams attached to this manual).

1.7. Machine life, demolition and decommissioning

The machine has been designed to last for 10 years in normal operating environments, if properly used and serviced.

Within this period, the manufacturer must carry out a complete inspection/overhaul.

If disposal of the unit is necessary, comply with current local regulations.

In Italy, the demolition/decommissioning must be notified to the local ASL / USL or ARPA.

The machine consists mainly of metal parts which are easy to be identified (steel for the most parts, and aluminium for the

hydraulic blocks); thus, we can state that the machine can be recycled at 90%.

European standards and those transposed by the member countries relating to respect for the

environment and the disposal of wastes envisage heavy administrative and penal fines in case of

infringement.

In case of demolition/decommissioning, carefully keep to the provisions of applicable regulations,

especially as regards materials such as hydraulic oil and batteries.

Use and Maintenance Manual –A12 A13 Series

Page 11

1.8. Identification

In order to identify the machine, when spare parts and service are required, always mention the information given in the

serial number plate. Should this plate (as well as the various stickers applied on the machine) be lost or illegible, it is to be

replaced as soon as possible. In order to identify the machine when no plate is available the serial number is also stamped

on the chassis. To locate the plate and the stamp of the serial number, see the following picture. It is recommended to copy

such data in the following boxes.

MODEL: __________________

CHASSIS: ____________________

YEAR: __________________

Fig.1

Use and Maintenance Manual –A12 A13 Series

Page 12

1.9. Location of main components

The picture shows the machine and its own components.

Fig. 2

1) Control panel

2) Electric control unit

3) Hydraulic control unit

4) Hydraulic drive motors

5) Turret rotation hydraulic motor

6) 220V socket

7) Spirit level for visual check of

machine levelling

8) Lifting cylinders

9) Battery

10) Power assisted steering

11) Inclinometer

12) Heat engine fuel tank

13) Overload controller sensor

(load cell)

14) Turntable

12

Use and Maintenance Manual –A12 A13 Series

Page 13

2. TECHNICAL FEATURES OF STANDARD MACHINES

THE TECHNICAL FEATURES OF THE PRODUCTS IN THE FOLLOWING PAGES CAN BE MODIFIED

WITHOUT PRIOR NOTICE

2.1. Model A12 E

A12 E

Dimensions:

Maximum working height

12

m

39’ 4”

ft

Max. platform height

10

m

32’ 10”

ft

Ground clearance

170

mm

6.7

in

Max. outreach from turntable centre

6.3

m

20’ 8”

ft

Turret rotation (not continuous)

360

°

360

°

Platform rotation (5)

0

°

0

°

Platform height for safety speed activation

< 3

m

< 9’ 10”

ft

Internal steering radius

0.95

m

3’ 1”

ft

External steering radius

2.95

m

9’ 8”

ft

Maximum capacity (m)

200

Kg

440

lbs

Max. number of people on the platform (n) –indoors

2

2

Tool and material weight (me) (2) –indoors

40

Kg

88

lbs

Max. number of people on the platform (n) –outdoors

2

2

Tool and material weight (me) (2) –outdoors

40

Kg

88

lbs

Maximum drive height

Max

Max

Maximum dimensions of platform

0.8 x 1.36

m

2’ 8” x 4’ 6”

ft

Max. hydraulic pressure

210

bar

3045

psi

Max. pressure of lifting circuit

210

bar

3045

psi

Min. pressure of braking circuit

35 ÷ 40

bar

508 ÷ 580

psi

Tyre dimensions (4)

Ø 584 x 324

mm

23 x 13

in

Tire type (4)

23 x 10 - 12

23 x 10 - 12

Transport dimensions

4.15 x 1.5 x 1.97

m

13’ 7” x4’ 11” x6’ 6”

ft

Transport dimensions with retracted jib

N.A.

m

N.A.

ft

Machine weight (unloaded) (1)

3900

Kg

8600

lbs

Stability limit:

Longitudinal slope

2

°

2

°

Transversal slope

2

°

2

°

Maximum wind speed (3)

12.5

m/s

27.96

mph

Maximum manual force:

400

N

90

lbf

Max. load per wheel

1740

Kg

3836

lbs

Performance:

Drive wheels

2

2

Max. drive speed

4

km/h

2.5

mph

Safety drive speed

0.6

km/h

0.4

mph

Oil tank capacity

40

Lt.

10.5

gal

Gradeability

25

%

25

%

Max. operating temperature

+50

°C

+122

°F

Min. operating temperature

-15

°C

+5

°F

Use and Maintenance Manual –A12 A13 Series

Page 14

Battery power:

Battery capacity and voltage

2 x 24 / 325

V/Ah

2 x 24 / 325

V/Ah

Total electrolyte quantity

2 x 54

Lt.

2 x 14

gal

Battery weight

2 x 220

Kg

2 x 485

lbs

Single-phase battery charger (HF)

48 / 45

V/A

48 / 45

V/A

Max. current absorbed by the battery charger

15

A

15

A

Max. installed power

4.5

kW

6

hp

Power electric pump 1

4.5

kW

6

hp

Max. absorbed current

160

A

160

A

Electric pump power 2

NA

kW

NA

hp

Max. absorbed current

NA

A

NA

A

Electric pump power 3

NA

kW

NA

hp

Max. absorbed current

NA

A

NA

A

(1) In some cases, different limits can be fixed. It is recommended to comply with the data shown on the machine plate.

(2) me = m –(n x 80)

(3) Wind speeds greater than or equal to 12,5 m/s identify machines that can also be used outdoors. Wind speeds equal to 0 m/s identify

machines FOR INTERNAL USE ONLY.

(4) Standard: extra flexible black tyres 23x10-12; Optional: extra flexible no-marking tyres 23x10-12.

(5) Standard: fixed platform; Optional: revolving platform 140° (70°+70°).

Use and Maintenance Manual –A12 A13 Series

Page 15

2.2. Model A12 ED

A12 ED

Dimensions:

Maximum working height

12

m

39’ 4”

ft

Max. platform height

10

m

32’ 10”

ft

Ground clearance

170

mm

6.7

in

Max. outreach from turntable centre

6.3

m

20’ 8”

ft

Turret rotation (not continuous)

360

°

360

°

Platform rotation (5)

0

°

0

°

Platform height for safety speed activation

< 3

m

< 9’ 10”

ft

Internal steering radius

0.95

m

3’ 1”

ft

External steering radius

2.95

m

9’ 8”

ft

Maximum capacity (m)

200

Kg

440

lbs

Max. number of people on the platform (n) –indoors

2

2

Tool and material weight (me) (2) –indoors

40

Kg

88

lbs

Max. number of people on the platform (n) –outdoors

2

2

Tool and material weight (me) (2) –outdoors

40

Kg

88

lbs

Maximum drive height

Max

Max

Maximum dimensions of platform

0.8 x 1.36

m

2’ 8” x 4’ 5”

ft

Max. hydraulic pressure

210

bar

3045

psi

Max. pressure of lifting circuit

210

bar

3045

psi

Min. pressure of braking circuit

35 ÷ 40

bar

508 ÷ 580

psi

Tyre dimensions (4)

Ø 584 x 324

mm

23 x 13

in

Tire type (4)

23 x 10 - 12

23 x 10 - 12

Transport dimensions

4.15 x 1.5 x 1.97

m

13’ 7”x 4’ 11”x 6’ 6”

ft

Transport dimensions with retracted jib

N.A.

m

N.A.

ft

Machine weight (unloaded) (1)

4140

Kg

9127

lbs

Stability limit:

Longitudinal slope

2

°

2

°

Transversal slope

2

°

2

°

Maximum wind speed (3)

12.5

m/s

27.96

mph

Maximum manual force:

400

N

90

lbf

Max. load per wheel

1840

Kg

4056

lbs

Performance:

Drive wheels

2

2

Max. drive speed

4

km/h

2.5

mph

Safety drive speed

0.6

km/h

0.4

mph

Oil tank capacity

67

Lt.

17.7

gal

Gradeability

25

%

25

%

Max. operating temperature

+50

°C

+122

°F

Min. operating temperature

-15

°C

+5

°F

Use and Maintenance Manual –A12 A13 Series

Page 16

Battery power:

Battery capacity and voltage

2 x 24 / 325

V/Ah

2 x 24 / 325

V/Ah

Total electrolyte quantity

2 x 54

Lt.

2 x 14

gal

Battery weight

2 x 220

Kg

2 x 485

lbs

Single-phase battery charger (HF)

48 / 45

V/A

48 / 45

V/A

Max. current absorbed by the battery charger

15

A

15

A

Max. installed power

4.5

kW

6

hp

Power electric pump 1

4.5

kW

6

hp

Max. absorbed current

160

A

160

A

Electric pump power 2

NA

kW

NA

hp

Max. absorbed current

NA

A

NA

A

Electric pump power 3

NA

kW

NA

hp

Max. absorbed current

NA

A

NA

A

Diesel Power HATZ

Diesel engine type (6)

1B40T

1B40T

Max. motor power

7.3

kW

10

hp

Adjusted Power

6.8

kW

9

hp

Starter battery

12 / 55

V/Ah

12 / 55

V/Ah

Total electrolyte quantity

3

Lt.

0.8

gal

Diesel oil tank capacity

5

Lt.

1.3

gal

Max. drive speed

4

km/h

2.5

mph

380V three-phase electrical pump (optional)

Motor power

NA

kW

NA

hp

Max. absorbed current

NA

A

NA

A

Max. drive speed

NA

km/h

NA

mph

230V single-phase electric pump (optional)

Motor power

NA

kW

NA

hp

Max. absorbed current

NA

A

NA

A

Max. drive speed

NA

km/h

NA

mph

(1) In some cases, different limits can be fixed. It is recommended to comply with the data shown on the machine plate.

(2) me = m –(n x 80)

(3) Wind speeds greater than or equal to 12,5 m/s identify machines that can also be used outdoors. Wind speeds equal to 0 m/s identify

machines FOR INTERNAL USE ONLY.

(4) Standard: extra flexible black tyres 23x10-12; Optional: extra flexible no-marking tyres 23x10-12.

(5) Standard: fixed platform; Optional: revolving platform 140° (70°+70°).

(6) HATZ 1B40T engine standard –6.6 kW; Optional HATZ 1B50T engine –7.4 kW.

Use and Maintenance Manual –A12 A13 Series

Page 17

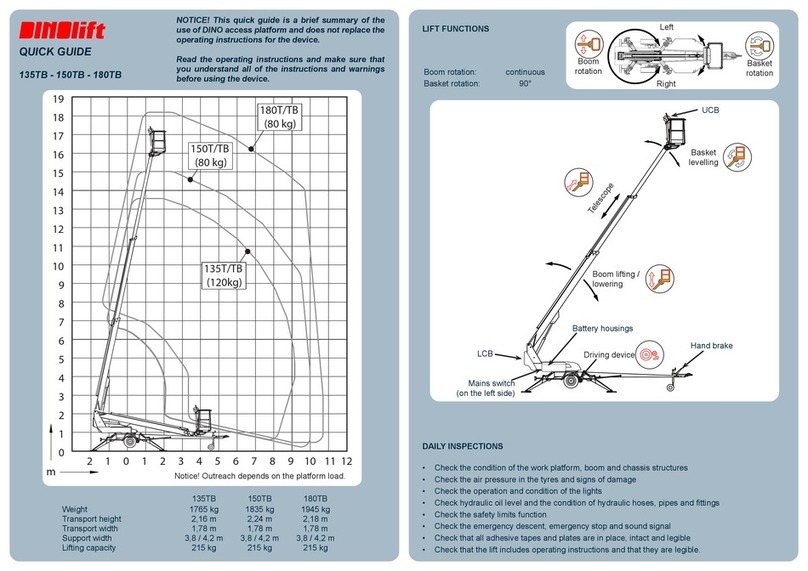

Fig. 3

Use and Maintenance Manual –A12 A13 Series

Page 18

2.3. Model A13 JE

A13 JE

Dimensions:

Maximum working height

13.1

m

42’ 11”

ft

Max. platform height

11.1

m

36’ 5”

ft

Ground clearance

170

mm

6.7

in

Max. outreach from turntable centre

8.1

m

26’ 7”

ft

Turret rotation (not continuous)

360

°

360

°

Platform rotation (5)

140

°

140

°

Platform height for safety speed activation

< 3

m

< 9’ 10”

ft

Internal steering radius

0.95

m

3’ 1”

ft

External steering radius

2.95

m

9’ 8”

ft

Maximum capacity (m)

200

Kg

440

lbs

Max. number of people on the platform (n) –indoors

2

2

Tool and material weight (me) (2) –indoors

40

Kg

88

lbs

Max. number of people on the platform (n) –outdoors

2

2

Tool and material weight (me) (2) –outdoors

40

Kg

88

lbs

Maximum drive height

Max

Max

Maximum dimensions of platform

0.8 x 1.36

m

2’ 8” x 4’ 5”

ft

Max. hydraulic pressure

220

bar

3191

psi

Max. pressure of lifting circuit

220

bar

3191

psi

Min. pressure of braking circuit

35 ÷ 40

bar

508 ÷ 580

psi

Tyre dimensions (4)

Ø 584 x 324

mm

23 x 13

in

Tire type (4)

23 x 10 - 12

23 x 10 - 12

Transport dimensions

5.06 x 1.5 x 1.97

m

16’ 7”x 4’ 11”x 6’ 6”

ft

Transport dimensions with retracted jib

N.A.

m

N.A.

ft

Machine weight (unloaded) (1)

5400

Kg

11905

lbs

Stability limit:

Longitudinal slope

4

°

4

°

Transversal slope

4

°

4

°

Maximum wind speed (3)

12.5

m/s

27.96

mph

Maximum manual force:

400

N

90

lbf

Max. load per wheel

2380

Kg

5247

lbs

Performance:

Drive wheels

2

2

Max. drive speed

4

km/h

2.5

mph

Safety drive speed

0.6

km/h

0.4

mph

Oil tank capacity

40

Lt.

10.5

gal

Gradeability

25

%

25

%

Max. operating temperature

+50

°C

+122

°F

Min. operating temperature

-15

°C

+5

°F

Use and Maintenance Manual –A12 A13 Series

Page 19

Battery power:

Battery capacity and voltage

2 x 24 / 325

V/Ah

2 x 24 / 325

V/Ah

Total electrolyte quantity

2 x 54

Lt.

2 x 14

gal

Battery weight

2 x 220

Kg

2 x 485

lbs

Single-phase battery charger (HF)

48 / 45

V/A

48 / 45

V/A

Max. current absorbed by the battery charger

15

A

15

A

Max. installed power

4.5

kW

6

hp

Power electric pump 1

4.5

kW

6

hp

Max. absorbed current

160

A

160

A

Electric pump power 2

NA

kW

NA

hp

Max. absorbed current

NA

A

NA

A

Electric pump power 3

NA

kW

NA

hp

Max. absorbed current

NA

A

NA

A

Diesel drive power

Diesel engine type

NA

NA

Motor power

NA

kW

NA

hp

Starter battery

NA

V/Ah

NA

V/Ah

Diesel oil tank capacity

NA

Lt.

NA

gal

Max. drive speed

NA

km/h

NA

mph

380V three-phase electrical pump (optional)

Motor power

NA

kW

NA

hp

Max. absorbed current

NA

A

NA

A

Max. drive speed

NA

km/h

NA

mph

230V single-phase electric pump (optional)

Motor power

NA

kW

NA

hp

Max. absorbed current

NA

A

NA

A

Max. drive speed

NA

km/h

NA

mph

(1) In some cases, different limits can be fixed. It is recommended to comply with the data shown on the machine plate.

(2) me = m –(n x 80)

(3) Wind speeds greater than or equal to 12,5 m/s identify machines that can also be used outdoors. Wind speeds equal to 0 m/s identify

machines FOR INTERNAL USE ONLY.

(4) Standard: extra flexible black tyres 23x10-12; Optional: extra flexible no-marking tyres 23x10-12.

(5) Revolving platform standard 140° (70°+70°).

Use and Maintenance Manual –A12 A13 Series

Page 20

2.4. Model A13 JED

A13 JED

Dimensions:

Maximum working height

13.1

m

42’ 11”

ft

Max. platform height

11.1

m

36’ 5”

ft

Ground clearance

170

mm

6.7

in

Max. outreach from turntable centre

8.1

m

26’ 7”

ft

Turret rotation (not continuous)

360

°

360

°

Platform rotation (5)

140

°

140

°

Platform height for safety speed activation

< 3

m

9’ 10”

ft

Internal steering radius

0.95

m

3’ 1”

ft

External steering radius

2.95

m

9’ 8”

ft

Maximum capacity (m)

200

Kg

440

lbs

Max. number of people on the platform (n) –indoors

2

2

Tool and material weight (me) (2) –indoors

40

Kg

88

lbs

Max. number of people on the platform (n) –outdoors

2

2

Tool and material weight (me) (2) –outdoors

40

Kg

88

lbs

Maximum drive height

Max

Max

Maximum dimensions of platform

0.8 x 1.36

m

2’ 8” x 4’ 5”

ft

Max. hydraulic pressure

220

bar

3191

psi

Max. pressure of lifting circuit

220

bar

3191

psi

Min. pressure of braking circuit

35 ÷ 40

bar

508 ÷ 580

psi

Tyre dimensions (4)

Ø 584 x 324

mm

23 x 13

in

Tire type (4)

23 x 10 - 12

23 x 10 - 12

Transport dimensions

5.06 x 1.5 x 1.97

m

16’ 7”x 4’ 11”x 6’ 6”

ft

Transport dimensions with retracted jib

N.A.

m

N.A.

ft

Machine weight (unloaded) (1)

5640

Kg

12434

lbs

Stability limit:

Longitudinal slope

4

°

4

°

Transversal slope

4

°

4

°

Maximum wind speed (3)

12.5

m/s

27.96

mph

Maximum manual force:

400

N

90

lbf

Max. load per wheel

2480

Kg

5467

lbs

Performance:

Drive wheels

2

2

Max. drive speed

4

km/h

2.5

mph

Safety drive speed

0.6

km/h

0.4

mph

Oil tank capacity

67

Lt.

17.7

gal

Gradeability

25

%

25

%

Max. operating temperature

+50

°C

+122

°F

Min. operating temperature

-15

°C

+5

°F

Other manuals for AIRO A Series

3

This manual suits for next models

6

Table of contents

Other TIGIEFFE Lifting System manuals