TimberPro TL775 Series Manual

TL/TN 775 MachiNe iNiTiaL SeT-UpGUide

Manufactured To Get

Your Job Done

Manufactured To Get

Your Job Done

By the Most Trusted and Versatile

Company in the Industry

By the Most Trusted and Versatile

Company in the Industry

2021 MY2021 MY

L9 Cummins EnginE

TrusTEd mosT ByThE ForEsTry indusTry

L9 Cummins EnginE

TrusTEd mosT ByThE ForEsTry indusTry

TL/TN 775 MachiNe iNiTiaL SeT-UpGUideTL/TN 775 MachiNe iNiTiaL SeT-UpGUide

PAGE INTENTIONALLY LEFT BLANK

L9 Cummins EnginE

TrusTEd mosT ByThE ForEsTry indusTry

L9 Cummins EnginE

TrusTEd mosT ByThE ForEsTry indusTry

P A1 of A3 P A2 of A3

TL/TN-775 MAchiNe iNiTiAL SeT-UPGUide

MachiNe SeT-UpOrder per MachiNe cONfiGUraTiON Type

The set-up instructions in this manual are created for all machine congurations.Depending on your purchased machine

conguration, the order of this set-up procedure may not be correct for your machine. Follow the Machine Set-up Order

outlined below to adequately set-up your machine conguration.

NOTE:

There are a variety of adjustment procedures outlined throughout this manual. These settings may only need to be adjusted

if the part is not calibrated to operator's preference or if there is an issue.

FELLER BUNCHER SET-UP ORDER

1. Setting Load Sense / Stand-By on Implement Pump (Section 1)

2. Setting Implement Pump POR / High-Side Pressure (Section 1)

3. Setting Charge Pressure (Section 4)

4. Hydraulic Fan Motor Set-up / Setting Fan Speed (Section 5)

5. Setting Valve LS Relief (Section 6)

6. Main Control Valve Set-Up - M4-15 Small Section (Section 6)

7. Setting Swing Pressure and Setting up the Swing Pump (Section 7)

8. Setting the Track Drive Pressures (Section 8)

9. Disc Saw Pump Set-up (Section 9)

SHOVEL/LOG LOADER SET-UP ORDER

1. Setting LS (Load Sense) / Stand-By on Implement Pump (Section 1)

and Auxiliary Pump (Section 2)

2. Setting Charge Pressure (Section 4)

3. Setting Implement Pump POR/High-Side Pressure (Section 1) and Auxil-

iary Pump POR/High-Side Pressure (Section 3)

4. Hydraulic Fan Motor Set-up / Setting Fan Speed (Section 5)

5. Setting Valve LS Relief (Section 6)

6. Main Control Valve Set-Up - M4-15 Small Section (Section 6)

7. Setting Swing Pressure and Setting up the Swing Pump (Section 7)

8. Setting the Track Drive Pressures (Section 8)

PROCESSOR SET-UP ORDER

1. Setting LS (Load Sense) / Stand-By on Implement Pump (Sec-

tion 1) and Auxiliary Pump (Section 2)

2. Setting Charge Pressure (Section 4)

3. Setting Implement Pump POR / High-Side Pressure (Section 1)

and Auxiliary Pump POR / High-Side Pressure (Section 4)

4. Hydraulic Fan Motor Set-up / Setting Fan Speed (Section 5)

5. Setting Valve LS Relief (Section 6)

6. Main Control Valve Set-Up - M4-15 Small Section (Section 6)

7. Setting Swing Pressure and Setting up the Swing Pump (Sec-

tion 7)

8. Setting the Track Drive Pressures (Section 8)

ADDITIONAL ITEMS TO CHECK

• Adjusting Port Relief (Section 10)

• Changing Min. Displacement (Section 11)

• Setting Shift Points (Section 12)

P A1 of A3 P A2 of A3P A2 of A3 P A3 of A3

TL/TN-775 MAchiNe iNiTiAL SeT-UPGUide

TiMber prO recOMMeNded preSSUreS fOr 765/775

IMPORTANT

All pressures are set with the machine running at minimum of 1500rpm except for Swing Pressure. Swing pressure is set to

2050rpm.

COMPONENT PRESSURE (PSI)

Implement Pump LS 350 - 600

Charge Pump 425

Implement Valve LS Relief 4200

Main, Tool, and Stick are set with the Valve LS Relief 4200

Implement Pump POR 4600

Swing Pump POR 5200

Swing Pump Main Reliefs 5800

Track Drive Pump POR 5500

Track Drive Pump Main Reliefs 6000

NOTE

• Set LS with LS line removed and plugged and Pump open to Atmosphere.

• Main, tool, stick, level, and M7-22 portion of valve are ALL set by the main valve LS Relief

• Minor Function, Clamp, Accumulator, and Rotate leave Timber Pro at 3600 psi or to the head manufacturer recommenda-

tions

GeNeraL KNOwLedGe

• AC system holds 4lbs of R134

• All gear lube in machine requires 75W90 Synthetic except nal drives require CAT50

• Hydraulic oil is ISO46

P A2 of A3 P A3 of A3

TL/TN-775 MAchiNe iNiTiAL SeT-UPGUide

TL/TN-775 MachiNe iNiTiaL SeT-Up

A series of individual set-up procedures need to be performed to properly set-up the machine for use and/or personal

preference. The following items need to be performed to properly set-up your machine.

• Rexroth Implement Pump, Valve Set-up

• Auxiliary Pump Set-up

• Hydraulic Fan motor Set-up

• Disc Saw Pump Set-up

• Track Drive Pressure Setting

• Shift Point, Beginning of Regulation Setting

• Swing Pump Pressure Setting

• Charge Pressure Setting

• Changing Min. Displacement Setting

priOr TO perfOrMiNG The abOve LiSTed prOcedUreS

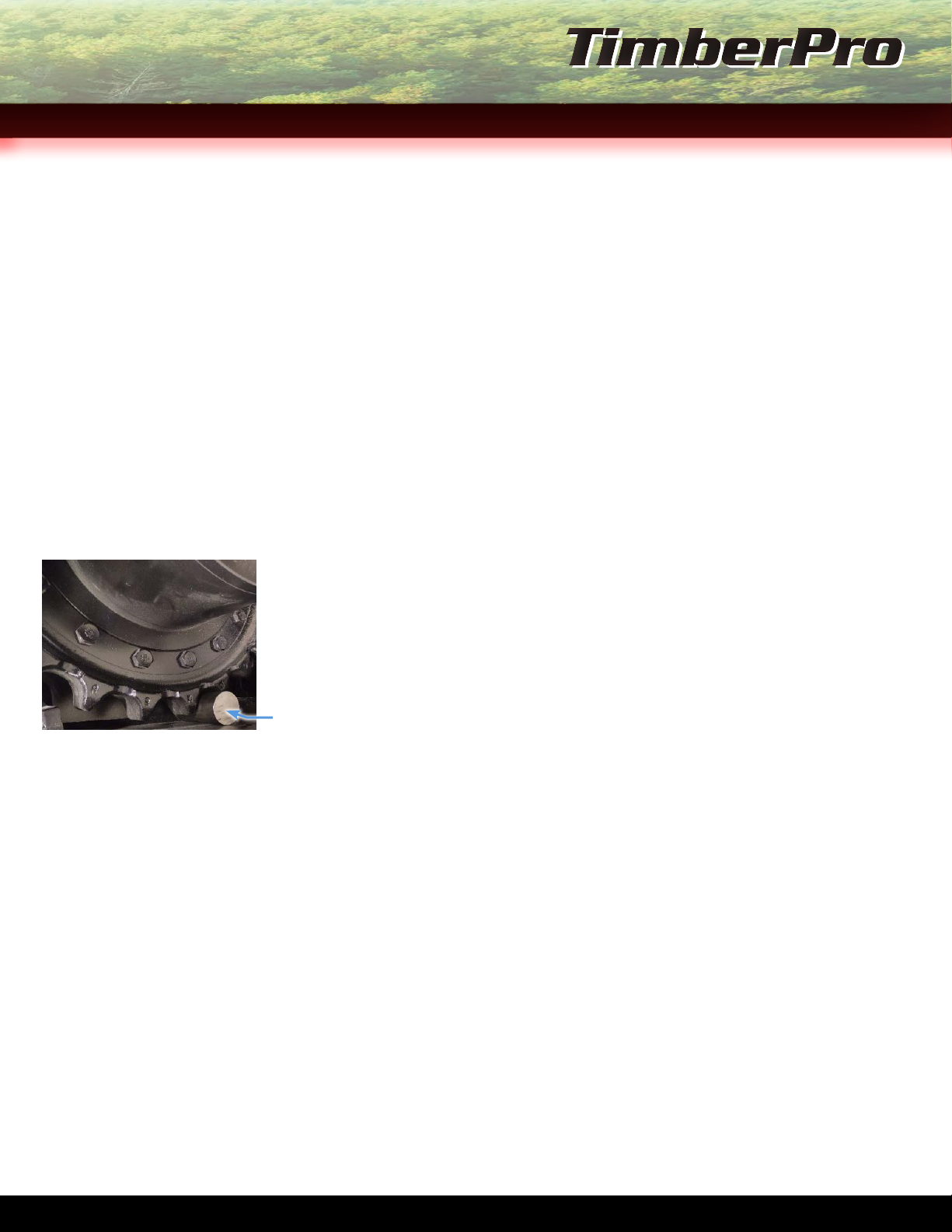

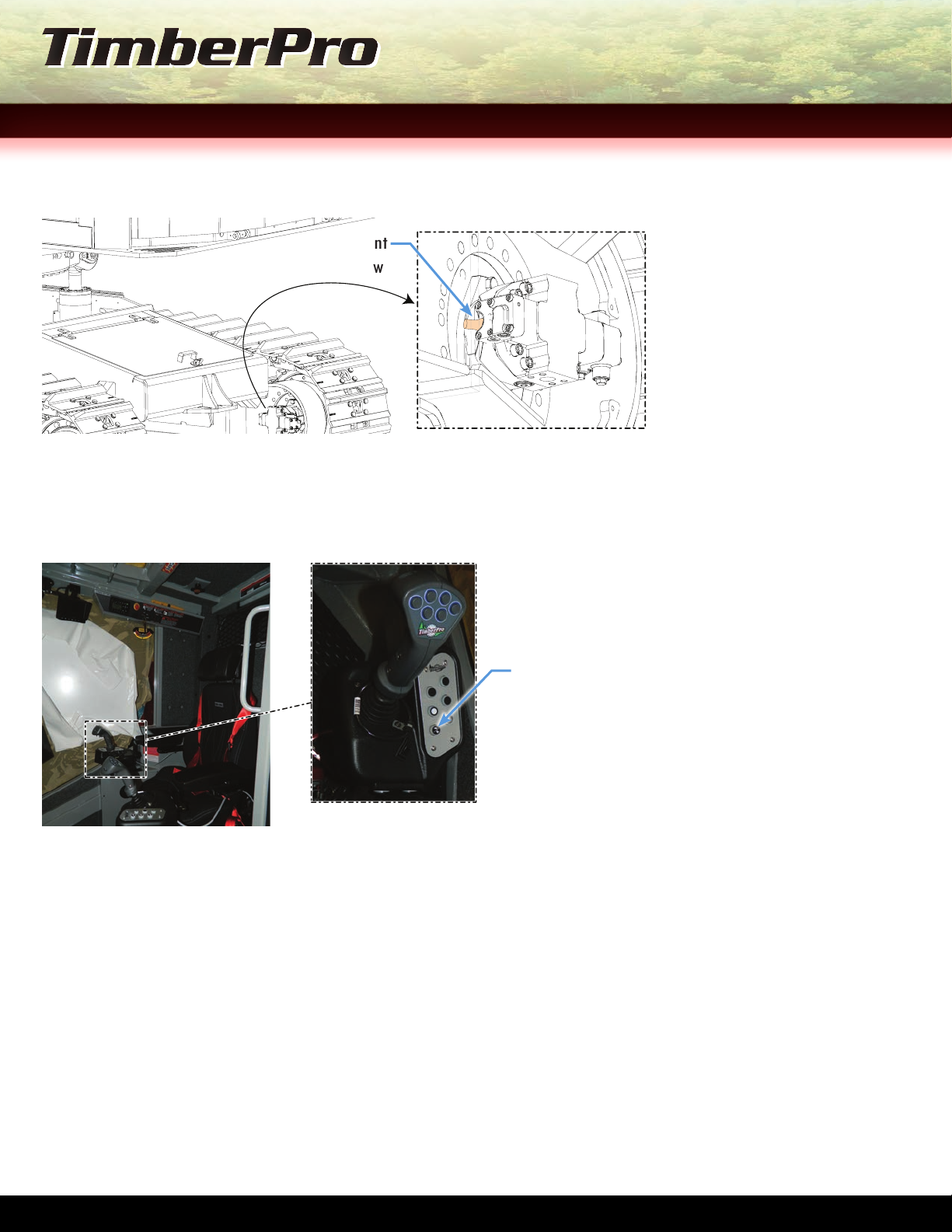

FIGURE 1, PIN INSTALLED

AT TRACK FINAL DRIVE

1. Install pin at track nal drive to stall the machine for maintenance. See Figure 1.

2. Warm the machine hydraulics to operating temperature of 140 F 60 C.

3. Warm engine coolant temperature to operating temperature.

IMPORTANT

• FOR PRESSURE CHECKS A 10,000 PSI DIGITAL PRESSURE GAUGE IS RECOMMENDED.

• FOR STAND-BY PRESSURE CHECKS A 600 PSI GAUGE IS CALLED FOR IN MANUAL, BUT PRESSURES COULD SPIKE IF CORRECT

SEQUENCE IS NOT FOLLOWED, DAMAGING THE GAUGE. IF A DIGITAL GAUGE IS USED, DAMAGE COULD BE PREVENTED.

• UTILIZE MODEL SPECIFIC MACHINE SET-UP CHECK SHEET FOR SPECIFIED PRESSURES.

reqUired TOOLS

• Tachometer • Standard Combination Wrenches, Assorted 3/8 in. - 1-3/8 in.

• Metric Combination Wrenches, Assorted 9 mm - 35 mm

• Standard Allen Wrenches, Assorted 5/32 in. & 1/4 in.

• Metric Allen Wrenches, Assorted 3 - 5 mm & 8 mm

• Pressure Gauge Various Sizes

• 0 - 600 psi 0 - 5 Mpa

• 0 - 6000 psi 0 - 50 Mpa

• 0 - 10,000 psi 0 - 8 Mpa

NOTE:

• A 10,000 psi Digital Gauge can be used in leu of Pressure Gauges listed above.

Pin installed at Track Final

Drive

P PB of 17 P 1 of 17

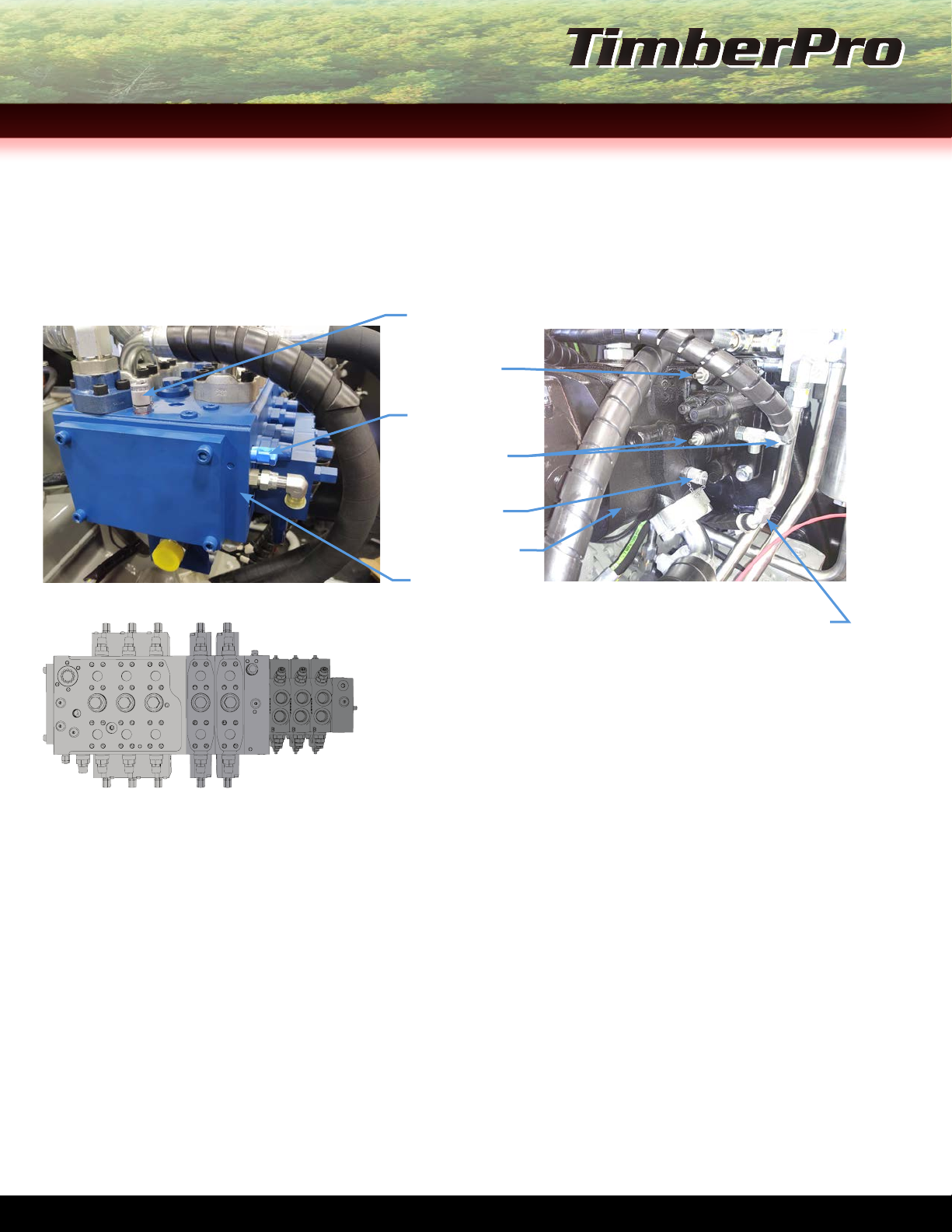

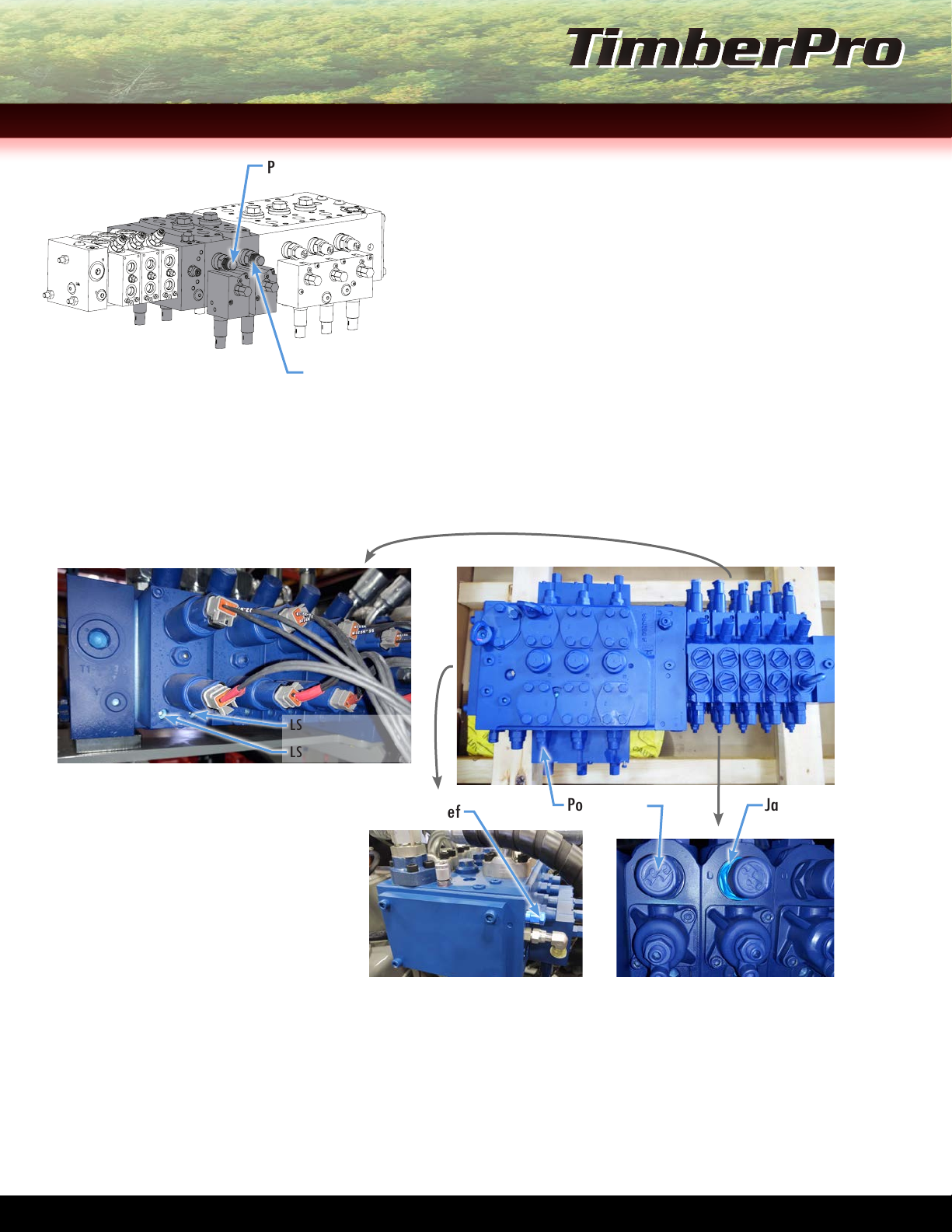

iMpLeMeNT pUMp, MaiN cONTrOL vaLve SeT-Up

IMPLEMENT PUMP/R9 LARGE SECTION, MAIN CONTROL VALVE SET-UP

1. Turn the LS (Load Sense) relief valve inward gently until it bottoms out. The reief valve is located on the main control

valve (Figure 1) . Once the relief valve bottoms out, back out ¼ turn.

R9 Section

MLS 1 Module Load

Sense Gauge Port

POR (Pressure

Over Relief) Port

LS (Load Sense)

Line

LS Gauge Port

Implement Pump

LS Relief Valve

FIGURE 1, MAIN CONTROL VALVE FIGURE 2, IMPLEMENT PUMP

LS Line shown removed and capped.

NOTE

Main Control Valve section quantities vary

depending on machine’s purpose and customer

spec’d options.

FIGURE 3, MAIN CONTROL VALVE SECTION TYPES

R9 Section M7-22 M4-15

2. Remove the LS line from the implement pump. See Figure 2 above.

3. Start the machine and install the pressure gauge on the implement pump gauge port.

4. Run the machine at 1500rpm.

5. Adjust the LS pressure to the appropriate setting spec’d on the Recommended Pressures at the beginning of this procedure.

6. Turn off the machine and re-install the LS line removed in Step 2.

7. Set the correct pressure by using the POR (Pressure-Over-Relief) adjustment port on the implement pump. See Figure 2 above for

POR adjustment port.

8. Set valve LS (Load Sense) back to working pressure.

IMPORTANT

IF THE MACHINE HAS AN AUXILIARY PUMP, THE SATURATION CIRCUIT WILL NEED TO BE BROKEN BY REMOVING THE LS LINE FROM

THE PUMP AND CAPPING THE HOSE. See Figure 2 above.

IMPLEMENT PUMP/R9 LARGE SECTION, MAIN CONTROL VALVE SET-UP PROCEDURE END

TL/TN-775 MAchiNe iNiTiAL SeT-UPGUideSecTioN 1

P 2 of 17 P 3 of 17

TL/TN-775 MAchiNe iNiTiAL SeT-UPGUide

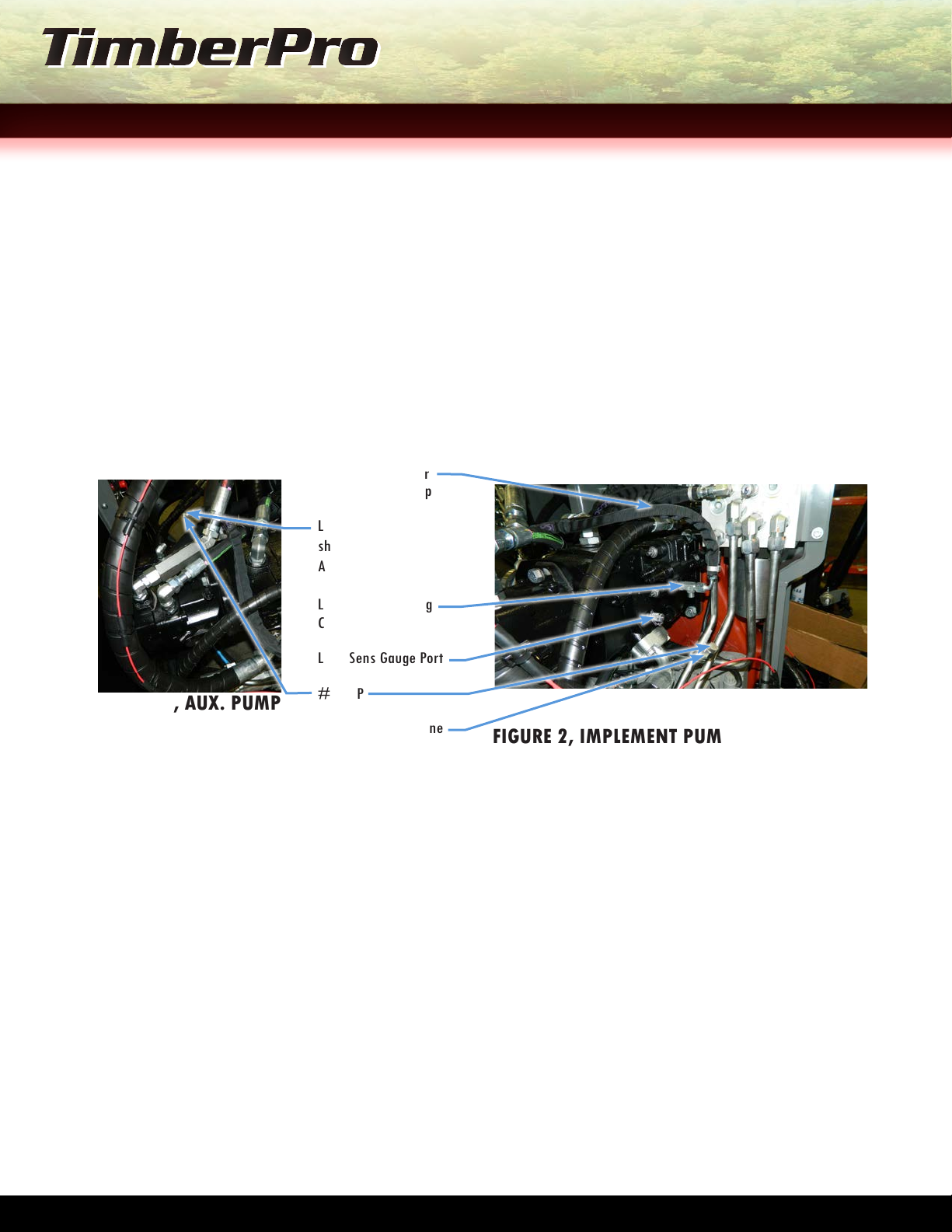

aUxiLiary pUMp SeT-Up

IMPORTANT

ALWAYS USE THE SAME GAUGE TO SET BOTH THE MAIN IMPLEMENT PUMP AND AUXILIARY PUMP.

1. Check the provided Recommended Pressures at the beginning of the procedure and note the settings for the implement

pump Stand-by Pressure and the implement pump POR (Pressure-Over-Relief) Pressure.

2. Remove the LS (Load Sense) Jumper line from the Auxiliary Pump and cap the hose with a #6 cap. See Figure 1 and/or

Figure 2 below.

IMPORTANT

DO NOT CAP THE 90° FITTING FROM THE AUX. PUMP PORT. IT IS IMPORTANT TO LEAVE THE PUMP OPEN TO BREATH.

FIGURE 2, IMPLEMENT PUMP LOAD SENSE

CONNECTION

Load Sense Jumper

at Implement Pump

Load Sense Jumper

shown removed from

Aux. Pump

Load Sense Existing

Connection at Tee

Load Sens Gauge Port

#6 CAP

Load Sense Hose Line

Shown removed from

Imp. Pump

FIGURE 1, AUX. PUMP

LS CONNECTIONS

3. Start the machine and run at 1500rpm.

SETTING AUXILIARY PUMP STAND-BY PRESSURE

1. Install the gauge on the auxiliary pump gauge port and check pressure. Set the pump Stand-by Pressure to 25 psi lower

than the implement pump pressure setting that was gathered in Step 1 above. See Figure 2 for the auxiliary pump

gauge port location.

EXAMPLE

If the implement pump Stand-by Pressure is 350 psi, set the Auxiliary Pump Pressure to 325 psi.

2. Install the LS Line on the main control valve (Figure 3) and connect directly to the auxiliary pump LS Port (Figure 4).

3. Run the engine at 1500rpm.

3a. Bottom out the stick boom.

3b. Adjust pressure if needed.

4. Start the machine and install the gauge on the implement pump LS gauge port. See Figure 2 on previous page for LS

gauge port location.

SecTioN 2

P 2 of 17 P 3 of 17

4a. Run the machine at 1500rpm.

4b. Have the machine operator bottom out the stick boom.

4c. Set the correct pressure by using the POR (Pressure-Over-Relief) adjustment port on the implement pump. See

Figure 2 on previous page for POR adjustment port.

AUXILIARY PUMP SET-UP PROCEDURE END

SeTTiNG aUxiLiary pUMp pOr / hiGh-Side preSSUre

1. Set the auxiliary pump POR (Pressure-Over-Relief) / High-side to the same psi that the implement pump POR Pressure

was set to in Step 1 of the Auxiliary Pump Set-up Procedure. See Figure 2 for POR/High-Side port location on the

auxiliary pump.

2. On the main control valve, turn the LS Relief in gently until it bottoms out. See Figure 1 below.

3. Install the LS Line that was disconnected earlier on to the auxiliary pump. See Figure 2 below for port location.

4. Set pressure to the setting spec’d on Page A3 of this procedure.

5. Install the gauge used earlier on the LS gauge port located on the main control valve to set the pressure. See Figure 1

below.

6. Run the engine at 1500rpm.

7. Bottom out the stick boom.

8. Set the main control valve LS Relief to the pressure spec’d on the provided Recommended Pressures at the beginning of

the procedure.

9. Set the LS Relief valve back to operating pressure spec'd at the beginning of this procedure.

LS Gauge Port

LS Relief

LS Hose/Line and Port

Location at Aux. Pump

LS/Stand-By

POR/High-Side

Gauge Port

LS Line at Main Control

Valve

FIGURE 1, MAIN CONTROL

VALVE END FIGURE 2, AUXILIARY PUMP

AUXILIARY PUMP POR/HIGH-SIDE PRESSURE PROCEDURE END

TL/TN-775 MAchiNe iNiTiAL SeT-UPGUideSecTioN 2 &SecTioN 3

P 4 of 17 P 5 of 17

TL/TN-775 MAchiNe iNiTiAL SeT-UPGUide

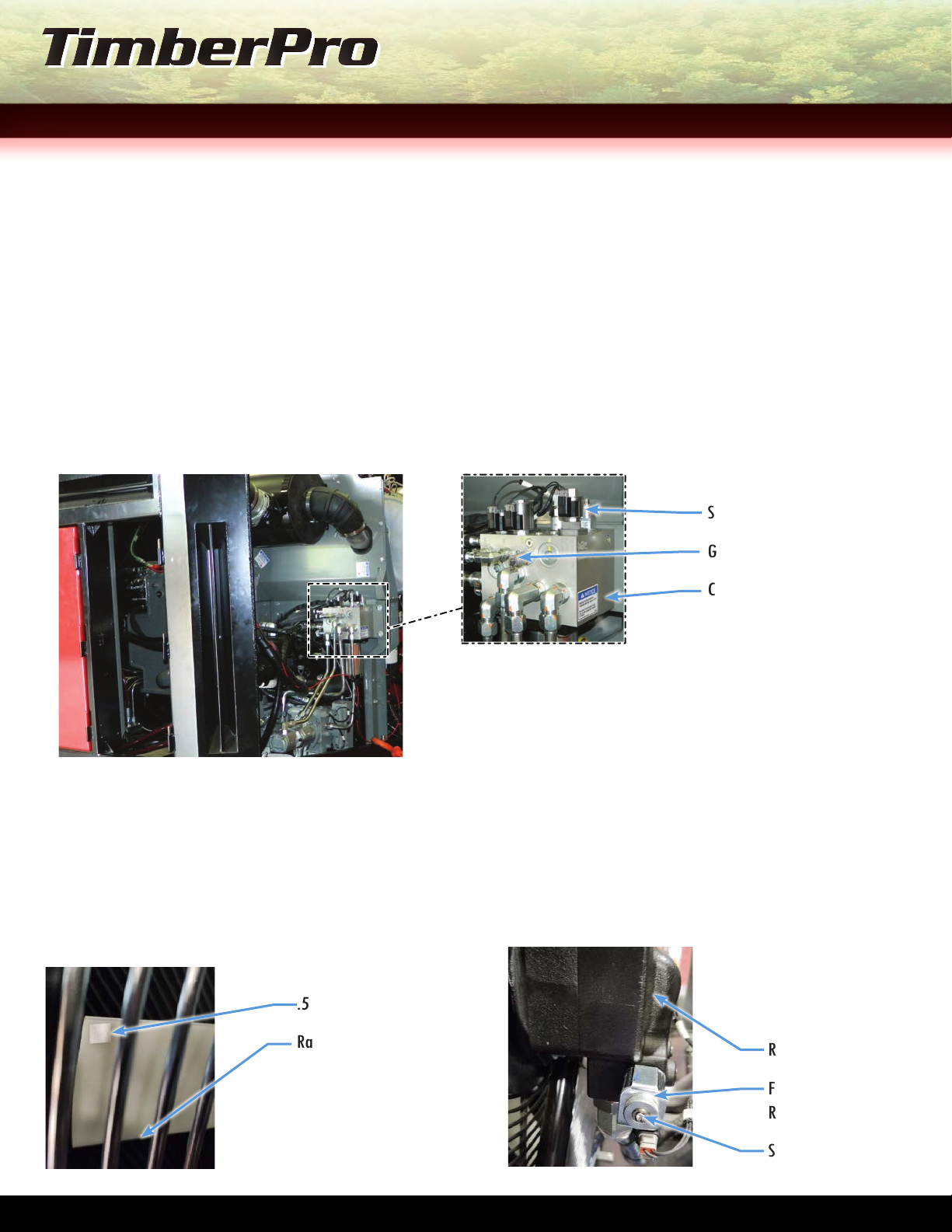

SeTTiNG charGe preSSUre

1. Start the engine and run at 1500rpm.

2. Once the machine is running, install a 600 psi gauge on the charge cooler gauge port location shown below. See Figure 1

below.

NOTE

Charge pressure should not deviate more than 25 psi up or down when setting adjustment. Setting pressure at 425 psi

provides the correct ow for the internal orices for ushing the hydrostatic pump controls.

3. If adjustment is needed, turn the SQ1 Cartridge clockwise to increase pressure and counter-clockwise to decrease. See

Figure 1 for SQ1 Cartridge location.

NOTE

Charge manifold may vary per machine model.

SQ1 Cartridge

Gauge Port

Charge Cooler

FIGURE 1, CHARGE MANIFOLD

SETTING CHARGE PRESSURE PROCEDURE END

hydraULic faN MOTOr SeT-Up

1. Install an approximately 1/2” square piece of reective tape on one of the radiator fan blades as shown on Figure 1

below.

.5" Reective Tape

Radiator Fan Blade

FIGURE 1, RADIATOR FAN BLADE TAPE LOCATION

Radiator Fan Motor

Fan Motor Relief

Relay

Safety Screw

FIGURE 2, RADIATOR FAN

MOTOR SAFETY SCREW LOCATION

2. Remove the Safety Screw installed on the Fan Motor Relief Relay. See Figure 2 on previous page.

SecTioN 4 & SecTioN 5

P 4 of 17 P 5 of 17

3. Once the screw has been removed, start the machine.

IMPORTANT

DO NOT UNPLUG THE COIL ON THE FAN TO GET FULL SPEED. DAMAGE TO THE CHARGE PUMP COULD OCCUR.

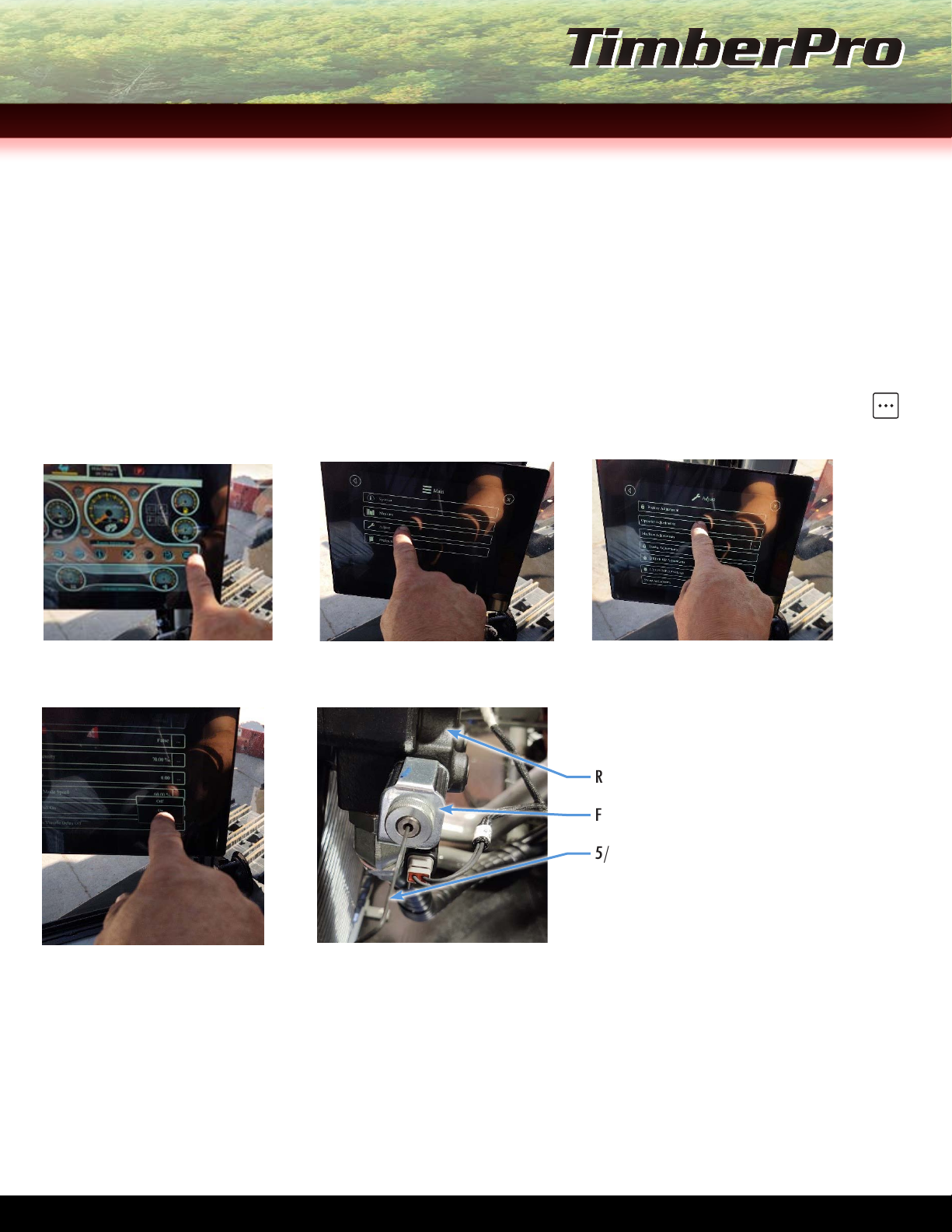

4. Using the IQAN touch screen located in operator cab, turn the fans to FULL ON. Follow the touch screen prompts on the

next page to set the function.

4a. Go to the IQAN touch main screen, select MENU on the main screen. See Figure 3 below.

4b. Once in the Menu screen, select the ADJUST prompt.

4c. On the Adjust screen, select OPERATOR ADJUSTMENTS

4d. The next screen will take you to the FANS FULL ON/OFF menu option. On the right side of the screen select the

. . .

function. Then select the ON function.

FIGURE 3, IQAN MENU OPTION

STEP 4b, ADJUST OPTION

STEP 4c, OPERATOR

ADJUSTMENTS OPTION

STEP 4d, FANS FULL ON/OFF

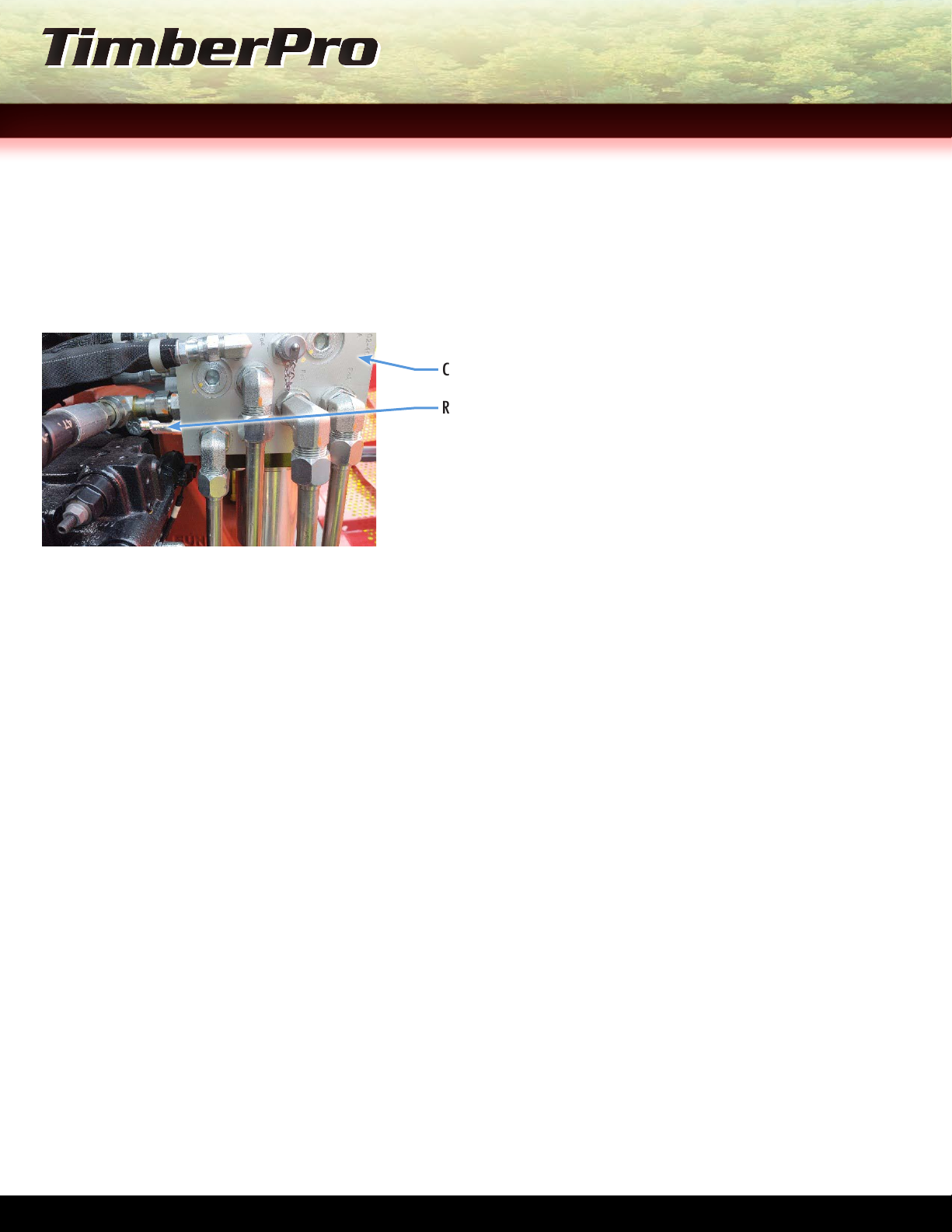

MENU FUNCTION

Radiator Fan Motor

Fan Motor Relief Relay

5/32” Allen Wrench

FIGURE 4, FAN MOTOR RELIEF

RELAY ADJUSTMENT

5. Run the machine at full engine rpm.

6. Using a photo laser tachometer, check the fan speed by pointing the tachometer laser on the reective tape installed on

the fan blade earlier.

6a. Document speed and save for later.

7. Using a 5/32” allen wrench, turn the Fan Motor Relief Adjustment Relay counter-clockwise for slower fan speed or

TL/TN-775 MAchiNe iNiTiAL SeT-UPGUideSecTioN 5

P 6 of 17 P 7 of 17

TL/TN-775 MAchiNe iNiTiAL SeT-UPGUide

clockwise for faster fan speed. See Figure 4 on previous page.

8. Set the fan speed to 1600 - 1650rpm. If the speed can’t be reached, try turning the RV2 in on the Charge Manifold Block

to adjust the fan speed. See Figure 5 below.

IMPORTANT

OPTIMAL SPEED FOR THE FAN IS 1600 - 1650RPM WITH THE FAN TURNED ON AND THE ENGINE AT FULL RPM.

Charge Manifold Block

RV2 Adjustment Valve

FIGURE 5, RV2 ADJUSTMENT,

CHARGE MANIFOLD BLOCK

9. Once the machine has reached the proper speed, using the RV2 Adjustment Valve and photo laser tachometer, adjust

the valve until you reach a tachometer reading that is 5 - 10rpm’s below your original reading. This will ensure that the

relief is set correctly and the ramping will function properly.

10. Install the gauge used earlier into the MLS 1 (Module Load Sense) port on the main control valve. See Figure 1 on

Page 1 for MLS 1 port location. Bottom out the stick boom and set to the correct pressure spec’d on the Recommended

Pressures at the beginning of this procedure by adjusting on the LS relief valve on the main control valve. See Figure 1

on Page 1 for LS relief valve location.

HYDRAULIC FAN MOTOR SET-UP PROCEDURE END

MaiN cONTrOL vaLve SeT-Up- M4-15 SMaLL SecTiON

An LS Relief for PORT A and PORT B is installed on all M4-15 lower valve sections. See Figure 1 on the next page. Find the

correct pressure for each relief port valve by following the provided Recommended Pressures at the beginning of this

procedure.

NOTE

The Leveling Reliefs are non-adjustable.

1. Start the engine, install the gauge into the MLS 1 Gauge Port on the main control valve. See Figure 1 on Page 1 for

location.

1a. Run the engine at 1500rpm.

SecTioN 5 &SecTioN 6

P 6 of 17 P 7 of 17

1b. Have the machine operator run the function to be set.

1c. Adjust the LS Reliefs on the current main control valve section to change the settings. See Figure 1 below for LS

Relief Valve.

FIGURE 1, MAIN CONTROL

VALVE M4 SECTION SET-UP

LS Relief, PORT A

LS Relief PORT B

ADJUSTING THE PORT RELIEFS ON THE M4-15 SMALL SECTION, MAIN CONTROL VALVE

All M4-15 port reliefs are adjustable on the Rexroth main control valve except the leveling reliefs.

2. Bottom out the function to be set. Read gauge and set A or B port to the pressure needed.

IMPORTANT

DO NOT OVERTIGHTEN THE VALVE.

MAIN CONTROL VALVE SET-UP - M4-15 SMALL SECTION PROCEDURE END

SeTTiNG SwiNG preSSUre

REQUIRED TOOLS

• 6000 psi Gauge

• 4mm Allen Wrench

• 5mm Allen Wrench

• 13mm Allen Wrench

• 18mm Wrench

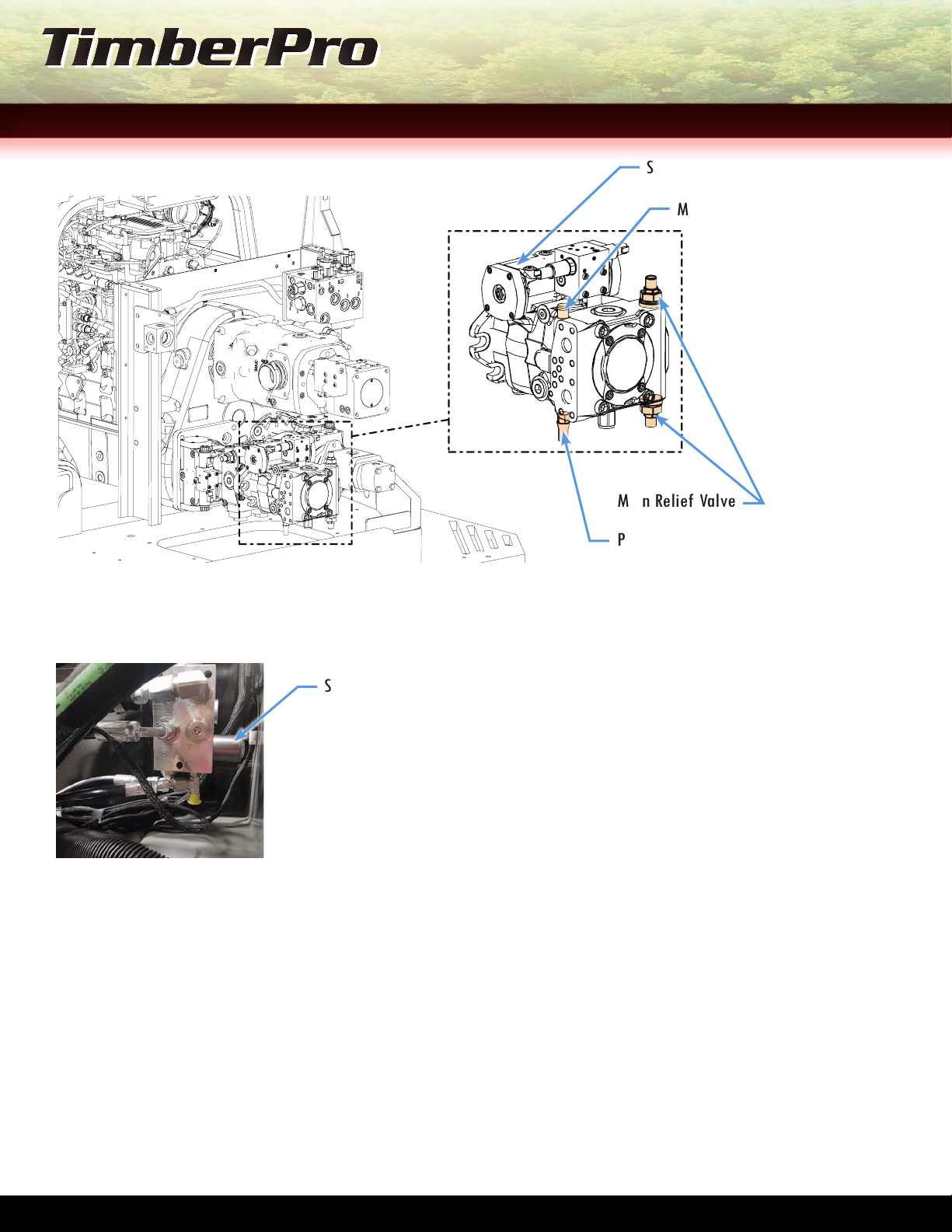

1. Install gauge in the MH Port on the Swing Pump. See Figure 1 on the next page.

TL/TN-775 MAchiNe iNiTiAL SeT-UPGUideSecTioN 6 &SecTioN 7

P 8 of 17 P 9 of 17

TL/TN-775 MAchiNe iNiTiAL SeT-UPGUide

FIGURE 1, SWING PUMP PORT AND VALVE

Main Relief Valve

POR Pressure Over Relief

MH Port

Swing Pump

2. Remove the Swing Brake Coil. See Figure 2 below.

Swing Brake Coil

FIGURE 2, SWING BRAKE COIL

3. On the swing pump, turn the POR Pressure Valve counterclockwise gently until it bottoms out. See Figure 1 above.

3a. Once bottomed out, turn clockwise 1/4 turn to back the system out.

IMPORTANT

GULLWING SWITCH MUST BE BYPASSED TO SET SWING PRESSURE. A WASHER OR ANY SUITABLE METAL OBJECT CAN BE USED TO

BYPASS THE SWITCH. SEE FIGURE 3 ON THE NEXT PAGE FOR SWITCH LOCATION.

MACHINE MUST BE RUN AT FULL ENGINE RPM, 2050, AND FULL mA ON THE IQAN CONTROL.

SecTioN 7

P 8 of 17 P 9 of 17

FIGURE 3, GULLWING SWITCH

Gullwing Switch

4. Start the engine and run at full rpm and mA (milliAmp).

4a. Push boom into ground and swing in one direction.

4b. Note the pressure on the gauge. Pressure reading will be the Main Relief setting.

ADJUSTING THE MAIN RELIEF SETTING:

To adjust the swing pump pressure, turn each swing pump Main Relief Valve either clockwise to raise the pressure or counter-

clockwise to lower the pressure. See Figure 1 on previous page for valve location.

5. Once the pressure is set for the rst Main Relief Valve, with the boom still pushed into the ground, swing in opposite

direction.

5a. Note the pressure on the gauge, and adjust as necessary following the same procedure as the previous steps.

ADJUSTING THE POR PRESSURE SETTING

6. Turn the Swing Pump POR Valve clockwise to raise the pressure or turn counter-clockwise to lower the pressure. See

Figure 1 on previous page for valve location.

NOTE

Unlike setting the Main Control Valve in the earlier steps, it is necessary to swing the boom in only one direction when

setting POR pressure setting.

7. Note the pressure on the gauge, and adjust as necessary by following the previous steps.

IMPORTANT

THE POR PRESSURE SHOULD ALWAYS BE 500 PSI LOWER THAN THE MAIN RELIEF PRESSURE SETTINGS.

8. Once the Main Relief and POR Relief settings are properly adjusted, reinstall the swing brake coil removed at the

beginning of this procedure.

SETTING SWING PRESSURE PROCEDURE END

TL/TN-775 MAchiNe iNiTiAL SeT-UPGUideSecTioN 7

P 10 of 17 P 11 of 17

TL/TN-775 MAchiNe iNiTiAL SeT-UPGUide

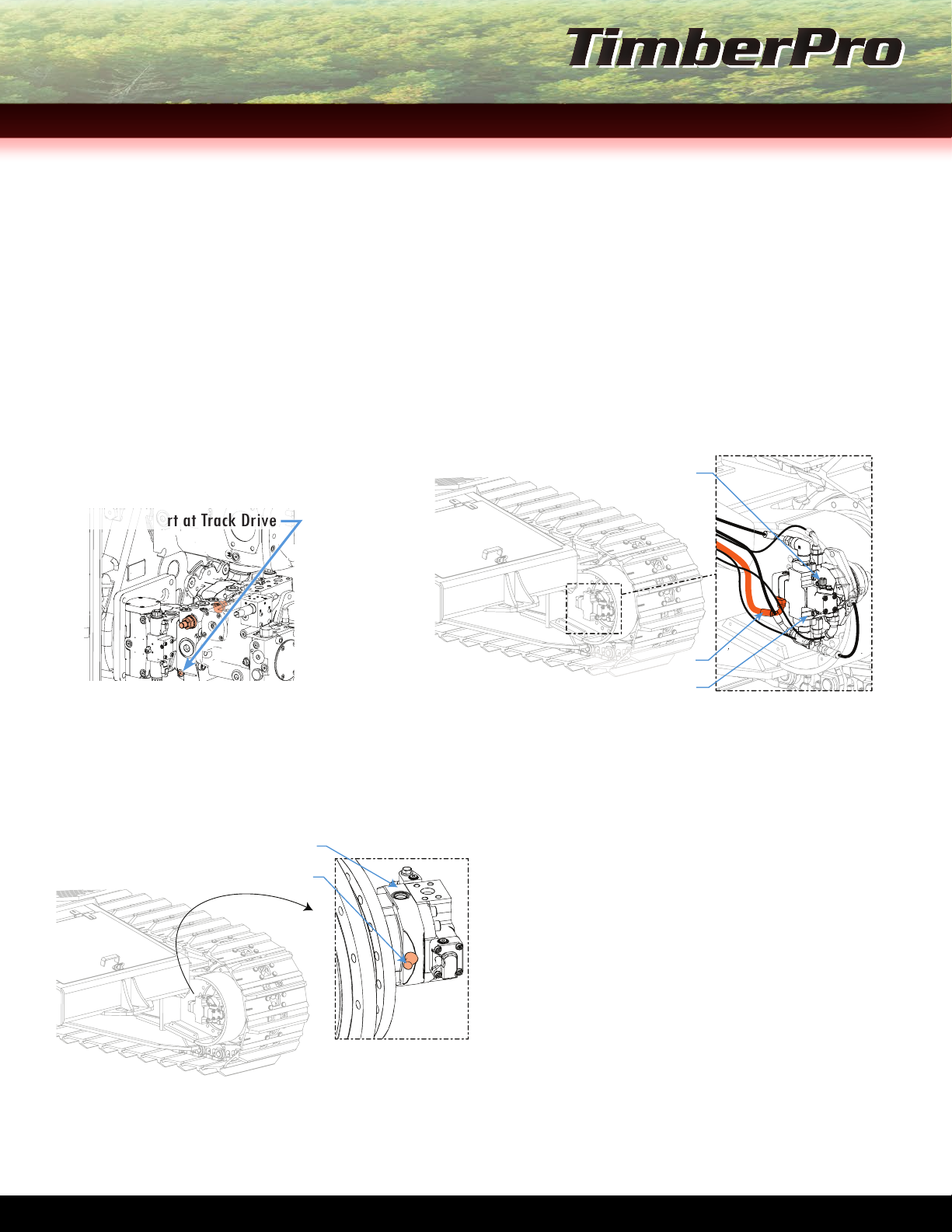

SeTTiNG The TracK drive preSSUreS

NOTE:

Rear track pump is designated for LEFT track and Forward track pump is designated for RIGHT track.

SETTING THE POR (PRESSURE-OVER-RELIEF) / HIGH-SIDE PRESSURE

1. Install pin at track nal drive to ensure safety while performing pressure settings on machine. See Figure 1 on Page A3

for pin installed location on track.

WARNING

NOT INSTALLING AN APPROPRIATELY SIZED PIN AT THE FINAL DRIVE COULD CAUSE SERIES DAMAGE TO THE MACHINE AND

CAUSE INJURY TO PERSONNEL.

Main Relief Valve

POR/High-Side

MH Test Port

FIGURE 1, TRACK DRIVE

2. Install a 10,000 psi gauge into the MH Test Port on the track drive. See Figure 1 above for MH Port.

3. Turn the POR all of the way in. See Figure 1 above for location.

IMPORTANT

DO NOT BOTTOM OUT WHEN TURNING THE POR/HIGH-SIDE VALVE IN.

4. Once the POR is all of the way in, back out 1/2 turn.

5. Start the machine, check the gauge, and ensure that the pressure is between 400 - 450 psi of charge pressure.

6. Run the engine rpm’s up to a minimum of 1500rpm.

TRACK DRIVE MAIN RELIEF VALVE PRESSURE ADJUSTMENT

The track drive Main Relief pressure settings need to be set/adjusted for the left and right track. There are two Main Relief

Valves per track drive pump and there are two pumps per machine. See Figure 1 above for track drive pump and main relief

valve location. On each pump, one Main Relief Valve is designated for forward operation and the other is designated for

reverse operation. The track drive pumps are mounted to the triple drive at the engine.

The rear track drive pump is designated for the left track, and the front pump is designated for the right track.

SecTioN 8

P 10 of 17 P 11 of 17

SETTING THE TRACK DRIVE MAIN RELIEF VALVE PRESSURE

1. Ensure the Parking Brake is off.

2. Pick one of the two track drive pumps/tracks to start with. Set the Main Relief Valve designated for forward operation.

See Figure 1 on previous page. To do so, drive the machine forward and adjust the relief valve pressure to the settings

spec’d on the attached Pressures Chart at the beginning of this procedure.

3. Once the Main Relief for the forward function is adjusted, drive in the machine in reverse and set the Main Relief for

the reverse function on the opposite side of the pump by following the same steps as forward operation.

4. Once the pump is properly adjusted, repeat operation for the other track drive pump.

TRACK DRIVE POR (PRESSURE-OVER-RELIEF) VALVE PRESSURE ADJUSTMENT

The POR (Pressure-Over-Relief) valve needs to be set on each track drive pump. Unlike the Main Relief valves, there is only

one POR relief valve per track drive pump. See Figure 1 on the previous page for POR Valve location.

SETTING THE TRACK DRIVE POR VALVE PRESSURE

1. Ensure the Parking Brake is off.

2. Pick one of the two pumps/tracks to start with. Set the POR Valve pressure by driving the machine forward and

adjusting the relief valve pressure based off the attached TimberPro Recommended Pressures chart.

3. Once the POR Valve pressure is properly adjusted, repeat operation for other track drive pump/track.

IMPORTANT

The Main Relief pressure setting should be 500 psi higher than the POR pressure.

SETTING THE TRACK DRIVE PRESSURES PROCEDURE END

diSc Saw pUMp SeT-Up

SETTING THE LS/STAND-BY PRESSURE

1. Start the engine and run at 1500rpm.

2. Once the machine is running, install a 600 psi gauge on the disc saw pump gauge port or check the pressure on IQAN

display in the cab. See Figure 1 on the next page for disc saw gauge port location.

3. Check the LS/STAND-BY pressure on the disc saw and set to the boom attachment/head manufacturer specied setting.

See Figure 1 on the next page for disc saw pump LS/STAND-BY location.

4. Remove 600 psi from the gauge port.

TL/TN-775 MAchiNe iNiTiAL SeT-UPGUideSecTioN 8 &SecTioN 9

P 12 of 17 P 13 of 17

TL/TN-775 MAchiNe iNiTiAL SeT-UPGUide

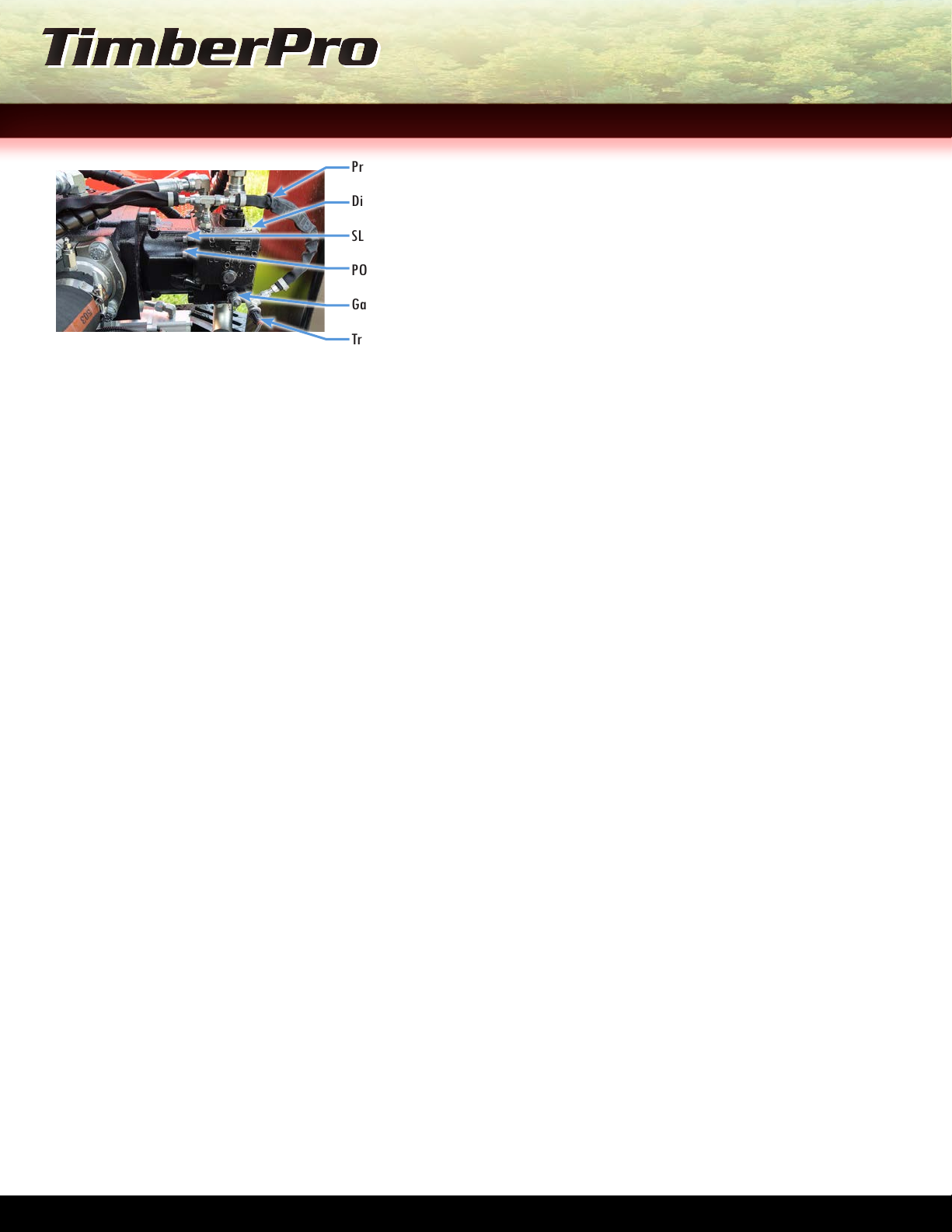

Pressure Jumper Hose

Disc Saw Pump

SL/Stand-By

POR/High-Side

Gauge Port

Transducer

FIGURE 1, DISC SAW PUMP

SETTING THE POR (PRESSURE-OVER-RELIEF)/HIGH-SIDE PRESSURE

IMPORTANT

FOLLOW THE BOOM ATTACHMENT/HEAD MANUFACTURER SETTINGS TO PROPERLY SET THE POR & HIGH-SIDE PRESSURE SETTINGS.

1. With the engine running at 1500rpm and disc saw stalled, turn the disc saw on and adjust the saw to manufacturer

settings.

2. Install a 600 psi gauge in the disc saw pump gauge port or check the pressure on the IQAN display in the cab to check

and verify 600 psi has been removed from pump. See Figure 1 for DS Gauge Port location.

SETTING THE SHIFT POINT PRESSURE

3. To set shift point, follow the instructions from the head attachment manufacturer.

NOTE

TIMBERPRO RECOMMENDS THE FOLLOW PUMP SETTINGS

• LS/STAND-BY: 150 - 160 PSI

• POR: 4500 PSI

• SHIFT POINT: 2000 PSI

adjUSTiNG The pOrT reLiefS ON The M7-22 Mid-SecTiON,

MaiN cONTrOL vaLve

1. Bottom out the LS (Load Sense) RELIEF on the M7-22 Valve and adjust the pressure per the setting on the provided

Recommended Pressures at the beginning of this procedure. DO NOT OVERTIGHTEN THE VALVE. See Figure 1 on the next

page.

2. Bottom out the function to the Port Relief setting.

SecTioN 9 &SecTioN 10

P 12 of 17 P 13 of 17

FIGURE 1, M7-22 SECTIONS

OF MAIN CONTROL VALVE

Jam Nut

Port Relief

NOTE

To get proper pressure from the Port Reliefs, it may be necessary

to turn the POR inward on the implement pump. See Figure 2 on

Page 1 for POR location on implement pump.

Port Reliefs should be 500 psi higher than the working pressure

in the valve section.

EXAMPLE

If the implement pump valve LS Relief pressure is 4200 psi, set

the Port Relief pressure to 4700 psi.

3. Back out the Port Relief until the needle on the gauge starts to move and tighten the jam nut once the relief is properly

set. See Figure 1 above.

4. Reset the Pump POR and LS settings as necessary.

LS Relief, PORT B

LS Relief, PORT A

FIGURE 2, MAIN CONTROL VALVE SECTIONS

Port Relief

LS Relief Jam Nut

ADJUSTING THE PORT RELIEFS ON THE M7-22 MID-SECTION PROCEDURE END

chaNGiNG MiN. diSpLaceMeNT

Some operators prefer having more speed while in driving Turtle mode. Turning the Min. Displacement screw clockwise

increases user speed while in Turtle mode.

The adjustment screw is located on the track drive motor, forward/center inside. See Figure 1 on the next page.

TL/TN-775 MAchiNe iNiTiAL SeT-UPGUideSecTioN 10 &SecTioN 11

P 14 of 17 P 15 of 17

TL/TN-775 MAchiNe iNiTiAL SeT-UPGUide

NOTE

By adjusting the Min. Displacement, a minimal amount of track power will be lost.

Min. Displacement

Adjustment Screw

FIGURE 1, MIN. DISPLACEMENT

SCREW LOCATION ON TRACK MOTOR

1. With the engine running, engage the motor shift selection located on the hand controls in the cab into Turtle Mode. See

Figure 2 below.

FIGURE 2, TURTLE MODE

SELECTION IN CAB

Turtle Mode Shift

Selection

2. Turn the track drive motor Min. Displacement Screw in until you feel it make contact with the internal swash-plate. See

Figure 1 for screw location.

3. Raise one track off the ground and time how long it takes for that track to make a complete revolution.

4. Turn the displacement screw inward on the raised track and calculate the time it takes to reach the desired rpm.

5. Once the desired rpm is reached, measure the portion of screw that is left above the locknut.

6. Use the measurement from the previous step to adjust the screw on the other track. The same measurement should be

applied.

7. Raise the other track off the ground and time the time how long it takes for the second track to make one complete

revolution. Adjust the Min. Displacement Screw as necessary to reach the same rpm as the side just adjusted.

CHANGING MIN. DISPLACEMENT PRESSURE PROCEDURE END

SecTioN 11

P 14 of 17 P 15 of 17

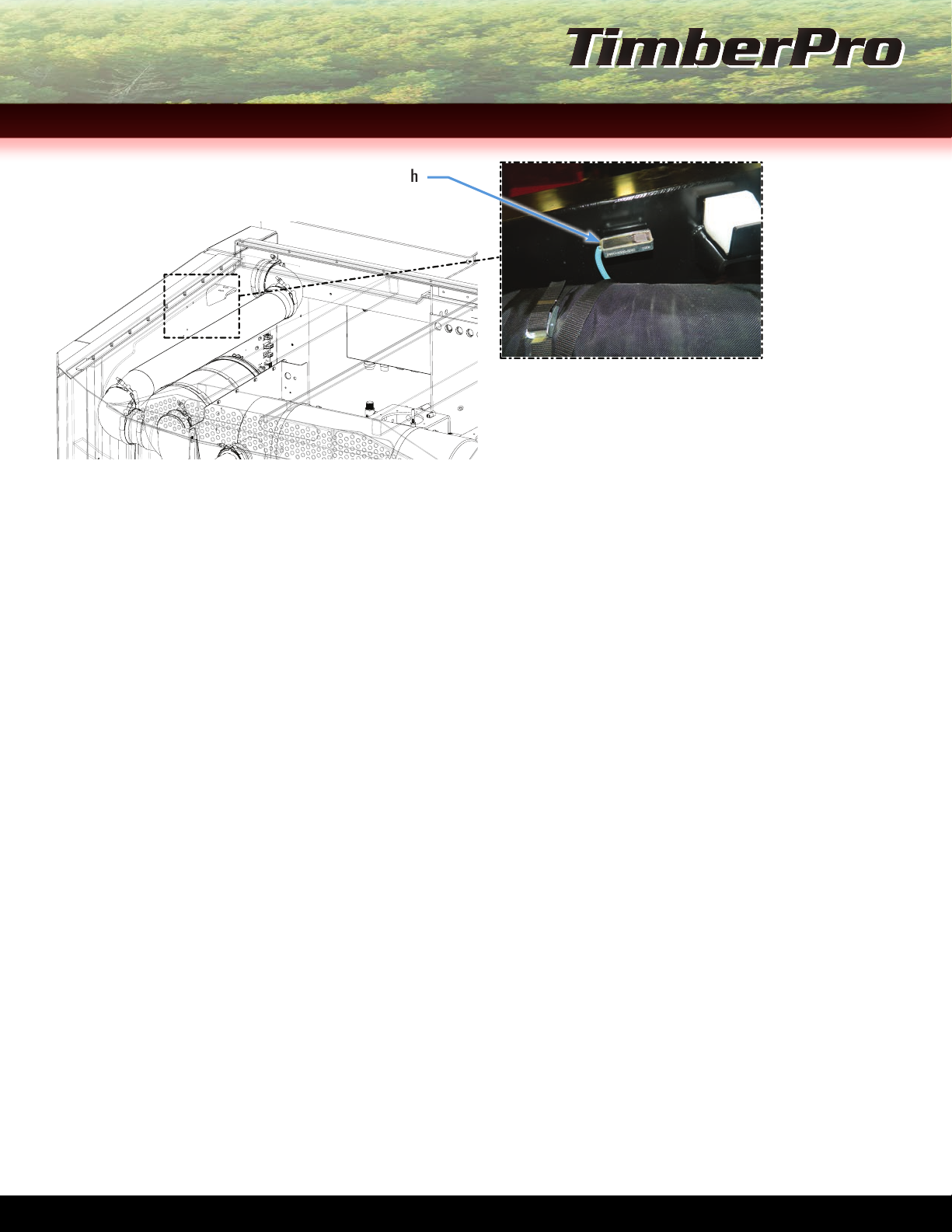

SeTTiNG ShifT-pOiNT aNd beGiNNiNG Of reGULaTiON

1. Disconnect and remove the Motor Shift Hose from the track drive motor. Leave the MS port open to breath. See Figure 2

below for MS Hose and port location on motor.

2. Install a 6,000 psi gauge into the MH Test Port. See Figure 1 on next page for MH Test Port location.

3. Run engine at a minimum of 1400rpm.

4. Have operator stroke pump and adjust POR to desired pressure.

5. Remove gauge from the track drive pump MH port and install gauge at M1 port on the track drive motor. See Figure 2

below for M1 Test Port location on motor.

FIGURE 1, MH TEST

PORT AT TRACK DRIVE

MH Test Port at Track Drive

M1 Port

Track Drive Motor

Motor Shift Hose

FIGURE 2,

TRACK DRIVE MOTOR

6. Once the gauge is installed on the track drive motor M1 port, have the operator stroke the pump once again. Use the

Pressure Adjustment Valve to set the Shift Pressure to 1/2 the amount that the track drive pump was set to in Step 2.

See Figure 3 below for pressure adjustment valve location.

PRESSURE ADJUSTMENT EXAMPLE

If the pressure gathered from the MH

Test Port on the track drive motor in

Step 2 was 5200 psi then the adjusted

p r e s s u r e s h o u l d b e s e t t o 2 6 0 0 p s i .

Pressure Adjustment Valve

Track Drive Motor

FIGURE 3, TRACK DRIVE MOTOR

ADJUSTMENT VALVE

TL/TN-775 MAchiNe iNiTiAL SeT-UPGUideSecTioN 12

This manual suits for next models

3

Table of contents

Other TimberPro Industrial Equipment manuals