PH

TIMBERWOLF TW S426TDHB SPECIFICATION

Engine type Kubota 4-cylinder turbo diesel

Maximum power 33kW (45hp)

Cooling method Water cooled

Overall weight 1350kg

Starting method Electric

Roller feed Hydraulic motor

Feed roller opening 426mm (17”) x 230mm (9")

Fuel capacity 33 litres

Hydraulic oil capacity 15 litres

Material processing capacity up to 3 tonnes/hr

Fuel type Diesel

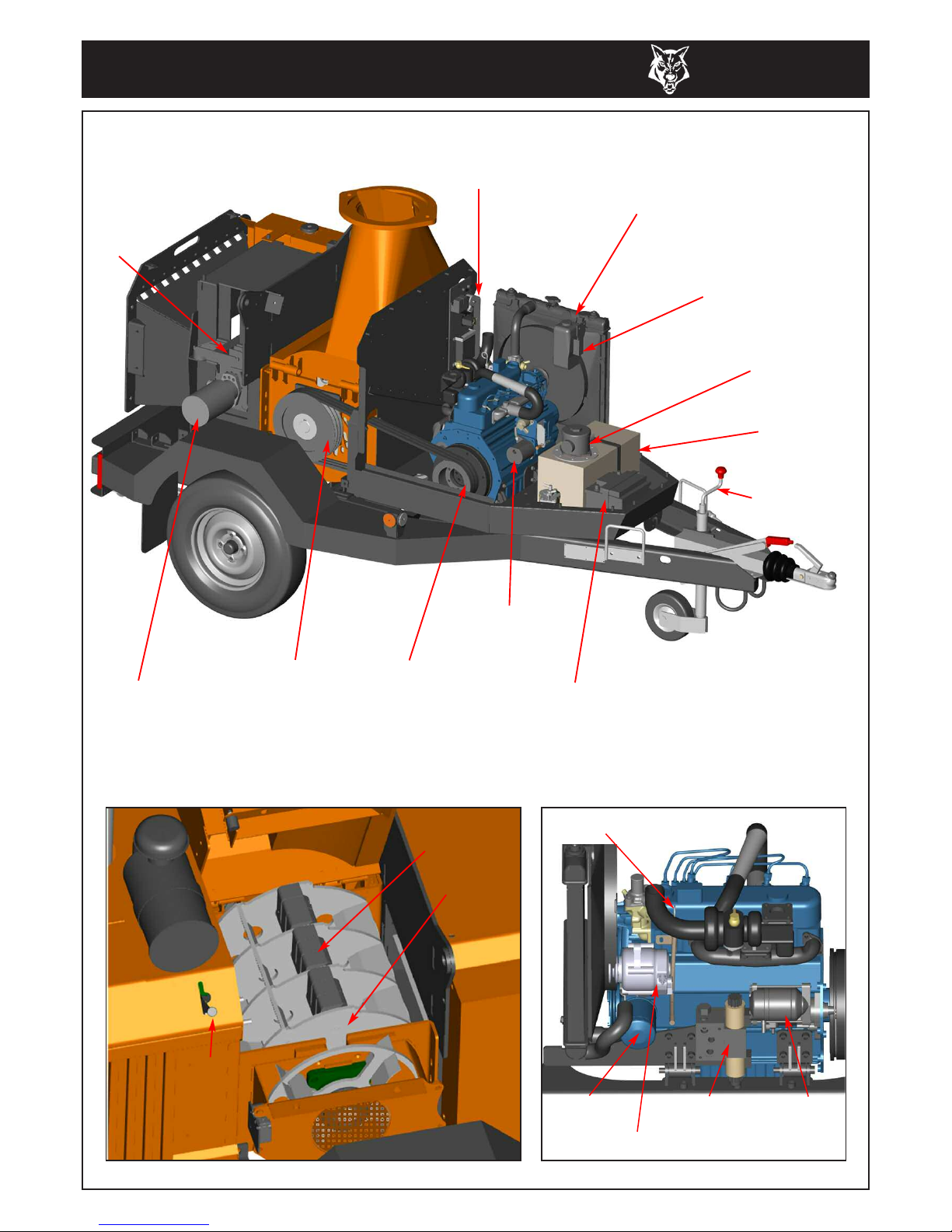

The Timberwolf TW S426TDHB

The Timberwolf S426TDHB is a high speed, heavy duty professional shredder. t is designed to shred general

green waste (brash, prunings, hedge trimmings, Leylandii, Christmas trees, rootballs, etc.),brushwood up to

100mm (4”), pallets, domestic doors, wooden and plastic window frames (all pre-cut to fit feed aperture),

contaminated timber, chipboard, MDF, packaging materials, uPVC plastic, cardboard, wooden furniture, fence

posts and similar items. The machine will tolerate drinks cans, plastic bottles, stones, rocks and concrete (up

to fist size), nails, metal door furniture, glass bottles and similar items.

TIMBERWOLF

TW S426TDHB

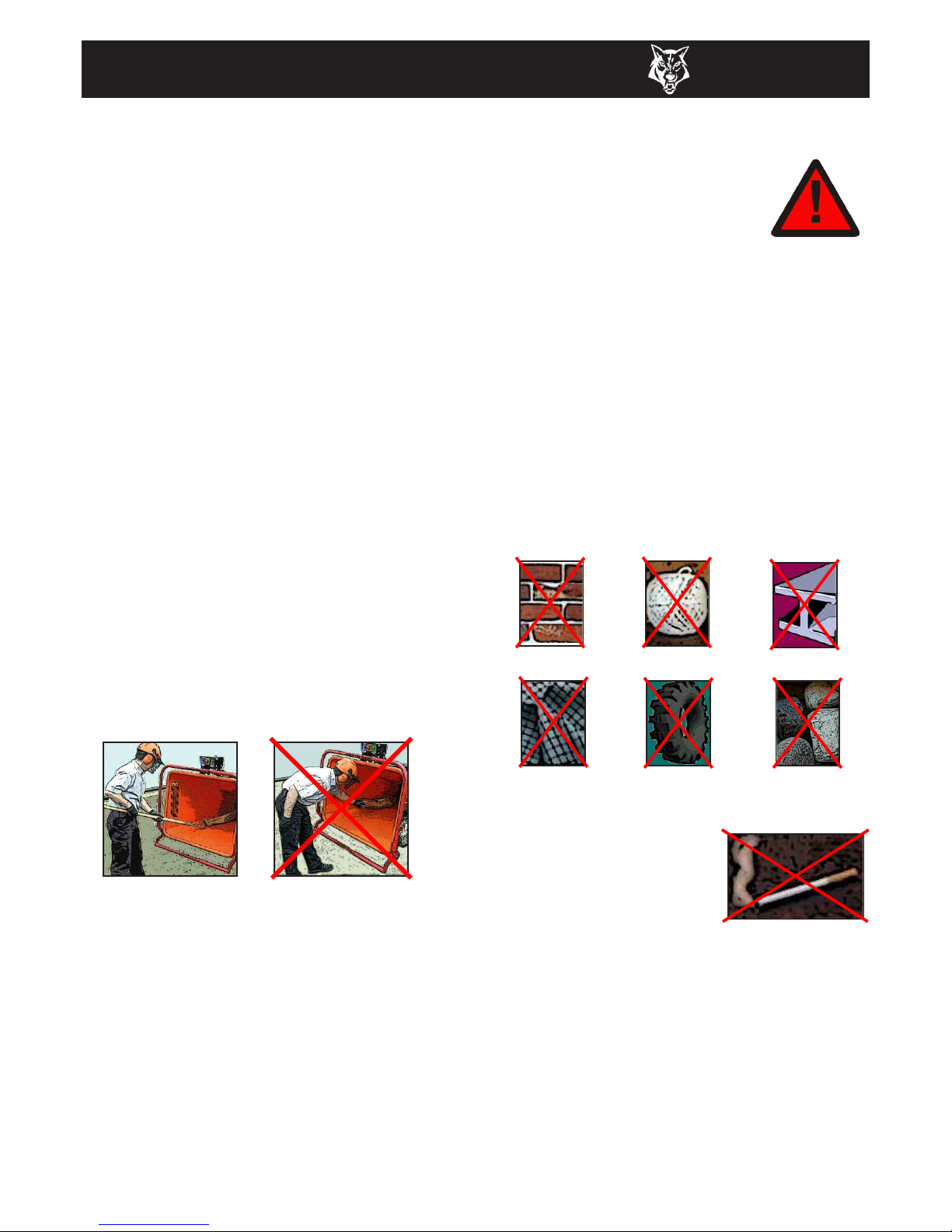

To properly control the speed of material entering the shredder chamber, the machine relies on the large feed

roller to grip the material. The feed roller can grip material down to 15mm in diameter. The machine will not

tolerate or process items such as tyres, mattresses, heavy duty plastic containers (used for oils, chemicals,

etc.), carpets, reinforced concrete, metallic items exceeding lightweight domestic door furniture, commercial

plastic gas pipe, alkathene water pipe, metal reinforced drainage/irrigation pipe, baler twine, rope, metal

banding, computer hard drives (which contain magnets) and any similar objects to the above.

NOTE: When materials are corrosive they may attack and degrade the individual components. It is essential that

the unit be thoroughly cleaned down after shredding anything that may contain materials of an aggressive nature.

Ejection of material – Warning! The S426TDHB shredder ejects material at high speed. Ensure there is an

adequate safety zone and that ejected material is aimed away from operators into a safe area, i.e. an

enclosure or container with a back stop (i.e. wall) behind it to prevent ejected material from leaving the work

area and causing injury and damage. f loading into a truck or trailer, ensure the structure is strong enough to

cope with the impact from ejected material.

DIMENSIONS

Serial No. Location

The serial number can be found

on the identification plate

located on the chassis beam.

Towing Length: 3600mm, Working Length with standard tow head: 4220mm

1506mm

2220mm, (1675mm with

discharge removed)

WARNING LIMITATIONS ON MATERIALS

2

TIMBERWOLF

TW S426TDHB