TIMBERWOLF

TW SX200

9SAFE WORKING

• CHECK ball head is well greased.

• W ND jockey wheel assembly anticlockwise until

the tow head is above the height of the ball hitch

on the vehicle.

• REVERSE vehicle so the ball hitch is directly below

the tow head.

• ATTACH breakaway cable to a strong point on the

vehicle, not the ball hitch.

• GRASP handle on tow head and push back catch

with thumb.

• W ND jockey wheel assembly clockwise, to lower

the tow head onto the ball hitch.

• RELEASE handle and continue to wind jockey

wheel clockwise. The tow head should snap into

place on the ball hitch. f it doesn't, repeat

previous 2 steps.

• W ND jockey wheel up until fully retracted and the

jockey wheel frame is seated in its notch on the

stem. The chipper weight should be fully on the

vehicle.

• RELEASE jockey wheel clamp and slide the jockey

wheel assembly fully up.

• T GHTEN clamp on jockey wheel assembly.

• CONNECT electrical plug to socket on rear of

towing vehicle and check operation of all the trailer

and vehicle lights.

• THE shredder is now properly attached to the vehicle.

SAFE TRANSPORTATION WARNING DO NOT RIDE ON THE

SHREDDER WHEN IT IS

BEING TOWED.

HITCHING ONTO THE TOW BALL

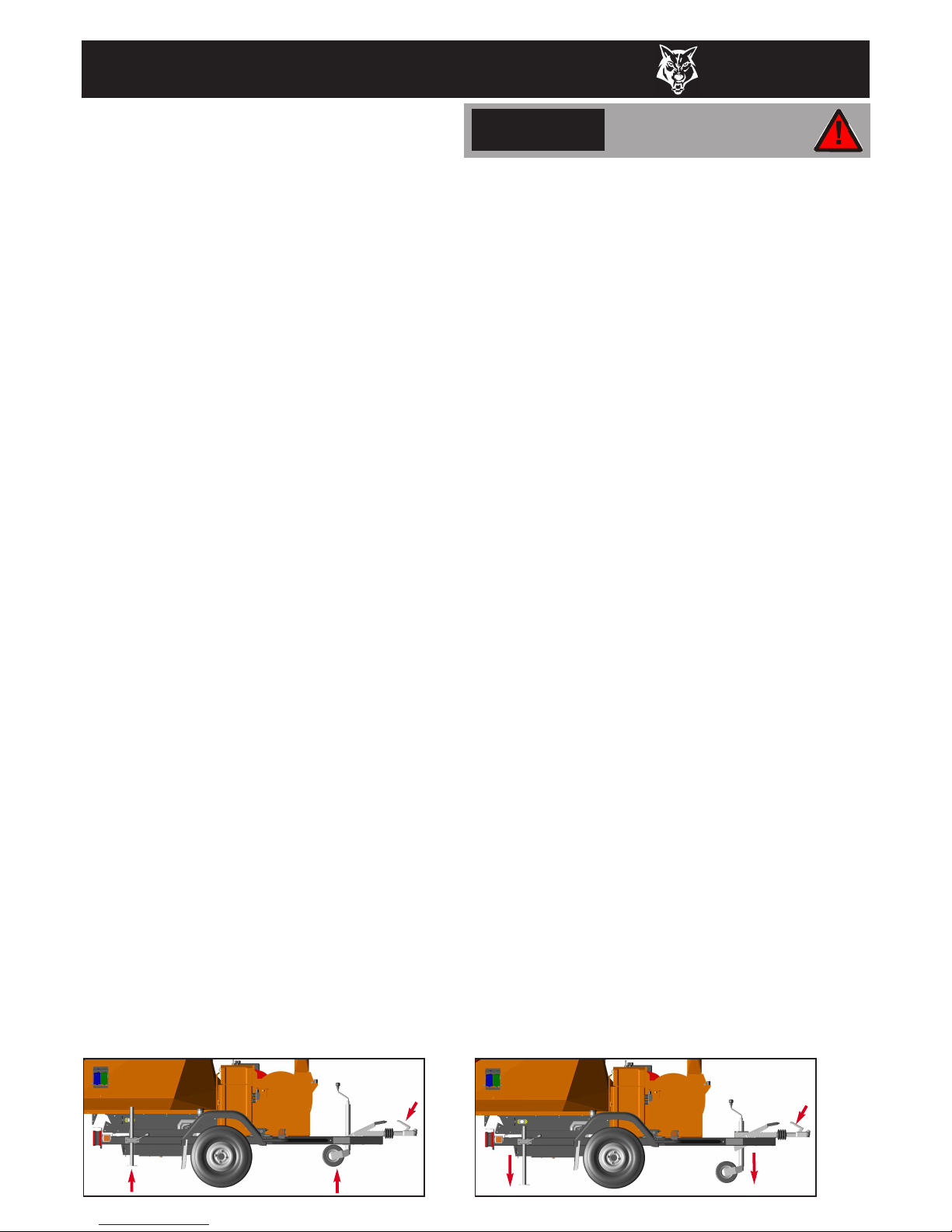

When the shredder is unhitched it should be made

secure before starting work by applying the handbrake

and lowering the prop stand and jockey wheel (b).

When hitched to a vehicle the shredder handbrake

should be released and the prop stand and jockey

wheel stored in the towing position (a).

• APPLY handbrake.

• D SCONNECT the electrical cable from the

vehicle socket.

• RELEASE breakaway cable.

• RELEASE the jockey wheel assembly clamp.

• LOWER the jockey wheel assembly fully.

• RET GHTEN the jockey wheel assembly clamp.

• W ND the jockey wheel assembly anticlockwise

until it starts to take the weight of the shredder.

• GRASP the handle and release the catch with

your thumb.

• CONT NUE to wind the jockey wheel anticlockwise.

This should lift the tow head clear of the ball hitch.

• DR VE the vehicle clear of the shredder.

• W ND the jockey wheel assembly to a suitable

point where the shredder is level.

• THE shredder is now fully detached from the

vehicle.

• WHEN towing a shredder the maximum speed limit

is 60 mph (100 kph).

•ON rough or bumpy road surfaces reduce speed

accordingly to protect your machine from

unnecessary vibration.

•WHEN towing off road be aware of objects that

may catch the shredder undergear.

•WHEN towing off road ensure inclination is not

excessive.

•AVO D excessively pot holed ground.

•WHEN reversing the shredder the short wheel

base will react quickly to steering.

•ALWAYS check the discharge is tight before moving.

•KEEP tyre pressures inflated to 2.2 bar (32 psi).

•CHECK wheel nuts are tightened to 90Nm (65 lbs ft).

•CLEAR loose shreddings and debris from the

machine before departing.

•ENSURE safety bar catch is properly engaged

before departing

(a) (b)

UNHITCHING THE SHREDDER

STABILISING THE SHREDDER